Abstract

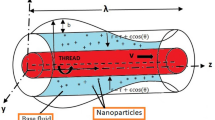

In this study, heat transfer and flow characteristics are numerically investigated in a two-dimensional pipe under turbulent flow conditions. In the numerical study, the effects of different types of wall corrugation (decreasing, increasing, and non-uniform wall corrugation), Reynolds numbers, and ternary hybrid nanofluid (Zn:Ag:Co/EG-H2O) on the Nusselt number, friction factor, and thermal performance factor are studied. The Reynolds number is chosen between 13,000 and 28,000. The nanoparticle volume fraction of Zn:Ag:Co/EG-H2O is 1.0%. When corrugations are added, the flow and temperature fields change significantly, which improves heat transfer. This is shown by comparing the results of the corrugated cases with those of the cases without corrugations. The results indicate that when using a smooth pipe with EG-H2O fluid, the Nusselt number rises by 24.53%, 51.77%, and 92.67% at Reynolds numbers of 18,000, 23,000, and 28,000, respectively, compared to that at a Reynolds number of 13,000. For all working fluids used, the Nusselt number is noticeably larger in the decreasing wall corrugation, increasing wall corrugation, and non-uniform wall corrugation pipes than in the smooth pipe. The Nusselt number values for the decreasing wall corrugation, increasing wall corrugation, and non-uniform wall corrugation pipes are notably higher than those for the smooth pipe with EG-H2O. Specifically, the Nusselt number values for the Zn:Ag:Co/EG-H2O hybrid nanofluid at a Reynolds number of 28,000 are 134.14%, 145.81%, and 137.06% higher for decreasing wall corrugation, increasing wall corrugation, and non-uniform wall corrugation pipes, respectively. With a non-uniform wall corrugation pipe, the value of the friction factor goes up the most, whereas with increasing wall corrugation pipe, the valuation of the friction factor goes up the least. The Zn:Ag:Co/EG-H2O hybrid nanofluid shows the greatest efficacy when transported via a pipe with increasing wall corrugation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Abbreviations

- DWC:

-

Decreasing wall corrugation

- IWC:

-

Increasing wall corrugation

- NWC:

-

Non-uniform wall corrugation

- TPF:

-

Thermal performance factor

- L :

-

Length of the pipe (m)

- D :

-

Diameter of the pipe (m)

- \(\phi\) :

-

Nanoparticle volume fraction

- \(u\) :

-

Velocity (m/s)

- \(E\) :

-

Total energy (J)

- \(P\) :

-

Pressure (Pa)

- k :

-

Turbulence kinetic energy (J/kg)

- \({C}_{1}\), \({C}_{2}\), \({\sigma }_{k}\),\({\sigma }_{\varepsilon }\) :

-

Constants

- C p :

-

Specific heat (j/kgK)

- \(\rho\) :

-

Density (kg/m3)

- q′′:

-

Heat flux (W/m2)

- \(\lambda\) :

-

Thermal conductivity (W/mK)

- \(\mu\) :

-

Viscosity (Pa.s)

- Pr:

-

Prandtl number

- Re:

-

Reynolds number

- \({D}_{h}\) :

-

Hydraulic diameter (m)

- h :

-

Heat transfer coefficient (W/m2K)

- FrFa:

-

Friction factor

- T :

-

Temperature (K)

- Nu:

-

Nusselt number

- thnf:

-

Ternary hybrid nanofluid

- w :

-

Wall

- b :

-

Bulk

- out:

-

Outlet

- in:

-

Inlet

References

Mohammed, A.; Al-Gburi, H.; Al-Abbas, A.: Experimental study of the thermal performance of corrugated helically coiled tube-in-tube heat exchanger, Front. Heat Mass Transf. (FHMT) 20, 17 (2023)

Khudheyer, A.F.; Al-Abbas, A.H.; Carutasiu, M.B.; Necula, H.: Turbulent heat transfer for internal flow of ethylene glycol-Al2O3 nanofluid in a spiral grooved tube with twisted tape inserts. J. Ther. Eng. 7, 761–772 (2021). https://doi.org/10.18186/thermal.928556

Sethumadhavan, R.; Raja Rao, M.: Turbulent flow friction and heat transfer characteristics of single- and multistart spirally enhanced tubes. J. Heat Transf. 108, 55–61 (1986). https://doi.org/10.1115/1.3246905

Harikrishnan, S.; Tiwari, S.: Effect of skewness on flow and heat transfer characteristics of a wavy channel. Int. J. Heat Mass Transf. 120, 956–969 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2017.12.120

Harikrishnan, S.; Tiwari, S.: Heat transfer characteristics of sinusoidal wavy channel with secondary corrugations. Int. J. Therm. Sci. 145, 105973 (2019). https://doi.org/10.1016/j.ijthermalsci.2019.105973

Pethkool, S.; Eiamsa-ard, S.; Kwankaomeng, S.; Promvonge, P.: Turbulent heat transfer enhancement in a heat exchanger using helically corrugated tube. Int. Commun. Heat Mass Transf. 38, 340–347 (2011). https://doi.org/10.1016/j.icheatmasstransfer.2010.11.014

Bahaidarah, H.M.: Entropy generation during fluid flow in sharp edge wavy channels with horizontal pitch. Adv. Mech. Eng. 8, 1687814016660929 (2016). https://doi.org/10.1177/1687814016660929

Ryu, D.N.; Choi, D.H.; Patel, V.C.: Analysis of turbulent flow in channels roughened by two-dimensional ribs and three-dimensional blocks. Part II: Heat transfer. Int. J. Heat Fluid Flow 28(5), 1112–1124 (2007). https://doi.org/10.1016/j.ijheatfluidflow.2006.11.007

Rainieri, S.; Bozzoli, F.; Pagliarini, G.: Experimental investigation on the convective heat transfer in straight and coiled corrugated tubes for highly viscous fluids: preliminary results. Int. J. Heat Mass Transf. 55, 498–504 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2011.08.030

Ekiciler, R.; Arslan, K.; Turgut, O.; Kurşun, B.: Effect of hybrid nanofluid on heat transfer performance of parabolic trough solar collector receiver. J. Therm. Anal. Calorim. 143, 1637–1654 (2021). https://doi.org/10.1007/s10973-020-09717-5

Pazarlıoğlu, H.K.; Ekiciler, R.; Arslan, K.; Mohammed, N.A.M.: Exergetic, Energetic, and entropy production evaluations of parabolic trough collector retrofitted with elliptical dimpled receiver tube filled with hybrid nanofluid. Appl. Ther. Eng. 223, 120004 (2023). https://doi.org/10.1016/j.applthermaleng.2023.120004

Korei, Z.; Louali, K.: Prediction of hybrid nanofluids behavior and entropy generation during the cooling of an electronic chip using the Lagrangian–Eulerian approach. Heat Transfer. 51, 6815–6835 (2022). https://doi.org/10.1002/htj.22625

Ambreen, T.; Saleem, A.; Tanveer, M.; Anirudh, K.; Shehzad, S.A.; Park, C.W.: Irreversibility and hydrothermal analysis of the MWCNTs/GNPs-based nanofluids for electronics cooling applications of the pin-fin heat sinks: multiphase Eulerian–Lagrangian modeling. Case Stud. Ther. Eng. 31, 101806 (2022). https://doi.org/10.1016/j.csite.2022.101806

Sharma, D.; Pandey, K.M.; Debbarma, A.; Choubey, G.: Numerical Investigation of heat transfer enhancement of SiO2-water based nanofluids in light water nuclear reactor. Mater. Today Proc. 4, 10118–10122 (2017). https://doi.org/10.1016/j.matpr.2017.06.332

Zheng, L.; Xie, Y.; Zhang, D.: Numerical investigation on heat transfer performance and flow characteristics in circular tubes with dimpled twisted tapes using Al2O3-water nanofluid. Int. J. Heat Mass Transf. 111, 962–981 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.062

Chyu, M.K.; Yu, Y.; Ding, H.; Downs, J.P.; Soechting, F.O.: Concavity Enhanced Heat Transfer in an Internal Cooling Passage. In: Volume 3: Heat Transfer; Electric Power; Industrial and Cogeneration, American Society of Mechanical Engineers, Orlando, Florida, USA, 1997: p. V003T09A080. https://doi.org/10.1115/97-GT-437

Hashemi Karouei, S.H.; Ajarostaghi, S.S.M.; Gorji-Bandpy, M.; Hosseini Fard, S.R.: Laminar heat transfer and fluid flow of two various hybrid nanofluids in a helical double-pipe heat exchanger equipped with an innovative curved conical turbulator. J. Therm. Anal. Calorim. 143, 1455–1466 (2021). https://doi.org/10.1007/s10973-020-09425-0

Sheikholeslami, M.; Ebrahimpour, Z.: Thermal improvement of linear Fresnel solar system utilizing Al2O3-water nanofluid and multi-way twisted tape. Int. J. Therm. Sci. 176, 107505 (2022). https://doi.org/10.1016/j.ijthermalsci.2022.107505

Qi, C.; Sun, L.; Wang, Y.; Wang, C.; Chen, G.: Thermo-hydraulic performance of nanofluids in a bionic fractal microchannel heat sink with traveling-wave fins. Korean J. Chem. Eng. 38, 1592–1607 (2021). https://doi.org/10.1007/s11814-021-0836-y

Khusnuriyalova, A.F.; Caporali, M.; Hey-Hawkins, E.; Sinyashin, O.G.; Yakhvarov, D.G.: Preparation of cobalt nanoparticles. Eur. J. Inorg. Chem. 2021, 3023–3047 (2021). https://doi.org/10.1002/ejic.202100367

Zahan, I.; Nasrin, R.; Khatun, S.: Thermal performance of ternary-hybrid nanofluids through a convergent-divergent nozzle using distilled water–ethylene glycol mixtures. Int. Commun. Heat Mass Transf. 137, 106254 (2022). https://doi.org/10.1016/j.icheatmasstransfer.2022.106254

Karki, P.; Gangawane, K.: Study of magnetohydrodynamics-based-mixed convection & entropy generation within the rectangular enclosure with two obstacles for Cu-SiO 2 multiwalled carbon nanotubes ternary hybrid nanofluids. Numer. Heat Transf. Part A Appl. (2023). https://doi.org/10.1080/10407782.2023.2220903

Maxwell, J.C.: A treatise on Electricity and Magnetism. Clarendon Press, Oxford (1881)

Benkhedda, M.; Boufendi, T.; Tayebi, T.; Chamkha, A.J.: Convective heat transfer performance of hybrid nanofluid in a horizontal pipe considering nanoparticles shapes effect. J. Therm. Anal. Calorim. 140, 411–425 (2020). https://doi.org/10.1007/s10973-019-08836-y

Nandi, S.; Vajravelu, K.: Analysis of entropy generation in Carreau ternary hybrid nanofluid flow over a stretching sheet. Numer. Heat Transf. Part A Appl. (2023). https://doi.org/10.1080/10407782.2023.2233730

Ağra, Ö.; Demir, H.; Atayılmaz, ŞÖ.; Kantaş, F.; Dalkılıç, A.S.: Numerical investigation of heat transfer and pressure drop in enhanced tubes. Int. Commun. Heat Mass Transf. 38, 1384–1391 (2011). https://doi.org/10.1016/j.icheatmasstransfer.2011.07.013

Mohammed, H.A.; Abbas, A.K.; Sheriff, J.M.: Influence of geometrical parameters and forced convective heat transfer in transversely corrugated circular tubes. Int. Commun. Heat Mass Transf. 44, 116–126 (2013). https://doi.org/10.1016/j.icheatmasstransfer.2013.02.005

ANSYS Fluent Theory Guide, Fluent Corporation, Lebanon, New Hampshire, (2006)

Kumar, K.; Kumar, R.; Bharj, R.S.; Said, Z.: Effect of arc corrugation initiation on the thermo-hydraulic performance and entropy generation of the corrugated tube. Int. Commun. Heat Mass Transf. 138, 106335 (2022). https://doi.org/10.1016/j.icheatmasstransfer.2022.106335

Ajeel, R.K.; Salim, W.S.-I.; Sopian, K.; Yusoff, M.Z.; Hasnan, K.; Ibrahim, A.; Al-Waeli, A.H.A.: Turbulent convective heat transfer of silica oxide nanofluid through corrugated channels: an experimental and numerical study. Int. J. Heat Mass Transf. 145, 118806 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2019.118806

Mousavi Ajarostaghi, S.S.; Shirzad, M.; Rashidi, S.; Li, L.K.B.: Heat transfer performance of a nanofluid-filled tube with wall corrugations and center-cleared twisted-tape inserts. Energy Sour. Part A Recover. Util. Environ. Effects. (2020). https://doi.org/10.1080/15567036.2020.1841860

Kurtulmuş, N.; Sahin, B.: A review of hydrodynamics and heat transfer through corrugated channels. Int. Commun. Heat Mass Transf. 108, 104307 (2019). https://doi.org/10.1016/j.icheatmasstransfer.2019.104307

Zhang, S.; Lu, L.; Wen, T.; Dong, C.: Turbulent heat transfer and flow analysis of hybrid Al2O3-CuO/water nanofluid: an experiment and CFD simulation study. Appl. Therm. Eng. 188, 116589 (2021). https://doi.org/10.1016/j.applthermaleng.2021.116589

Nabi, H.; Pourfallah, M.; Gholinia, M.; Jahanian, O.: Increasing heat transfer in flat plate solar collectors using various forms of turbulence-inducing elements and CNTs-CuO hybrid nanofluids. Case Stud. Therm. Eng. 33, 101909 (2022). https://doi.org/10.1016/j.csite.2022.101909

Boelter,L.M.K.; Dittus F.W.: Heat transfer in automobile radiators of tubular type, Berkeley (1930)

Petukhov, B.S.: Heat Transfer and Friction in Turbulent Pipe Flow with Variable Physical Properties. In: Advances in Heat Transfer, pp. 503–564. Elsevier, Amsterdam (1970). https://doi.org/10.1016/S0065-2717(08)70153-9

Blasius P.R.H.: Das Aehnlichkeitsgesetz bei Reibungsvorgangen in Flüssigkeiten, Forschungsheft (1913)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ekiciler, R. Analysis and Evaluation of the Effects of Uniform and Non-uniform Wall Corrugation in a Pipe Filled with Ternary Hybrid Nanofluid. Arab J Sci Eng 49, 2681–2694 (2024). https://doi.org/10.1007/s13369-023-08459-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08459-4

Keywords

Profiles

- Recep Ekiciler View author profile