Abstract

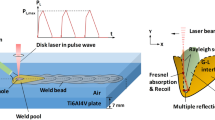

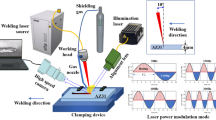

The keyhole behaviors were observed directly by laser welding experiment with quartz glass. Based on Fresnel absorption of laser beam and multi-reflection combined with volume of fluid (VOF) method, a three-dimensional mathematical model was established to study the role of welding speed on keyhole behaviors and keyhole-induced porosity formation in laser welding of aluminum alloy. The keyhole behaviors and weld pool fluid flow were discussed, and the result shows that, although the welding speed varies, the mechanism of keyhole collapse was similar. However, the keyhole stability at higher welding speed was improved due to reduced weld depth fluctuations, spatter number, keyhole depth to width ratio, and keyhole collapse frequency. Furthermore, the improved keyhole stability impeded the keyhole collapse, and the lower weld depth and solidification rate facilitated bubble escaping from the weld pool easily, which are the main factors for suppression of porosity at higher welding speed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Huang L, Hua X, Wu D, Jiang Z, Ye Y (2019) A study on the metallurgical and mechanical properties of a GMAW-welded Al-Mg alloy with different plate thicknesses. J Manuf Process 37:438–445

Huang L, Hua X, Wu D, Jiang Z, Li F, Wang H, Shi S (2017) Microstructural characterization of 5083 aluminum alloy thick plates welded with GMAW and twin wire GMAW processes. Int J Adv Manuf Technol 93:1809–1817

Jiang Z, Hua X, Huang L, Wu D, Li F, Zhang Y (2018) Double-sided hybrid laser-MIG welding plus MIG welding of 30-mm-thick aluminum alloy. Int J Adv Manuf Technol 97(1–4):903–913

Jiang Z, Hua X, Huang L, Wu D, Li F (2017) Effect of multiple thermal cycles on metallurgical and mechanical properties during multi-pass gas metal arc welding of Al 5083 alloy. Int J Adv Manuf Technol 93:3799–3811

Norris J, Robino C, Hirschfeld D, Perricone M (2011) Effects of laser parameters on porosity formation: investigating millimeter scale continuous wave Nd: YAG laser welds. Weld J, 90(10)

Katayama S, Kawahito Y (2009) Elucidation of phenomena in high-power fiber laser welding and development of prevention procedures of welding defects. Proceedings of SPIE 146(1):124–6

Meng W, Li Z, Lu F, Wu Y, Chen J, Katayama S (2014) Porosity formation mechanism and its prevention in laser lap welding for T-joints. J Mater Process Technol 8:1658–1664

Ola O, Doern F (2015) Keyhole-induced porosity in laser-arc hybrid welded aluminum. Int J Adv Manuf Technol 80(1–4):3–10

Li L, Peng G, Wang J, Gong J, Meng S (2019) Numerical and experimental study on keyhole and melt flow dynamics during laser welding of aluminium alloys under subatmospheric pressures. Int J Heat Mass Tranf 133:812–816

Zhou J, Tsai H (2007) Porosity formation and prevention in pulsed laser welding. J Heat Transf 129:1014–1024

Lu F, Li X, Li Z, Tang X, Cui H (2015) Formation and influence mechanism of keyhole-induced porosity in deep-penetration laser welding based on 3D transient modeling. Int J Heat Mass Tranf 90:1143–1152

Pang S, Chen L, Zhou J, Yin Y, Chen T (2011) A three dimensional sharp interface model for self-consistent keyhole and weld pool dynamics in deep penetration laser welding. J Phys D Appl Phys 44:025301

Wu D, Hua X, Li F, Huang L (2017) Understanding of spatter formation in fiber laser welding of 5083 aluminum alloy. Int J Heat Mass Transf 113(2017):730–740

Wang C, Lei B, Jiang P, Xu X, Mi G (2018) Numerical and experimental investigation of vacuum-assisted laser welding for DP590 galvanized steel lap joint without prescribed gap. Int J Adv Manuf Technol 94(9–12):4177–4185

Ning J, Zhang L, Na S, Yin X, Niu J, Zhang J, Wang H (2017) Numerical study of the effect of laser-arc distance on laser energy coupling in pulsed Nd: YAG laser/TIG hybrid welding. Int J Adv Manuf Technol 91(1–4):1129–1143

Ducharme R, Williams K, Kapadia P, Dowden J, Steen B, Glowacki M (1999) The laser welding of thin metal sheets: an integrated keyhole and weld pool model with supporting experiments. J J Phys D Appl Phys 27(8):1619–1627

Huang L, Hua X, Wu D, Li F (2018) Numerical study of keyhole instability and porosity formation mechanism in laser welding of aluminum alloy and steel. J Mater Process Technol 252:421–431

Cho W, Na S, Cho M, Lee J (2010) Numerical study of alloying element distribution in CO2 laser-GMA hybrid welding. Comput Mater Sci 49(4):792–800

Wu D, Hua X, Ye Y, Huang L, Li F, Huang Y (2018) Experimental and numerical study of spatter formation and composition change in fiber laser welding of aluminum alloy. J Phys D Appl Phys 51:185604

Huang L, Wu D, Hua X, Liu S, Jiang Z, Li F, Wang H, Shi S (2018) Effect of the welding direction on the microstructural characterization in fiber laser-GMAW hybrid welding of 5083 aluminum alloy. J Manuf Process 31:514–522

Li X, Lu F, Cui H, Tang X, Wu Y (2014) Numerical modeling on the formation process of keyhole-induced porosity for laser welding steel with T-joint. Int J Adv Manuf Technol 72(1):241–254

Zhang L, Zhang J, Gumenyuk A, Rethmeier M, Na S (2014) Numerical simulation of full penetration laser welding of thick steel plate with high power high brightness laser. J Mater Process Technol 214(8):1710–1720

Huang L, Hua X, Wu D, Li F, Cai Y, Ye Y (2018) Effect of magnesium content on keyhole-induced porosity formation and distribution in aluminum alloys laser welding. J Manuf Process 33:43–53

Pang S, Chen W, Wang W (2014) A quantitative model of keyhole instability induced porosity in laser welding of titanium alloy. Metall Mater Trans A 45(6):2808–2818

Blecher J, Galbraith C, Vlack C, Palmer T, Fraser J, Webster P, DebRoy T (2014) Real time monitoring of laser beam welding keyhole depth by laser interferometry. Sci Technol Weld Join 19(7):560–564

Xu J, Rong Y, Huang Y, Wang P, Wang C (2018) Keyhole-induced porosity formation during laser welding. J Mater Process Technol 252:720–727

Zhang D, Li C, Liu X, Cao Y, Wu D (2018) Numerical study of spatter formation during fiber laser welding of aluminum alloy. J Manuf Process 31:72–79

Huang L, Hua X, Wu D (2018) Relationship between the weld pool convection and metallurgical and mechanical properties in hybrid welding for butt joint of 10-mm-thick aluminum alloy plate. Weld World 62:895–903

Chen J, Wei Y, Zhan X, Li Y, Ou W, Zhang T (2017) Melt flow and thermal transfer during magnetically supported laser beam welding of thick aluminum alloy plates. J Mater Process Technol 254:325–327

Kawaguchi I, Tsukamoto S, Arakane G, Nakata K (2006) Formation mechanism of porosity in deep penetration laser welding-study on prevention of porosity in high power CO2 laser welding (report 2). J Jn Weld Soc 24(4):338–343

Acknowledgments

This work was supported the Ministry of Industry and Information Technology of China under the project of LNG shipbuilding.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, L., Hua, X., Wu, D. et al. Role of welding speed on keyhole-induced porosity formation based on experimental and numerical study in fiber laser welding of Al alloy. Int J Adv Manuf Technol 103, 913–925 (2019). https://doi.org/10.1007/s00170-019-03502-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03502-x