Abstract

Advances in the ethanol fermentation process are essential to improving the performance of bioethanol production. Fed-batch fermentation is a promising approach to increase the final ethanol titer, which benefits the recovery in the bioethanol industry’s downstream process. However, the development of feeding strategies, a crucial control variable in the fed-batch approach, is limited. Thus, in the present work, different modes of substrate delivery—fixed feeding, adapted feeding—were investigated in fed-batch cultures of Saccharomyces cerevisiae in a 5-L bioreactor. Evolved gas production, which was positively correlated with glucose consumption, was used to adjust the sugar feed rate in fed-batch fermentations under an adapted feeding strategy. The adapted feeding strategy enhanced ethanol productivity by 21% compared to the fixed feeding strategy, in which the sugar feed rate was stable, and the ethanol titer reached 91 g/L (~ 11.5%, v/v) at the end of fermentation. Moreover, cell biomass accumulation and cell growth rate were significantly improved when using the adapted feeding strategy. The effect of nitrogen availability on the performance of the adapted feeding strategy was further explored using a low-nitrogen content medium. The results showed that, even under low nitrogen feeding conditions (N/C = 0.046:10), the adapted feeding strategy maintained the same ethanol productivity as nitrogen-rich medium feeding. Overall, these results suggest that sugar delivery with low nitrogen content using the adapted feeding strategy could help reduce medium costs and improve the productivity of current facilities in the ethanol industry.Future work will integrate adapted feeding strategies with other fermentation approaches to improve ethanol production.

Graphical abstract

Key points

• Novel continuous sugar delivery was developed for fed-batch ethanol fermentation.

• The adapted feeding strategy improved ethanol productivity by 21%.

• The final ethanol concentration reached 91 g/L (11.5%, v/v) with no residual sugar.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Avoid common mistakes on your manuscript.

Introduction

Bioethanol now plays an important role as a source of energy for land transportation, and not only benefits greenhouse gas reduction from burning fuels but also supports energy security in many countries (Melendez et al. 2022). To expand the long-term application of bioethanol as a sustainable energy source, the use of lignocellulosic feedstocks is critical. For example, corn stove, wheat straw, rice bran, and sugarcane bagasse have all been shown to have substantial potential for lignocellulosic ethanol production (Aghaei et al. 2022; Periyasamy et al. 2023). However, the use of lignocellulosic feedstocks for commercial ethanol production is still under development; production efficiency being one of the main hindrances at an industrial scale.

The general process for lignocellulosic ethanol production includes pretreatment, hydrolysis (or saccharification), fermentation, and recovery (or purification) steps. The complexity of the cell wall of lignocellulosic biomass creates a need for further improvements in the pretreatment stages. Saccharification steps have been improved through advancements resulting in high sugar content from hydrolysis which has enabled high ethanol yield from fermentation (Raj et al. 2022). In this context, increasing production efficiency and reducing processing costs can create further opportunities for efficient commercial lignocellulosic ethanol production. In this study, we aimed to improve ethanol productivity and yield in the fermentation stage.

There are three general fermentation modes for bioethanol production—batch, fed-batch, and continuous—each involving different substrate-loading strategies and facing potential substrate inhibition (Bai et al. 2008). For example, Chang et al. (2018) evaluated the impact of sugar concentration on ethanol production with Saccharomyces cerevisiae and showed that the rate of ethanol production started to decrease at sugar concentrations exceeding 100 g/L. It is worth noting that fed-batch fermentation helps mitigate substrate inhibition by controlling the rate of sugar addition to keep its concentration low while allowing high cell density and product titer (Phukoetphim et al. 2017). Achieving high ethanol concentration facilitates the recovery and purification of ethanol, and is critical to making the process economically favorable (Koppram et al. 2013; Zacchi and Axelsson 1989). However, the development of efficient fed-batch operations for lignocellulosic ethanol production is limited, in which most studies are carried out at a laboratory scale. Understanding the pathway from laboratory-scale to bench-scale is critical to addressing the possible hindrances for industrial ethanol production (Amorim et al. 2011). Thus, developing an effective fed-batch strategy for sugar delivery to improve the performance of ethanol production at a bench-scale has the potential to significantly advance lignocellulosic ethanol production in the bioethanol industry.

Ethanol fed-batch fermentation typically relies on intermittent or continuous feeding. In the former, also named pulsed feeding, specific amounts of a limiting nutrient are added intermittently, leading to spikes in substrate concentration followed by depletion until the next feeding (Bhargava et al. 2003; Laopaiboon et al. 2007). On the other hand, continuous feeding consists of a continuous addition of a limiting nutrient (typically through pumping) to the bioreactor either at a fixed or changing (adapted) rate (Balat 2011; Phukoetphim et al. 2017). When lignocellulosic hydrolysate is used as a substrate, continuous feeding results in relatively less exposure of the microorganisms to inhibitors, such as furfural derivatives, compared to pulsed feeding, in which higher concentrations of substrate and inhibitor are observed immediately after the pulsed addition. Some ethanologenic microorganisms have the capability to convert inhibitors, which reduces the metabolic stress on cells (Liu et al. 2005; Taherzadeh et al. 1999). Moreover, continuous feeding can mitigate heterogeneity between the fermentation broth and the fresh feed medium, which may lead to greater performance in ethanol fermentation as compared to pulsed feeding. The heterogeneity of a fermentation broth becomes critical especially when the fermentation process is implemented at an industrial scale (Hewitt and Nienow 2007). It is worth noting that, although both pulsed and continuous feeding operations lead to elevated product formation (Lim and Shin 2013), developing an efficient feeding strategy for substrate delivery in fed-batch fermentation is essential to optimize the metabolic performance of microorganisms. Even within continuous feeding, different strategies can be adopted to further improve performance. For example, adapted feeding is a tailored approach to supplying nutrients in fed-batch fermentation according to the level, growth, or metabolic activity of the culture, leading to an efficient control for cell growth and product formation. Compared to the fixed feeding mode, in which the rate of substrate addition is kept constant, adapted feeding strategies provide greater flexibility in substrate delivery through process-informed and, sometimes, real-time adjustments. In these cases, the adjustment of the substrate feed rate is critical for achieving high cell density and product titer (Bolmanis et al. 2023). Once an efficient fermentation process is established, bench-scale evaluations can provide practical insights for transitioning the process from laboratory experiments to commercial production (Siqueira et al. 2008).

Therefore, the present work focused on developing adapted continuous feeding strategies for sugar delivery to enhance ethanol productivity in cultures of S. cerevisiae and comparing their performance with fixed continuous feeding in a 5-L bioreactor. To this end, evolved gas production from the yeast during ethanol fermentation was assessed as a monitoring parameter to guide the sugar feeding rate. Fermentation performance was determined based on sugar utilization, ethanol titer, efficiency (sugar-to-ethanol conversion), and productivity. In addition, the impact of nitrogen content in the feed medium on the performance of the fermentation was investigated. Overall, this work provides practical insights to develop and/or implement adapted feeding strategies for efficient substrate delivery and further improve the performance of industrial bioethanol production.

Materials and methods

Yeast, media, and cultivation

The industrial yeast for fuel ethanol production, Superstart™ active distillers dry yeast, Saccharomyces cerevisiae, was purchased from Lallemand Ethanol Technology (Milwaukee, WI, USA) and used in this study. Media for seed cultures and ethanol fermentation as well as the cultivation conditions were used as described in Wang et al. (2017). Briefly, yeast nitrogen base (YNB) medium was made of 50 g/L glucose (MilliporeSigma, Burlington, MA, USA) and 6.7 g/L yeast nitrogen base with amino acids (MilliporeSigma) in 0.1 M sodium phosphate buffer (\(NaH_2PO_4\cdot2H_2O/Na_2HPO_4\cdot2H_2O,pH\;6.0\), Thermo Fisher Scientific, Waltham, MA, USA), and the medium was sterilized by filtration (0.2 µm Sartolab™ P20 Pressure Filters, Sartorius, Göttingen, Germany). A glycerol stock of the yeast was thawed and steaked on a yeast-peptone-dextrose agar (YPDA) plate which was made of 50 g/L yeast-peptone-dextrose medium (BD Difco™, Bergen Country, NJ, USA) and 15 g/L agar (Thermo Fisher Scientific) sterilized by autoclaving (121 °C/15 min). The YPDA plates were incubated at 30 °C for 2–3 days in an incubator shaker (New Brunswick Innova 44). A single isolated colony was then transferred to 20 mL YNB medium (in a 50-mL Erlenmeyer flask) and grown at 30 °C/230 rpm for 18–20 h in the incubator shaker to make up the first seed culture. A sample from this first seed culture was transferred to 200 mL YNB medium (in a 500-mL Erlenmeyer flask) to reach an initial optical density at 600 nm (OD600) of ~ 0.2 and grown at 30 °C/250 rpm to make up the second seed culture. Finally, when an OD600 of ~ 0.5 was reached, the active yeast culture was transferred to the 5-L bioreactor as inoculum for fed-batch fermentation.

Fed-batch fermentation

Settings and accessories for 5-L bioreactors

All fermentation experiments were performed in a 5-L stirred tank bioreactors (Infors-HT, Bottmingen, Switzerland), and the operation settings and accessories were used as described in Hung et al. (2023); Wang et al. (2020). Briefly, 160 mL from the second seed culture at OD600 ~ 0.5 was added to 1.84 L of YNB medium for an initial working volume of 2.00 L, where the inoculum was 8% (v/v). The bioreactors were operated anaerobically at 30 °C and 600 rpm. Dissolved oxygen and pH were monitored using a dissolved oxygen probe (VisiFerm DO ECS 325 mm H0, Hamilton Company, Reno, NV, USA) and a pH probe (EasyFerm Plus PHI K8 325 mm, Hamilton Company), respectively, via the software Iris 6.0 (Infors-HT). 2 N NaOH (Thermo Fisher Scientific) was used for pH control (set point at pH > 4.0) to mitigate contamination and reduce metabolic inhibition at low pH. A mass flow meter (M-200SCCM-D/5 M, Alicat Scientific Inc., Tucson, AZ, USA) was connected to the effluent of the bioreactor to monitor the evolved gas flow rate and cumulative gas production in real time. The evolved gas flow rate has been shown to be an effective monitoring parameter for ethanol fermentation (Wang et al. 2020).

Continuous feeding strategies

The feed medium added during fed-batch fermentation was a modified YNB medium: 500 g/L glucose (MilliporeSigma), 6.7 g/L yeast nitrogen base with amino acids (MilliporeSigma), and 47.7 g/L urea (MilliporeSigma) in 0.1 M sodium phosphate buffer (pH 6.0). The nitrogen-to-carbon ratio (N/C) in the feed medium was 0.95:10 (mol/mol), which is similar to the N/C ratio of 1:10 commonly used to support yeast growth and ethanol production in industrial settings (Kiran and Liu 2015).

Continuous feeding was performed using a peristaltic pump (MFLX78001-62, Masterflex Ismatec Reglo Independent Channel Control Peristaltic Pumps, Avantor, Mississauga, Ontario, Canada).

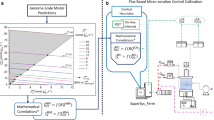

Evolved gas produced per reactor volume (E with units of mL/L), also known as evolved gas production—the amount of gas released from the metabolic activity of the cell culture per volume, during fermentation positively correlated with glucose consumed per reactor volume (G with units of g/L), as expressed in Eq. 1 (R2 = 0.895; Supplementary Fig. S1):

Evolved gas from the bioreactor was used to control the glucose addition in adapted continuous feedings, and the real-time evolved gas flow rate was used as a monitoring parameter to indicate the end of the initial batch phase, at which point the fed-batch phase was initiated.

Details for fixed and adapted feeding are stated as follows.

-

(1)

In the fixed continuous feeding strategy, glucose was fed at a rate of 2.1 g/L/h. This glucose feed rate was set based on the average glucose consumption rate in batch fermentation of S. cerevisiae in previous works.

-

(2)

In the adapted continuous feeding strategy, glucose was fed at a rate of 2.1 g/L/h at the beginning of the fed-batch fermentation. Glucose consumed per reactor volume (g/L) was evaluated every 12 h based on the evolved gas production (using Eq. 1). The glucose feed rate (F) was adjusted according to Eq. 2:

$$F_t=F_{(t-1)}\cdot\frac{(E_{(t-1)}+\Delta E)}{E_{(t-1)}}$$(2)where Ft is the adapted glucose feed rate at time t (g/L/h), F(t−1) is the glucose feed rate in the previous time interval (g/L/h), E(t−1) is the total evolved gas at the previous sampling time (mL), and \(\Delta E\) is the increase in evolved gas over the time interval (mL/h).

When the estimated glucose consumption rate was lower than the current feed rate, the glucose feed rate was maintained to ensure that ethanol fermentation was not limited due to insufficient substrate input. Overall, for both fixed and adapted feeding strategies, glucose was continuously fed until the total glucose added reached approximately 200 g/L, this ensured the ethanol contents could reach above 11% (v/v), a common target for the fuel industry for recovery in the downstream process.

To further investigate the application of adapted feeding strategies on ethanol production, the composition of the feed medium was modified to reduce its nitrogen content. As the addition of a nitrogen source is often required for high-density cell cultures, which can represent a substantial added cost, we tested whether a medium with reduced nitrogen content could sustain the same level of growth and ethanol production. The lower nitrogen-to-carbon ratio was obtained by removing urea from the medium. The modified feed medium thus contained 500 g/L glucose and 6.7 g/L YNB with amino acids in 0.1 M sodium phosphate buffer (N/C = 0.046:10, mol/mol). This feed medium composition was tested with both the adapted and fixed continuous feeding strategies, with all other fermentation conditions kept the same.

Analyses of fermentation samples

The biomass content of samples from the bioreactors was assessed by OD600 using a UV–Vis spectrophotometer (Ultrospec 4300 Pro, Amersham Biosciences, Mississauga, ON, Canada) and converted to cell dry weight (CDW, g/L) using a calibration curve (\(CDW=0.4412\cdot OD_{600}+0.049;\;R^2=0.967\); Supplementary Fig. S2). Fermentation samples were also centrifuged at 10,100g for 10 min (Eppendorf® Centrifuge 5418, Eppendorf AG, Hamburg, Germany), and the supernatants were analyzed by high-performance liquid chromatography (HPLC) and gas chromatography (GC) for determining glucose and ethanol concentrations, respectively (Parashar et al. 2016).

Briefly, the HPLC (Agilent 1200 series, Agilent, Santa Clara, CA, USA) was equipped with an Aminex HPX-87H column (300 \(\times\) 7.8 mm; Bio-Rad Laboratory, Hercules, CA, USA) held at 60 °C and a refractive index detector. A 5 mM sulfuric acid was used as the mobile phase with a constant flow rate of 0.5 mL/min. Glucose concentration was determined based on the peak area on the chromatogram and a calibration curve relating it to glucose standards (0.188–60.0 g/L).

The GC system (Agilent 7890A series, Agilent Technologies, Mississauga, ON, Canada) was equipped with the Agilent 7693 series autosampler (injector temperature, 170 °C; pressure, 7.5 psi; septum purge flow, 3 mL/min; spill ratio, 10 to 1), a Restek™ Stabilwax-DA column (30 m \(\times\) 0.53 mm \(\times\) 0.5 µm; Restek, Bellefonte, PA, USA), and a flame ionization detector (temperature, 190 °C; airflow, 400 mL/min; hydrogen flow, 40 mL/min; nitrogen flow, 25 mL/min). A programmed temperature sequence was applied to the column (35 °C held for 3 min, heating by 20 °C/min, and then 190 °C held for 1 min) after injection. 1% (v/v) butanol was used as the internal standard added in the sample for ethanol quantification, and helium was used as the carrier gas (constant pressure: 51.710 kPa).

Statistical analysis

All fermentation experiments were run in independent triplicates. Data were expressed as means ± standard deviation. Statistical analysis for comparing multiple groups was performed by one-way analysis of variance (ANOVA) and Tukey’s honestly significant difference test, where p < 0.05 indicated significant differences.

Results

Impact of feeding strategies on ethanol fermentation

Fed-batch fermentation has been shown to improve ethanol production through enabling higher cell density and avoiding substrate inhibition (Zabed et al. 2014). However, in that operational approach, the feeding regime must be properly controlled (Azhar et al. 2017). In this study, we developed a feeding strategy in which the sugar delivery was adapted to the glucose consumption rate to improve ethanol productivity and compared its performance with a fixed feeding strategy. Figure 1 shows the trends in yeast cell dry weight, glucose concentration, ethanol concentration, and evolved gas flow rate for the fixed (Fig. 1a–d), adapted (Fig. 1e–h), and low-nitrogen adapted (Fig. 1i–l) continuous feeding strategies.

Cell dry weight (a, e, and i), glucose concentration (b, f, and j), ethanol concentration (c, g, and k), and evolved gas flow rate (d, h, and l) in fed-batch fermentation of S. cerevisiae cultures undergoing fixed (a–d, circle) and adapted (e–h, triangle) continuous-feeding strategies and adapted continuous feeding strategy with low nitrogen feed medium (i–l, diamond). Means are reported for analytical triplicates (n = 3), with error bars representing standard deviation

The comparison of the fixed and adapted feeding at an N/C ratio of 0.95:10 yields a direct assessment of the impact of substrate addition strategies on growth and ethanol production. Firstly, cell dry weight increased with both fixed and adapted feedings; however, the latter led to higher final biomass (~ 3.4 g/L) than the fixed feeding (~ 2.6 g/L) (Fig. 1a and e). This suggests that the adapted feeding strategy provides more efficient sugar delivery for cell growth.

Sugar concentration is an essential variable for the performance of ethanol fermentation. In the present work, glucose addition was tightly controlled to stay well below 100 g/L and mitigate the risk of substrate inhibition on the yeast. The residual glucose content at the end of each feeding period was at or near zero (Fig. 1b and 1f) until approximately 83 h for fixed feeding and until 95 h for adapted feeding. This indicates that, over that time period, the glucose consumption rate was likely equivalent to or limited by the glucose addition rate; in fact, it should be noted that the glucose addition rate was increased gradually in the adapted feeding strategy. Considering that from approximately 24 h onward the cell dry weight did not change substantially, this suggests that more glucose was utilized by the yeast for producing ethanol or cell biomass when applying the adapted feeding strategy. This is supported by the glucose consumption rate (Fig. 2) which was greater in cultures undergoing adapted feeding compared to those undergoing fixed feeding. The comparison of the areas under the curve of the glucose consumption rate—which is an indicator of performance based on the overall glucose consumed per liter of the reactor—demonstrates that the adapted feeding strategy enhanced overall glucose consumption (115 g/L compared to 105 g/L for fixed feeding). The rise in residual glucose at ~ 83 h for fixed feeding and ~ 95 h for adapted feeding (Fig. 1b and f) is indicative of a decrease in glucose conversion rate. This occurred later in adapted feeding, likely because this strategy improved cell biomass accumulation which correlates with glucose consumption.

Glucose consumption rate in fed-batch fermentation of S. cerevisiae cultures undergoing fixed and adapted continuous feeding strategies. The numbers shown indicate the areas under the curve of glucose consumption rate, i.e., the sum of glucose consumption (g/L) from the start of the fed-batch operation to the mid-feeding period, beyond which the rate decreased. The two values were statistically different (p < 0.05) based on a two-tailed t-test, indicated by an asterisk sign (*)

The total glucose fed was controlled in both fixed and adapted feeding strategies to ensure they could reach the same ethanol concentration at the end of fermentation for comparison. In the fixed feeding strategy, glucose addition was stopped at ~ 136 h, while in the adapted feeding strategy it was stopped earlier, at ~ 123 h. Moreover, the peak in residual glucose was lower in the adapted feeding strategy (15 g/L) than in the fixed feeding strategy (28 g/L). This also suggests that the glucose consumption was more efficient when operating the adapted feeding strategy.

The impacts of the adapted feeding strategy were also observed in trends in ethanol concentration. Ethanol was produced and accumulated during the feeding period, due to continuous glucose feeding. Interestingly, for both feeding strategies, the onset of glucose accumulation aligned with the ethanol concentration reaching ~ 60 g/L (Fig. 1b c, f, and g). Since ethanol is a product that can stress yeast cells (Bai et al. 2008; Russell 2003), we surmise that 60 g/L ethanol was likely a threshold to trigger metabolic inhibition. It is also important to note that after stopping the feeding, glucose stopped accumulating and decreased to complete depletion (Fig. 1b and f), which shows that the cells retained metabolic activity.

The evolved gas flow rate was monitored over the entire fermentation process to track metabolic activity and infer the glucose consumption rate. As shown in Fig. 1d and h, the evolved gas flow rate from the fixed and the adapted feeding strategies were maintained at ~ 14 ccm at the beginning of the feeding period. However, as glucose addition was increased in the adapted feeding strategy, the evolved gas flow rate increased to ~ 16 ccm; inferring that the glucose consumption rate might increase under this mode of operation. Indeed, as shown in Fig. 2, the glucose consumption rate in the adapted feeding strategy was generally greater than in the fixed feeding strategy. It is worth noting that as the evolved gas flow rate increased, the evolved gas production increased as well, indicating more glucose was required for ethanol fermentation. Through monitoring changes in evolved gas flow rate, the performance of ethanol fermentation can be tracked. This allowed us to identify events, such as the accumulation of glucose and its complete depletion (Fig. 1d and h), corresponding to trends observed by HPLC analysis (Fig. 1b and f). In fact, as the fresh medium was continuously fed until ~ 83 h and ~ 95 h in the fixed and adapted feeding strategy respectively, the evolved gas flow rate started to decrease, aligning with the increase in residual glucose (Fig. 1).

The potential application of the adapted continuous feeding strategy was further investigated by testing the system with reduced nitrogen content (N/C = 0.046:10) in the feed medium (Fig. 1i–l). Much like in nitrogen-replete experiments (N/C = 0.95:10; Fig. 1a and e), the adapted feeding strategy led to more efficient glucose feeding and higher cell content compared to the fixed feeding strategy. The trends in glucose and ethanol concentrations were similar with low or high nitrogen content for both adapted feeding strategies (Fig. 1e–h and i–l); with ethanol reaching 89 g/L (~ 11.3%, v/v) at the end of fermentations with low nitrogen content. Here again, glucose accumulation was observed once the ethanol concentration reached 60 g/L (at ~ 83 h). Residual glucose concentration reached 18 g/L in the adapted feeding, at which point feeding was stopped and the residual was consumed until depletion (Fig. 1j). The complete fermentation process was, again, faster using the adapted feeding strategy. For comparison, the results of the fixed feeding strategy with a low N/C feed medium can be found in Supplementary Figs. S3 and S4. These results suggest that the substrate delivery in the adapted feeding strategy could enhance the rates of glucose consumption and ethanol production compared to the fixed feeding operation, even when the low nitrogen feed medium was used.

Overall advancements in ethanol fermentation by adapted feeding strategies

Table 1 highlights critical fermentation performance parameters from fixed and adapted feeding strategies with high- and low-nitrogen feed media. In all cases, the residual glucose contents at the end of the fermentation were near zero and represented less than 0.5% of the total glucose added. Since the glucose addition was controlled to reach a given ethanol content, all fermentations reached statistically equivalent ethanol concentrations (~ 90 g/L or ~ 11%, v/v) and efficiency (~ 70.5% of the theoretical maximum sugar-to-ethanol conversion). However, it is worth noting that ethanol productivity was improved by approximately 21% when the adapted feeding strategy was applied, regardless of nitrogen content in the feed medium. This supports our hypothesis that adjusting glucose addition based on the evolved gas production during ethanol fermentation can enhance sugar utilization and ethanol productivity. The adapted feeding strategy provides a more efficient way for continuous sugar delivery in fed-batch fermentation, while the fixed feeding strategy may limit substrate addition and even ethanol production. Regulating sugar concentration in fermentation becomes important because it can affect yield and efficiency (Dodić et al. 2009; Phukoetphim et al. 2017).

Discussion

In fed-batch fermentation, feeding strategy is a crucial variable to control limiting nutrients in the fermentation process. Fermentable sugar is a known limiting nutrient and a major carbon source that impacts the yeasts’ metabolism, ethanol yield, and ethanol productivity (Russell 2003). Controlling the sugar stream in the fed-batch fermentation is particularly critical for optimizing ethanol production. However, studies of adaptable feeding strategies for sugar delivery in lignocellulosic ethanol production are still very limited. A fixed-rate substrate supply may not address limited fermentation performance and maximize ethanol production.

In the present work, a novel adapted pathway of sugar delivery was developed for improving ethanol fermentation. Similar to Unrean and Nguyen (2013) and Phukoetphim et al. (2017), we observed that the substrate feeding rate impacts ethanol productivity in fed-batch fermentation. However, our study goes further by demonstrating that evolved gas production can serve as an effective parameter for gradually increasing glucose addition during ethanol fermentation with S. cerevisiae. While fixed feeding strategies with excessive feed rates may cause residual glucose accumulation and limit ethanol production (Cheng et al. 2009), the adapted continuous feeding strategy allowed for more efficient sugar usage. Additionally, continuous feeding operations reduce heterogeneity between the fermentation broth and fresh feed medium, unlike pulse feedings which deliver substrates all at once, potentially causing osmotic stress on the yeast. These findings align with Phukoetphim et al. (2017), who observed that continuous feeding results in lower substrate inhibition than pulse feeding. It is also worth noting that through controlling the sugar delivery in continuous feedings, the residual sugar was near zero for most of the fermentation until the yeast was metabolically impacted by the ethanol accumulated (Fig. 1). The low residual sugar can reduce the risk of the growth of contaminants. This strategy represents a valuable advancement for the biofuel industry to better control fermentation processes.

In the entire fermentation process, we managed glucose levels to stay under 100 g/L to prevent substrate inhibition in yeast. Chang et al. (2018) reported that the specific growth rate and ethanol productivity increased in batch cultures of S. cerevisiae as the initial glucose concentration was increased from 10 to 100 g/L. Beyond 100 g/L, the sugar concentration needs to be controlled to avoid strong osmotic stress on the microorganism (Flevaris and Chatzidoukas 2021). This is also supported by Chang et al. (2018) who showed decreases in yeast-specific growth rate and ethanol productivity when the initial glucose concentration increased from 100 to 260 g/L. Overall, our study demonstrates that the adapted feeding strategy provides better sugar management than the fixed feeding strategy, resulting in higher ethanol productivity in ethanol fermentation. The development of feeding strategies can become more complex when substrate delivery shifts from pulse to continuous operations, as the substrate addition rate can be controlled based on continuous, real-time monitoring of key parameters tied to cell growth during fermentation.

Monitoring metabolic responses during ethanol fermentation is critical for applying feedback control to substrate delivery. Ethanol production under anaerobic conditions is linked to the primary metabolism of S. cerevisiae: when glucose is consumed, ethanol and carbon dioxide are produced, and adenosine triphosphate (ATP) is generated for cell growth, maintenance, or reproduction (Lin and Tanaka 2006; Zabed et al. 2017). For example, a viable cell sensor is used to estimate the cell number by measuring the capacitance of the fermentation medium and determining the time for supplying fresh medium in the fed-batch fermentation (Feng et al. 2021). While spectroscopy has been used as an in-line monitoring system for glucose addition during ethanol fermentation (Hirsch et al. 2019), its measurement may be interfered with by non-dissolved particles, bubbles, or cell agglomerates present in the fermentation medium (Schalk et al. 2017; Shaw et al. 1999; Wang et al. 2014). Based on the metabolic pathway of ethanol fermentation, carbon dioxide can also be effectively used as a monitoring parameter to control the fermentation process. Wang et al. (2020) applied the evolved gas flow rate to monitor and operate self-cycling ethanol fermentation for ethanol production. Hung et al. (2023) determined the appropriate feeding point for pulsed fed-batch fermentation based on evolved gas flow rate. In our present work, we utilized evolved gas production to guide sugar delivery in the adapted continuous feeding strategy, leading to higher ethanol productivity than using the fixed feeding strategy. Furthermore, changes in evolved gas flow rate can infer the metabolic response in ethanol fermentation. In ethanol fermentation, ethanol is a product that can stress yeast cells. Through continuous feeding operations, we found that 60 g/L of ethanol likely represents a threshold that triggers metabolic inhibition, leading to the onset of glucose accumulation and evolved gas flow rate reduction. This is supported by Cot et al. (2007), who showed that, in fed-batch fermentation, cell viability was reduced when ethanol reached 60–80 g/L; and that cell viability decreased sharply when ethanol reached 100 g/L. As ethanol is accumulated during fermentation, its negative metabolic impact on the yeast can be viewed differently, such as the trigger for mild or complete inhibition. Thus, the evolved gas from the bioreactor was used not only to manage the sugar feed rate but also to monitor the yeast’s metabolic response during ethanol fermentation in the present study. To overcome the high ethanol titer limitation in industrial settings, the continuous adaptive fed-batch strategy could be combined with different ethanol extractive approaches, such as adsorption or continuous membrane separation (Beluhan et al. 2023; Zentou et al. 2019). The application of evolved gas is worth further investigating for fermentation optimization in the future.

In addition to providing an efficient pathway for sugar delivery, we further demonstrate the flexibility of conducting the adapted feeding strategy with a low nitrogen feed medium in ethanol fermentation. Although nitrogen is essential to the growth of microorganisms, quantifying and unifying the nitrogen content in every batch of lignocellulosic hydrolysate may not be practical. In our study, even using low nitrogen (N/C = 0.046:10) feed medium, the adapted feeding strategy still enhanced ethanol productivity compared to the fixed feeding strategy. Indeed, nitrogen is essential to yeast cell formation (Kiran and Liu 2015; Russell 2003). However, the impact of nitrogen content on the performance of ethanol fermentation may not necessarily align with the above situation. For example, high ethanol concentration was observed in low N/C ratio conditions with S. cerevisiae (Kiran and Liu 2015) and Escherichia coli KO11 (Imamoglu and Sukan 2014), respectively. Furthermore, Pinilla et al. (2011) reported that ethanol yield and specific ethanol productivity were higher when the N/C ratio was 0.22:10, as compared to either lower or higher N/C ratio at 0.11:10 and 1.1:10 in the fermentation of Zymomonas mobilis. The minimal nitrogen requirement of yeast determines the point below which sluggish or stuck fermentation may take place (Bisson and Butzke 2000). Mendes‐Ferreira et al. (2004) reported that 267 mg Nitrogen/L was the minimal nitrogen content for growing S. cerevisiae PYCC 4072 (an industrial wine yeast) in a synthetic grape juice medium, avoiding sluggish or stuck fermentation. In the present study, the feed with lower nitrogen content (1.06 g nitrogen/L) had no impact on ethanol productivity when applying the adapted feeding strategy. This suggests that nitrogen availability from two feed media may not significantly influence ethanol production under adapted conditions. Overall, the low-nitrogen feed medium was applicable for growing the yeast strain in adaptive fed-batch fermentation, providing more economic flexibility to the bioethanol industry. Beyond the cost implications, reducing nitrogen content has the potential to minimize byproduct formation. Barbosa et al. (2009) reported that nitrogen addition influenced the profile of volatile compounds during ethanol fermentation by S. cerevisiae. It was also reported that excess nitrogen can increase the production of non-ethanol byproducts, such as organic acids, ethyl esters, and higher alcohols, which divert carbon flux away from ethanol synthesis. Sheikh et al. (2016) observed that reducing nitrogen addition from 8 g/L to 2 g/L improved ethanol production from potato peel wastes. The change in nitrogen flux during adaptive fed-batch fermentation represents an interesting topic for further investigation. In addition, reducing nitrogen content can decrease nitrogen-rich waste in the downstream process, contributing to process sustainability and lowering the environmental burden associated with wastewater treatment. Moving forward, evaluating nitrogen availability as a critical variable will provide valuable insights for optimizing ethanol biosynthesis pathways in adaptive fed-batch fermentation.

In the bioethanol industry, high ethanol concentration is important to reduce the cost and improve the efficiency of ethanol recovery in the downstream process. For example, the minimal ethanol content for economic recovery at the industrial scale is 4% (w/v) (Koppram et al. 2013; Zacchi and Axelsson 1989), but fermentation ethanol contents commonly reach up to 11% (v/v) in the industry (Elliston et al. 2013). In the present work, with both fixed and adapted feeding strategies, final ethanol contents reached 11% (v/v). The bench-scale performance demonstrated in this work is promising for large-scale processes. Operational and economic information from advanced bioethanol production can be imparted through scaling up to the bench scale (Kang et al. 2019), contributing further insights into potential commercial-scale production. In this study, we used Saccharomyces cerevisiae for ethanol fermentation. The biofuel industry commonly employs this yeast strain for ethanol production due to its high fermentation rate and stress tolerance. For example, S. cerevisiae can tolerate a wide range of pH levels and higher ethanol concentrations compared to other ethanolic microorganisms. (Tesfaw and Assefa 2014). These characteristics offered more applicability to the industry for ethanol production. Moreover, the adapted feeding strategy showed the highest ethanol productivity and reached above 11% (v/v) ethanol, regardless of the nitrogen contents. Such advancements can be attractive to the bioethanol industry as they can be implemented in the current infrastructures without major changes in equipment or operation (e.g., merely changing the substrate feed rate).

In summary, this study successfully demonstrated how an adapted feeding strategy could improve ethanol productivity by 21% in fed-batch fermentation based on evolved gas, as compared to a fixed feeding strategy. The performance of the adapted feeding strategy was shown to be maintained even when using a feed medium with low nitrogen content (N/C = 0.046:10). In all cases tested the final ethanol concentration was ~ 90 g/L (~ 11%, v/v) in 5-L bioreactors. These advancements can serve in the development of efficient practices for substrate delivery and improving ethanol production from sugar-based or lignocellulosic feedstocks. Moreover, we showed the point at which ethanol concentration can impede glucose utilization. Efficient yeast ethanol fermentation could be identified using the evolved gas increased, as a correlate of glucose consumed per liter of reactor. Overall, this study presents a flexible and effective sugar-feeding strategy for fed-batch fermentation which could be potentially integrated into existing fermentation infrastructures to optimize production in the ethanol industry. Future work should focus on investigating the integration of the continuously adapted feeding strategy to further improve ethanol production and productivity.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and/or its supplementary materials upon request.

References

Aghaei S, Alavijeh MK, Shafiei M, Karimi K (2022) A comprehensive review on bioethanol production from corn stover: Worldwide potential, environmental importance, and perspectives. Biomass Bioenergy 161:106447. https://doi.org/10.1016/j.biombioe.2022.106447

Amorim HV, Lopes ML, de Castro Oliveira JV, Buckeridge MS, Goldman GH (2011) Scientific challenges of bioethanol production in Brazil. Appl Microbiol Biotechnol 91:1267–1275. https://doi.org/10.1007/s00253-011-3437-6

Azhar SHM, Abdulla R, Jambo SA, Marbawi H, Gansau JA, Faik AAM, Rodrigues KF (2017) Yeasts in sustainable bioethanol production: A review. Biochem Biophys Rep 10:52–61. https://doi.org/10.1016/j.bbrep.2017.03.003

Bai F, Anderson W, Moo-Young M (2008) Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol Adv 26(1):89–105. https://doi.org/10.1016/j.biotechadv.2007.09.002

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energ Convers Manage 52(2):858–875. https://doi.org/10.1016/j.enconman.2010.08.013

Barbosa C, Falco V, Mendes-Faia A, Mendes-Ferreira A (2009) Nitrogen addition influences formation of aroma compounds, volatile acidity and ethanol in nitrogen deficient media fermented by Saccharomyces cerevisiae wine strains. J Biosci Bioeng 108(2):99–104. https://doi.org/10.1016/j.jbiosc.2009.02.017

Beluhan S, Mihajlovski K, Šantek B, Ivančić Šantek M (2023) The production of bioethanol from lignocellulosic biomass: Pretreatment methods, fermentation, and downstream processing. Energies 16(19):7003. https://doi.org/10.3390/en16197003

Bhargava S, Nandakumar M, Roy A, Wenger KS, Marten MR (2003) Pulsed feeding during fed-batch fungal fermentation leads to reduced viscosity without detrimentally affecting protein expression. Biotechnol Bioeng 81(3):341–347. https://doi.org/10.1002/bit.10548

Bisson LF, Butzke CE (2000) Diagnosis and rectification of stuck and sluggish fermentations. Am J Enol Vitic 51(2):168–177. https://doi.org/10.5344/ajev.2000.51.2.168

Bolmanis E, Dubencovs K, Suleiko A, Vanags J (2023) Model predictive control—a stand out among competitors for fed-batch fermentation improvement. Fermentation 9(3):206. https://doi.org/10.3390/fermentation9030206

Chang Y-H, Chang K-S, Chen C-Y, Hsu C-L, Chang T-C, Jang H-D (2018) Enhancement of the efficiency of bioethanol production by Saccharomyces cerevisiae via gradually batch-wise and fed-batch increasing the glucose concentration. Fermentation 4(2):45. https://doi.org/10.3390/fermentation4020045

Cheng NG, Hasan M, Kumoro AC, Ling CF, Tham M (2009) Production of ethanol by fed-batch fermentation. Pertanika J Sci Technol 17(2):399–408

Cot M, Loret M-O, François J, Benbadis L (2007) Physiological behaviour of Saccharomyces cerevisiae in aerated fed-batch fermentation for high level production of bioethanol. FEMS Yeast Res 7(1):22–32. https://doi.org/10.1111/j.1567-1364.2006.00152.x

Dodić S, Popov S, Dodić J, Ranković J, Zavargo Z, Mučibabić RJ (2009) Bioethanol production from thick juice as intermediate of sugar beet processing. Biomass Bioenergy 33(5):822–827. https://doi.org/10.1016/j.biombioe.2009.01.002

Elliston A, Collins SR, Wilson DR, Roberts IN, Waldron KW (2013) High concentrations of cellulosic ethanol achieved by fed batch semi simultaneous saccharification and fermentation of waste-paper. Bioresour Technol 134:117–126. https://doi.org/10.1016/j.biortech.2013.01.084

Feng Y, Tian X, Chen Y, Wang Z, Xia J, Qian J, Zhuang Y, Chu J (2021) Real-time and on-line monitoring of ethanol fermentation process by viable cell sensor and electronic nose. Bioresour Bioprocess 8(1):1–10. https://doi.org/10.1186/s40643-021-00391-5

Flevaris K, Chatzidoukas C (2021) Optimal fed-batch bioreactor operating strategies for the microbial production of lignocellulosic bioethanol and exploration of their economic implications: A step forward towards sustainability and commercialization. J Clean Prod 295:126384. https://doi.org/10.1016/j.jclepro.2021.126384

Hewitt CJ, Nienow AW (2007) The scale-up of microbial batch and fed-batch fermentation processes. Adv Appl Microbiol 62:105–135. https://doi.org/10.1016/S0065-2164(07)62005-X

Hirsch E, Pataki H, Domján J, Farkas A, Vass P, Fehér C, Barta Z, Nagy ZK, Marosi GJ, Csontos I (2019) Inline noninvasive Raman monitoring and feedback control of glucose concentration during ethanol fermentation. Biotechnol Prog 35(5):e2848. https://doi.org/10.1002/btpr.2848

Hung Y-HR, Chae M, Sauvageau D, Bressler DC (2023) Adapted feeding strategies in fed-batch fermentation improve sugar delivery and ethanol productivity. Bioengineered 14(1):2250950. https://doi.org/10.1080/21655979.2023.2250950

Imamoglu E, Sukan FV (2014) The effects of single and combined cellulosic agrowaste substrates on bioethanol production. Fuel 134:477–484. https://doi.org/10.1016/j.fuel.2014.05.087

Kang KE, Jeong J-S, Kim Y, Min J, Moon S-K (2019) Development and economic analysis of bioethanol production facilities using lignocellulosic biomass. J Biosci Bioeng 128(4):475–479. https://doi.org/10.1016/j.jbiosc.2019.04.004

Kiran EU, Liu Y (2015) Bioethanol production from mixed food waste by an effective enzymatic pretreatment. Fuel 159:463–469. https://doi.org/10.1016/j.fuel.2015.06.101

Koppram R, Nielsen F, Albers E, Lambert A, Wännström S, Welin L, Zacchi G, Olsson L (2013) Simultaneous saccharification and co-fermentation for bioethanol production using corncobs at lab. PDU and Demo Scales Biotechnol Biofuels 6(1):1–10. https://doi.org/10.1186/1754-6834-6-2

Laopaiboon L, Thanonkeo P, Jaisil P, Laopaiboon P (2007) Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World J Microbiol Biotechnol 23(10):1497–1501. https://doi.org/10.1007/s11274-007-9383-x

Lim HC, Shin HS (2013) Fed-batch cultures: Principles and applications of semi-batch bioreactors. Cambridge University Press

Lin Y, Tanaka S (2006) Ethanol fermentation from biomass resources: Current state and prospects. Appl Microbiol Biotechnol 69(6):627–642. https://doi.org/10.1007/s00253-005-0229-x

Liu ZL, Slininger PJ, Gorsich SW (2005) Enhanced biotransformation of furfural and hydroxymethylfurfural by newly developed ethanologenic yeast strains. Appl Biochem Biotechnol 121:451–460. https://doi.org/10.1385/ABAB:121:1-3:0451

Melendez JR, Mátyás B, Hena S, Lowy DA, El Salous A (2022) Perspectives in the production of bioethanol: A review of sustainable methods, technologies, and bioprocesses. Renew Sustain Energ Rev 160:112260. https://doi.org/10.1016/j.rser.2022.112260

Mendes-Ferreira A, Mendes-Faia A, Leão C (2004) Growth and fermentation patterns of Saccharomyces cerevisiae under different ammonium concentrations and its implications in winemaking industry. J Appl Microbiol 97(3):540–545. https://doi.org/10.1111/j.1365-2672.2004.02331.x

Parashar A, Jin Y, Mason B, Chae M, Bressler DC (2016) Incorporation of whey permeate, a dairy effluent, in ethanol fermentation to provide a zero waste solution for the dairy industry. J Dairy Sci 99(3):1859–1867. https://doi.org/10.3168/jds.2015-10059

Periyasamy S, Isabel JB, Kavitha S, Karthik V, Mohamed BA, Gizaw DG, Sivashanmugam P, Aminabhavi TM (2023) Recent advances in consolidated bioprocessing for conversion of lignocellulosic biomass into bioethanol–a review. Chem Eng J 453:139783. https://doi.org/10.1016/j.cej.2022.139783

Phukoetphim N, Salakkam A, Laopaiboon P, Laopaiboon L (2017) Improvement of ethanol production from sweet sorghum juice under batch and fed-batch fermentations: Effects of sugar levels, nitrogen supplementation, and feeding regimes. Electron J Biotechnol 26:84–92. https://doi.org/10.1016/j.ejbt.2017.01.005

Pinilla L, Torres R, Ortiz C (2011) Bioethanol production in batch mode by a native strain of Zymomonas mobilis. World J Microbiol Biotechnol 27:2521–2528. https://doi.org/10.1007/s11274-011-0721-7

Raj T, Chandrasekhar K, Kumar AN, Banu JR, Yoon J-J, Bhatia SK, Yang Y-H, Varjani S, Kim S-H (2022) Recent advances in commercial biorefineries for lignocellulosic ethanol production: Current status, challenges and future perspectives. Bioresour Technol 344:126292. https://doi.org/10.1016/j.biortech.2021.126292

Russell I (2003) Chapter 9 - understanding yeast fundamentals. In: Jacques KA, Lyons TP, Kelsall DR (eds) The alcohol textbook: a reference for the beverage, fuel and industrial alcohol industries. 4 edn. Nottingham University Press., pp 531–537

Schalk R, Braun F, Frank R, Rädle M, Gretz N, Methner F-J, Beuermann T (2017) Non-contact Raman spectroscopy for in-line monitoring of glucose and ethanol during yeast fermentations. Bioprocess Biosyst Eng 40(10):1519–1527. https://doi.org/10.1007/s00449-017-1808-9

Shaw AD, Kaderbhai N, Jones A, Woodward AM, Goodacre R, Rowland JJ, Kell DB (1999) Noninvasive, on-line monitoring of the biotransformation by yeast of glucose to ethanol using dispersive Raman spectroscopy and chemometrics. Appl Spectrosc 53(11):1419–1428

Sheikh RA, Al-Bar OA, Soliman YMA (2016) Biochemical studies on the production of biofuel (bioethanol) from potato peels wastes by Saccharomyces cerevisiae: Effects of fermentation periods and nitrogen source concentration. Biotechnol Biotechnol Equip 30(3):497–505. https://doi.org/10.1080/13102818.2016.1159527

Siqueira PF, Karp SG, Carvalho JC, Sturm W, Rodríguez-León JA, Tholozan J-L, Singhania RR, Pandey A, Soccol CR (2008) Production of bio-ethanol from soybean molasses by Saccharomyces cerevisiae at laboratory, pilot and industrial scales. Bioresour Technol 99(17):8156–8163. https://doi.org/10.1016/j.biortech.2008.03.037

Taherzadeh MJ, Gustafsson L, Niklasson C, Lidén G (1999) Conversion of furfural in aerobic and anaerobic batch fermentation of glucose by Saccharomyces cerevisiae. J Biosci Bioeng 87(2):169–174. https://doi.org/10.1016/S1389-1723(99)89007-0

Tesfaw A, Assefa F (2014) Current trends in bioethanol production by Saccharomyces cerevisiae: Substrate, inhibitor reduction, growth variables, coculture, and immobilization. Int Sch Res Notices 2014:1–12. https://doi.org/10.1155/2014/532852

Unrean P, Nguyen NH (2013) Optimized fed-batch fermentation of Scheffersomyces stipitis for efficient production of ethanol from hexoses and pentoses. Appl Biochem Biotechnol 169(6):1895–1909. https://doi.org/10.1186/s40643-015-0069-1

Wang J, Chae M, Bressler DC, Sauvageau D (2020) Improved bioethanol productivity through gas flow rate-driven self-cycling fermentation. Biotechnol Biofuels 13(1):14. https://doi.org/10.1186/s13068-020-1658-6

Wang J, Chae M, Sauvageau D, Bressler DC (2017) Improving ethanol productivity through self-cycling fermentation of yeast: A proof of concept. Biotechnol Biofuels 10(1):193. https://doi.org/10.1186/s13068-017-0879-9

Wang Q, Li Z, Ma Z, Liang L (2014) Real time monitoring of multiple components in wine fermentation using an on-line auto-calibration Raman spectroscopy. Sens Actuators B Chem 202:426–432. https://doi.org/10.1016/j.snb.2014.05.109

Zabed H, Faruq G, Sahu JN, Azirun MS, Hashim R, Nasrulhaq Boyce A (2014) Bioethanol production from fermentable sugar juice. Sci World J 2014:1–12. https://doi.org/10.1155/2014/957102

Zabed H, Sahu J, Suely A, Boyce A, Faruq G (2017) Bioethanol production from renewable sources: Current perspectives and technological progress. Renew Sustain Energ Rev 71:475–501. https://doi.org/10.1016/j.rser.2016.12.076

Zacchi G, Axelsson A (1989) Economic evaluation of preconcentration in production of ethanol from dilute sugar solutions. Biotechnol Bioeng 34(2):223–233. https://doi.org/10.1002/bit.260340211

Zentou H, Abidin ZZ, Yunus R, Awang Biak DR, Korelskiy D (2019) Overview of alternative ethanol removal techniques for enhancing bioethanol recovery from fermentation broth. Processes 7(7):458. https://doi.org/10.3390/pr7070458

Funding

This research was funded and supported by the Future Energy Systems (T01-P01) at the University of Alberta, part of the Canada First Research Excellence Fund, and by the Natural Sciences and Engineering Research Council of Canada (NSERC) (Discovery Grants, NSERC; RGPIN 298352–2013).

Author information

Authors and Affiliations

Contributions

DCB, DS, and Y-HRH conceived and designed experiments. Y-HRH performed experiments and analyzed data. Y-HRH and DS wrote the manuscript. DCB and DS provided assistance in data analysis and troubleshooting and edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

(PDF 164 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hung, YH.R., Sauvageau, D. & Bressler, D.C. An adaptive, continuous substrate feeding strategy based on evolved gas to improve fed-batch ethanol fermentation. Appl Microbiol Biotechnol 109, 64 (2025). https://doi.org/10.1007/s00253-025-13447-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00253-025-13447-9