Abstract

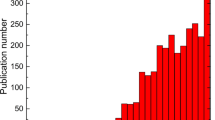

In recent years, cold spray technology has attracted more and more attentions. After more than 30 years of rapid development, research focus of cold spray technology is gradually shifting from fundamental and theoretical studies to application developments, some of which have been industrialized and mass-produced. In this paper, the characteristics of cold spray technology, cold spray materials perspectives and cold spray system developments were briefly introduced. Besides, the recent developments of cold spray applications in different fields including aerospace, biomedical, energy, electronics, semiconductor fields were discussed. Although cold spray technology is in the early stages of implementation, it has demonstrated a great potential to reduce costs and improve performance. World-wide awareness of ongoing and planned cold spray programs is critical to expand its applications and benefits.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

A. Papyrin, Cold Spray Technology, Adv. Mater. Process., 2001, 159(9), p 49-49.

J. Villafuerte, Modern cold spray: materials, process, and applications, Springer, (2015)

R. Huang and H. Fukanuma, Future trends in cold spray techniques, Elsevier, Future Development of Thermal Spray Coatingsed., 2015, p 143–162

H. Assadi, H. Kreye, F. Gärtner and T. Klassen, Cold Spraying – A Materials Perspective, Acta Mater., 2016, 116, p 382–407.

A. Moridi, S.M. Hassani-Gangaraj, M. Guagliano and M. Dao, Cold Spray Coating: Review of Material Systems and Future Perspectives, Surf. Eng., 2014, 30(6), p 369–395.

S. Yin, P. Cavaliere, B. Aldwell, R. Jenkins, H. Liao, W. Li and R. Lupoi, Cold Spray Additive Manufacturing and Repair: Fundamentals and Applications, Addit. Manuf., 2018, 21, p 628–650.

X. Chu, H. Che, C. Teng, P. Vo and S. Yue, A Multiple Particle Arrangement Model to Understand Cold Spray Characteristics of Bimodal Size 316L/Fe Powder Mixtures, Surf. Coat. Technol., 2020, 381, p 125137.

X.-T. Luo, S.-P. Li, G.-C. Li, Y.-C. Xie, H. Zhang, R.-Z. Huang and C.-J. Li, Cold spray (CS) Deposition of a Durable Silver Coating with High Infrared Reflectivity for Radiation Energy Saving in the Polysilicon CVD Reactor, Surf. Coat. Technol., 2021, 409, p 126841.

R. Huang, M. Sone, W. Ma and H. Fukanuma, The Effects of Heat Treatment on the Mechanical Properties of Cold-Sprayed Coatings, Surf. Coat. Technol., 2015, 261, p 278–288.

W.-Y. Li, C. Zhang, X. Guo, G. Zhang, H. Liao and C. Coddet, Deposition Characteristics of Al–12Si Alloy Coating Fabricated by Cold Spraying with Relatively Large Powder Particles, Appl. Surf. Sci., 2007, 253(17), p 7124–7130.

X.-J. Ning, J.-H. Jang, H.-J. Kim, C.-J. Li and C. Lee, Cold Spraying of Al–Sn Binary Alloy: Coating Characteristics and Particle Bonding Features, Surf. Coat. Technol., 2008, 202(9), p 1681–1687.

L. Ajdelsztajn, A. Zuniga, B. Jodoin and E. Lavernia, Cold-Spray Processing of a Nanocrystalline Al−Cu−Mg−Fe−Ni Alloy with Sc, J. Therm. Spray Technol., 2006, 15(2), p 184–190.

J. Huang, X. Yan, C. Chang, Y. Xie, W. Ma, R. Huang, R. Zhao, S. Li, M. Liu and H. Liao, Pure Copper Components Fabricated by Cold Spray (CS) and Selective Laser Melting (SLM) Technology, Surf. Coat. Technol., 2020, 395, p 125936.

C. Borchers, F. Gärtner, T. Stoltenhoff and H. Kreye, Microstructural Bonding Features of Cold Sprayed Face Centered Cubic Metals, J. Appl. Phys., 2004, 96(8), p 4288–4292.

Y. Feng, W. Li, C. Guo, M. Gong and K. Yang, Mechanical Property Improvement Induced by Nanoscaled Deformation Twins in Cold-Sprayed Cu Coatings, Mater. Sci. Eng., A, 2018, 727, p 119–122.

W. Sun, A.W.Y. Tan, I. Marinescu, W.Q. Toh and E. Liu, Adhesion, Tribological and Corrosion Properties of Cold-Sprayed CoCrMo and Ti6Al4V Coatings on 6061–T651 Al alloy, Surf. Coat. Technol., 2017, 326, p 291–298.

A.W.-Y. Tan, W. Sun, A. Bhowmik, J.Y. Lek, I. Marinescu, F. Li, N.W. Khun, Z. Dong and E. Liu, Effect of Coating Thickness on Microstructure, Mechanical Properties and Fracture Behaviour of Cold Sprayed Ti6Al4V Coatings on Ti6Al4V Substrates, Surf. Coat. Technol., 2018, 349, p 303–317.

A.W.-Y. Tan, W. Sun, Y.P. Phang, M. Dai, I. Marinescu, Z. Dong and E. Liu, Effects of Traverse Scanning Speed of Spray Nozzle on the Microstructure and Mechanical Properties of Cold-Sprayed Ti6Al4V Coatings, J. Therm. Spray Technol., 2017, 26(7), p 1484–1497.

H. Aydin, M. Alomair, W. Wong, P. Vo and S. Yue, Cold Sprayability of Mixed Commercial Purity Ti Plus Ti6Al4V Metal Powders, J. Therm. Spray Technol., 2017, 26(3), p 360–370.

A.W.-Y. Tan, W. Sun, A. Bhowmik, J.Y. Lek, X. Song, W. Zhai, H. Zheng, F. Li, I. Marinescu and Z. Dong, Effect of Substrate Surface Roughness on Microstructure and Mechanical Properties of Cold-Sprayed Ti6Al4V Coatings on Ti6Al4V Substrates, J. Therm. Spray Technol., 2019, 28(8), p 1959–1973.

D. Boruah, B. Ahmad, T.L. Lee, S. Kabra, A.K. Syed, P. McNutt, M. Doré and X. Zhang, Evaluation of Residual Stresses Induced by Cold Spraying of Ti-6Al-4V on Ti-6Al-4V Substrates, Surf. Coat. Technol., 2019, 374, p 591–602.

W. Ma, Y. Xie, C. Chen, H. Fukanuma, J. Wang, Z. Ren and R. Huang, Microstructural and Mechanical Properties of High-Performance Inconel 718 Alloy by Cold Spraying, J. Alloy. Compd., 2019, 792, p 456–467.

W. Sun, A.W.-Y. Tan, D.J.Y. King, N.W. Khun, A. Bhowmik, I. Marinescu and E. Liu, Tribological Behavior of Cold Sprayed Inconel 718 Coatings at Room and Elevated Temperatures, Surf. Coat. Technol., 2020, 385, p 125386.

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen and R. Lupoi, Deposition of FeCoNiCrMn High Entropy Alloy (HEA) Coating Via Cold Spraying, J. Mater. Sci. Technol., 2019, 35(6), p 1003–1007.

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau and S.-Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303.

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu and Y. Yang, High-Entropy Alloy: Challenges and Prospects, Mater. Today, 2016, 19(6), p 349–362.

C. Chen, Y. Xie, L. Liu, R. Zhao, X. Jin, S. Li, R. Huang, J. Wang, H. Liao and Z. Ren, Cold Spray Additive Manufacturing of Invar 36 alloy: Microstructure, Thermal Expansion and Mechanical Properties, J. Mater. Sci. Technol., 2021, 72, p 39–51.

X. Xie, C. Chen, Z. Chen, W. Wang, S. Yin, G. Ji and H. Liao, Achieving Simultaneously Improved Tensile Strength and Ductility of a Nano-TiB2/AlSi10Mg Composite Produced by Cold Spray Additive Manufacturing, Compos. Part B Eng., 2020, 202, p 108404.

C. Chen, Y. Xie, X. Yan, M. Ahmed, R. Lupoi, J. Wang, Z. Ren, H. Liao and S. Yin, Tribological Properties of Al/Diamond Composites Produced by Cold Spray Additive Manufacturing, Addit. Manuf., 2020, 36, p 101434.

J. Karthikeyan, Cold Spray Technology: The Cold Spray Process has the Potential to Reduce Costs and Improve Quality in Both Coatings and Freeform Fabrication of Near-Net-Shape Parts, Adv. Mater. Process., 2005, 163(3), p 33–36.

G. Huang, D. Gu, X. Li, L. Xing and H. Wang, Numerical Simulation on Syphonage Effect of Laval Nozzle for Low Pressure Cold Spray System, J. Mater. Process. Technol., 2014, 214(11), p 2497–2504.

Z.H. Chen, X.F. Sun, Y.L. Huang, A brief discussion about nickel aluminum bronze propeller failure modes and its repair methods. Key Engineering Materials, Trans Tech Publ, pp 125-129 (2017)

W. Tillmann, L. Hagen, M. Kensy, M. Abdulgader and M. Paulus, Microstructural and Tribological Characteristics of Sn-Sb-Cu-Based Composite Coatings Deposited by Cold Spraying, J. Therm. Spray Technol., 2020, 29, p 1027–1039.

M.J. Azizpour and S.N.H.M. Majd, Babbitt Casting and Babbitt Spraying Processes Case Study, Int. J. Mech. Mechatron. Eng., 2011, 5(8), p 1628–1630.

B.S. DeForce, T.J. Eden and J.K. Potter, Cold Spray Al-5% Mg Coatings for the Corrosion Protection of Magnesium Alloys, J. Therm. Spray Technol., 2011, 20(6), p 1352–1358.

A. Sova, S. Grigoriev, A. Kochetkova and I. Smurov, Influence of Powder Injection Point Position on Efficiency of Powder Preheating in Cold Spray: Numerical Study, Surf. Coat. Technol., 2014, 242, p 226–231.

M. Rokni, S. Nutt, C. Widener, V. Champagne and R. Hrabe, Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray, J. Therm. Spray Technol., 2017, 26(6), p 1308–1355.

S. Glass, J. Lareau, K. Ross, S. Ali, F. Hernandez, B. Lopez, Magnetostrictive cold spray sensor for harsh environment and long-term condition monitoring, AIP Conference Proceedings, AIP Publishing LLC, p 020018 (2019)

T.J. Eden, K.G. Judd, R. Girrior, Properties for AA7050 deposits produced by the cold spray process, SAMPE 2019 Conference and Exhibition, p 11 (2019)

H. Wu, X. Xie, M. Liu, C. Verdy, Y. Zhang, H. Liao and S. Deng, Stable Layer-Building Strategy to Enhance Cold-Spray-Based Additive Manufacturing, Addit. Manuf., 2020, 35, p 101356.

H. Wu, X. Xie, M. Liu, C. Chen, H. Liao, Y. Zhang and S. Deng, A new approach to simulate coating thickness in cold spray, Surf. Coat. Technol., 2020, 382, p 125151.

A.A. Filippov, V.M. Fomin, A.M. Orishich, A.G. Malikov, N.S. Ryashin, A.A. Golyshev, Investigation of the microstructure of Ni and B4C ceramic-metal mixtures obtained by cold spray coating and followed by laser cladding, AIP Conference Proceedings, p 030019 (2017)

D. Wilmot, C.D. Howe, R. Todorovic, B. Hoiland, Case Study of Low-Pressure Cold Spray Conductive Coating, Adv. Mater. Process., 168, S12+ (2010) (in English)

Z. Zhang, F. Liu, E.-H. Han, L. Xu and P.C. Uzoma, Effects of Al2O3 on the Microstructures and Corrosion Behavior of Low-Pressure Cold Gas Sprayed Al 2024-Al2O3 Composite Coatings on AA 2024–T3 Substrate, Surf. Coat. Technol., 2019, 370, p 53–68.

V. Champagne and D. Helfritch, Critical Assessment 11: Structural Repairs by Cold Spray, Mater. Sci. Technol., 2015, 31(6), p 627–634.

O.C. Ozdemir and C.A. Widener, Influence of Powder Injection Parameters in High-Pressure Cold Spray, J. Therm. Spray Technol., 2017, 26(7), p 1411–1422.

A. Moridi, S.M.H. Gangaraj, S. Vezzu and M. Guagliano, Number of Passes and Thickness Effect on Mechanical Characteristics of Cold Spray Coating, Procedia Eng., 2014, 74, p 449–459.

D. MacDonald, S. Leblanc-Robert, R. Fernández, A. Farjam and B. Jodoin, Effect of Nozzle Material on Downstream Lateral Injection Cold Spray Performance, J. Therm. Spray Technol., 2016, 25(6), p 1149–1157.

C. Massar, K. Tsaknopoulos, B.C. Sousa, J. Grubbs and D.L. Cote, Heat Treatment of Recycled Battlefield Stainless-Steel Scrap for Cold Spray Applications, JOM, 2020, 72(9), p 3080–3089.

GEN III™ portable high-pressure cold spray system, https://vrcmetalsystems.com/gen-iii-portable-high-pressure-cold-spray-system/

C. Widener, M. Carter, O. Ozdemir, R. Hrabe, B. Hoiland, T. Stamey, V. Champagne and T. Eden, Application of High-Pressure Cold Spray for an Internal Bore Repair of a Navy Valve Actuator, J. Therm. Spray Technol., 2016, 25(1–2), p 193–201.

Impact cold spray system EvoCSII, https://impact-innovations.com/en/portfolio-item/impact-cold-spray-system/

Cold spray equipment, http://plasma.co.jp/en/products/coldspray.html

W. Wong, E. Irissou, P. Vo, M. Sone, F. Bernier, J.-G. Legoux, H. Fukanuma and S. Yue, Cold Spray Forming of Inconel 718, J. Therm. Spray Technol., 2013, 22(2–3), p 413–421.

Spraying equipment DYMET®, http://en.dymet.net/spraying-equipment-dymet.html

Cold spray - SST™ equipment & supplies, https://www.cntrline.com/products/cold-spray-sst-equipment-supplies

W.-Y. Li, H. Liao, H.-T. Wang, C.-J. Li, G. Zhang and C. Coddet, Optimal Design of a Convergent-Barrel Cold Spray Nozzle by Numerical Method, Appl. Surf. Sci., 2006, 253(2), p 708–713.

S. Kumar, M. Ramakrishna, N.M. Chavan and S.V. Joshi, Correlation of Splat State with Deposition Characteristics of Cold Sprayed Niobium Coatings, Acta Mater., 2017, 130, p 177–195.

V. Varadaraajan and P. Mohanty, Design and Optimization of Rectangular Cold Spray Nozzle: Radial Injection Angle, Expansion Ratio and Traverse Speed, Surf. Coat. Technol., 2017, 316, p 246–254.

S. Yin, X.-F. Wang and W.-Y. Li, Computational Analysis of the Effect of Nozzle Cross-Section Shape on Gas Flow and Particle Acceleration in Cold Spraying, Surf. Coat. Technol., 2011, 205(8), p 2970–2977.

X.K. Suo, T.K. Liu, W.Y. Li, Q.L. Suo, M.P. Planche and H.L. Liao, Numerical Study on the Effect of Nozzle Dimension on Particle Distribution in Cold Spraying, Surf. Coat. Technol., 2013, 220, p 107–111.

A. Sova, I. Smurov, M. Doubenskaia and P. Petrovskiy, Deposition of Aluminum Powder by Cold Spray Micronozzle, The Int. J. Adv. Manuf. Technol., 2018, 95(9), p 3745–3752.

T. Schmidt, F. Gaertner and H. Kreye, New Developments in Cold Spray Based on Higher Gas and Particle Temperatures, J. Therm. Spray Technol., 2006, 15(4), p 488–494.

Y.Y. Wang, Y. Liu, C.J. Li, G.J. Yang and K. Kusumoto, Electrical and Mechanical Properties of Nano-Structured TiN Coatings Deposited by Vacuum Cold Spray, Vacuum, 2012, 86(7), p 953–959.

V.K. Champagne Jr, O.C. Ozdemir, A. Nardi, Practical Cold Spray, Springer, (2021)

T. Stamey, Main circulating water pump: case study, Cold Spray Action Team (CSAT) Conference, (2016)

A. Moridi, E.J. Stewart, A. Wakai, H. Assadi, F. Gartner, M. Guagliano, T. Klassen and M. Dao, Solid-State Additive Manufacturing of Porous Ti-6Al-4V by Supersonic Impact, Appl. Mater. Today, 2020, 21, p 100865.

H. Koivuluoto, J. Näkki and P. Vuoristo, Corrosion Properties of Cold-Sprayed Tantalum Coatings, J. Therm. Spray Technol., 2008, 18(1), p 75–82.

X. Chu, R. Chakrabarty, H. Che, L. Shang, P. Vo, J. Song and S. Yue, Investigation of the Feedstock Deposition Behavior in a Cold Sprayed 316L/Fe Composite Coating, Surf. Coat. Technol., 2018, 337, p 53–62.

R. Ma and T. Tang, Current Strategies to Improve the Bioactivity of PEEK, Int. J. Mol. Sci., 2014, 15(4), p 5426–5445.

K. Ravi, Y. Ichikawa, T. Deplancke, K. Ogawa, O. Lame and J.-Y. Cavaille, Development of Ultra-High Molecular Weight Polyethylene (UHMWPE) Coating by Cold Spray Technique, J. Therm. Spray Technol., 2015, 24(6), p 1015–1025.

K. Ravi, Y. Ichikawa, K. Ogawa, T. Deplancke, O. Lame and J.-Y. Cavaille, Mechanistic Study and Characterization of Cold-Sprayed Ultra-High Molecular Weight Polyethylene-Nano-Ceramic Composite Coating, J. Therm. Spray Technol., 2016, 25(1–2), p 160–169.

P.C. King, A.J. Poole, S. Horne, R. de Nys, S. Gulizia and M.Z. Jahedi, Embedment of Copper Particles into Polymers by Cold Spray, Surf. Coat. Technol., 2013, 216, p 60–67.

A.C. Noorakma, H. Zuhailawati, V. Aishvarya and B. Dhindaw, Hydroxyapatite-Coated Magnesium-Based Biodegradable Alloy: Cold Spray Deposition and Simulated Body Fluid Studies, J. Mater. Eng. Perform., 2013, 22(10), p 2997–3004.

Y. Liu, Z. Dang, Y. Wang, J. Huang and H. Li, Hydroxyapatite/Graphene-Nanosheet Composite Coatings Deposited by Vacuum Cold Spraying for Biomedical Applications: Inherited Nanostructures and Enhanced Properties, Carbon, 2014, 67, p 250–259.

N. Sanpo, M.L. Tan, P. Cheang and K.A. Khor, Antibacterial Property of Cold-Sprayed HA-Ag/PEEK Coating, J. Therm. Spray Technol., 2009, 18(1), p 10–15.

McGill researchers’ cold-spray coating deactivates COVID-19 virus, https://www.design-engineering.com/mcgill-researchers-cold-spray-coating-deactivates-covid-19-virus-1004035583/

A. Vardelle, C. Moreau, J. Akedo, H. Ashrafizadeh, C.C. Berndt, J.O. Berghaus, M. Boulos, J. Brogan, A.C. Bourtsalas and A. Dolatabadi, The 2016 Thermal Spray Roadmap, J. Therm. Spray Technol., 2016, 25(8), p 1376–1440.

V. Kosarev, S. Klinkov, B. Melamed, Y.K. Nepochatov, N. Ryashin, V. Shikalov, Cold spraying for power electronics: Deposition of thick topologically patterned copper layers on ceramics, AIP Conference Proceedings, AIP Publishing LLC, p 030047 (2018)

H. Yeom and K. Sridharan, Recent Advances of Cold Spray Technology in Nuclear Energy Applications, J. Adv. Mater. Process., 2020, 178(5), p 61–63.

B. Maier, H. Yeom, G. Johnson, T. Dabney, J. Walters, P. Xu, J. Romero, H. Shah and K. Sridharan, Development of Cold Spray Chromium Coatings for Improved Accident Tolerant Zirconium-Alloy Cladding, J. Nucl. Mater., 2019, 519, p 247–254.

H. Yeom, B. Maier, G. Johnson, T. Dabney, M. Lenling and K. Sridharan, High Temperature Oxidation and Microstructural Evolution of Cold Spray Chromium Coatings on Zircaloy-4 in Steam Environments, J. Nucl. Mater., 2019, 526, p 151737.

M. Ševeček, A. Gurgen, A. Seshadri, Y. Che, M. Wagih, B. Phillips, V. Champagne and K. Shirvan, Development of Cr Cold Spray–Coated Fuel Cladding with Enhanced Accident Tolerance, Nucl. Eng. Technol., 2018, 50(2), p 229–236.

H. Yeom, T. Dabney, G. Johnson, B. Maier, M. Lenling and K. Sridharan, Improving Deposition Efficiency in Cold Spraying Chromium Coatings by Powder Annealing, The Int. J. Adv. Manuf. Technol., 2019, 100(5), p 1373–1382.

J. Tam, W. Li, B. Yu, D. Poirier, J.-G. Legoux, P. Lin, G. Palumbo, J.D. Giallonardo and U. Erb, Reducing Complex Microstructural Heterogeneity in Electrodeposited and Cold Sprayed Copper Coating Junctions, Surf. Coat. Technol., 2020, 404, p 126479.

NASA additively manufactured rocket engine hardware passes cold spray, hot fire tests, https://www.nasa.gov/centers/marshall/news/releases/2021/nasa-additively-manufactured-rocket-engine-hardware-passes-cold-spray-hot-fire-tests.html

K. Malamousi, K. Delibasis, B. Allcock, S. Kamnis, Digital Transformation of Thermal and Cold Spray Processes with Emphasis on Machine Learning. Surf. Coat. Technol., 128138 (2022)

D. Ikeuchi, A. Vargas-Uscategui, X. Wu and P.C. King, Neural Network Modelling of Track Profile in Cold Spray Additive Manufacturing, Materials, 2019, 12(17), p 2827.

H. Canales, I. Cano and S. Dosta, Window of Deposition Description and Prediction of Deposition Efficiency Via Machine Learning Techniques in Cold Spraying, Surf. Coat. Technol., 2020, 401, p 126143.

Acknowledgments

This project is supported by Guangdong Academy of Sciences Special Fund for Comprehensive Industrial Technology Innovation Center Building (2022GDASZH-2022010107), Key-Area Research and Development Program of Guangdong Province (2020B0101330001), International Science & Technology Cooperation Program of Guangdong Province (2020A0505100046), Science and Technology Program of Guangzhou (202007020008) and Research Fund of State Key Laboratory for Marine Corrosion and Protection of Luoyang Ship Material Research Institute (LSMRI) under the contract No. 6142901200303.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special issue focus in the Journal of Thermal Spray Technology celebrating the 30th anniversary of the journal. The papers and topics were curated by the Editor-in-Chief Armelle Vardelle, University of Limoges/ENSIL

Rights and permissions

About this article

Cite this article

Sun, W., Chu, X., Lan, H. et al. Current Implementation Status of Cold Spray Technology: A Short Review. J Therm Spray Tech 31, 848–865 (2022). https://doi.org/10.1007/s11666-022-01382-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01382-4