Abstract

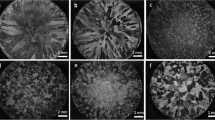

The grain refinement behavior of Si-3P, Si-25Mn-10P, and Al-10Si-2Fe-3P master alloys on hypereutectic Al-24Si alloy was studied. Microstructure analysis indicates that the P-containing compounds in the three master alloys are SiP, MnP, and AlP, respectively. The coarse flower-like primary silicon in the Al-24Si alloy transforms into smaller, well-distributed blocks with the addition of various master alloys. When pouring at 840 °C, the average grain size of the primary silicon refined by Si-25Mn-10P master alloy with a holding time of 30 min is about 18 µm, which is significantly smaller than those refined by Si-3P and Al-10Si-2Fe-3P master alloys. The grain size shows an increasing trend when the holding time is further prolonged. Higher holding temperature has a positive effect on the grain refinement of Si-25Mn-10P master alloy. The grain refinement mechanism of the three master alloys was also discussed.

Similar content being viewed by others

References

Gong C J, Tu H, Wu C J, et al. Study on microstructure and mechanical properties of hypereutectic Al-18Si alloy modified with Al-3B. Materials, 2018, 11(3): 456. doi:https://doi.org/10.3390/ma11030456.

Wu Y P, Wang S J, Li H, et al. A new technique to modify hypereutectic Al-24%Si alloys by a Si-P master alloy, Journal of Alloys and Compounds, 2009, 477(1–2): 139–144. doi:https://doi.org/10.1016/j.jallcom.2008.10.015.

Wang K, Wei M, Zhang L J, et al. Morphologies of primary silicon in hypereutectic Al-Si alloys: phase-field simulation supported by key experiments. Metallurgical and Materials Transactions A, 2016, 47(4): 1510–1516. doi:https://doi.org/10.1007/s11661-016-3358-1.

Singh R K, Telang A, Das S. Microstructure and mechanical properties of Al-Si alloy in as-cast and heat treated condition. American Journal of Engineering Research, 2016, 5(8): 133–137.

Biswas P, Patra S, Mondal M K. Effects of Mn addition on microstructure and hardness of Al-12.6Si alloy. IOP Conf. Series—Materials Science and Engineering, 2018, 338: 012043. doi:https://doi.org/10.1088/1757-899X/338/1/012043.

Gao T, Zhu X Z, Qiao H, et al. A new Al-Fe-P master alloy designed for application in low pressure casting and its refinement performance on primary Si in A390 alloy at low temperature. Journal of Alloys and Compounds, 2014, 607: 11–15. doi:https://doi.org/10.1016/j.jallcom.2014.04.030.

Meena P C, Sharma A, Singh S. Effect of grain refinement on microstructure and wear behavior of cast Al-7Si alloys. La Metallurgia Italiana, 2015, 107(1): 25–34.

Marchwica P. Microstructural and thermal analysis of aluminum-silicon and magnesium-aluminum alloys subjected to high cooling rates. Dissertations: University of Windsor, 2012. http://scholar.uwindsor.ca/etd/5572.

Xing P F, Gao B, Zhuang Y X, et al. On the modification of hypereutectic Al-Si alloys using rare earth Er. Acta Metallurgica Sinica, 2010, 23(5): 327–333. doi:https://doi.org/10.1128/AEM.07790-11.

Wu Y Y, Liu X F. Effect of AlB2 on the P-threshold in Al-Si alloy. Results in Physics, 2018, 9: 734–739. doi:https://doi.org/10.1016/j.rinp.2018.03.018.

Jung J G, Lee S H, Lee J M, et al. Improved mechanical properties of near-eutectic Al-Si piston alloy through ultrasonic melt treatmen. Materials Science and Engineering A, 2016, 669: 187–195. doi:https://doi.org/10.1016/j.msea.2016.05.087.

Qiu H X, Yan H, Hu Z. Modification of near-eutectic Al-Si alloys with rare earth element samarium. Journal of Materials Research, 2014, 29(11): 1270–1277. doi:https://doi.org/10.1557/jmr.2014.113.

Ho C R, Cantor B. Modification of hypoeutectic Al-Si alloys. Journal of Materials Science, 1995, 30: 1912–1920. doi:https://doi.org/10.1007/BF00353013.

Wang E Z, Liu S D, Nie J F, et al. A new kind of Al-5Ti-0.3C master alloy and its refining performance on 6063 alloys. Light Metals, 2015: 961–964. doi:https://doi.org/10.1007/978-3-319-48248-4_161.

Nie J F, Zhao Y H, Li Y S, et al. Reactive synthesis of hexagonal Ti5P3.16 crystals and their heterogenous nucleating mechanism on primary Si. Journal of Alloys and Compounds, 2019, 777: 8–17. doi:https://doi.org/10.1016/j.jallcom.2018.09.038.

Safarian J, Tangstad M. Phase diagram study of the Si-P system in Si-rich region. Journal of Materials Research, 2011, 26(12): 1494–1503. doi:https://doi.org/10.1557/jmr.2011.130.

Zhou X L, Zhu X Z, Gao T, et al. Evolution of a novel Si-18Mn-16Ti-11P alloy in Al-Si melt and its influence on microstructure and properties of high-Si Al-Si alloy. Results in Physics, 2016, 6: 737–745. doi:https://doi.org/10.1016/j.rinp.2016.10.006.

Liang S M, Schmid-Fetzer R. Phosphorus in Al-Si cast alloys: Thermodynamic prediction of the AlP and eutectic (Si) solidification sequence validated by microstructure and nucleation undercooling data. Acta Materialia, 2014, 72: 41–56. doi:https://doi.org/10.1016/j.actamat.2014.02.042.

Wu Y P, Wang S J, Li H, et al. A new technique to modify hypereutectic Al-24% Si alloys by a Si-P master alloy. Journal of Alloys and Compounds, 2009, 477(1–2): 139–144. doi:https://doi.org/10.1016/j.jallcom.2008.10.015.

Zhou X L, Wu Y Y, Li Y F, et al. Absorbing formation mechanism of AlP on TiB2 substrate and their application as high-efficiency nucleating agent in Al-45Si alloy. Journal of Alloys and Compounds, 2017, 693: 853–858.

Li J H, Hage F S, Liu X F, et al. Revealing heterogeneous nucleation of primary Si and eutectic Si by AlP in hypereutectic Al-Si alloys. Scientific Reports, 2016, 6: 1–8.

Jung J G, Ahn T Y, Cho Y H, et al. Synergistic effect of ultrasonic melt treatment and fast cooling on the refinement of primary Si in a hypereutectic Al-Si alloy. Acta Materialia, 2018, 144: 31–40. doi:https://doi.org/10.1016/j.actamat.2017.10.039.

Acknowledgements

The authors gratefully acknowledge the support of the National Natural Science Foundation of China (51974057 and 5174057), the Open Project of State Key Laboratory of Advanced Special Steel, Shanghai Key Laboratory of Advanced Ferrometallurgy, Shanghai University (SKLASS 2019-19) and the Science and Technology Commission of Shanghai Municipality (No. 19DZ2270200).

Author information

Authors and Affiliations

Corresponding author

Additional information

Peng-ting Li Male, Ph.D., Associate Professor. He is engaged in the research on microstructure modification and solidification control of Al-Si alloys and superalloys.

Rights and permissions

About this article

Cite this article

Njuguna, B.K., Li, Jy., Tan, Y. et al. Grain refinement of primary silicon in hypereutectic Al-Si alloys by different P-containing compounds. China Foundry 18, 37–44 (2021). https://doi.org/10.1007/s41230-021-0074-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41230-021-0074-2