Abstract

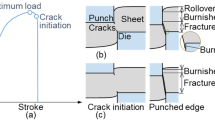

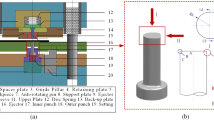

In the design process of a manual or electrically actuated punch and bind machine, the required force to punch a stack of paper sheets is a crucial parameter that affects ergonomics, product design, power requirements, and ultimately product cost. The required punch force profile considered two punch pin geometries, introducing some innovative aspects. Measurements were performed using a tensile/compression machine and the punching force profile of the 21 punching pins arrangement during punching cycle was extracted for both geometries. Results show a smoother force profile for the double shear angle punching pin arrangement as opposed to the concave pin geometry pin arrangement with a lower peak punching force value.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ye, Y., Yang, C., Ma, Z.: The test and CAE simulation way in the punching-binding machine design. Ningxia Eng. Technol. 4, 352–354 (2009)

Zhang, M., Pan, B., Liang, L.: Multi-objective optimization design of punching blade structures. Mech. Sci. Technol. Aerosp. Eng. 12, 1718–1722 (2010)

Jia, S., Liang, L., Pan, B.: Research on working performance of punch pin used in comb binding machines. Light Ind. Mach. 1, 94–97 (2011)

Klocke, F.: Manufacturing Processes 4. Springer, Heidelberg (2013)

Bierzer, F., Schmidt, R.-A.: Cold Forming and Fineblanking: A Handbook on Cold Processing Steel Material Properties Component Design. Carl Hanser Verlag GmbH & Co, Germany (2007)

Sousa J., Pinho T., Figueiredo L., Mendonça J., Machado J.: Development and optimization of a paper punching system. Adv Manuf. 2B, V02BT02A028 (2015)

Felton G., Aries P.A., Kandasamy B.: Punching and binding machine. WO 1999051406 A1, (1998)

Szoke E., Coric M.: Binding machine, US 8434987 B2, (2009)

Figueiredo L., Sousa J., Monteiro L., Mendonça J., Machado J.: Innovative mechatronic approach to redesign a punch and bind machine. Adv. Manuf. 2, V002T02A043 (2016)

Acknowledgements

The authors want to acknowledge the support from ACCO Brands Portuguesa, Lda. The authors also would like to thank the University of Minho’s Materials Testing Laboratory for the required testing facilities and support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Sousa, J., Figueiredo, L., Machado, J., Mendonca, J.P. (2018). Measuring the Punching Profile of a Punch And Bind Machine. In: Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M. (eds) Advances in Manufacturing. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-68619-6_70

Download citation

DOI: https://doi.org/10.1007/978-3-319-68619-6_70

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68618-9

Online ISBN: 978-3-319-68619-6

eBook Packages: EngineeringEngineering (R0)