Abstract

Flow measurement is critical in various sectors, including industry, agriculture, medicine, and environmental monitoring. There is a growing need for compact, sensitive, scalable, and energy-efficient flow sensors, particularly for applications in unmanned aerial vehicles, unmanned underwater vehicles, biomedicine, and bionic robotics. Inspired by biological mechanosensory structures, artificial hair and hair cell flow sensors have emerged as promising solutions. This study offers a comprehensive review of the progress, underlying principles, performance optimization techniques, and applications of hair flow sensors. We provide an overview of the biological mechanisms of hair as mechanical receptors. Subsequently, we explain the design and fabrication techniques of artificial hair flow sensors, highlighting the challenges associated with replicating and integrating hair structures. The study further explores strategies for sensor enhancement and their diverse applications. Finally, we conclude by outlining the challenges and prospects of hair sensor technology, along with its potential to address specific flow-sensing requirements. While most applications of artificial hair cell flow sensors are still in the research stage, they offer substantial potential for flow measurement. Future progress in materials science, structural design, and sensing mechanisms is anticipated to drive the development of these sensors, opening up new avenues for scientific research and commercial applications.

Similar content being viewed by others

Introduction

Flow measurement technology is crucial for assessing various fluid flow parameters, including velocity, pressure, and acceleration. Conventional measurement techniques, such as hot-wire anemometry (HWA)1,2,3, turbine flow meters4, acoustic Doppler velocimeters5,6, and particle image velocimetry7,8, are widely used in various industries9,10, including energy measurement11 and environmental monitoring12. While traditional flow measurement instruments are widely used, their size, complexity, and limited sensitivity restrict their broader application. Emerging fields such as unmanned aerial vehicles (UAVs), unmanned underwater vehicles (UUVs), micro air vehicles (MAVs), bio-robotics, biomedicine, and microfluidics require more compact, energy-efficient, and sensitive flow sensors. Consequently, the development of innovative flow sensor technologies is crucial to address the needs of these advanced applications.

Micro-electro-mechanical system (MEMS) technology enables the development of compact, low-cost, and energy-efficient flow sensors. MEMS-based flow sensors are categorized into thermal13 and non-thermal types14. Thermal sensors, such as MEMS HWA15, MEMS hot-film sensors16, calorimetric17,18 and time-of-flight19 sensors rely on heat transfer principles. Non-thermal sensors, including piezoresistive20, piezoelectric21, and capacitive sensors22, use mechanical deformation to measure flow parameters. Thermal flow sensors offer the advantages of lack of moving parts and ease of fabrication13. However, heat transfer mechanisms lead to slower response times than some non-thermal sensors, such as piezoelectric sensors23,24. Moreover, undesired heat conduction causes heat loss, which increases power consumption and reduces sensitivity, particularly in detecting low-speed flows14. In contrast, non-thermal flow sensors operate independently of heat transfer, eliminating the need for external heaters or stable heat sources, which results in relatively lower power consumption. Diverse sensing mechanisms enable measuring multiple flow parameters, including velocity, direction, pressure25, shear stress26, and composition27, whereas thermal sensors primarily measure flow velocity and direction. However, non-thermal flow sensors often require more complex and precisely movable structures to ensure effective flow detection. These sensors are used to measure various fluid flows, such as gas flow28, turbulence29, nano-fluidic30, and flow separation31. MEMS flow sensors have found applications in diverse fields such as biomedicine32, aerospace33, and harsh environment sensing34.

Bio-inspired artificial hair and hair cell (AHC) flow sensors represent a significant category within MEMS flow sensors. Inspired by nature’s efficient mechanosensory systems, AHC sensors aim to replicate the sensitivity and energy efficiency of biological hair and hair cells. These natural structures excel at detecting subtle environmental changes, such as sound and fluid flow35. These receptors transduce mechanical stimuli into electrical signals processed by the central nervous system. Natural hair cell receptors include auditory hair cells in the human cochlea36,37, hair cells in the lateral line of fish38,39, filiform hair of crickets40,41,42, whiskers of harbor seals43,44, and fine hairs on spider exoskeletons45. Understanding the structure and function of these natural systems can significantly advance the development of artificial hair flow sensors.

This review offers an in-depth examination of recent progress in bio-inspired AHC flow sensors. It begins with a discussion of the biological principles of hair flow sensing and then explores AHC flow sensors using various sensing mechanisms and fabrication technologies, including MEMS and other emerging technologies. The review also highlights the technical challenges in fabricating and integrating artificial hair structures. We then assess their performance improvements and applications. This study concludes by highlighting current challenges and future research directions in the field. The development of bio-inspired AHC flow sensors is a promising area in flow measurement research, with the potential to introduce a new generation of highly sensitive and selective sensors for diverse applications.

Hair and hair cell receptors in nature

Natural organism’s hair and hair cells demonstrate exceptional information-gathering abilities. Examples include cochlear hair cells in humans, hair cells in the fish lateral line, hair receptors on bat wings, and arthropod hair receptors. Advancing our knowledge of their structure, function, and biological mechanisms can significantly enhance the design of AHC sensors for various applications.

Mammals possess sensitive and efficient flow-sensing systems. Bats, the only mammals capable of sustained flight, employ microscopic hairs on their wings (Fig. 1a) to gather aerodynamic data46. These sensory hairs aid in flight control, particularly in monitoring speed and airflow conditions associated with stalling47. Similarly, harbor seals, inhabiting dark or turbid aquatic environments, depend on their whiskers (Fig. 1b) to detect hydrodynamic wake signatures left by other animals, facilitating navigation and prey detection48,49. The distinctive undulatory asymmetric geometry of their whiskers mitigates vortex-induced vibrations (VIVs)50.

Mammals exhibit hair cell receptors in various forms, including a the sensory hairs on the bat wings (reprinted and modified from ref. 46 with permission from IOP science), and b the whiskers of harbor seals (reprinted and modified from ref. 49 with permission from Wiley). Similarly, arthropods possess receptor hairs, such as c the cerci of crickets (reprinted and modified from ref. 51 with permission from Springer) and d the fine hairs on the spider exoskeleton (reprinted and modified from ref. 53 with permission from Elsevier). In fish, hair cells are prominently found in the lateral line system, e as exemplified by the hair bundles in the central annular region of the sensory plate of deep-sea fish (reprinted and modified from ref. 58 with permission from Wiley) and f the cupulas of SN row arrays (stained with methylene blue) in the blind cavefish Astyanax fasciatus (reprinted and modified from ref. 59 with permission from the Royal Society of Chemistry). g Schematic diagram of representative biological hair cell sensing mechanism

Arthropods showcase exceptional hair-based sensory abilities. Crickets, for instance, use sensory hairs called cerci (Fig. 1c) on their appendages to discern low-frequency sounds from various instructions by consolidating neural inputs from these sensors40,51. Spiders, however, employ fine sensory hairs (Fig. 1d) on their exoskeletons to perceive airflow changes induced by predators or prey52,53, as well as assist in spatial orientation and motion detection45.

Aquatic organisms have developed intricate sensory systems to perceive hydrodynamic stimuli38,54. Fish, in particular, leverage hydrodynamic information for diverse purposes such as prey detection, predator avoidance, intraspecific communication, schooling, object discrimination, entrainment, and rheotaxis38,55. In both fish and aquatic amphibians, the mechanosensory lateral line is the primary sensory structure responsible for detecting hydrodynamic stimuli. The neuromast, the smallest functional unit of the lateral line system, can exist as either superficial neuromasts (SNs) located on the skin or canal neuromasts (CNs) housed within fluid-filled canals that typically communicate with the external environment via a series of pores56. The hair cell is the primary sensory cell of the lateral line system. It possesses an apical hair bundle comprising up to 150 stereocilia, along with a single kinocilium located at the bundle’s tall edge. These hair bundles extend into a cupula, connecting them to the surrounding water or canal fluid57. Lateral line neuromasts are innervated by both afferent and efferent nerve fibers. The peripheral lateral line system appears to transmit sensory information to the brain via four parallel pathways: one originating from the SNs, another from the CNs, one from hair cells polarized in a specific orientation within the cupula, and the last from hair cells polarized in the opposite orientation38. Figure 1e illustrates hair bundles from the central ring area of the sensory plate within the CNs of a deep-sea fish58, while Fig. 1f depicts an optical micrograph of a stained cupula from the lateral line of a blind cavefish59.

Although the morphologies and sizes of biological hair are different, their fundamental structure and signal transmission mechanisms are similar. Hair structures extending from the tops of hair cells are connected to neurons, where their displacement generates electrical signals as shown in Fig. 1g60. Inspired by this, artificial hair sensors are designed to mimic the function of biological hair. They utilize various signal transmission mechanisms, such as piezoresistive, piezoelectric, and optical, to simulate neuronal responses. When exposed to flow fields, the artificial hair bends and converts mechanical motion into electrical signals, enabling accurate measurement of flow field information.

Bio-inspired artificial hair and hair cell flow sensors

Researchers have developed diverse AHC sensors to emulate the exceptional functional capabilities of biological hair and hair cells. These sensors are categorized by their sensing mechanisms, including piezoresistive, piezoelectric, capacitive, magnetic, optical, and other types.

Piezoresistive hair and hair cell flow sensors

Doped silicon-based piezoresistive hair flow sensor

Piezoresistance semiconductors exhibit changes in electrical resistivity when subjected to mechanical stress61. Early research at the University of Illinois at Urbana-Champaign yielded a series of piezoresistive AHC flow sensors based on doped silicon. Inspired by the lateral line system of fish, Fan et al. introduced a micromachined, distributed piezoresistive cantilever AHC flow sensor, as shown in Fig. 2a, fabricated using the plastic deformation magnetic assembly (PDMA)62 technique. Initial characterization demonstrated the output current’s response to flow rates ranging from 0 to 1 m/s63. Expanding upon this work, Junjun Li and Jack Chen refined the PDMA process by mitigating stress concentration, thereby improving the sensor yield64. They also successfully developed flow sensor arrays incorporating diverse frontal orientations and hair heights65. Subsequent advancements from this lab include a durable AHC flow sensor created using polymer surface micromachining and 3D assembly techniques66. Alternatively, Nannan et al. employed SU-8 to fabricate a cantilever-based AHC flow sensor with high-aspect-ratio hairs reaching heights of up to 700 µm, as depicted in Fig. 2b. The sensor demonstrated effectiveness in both water and air, measuring AC flow velocities as low as 0.7 mm/s in water and achieving an angular resolution of 2.16° in air60,67. Using similar AHC sensor arrays, Yang et al. developed an artificial lateral line for biomimetic hydrodynamic localization and tracking68. Nam Nguyen further improved this system by integrating an adaptive beamforming algorithm to enable 3D imaging of oscillating dipole locations underwater69. Kong et al. proposed a torpedo-shaped biomimetic piezoresistive vector wake detector. Experimental results demonstrated its ability to discern wake direction and offer a valuable method for cluster perception in underwater vehicles70. Zhang et al. developed a self-bending piezoresistive microcantilever hair flow sensor, as illustrated in Fig. 2c, using doped silicon. The upward curvature of the microcantilever was achieved by exploiting residual stress differentials between silicon and silicon dioxide layers. This sensor exhibited a flow rate measurement range of 0–23 cm/s, a sensitivity of 1.5–3.5 Ω/cm/s, and a repeatability of 6% across its full scale71.

a Doped silicon AHC flow sensor fabricated with the PDMA process (reprinted and modified from ref. 63 with permission from IOP science). b High-aspect-ratio SU-8 artificial hairs for doped silicon AHC sensors (reprinted and modified from ref. 60 with permission from IEEE). c Self-bending doped silicon microcantilever hair flow sensor using residual stress differences between silicon and silicon dioxide (reprinted and modified from ref. 71 with permission from Elsevier). d Self-bending nichrome strain gauge-based AHC sensor (reprinted and modified from ref. 74 with permission from Elsevier) and e bidirectional flow sensor (reprinted and modified from ref. 77 with permission from the Beilstein-Institut). f AHC flow sensor using an LCP membrane and gold strain gauge (reprinted and modified from ref. 79 with permission from IEEE). g AHC flow sensor schematic based on MWCNT-PDMS composite FSRs (reprinted and modified from ref. 228 with permission from SPIE). h All-polymer airflow sensor using carbon black material (reprinted and modified from ref. 97 with permission from IOP science). i AHC flow sensor array using carbon black/PU FSRs on a flexible PI substrate (reprinted and modified from ref. 99 with permission from IEEE). j Schematic of a hair flow sensor with PDMS cantilever and graphene strain gauge (reprinted and modified from ref. 169 with permission from MDPI). k Graphene/PDMS cantilever AHC flow sensor fabricated with 3D printing and replica molding (reprinted and modified from ref. 105 with permission from IOP science). l Hair flow sensor schematic made from liquid metal and PDMS (reprinted and modified from ref. 108 with permission from IEEE)

The piezoresistive effect in doped silicon depends on the resistivity and geometry of the resistor material. The geometric contribution is similar to that observed in metal strain gauges. The high sensitivity of doped silicon piezoresistive flow sensors mainly arises from resistivity changes in the doped silicon. Specific impurities introduced into the silicon lattice enhance the piezoresistive coefficient, improving sensitivity to small mechanical stresses and low fluid flow rates72. Furthermore, microcantilever and thin film structures could concentrate on mechanical stress and enhance the signal of piezoresistive AHC flow sensors. These sensors also benefit from MEMS technology, offering advantages like compact size, integration capability, and low power consumption. However, temperature variations can influence their performance14,73, and the complex fabrication process increases production challenges and costs.

Metal strain gauge-based piezoresistive AHC flow sensor

In metal strain gauges, resistance variations primarily result from changes in material geometry. Qualtieri et al. developed a hair flow sensor using a metal strain gauge, featuring a stress-driven aluminum nitride (AlN)/molybdenum (Mo) cantilever as the hair element and a nichrome 80/20 alloy as the piezoresistor, as illustrated in Fig. 2d. Measurements conducted in a nitrogen flow demonstrated the sensor’s ability to detect low pressures and distinguish flow direction74. Subsequent enhancements included the application of a conformal parylene coating to improve waterproofing. This sensor demonstrated a responsivity of 0.7 mV/(cm/s) and exhibited a linear response in signal amplitude for flow pulses up to 30 Hz75. The soft parylene conformal coating effectively controlled the mechanical and sensory properties of the hair flow sensor, enabling the tuning of mechano-receptive responsivity from sub-linear to super-linear behavior76. Building on this foundation, the laboratory developed a bidirectional flow sensor composed of two curved cantilevers oriented antiparallel to each other, as depicted in Fig. 2e. This design improved directional sensitivity compared with the previous single cantilever hair sensor and provided a sinusoidal response to variations in flow angle while also enhancing performance in compensating for temperature fluctuations77.

In contrast to the cantilever structure previously mentioned, Kottapalli et al. developed a liquid crystal polymer (LCP) membrane MEMS sensor using gold strain gauges for fish-like underwater flow sensing78. Subsequently, they developed a biomimetic MEMS hair flow sensor that integrated the LCP sensing membrane with a Si60 polymer artificial hair fabricated through stereolithography, as shown in Fig. 2f. Preliminary tests in wind and water tunnels demonstrated the sensor’s high sensitivity and exceptional resolution79. Using this sensor, they devised artificial SNs and CNs to measure flow velocity and acceleration80. Furthermore, inspired by the gelatinous cupula of cavefish, they introduced and characterized an artificial cupula composed of pyramid-shaped nanofibers and hyaluronic acid-methacrylic anhydride (HA-MA) to enhance sensor performance81. A nanofiber-enhanced MEMS artificial hydrogel neuromast was developed, featuring Young’s modulus closely approximating the biological cupula (ranging from 10 to 100 Pa). The hydrogel cupula sensor demonstrated a 3.5–5-fold sensitivity improvement over conventional hair cell sensors in steady-state flow detection82. Comprehensive characterization studies evaluated the hyaluronic acid hydrogel’s morphological, swelling, porosity, and mechanical properties83.

A novel flexible hair-like airflow sensor was developed by Shen et al. using MEMS technology. The sensor features a platinum piezoresistor embedded in a polyimide (PI) cantilever with a curved, three-dimensional (3D) design. Experimental evaluation revealed a detection range of 0–40.5 m/s with a maximum resolution of 4 mm/s. It also demonstrated directional airflow-sensing capabilities84. Gleason et al. introduced an innovative hair flow sensor array with self-healing properties, using metal strain gauges embedded in a flexible substrate over extrusion channels. This method, though pioneering, is still in the early research stages85. AHC flow sensors based on metal strain gauges offer a simpler fabrication process and lower production costs but have lower sensitivity than doped silicon piezoresistive AHC flow sensors.

Polymer conductive composite-based piezoresistive AHC flow sensor

Flexible and stretchable electrically conductive polymer piezoresistive materials have gained significant attention due to their exceptional deformation capabilities86, in contrast to traditional rigid doped silicon or metal strain gauges. Composites of elastic materials such as polydimethylsiloxane (PDMS) and polyurethane (PU) with conductive materials such as carbon nanotubes (CNTs)87,88, carbon nanofibers (CNFs)89, and graphene90 have been used in constructing AHC flow sensors.

The combination of carbon-based materials (such as CNTs, CNFs, carbon papers, and carbon black) and elastic polymers has been used in AHC flow sensor design. Lee et al. developed an AHC flow sensor, illustrated in Fig. 2g, using multi-walled CNT-PDMS (MWCNT-PDMS) composite as a force-sensitive resistor (FSR), leveraging the material’s superior electrical conductivity, flexibility, and mechanical properties, inspired by biological fish hair cells. However, the MWCNT-PDMS-based FSR exhibited insufficient sensitivity for small signals and demonstrated a nonlinear response. To address this limitation, the authors proposed a novel material combining pressure-variable resistor ink, conductive ink, and carbon paste for FSR fabrication91. CNTs/PDMS composites show significant promise for applications in wearable and flexible electronics. Jung et al. unveiled a multifunctional electronic dermal sensor, featuring a piezoresistive hair-type flow sensor based on CNTs and PDMS92.

CNFs and carbon paper play a pivotal role in the development of polymer-based piezoresistive materials. Sengupta et al. developed a hair flow sensor using electrospun CNFs as the sensing element, paired with a high-aspect-ratio titanium pillar serving as an artificial hair. The sensor demonstrated sensitivities of 6.16 mV/(m/s) for steady-state airflow and 26 mV/(m/s) for oscillatory flow, with a detection threshold of 12.1 mm/s93. Moshizi et al. developed a Pt-CNF/PDMS nanocomposite hair sensor capable of mimicking semicircular canal vestibular hair cell functionality94. Liu et al. created an electronic hair sensor using carbonized paper as a piezoresistive mechanoreceptor, employing nylon fibers and PDMS to simulate human hair and skin. This sensor demonstrated proficiency in detecting pressure, surface roughness, and airflow rate with performance analogous to human skin sensory properties95.

Carbon black represents an economical and effective nanomaterial for electrochemical sensor development96. Aiyar et al. introduced an all-polymer flexible piezoresistive airflow sensor employing a carbon black-based conductive composite as a piezoresistor. This sensor includes an out-of-plane curved PI cantilever for flow sensing, exhibiting a sensitivity of 66 Ω/(m/s) with dimensions of 1.5 mm in length and 0.4 mm in width, as depicted in Fig. 2h97. Expanding on the all-polymer piezoresistive flow sensor, Song et al. introduced a peak-to-peak vibration amplitude technique to reduce resistance and output drift. The sensor exhibited a sensitivity of 14.5 mV/(m/s) and demonstrated less than 1% non-linearity within a velocity range of 5–16 m/s. This approach offers the potential for reducing drift caused by material properties and environmental factors98. In contrast to carbon/PDMS composites, Engel et al. introduced an all-polymer piezoresistive hair sensor using PU artificial hair and carbon/PU FSRs, as illustrated in Fig. 2i. Compared with PDMS, PU offers superior mechanical tear resistance and improved substrate adhesion. The sensors demonstrated a sensitivity of 245 ppm/μm of tip deflection. With a detection threshold of 3 μm, the sensors significantly outperformed insect tactile hair cells, which typically have thresholds ranging from 30 to 50 μm99. These sensors were subsequently employed to detect flow features in unsteady separating flows. Simulations of AHC sensor arrays on a cylinder wall demonstrated the successful detection of diverse flow characteristics, involving the onset and extent of reversed flow and the movement of zero-shear stress point100.

Graphene/elastic composites constitute another class of piezoresistive materials. Abolpour Moshizi et al. presented a flexible piezoresistive flow sensor employing vertical graphene nanosheets (VGNs) embedded in PDMS. The sensor demonstrated a sensitivity of 103.91 mV/(mm/s) and a low-velocity sensitivity limit of 1.127 mm/s in steady-state flow. This sensor was embedded into an artificial lateral semicircular canal to emulate the behavior of vestibular hair cell sensors. This integration facilitates the discrimination of subtle variations in rotational axis geometry, frequency, and amplitude101. In addition, they developed a VGNs/polyvinyl alcohol (PVA) ultra-flexible flow sensor competent for detecting ultralow-velocity flows of 0.022 mm/s and low-frequency oscillatory flows as low as 0.1 Hz. This sensor could replicate diverse physiological states of vestibular hair cells, laying the foundation for prospective applicability in vestibular organ prostheses102. Moreover, Jiang et al. presented a novel fabrication technique for a flexible graphene/PI piezoresistive hair-like airflow sensor, achieving a sensitivity of 37.5 kΩ/(m/s), a high resolution of 0.5 m/s, and a broad detection range of 0–20 m/s103. In addition, Kei Ohara unveiled a laser-induced graphene cantilever hair sensor for airflow sensing104.

Additive manufacturing techniques were used to construct graphene-based piezoresistive AHC sensors. Kamat et al. developed a graphene-based piezoresistive hair flow sensor using 3D printing and casting processes, as shown in Fig. 2j. The sensor demonstrated a detection threshold of 58 mm/s when exposed to water flow stimuli. Consequently, a PDMS-graphene cantilever hair flow sensor was developed using 3D printing and replica molding, as illustrated in Fig. 2k. Wind tunnel testing revealed an airflow responsiveness of 5.8 kΩ·m/s, a detection range of 0–9 m/s, and a low hysteresis of 11% of full-scale deflection. The sensor demonstrated the capacity to detect oscillatory flow velocities as low as 16–30 μm/s at a frequency of 15 Hz105. Moreover, a soft polymer graphene hair flow sensor was developed using sacrificial metal 3D printing technology, combining metal 3D printing, soft polymer casting, and acidic etching processes106. Furthermore, Zheng et al. presented a hair flow sensor inspired by harbor seal whiskers, wherein both the hair and cantilever were fabricated via 3D printing107. Additional research has explored liquid metal/PDMS composite-based AHC flow sensors, as depicted in Fig. 2l108.

Contemporary polymer conductive composite-based piezoresistive AHC flow sensors predominantly use composites of carbon/elastic materials, graphene/elastic materials, and liquid metal/elastic materials. These advanced piezoresistive composites offer superior flexibility and deformability compared with traditional rigid doped silicon or metallic strain gauges, enabling innovative applications in wearable electronics, electronic skin, and soft robotics. The key challenges in designing and applying this type of sensor include stretchability, linearity, hysteresis, performance uniformity, and structural robustness, particularly in large-scale production109,110.

Piezoelectric hair and hair cell flow sensors

Barium titanate (BaTiO₃) was the first polycrystalline ceramic to exhibit ferroelectricity. Leveraging this material, Tran et al. developed a piezoelectric hair-like sensor as depicted in Fig. 3a for UUV maneuvering. This sensor features an array of piezoelectric hair structures made from a composite of BaTiO₃, MWCNT, and ethylene-vinyl acetate. Experiments showed a voltage increase from 1.8 to 2.7 mV in response to airflow111.

a A BaTiO₃-based piezoelectric composite was used to construct a hair flow sensor (reprinted and modified from ref. 111 with permission from IEEE). b A piezoelectric hair sensor was developed using electrospun PVDF nanofiber tip links integrated with PDMS micropillars (reprinted and modified from ref. 114 with permission from Springer Nature). c A piezoelectric nanofiber-based cantilever is used in an artificial lateral line sensor (reprinted and modified from ref. 116 with permission from IEEE). d A self-powered MEMS AHC sensor integrates a polymer hair cell with a PZT micro-diaphragm (reprinted and modified from ref. 118 with permission from The Royal Society). e A self-bending flexible piezoelectric hair-like sensor is made from PI and PZT materials (reprinted and modified from ref. 120 with permission from IEEE). f A self-powered hydrodynamic sensor employs a PZT piezoelectric diaphragm and a high-aspect-ratio pillar (reprinted and modified from ref. 121 with permission from Elsevier)

Polyvinylidene fluoride (PVDF) is extensively employed in sensors and actuators for its outstanding piezoelectric properties, flexibility, thermal stability, and mechanical strength112. Weiting Liu et al. developed a hair sensor using aligned micro/nano PVDF fibers as sensitive elements. Initial experiments validated the sensor’s ability to detect flow medium speed, wind properties, and environmental vibrations, suggesting its potential application in sensing systems for mini/micro bio-robots113. Asadnia et al. developed soft all-polymer nanosensors as illustrated in Fig. 3b, mimicking biological hair cell mechanosensory bundles. The sensor incorporated PDMS micropillars with graded heights, electrospun PVDF piezoelectric nanofiber tip links, and a dome-shaped HA hydrogel cupula created through precision drop-casting and swelling techniques. The sensor demonstrated a sensitivity of 300 mV/(m/s) and a threshold detection limit of 8 μm/s114. Furthermore, multiple research institutions have reported hair sensors using PVDF membranes115 and P(VDF-TrFE)/BTO nanofiber membranes, as shown in Fig. 3c116.

Lead zirconate titanate (PZT), a well-established piezoelectric material, was discovered in 1952 and offers exceptional piezoelectric properties117. Inspired by biological systems, researchers have developed artificial self-powered piezoelectric hair sensors. Kottapalli and Asadnia et al. used stereolithography to fabricate polymer hair structures incorporating Pb(Zr₀.₅₂-Ti₀.₄₈)O₃ micro-diaphragms as floating bottom electrodes, as illustrated in Fig. 3d. This innovative design enables the sensing of hydrodynamic flow phenomena. The sensors exhibited flow sensitivities of 0.8 mV/(mm/s) for air and 22 mV/(mm/s) for water at 35 Hz. They also achieved threshold velocity detection limits of 2.5 mm/s for air and 8.2 mm/s for water. Researchers used the sensor arrays to locate objects and filter oscillatory flows below 10 Hz118, developing artificial CNs. Additionally, they introduced a biomimetic HA-MA hydrogel that mimics the CN cupula in blind cavefish. This hydrogel meticulously replicates the morphology, material composition, and structure of the natural cupula, with a porous and high mechanical strength structure analogous to that of biological CNs. The sensor output was notably amplified twofold for oscillatory flows attributed to the hydrogel cupula119. Inspired by seal whiskers, the researchers developed a bio-inspired artificial whisker MEMS sensor. Experimental results demonstrated a velocity detection limit as low as 193 μm/s, effectively suppressing VIV50. Jin developed a flexible piezoelectric hair-like sensor with a wind speed detection threshold of 0.07 m/s, made from flexible PI and PZT materials. Figure 3e presents the flexible hair-like cantilever sensor120. Zhang et al. introduced a piezoelectric hair sensor using the self-powered d₃₃ mode of a PZT sensing diaphragm, as depicted in Fig. 3f, achieving a sensitivity of 2.476 mV/(mm/s) and demonstrating a strong response to low-frequency flow121. In addition, they proposed a sensor with a high-aspect-ratio elliptical hair, inspired by the geometric properties of harbor seal whiskers. Experimental results indicated that the sensor could detect distinct water flow angles of attack, with a sensitivity of 1.445 V/(m/s)122. Yu et al. also proposed a hair-like sensor for flow sensing based on spiral resonant base and PZT123.

PZT fibers have been integrated into the design of piezoelectric hair flow sensors. Tao et al. developed a PZT microfiber-based sensor to emulate the directional sensing capabilities of biological hair cells. The microfiber served as both the hair shaft and the transduction element. Theoretical and experimental analyses validated the sensor’s directional sensitivity124. Likewise, Bian et al. developed a hair airflow sensor using a multi-electrode metal-core piezoelectric fiber (MMPF) to emulate the filiform sensory hairs of crickets. Theoretical and experimental analyses demonstrated the sensor’s capability to detect both the direction and magnitude of airflow125. To further enhance sensor sensitivity and capture more comprehensive 3D information, the researchers designed sensors incorporating symmetrical electrode MMPFs126 and dual multi-electrode MMPFs127.

MEMS piezoelectric AHC sensors are self-powered, eliminating the need for external excitation. This feature makes them suitable for long-term flow detection applications due to their high sensitivity and low power consumption. However, their reliance on dynamic stimuli limits their ability to detect static flow. Consequently, these sensors may struggle to accurately measure slowly varying or constant flow fields, posing challenges for applications requiring precise long-term static flow field measurements.

Capacitive hair and hair cell flow sensors

Capacitive AHC flow sensors measure fluid flow by detecting variations in capacitance. Inspired by cricket cerci’s flow-sensitive receptor hairs, researchers developed a capacitive hair sensor for acoustic and flow perception, as presented in Fig. 4a (left). This sensor employs variable capacitors with suspended SixNy membranes and a bottom substrate, augmented with an SU-8 structure to emulate cricket cerci hair. Two forms of suspended membranes, spiral suspension and torsional suspension, were designed and validated to demonstrate the concept’s effectiveness128. They later introduced several optimization strategies for sensor design. Employing multiple layers of SU-8 effectively increased hair height. A double-exposed SU-8 hair (~1 mm) depicted in Fig. 4a (middle) successfully elevated the hair above the boundary layer, significantly enhancing the torques on the hair128,129. Thereafter, they refined the double-exposed hair design by reducing the diameter of the top hair layer, as illustrated in Fig. 4a (right), resulting in approximately a 65% reduction in the hair’s moment of inertia. This adjustment maintained adequate bandwidth while reducing the torsional spring constant. Experimental results demonstrated a sensitivity of 0.85 mm/s at 400 Hz to oscillating airflows and exhibited a figure-of-eight response130. Enhancements to the capacitive hair flow sensor included electrostatic spring softening (ESS) and electrostatic spring hardening (ESH), which significantly improved its performance. The application of a DC-bias voltage reduced the sensory threshold, enhancing the flow detection limit by over 6 dB. Responsivity increased by up to 80% for flow signals below the sensor’s resonance frequency. The integration of a frequency-matched AC-bias voltage enabled tunable filtering, providing frequency and phase selective gain up to 20 dB. Furthermore, a non-frequency-matched AC-bias voltage enhanced the quality and fidelity of low-frequency flow measurements, attaining a detection limit as minimal as 5 mm/s at 30 Hz131,132. Integrating ESH significantly advanced the hair flow sensor, enabling adjustable detection limits, responsivity, range, and bandwidth. Applying a DC-bias voltage to the ESH capacitive sensor expanded its bandwidth but reduced responsivity133. Researchers have also undertaken further initiatives to enhance these sensors, including developing a novel fabrication process for capacitive sensor arrays with flexible SU-8 membranes and hairs134, designing differential capacitive interfaces135, conducting harmonic measurements136, and evaluating five engineering criteria: responsivity, power transfer, power efficiency, response time, and detection threshold137.

a MEMS AHC flow sensor using variable capacitors with suspended SixNy membranes and a bottom substrate (left) (reprinted and modified from ref. 128 with permission from IOP science); a sensor with double-exposed hairs of uniform (middle) (reprinted and modified from ref. 129 with permission from IOP science) and varying diameters (right) (reprinted and modified from ref. 130 with permission from IEEE). b Schematic demonstrating capacitive hair flow sensor’s differential sensing for directional airflow detection (reprinted and modified from ref. 138 with permission from IEEE). c Monolithic capacitive flow sensor integrating MEMS and CMOS technologies (reprinted and modified from ref. 139 with permission from Elsevier). d Capacitive hair-like sensor converting airflow into hydraulic pressure (were reprinted and modified from ref. 140 with permission from IEEE). e Capacitive hair sensor fabricated via 3D printing, with potential applications in MAVs (reprinted and modified from ref. 142 with permission from IEEE)

Modeled after the bat hair sensory system, Castro et al. proposed a hair capacitive sensor for detecting directional airflow via differential sensing, as depicted in Fig. 4b. Their design and simulations demonstrated the sensor’s ability to detect airspeeds of 0.5 m/s138. André et al. exemplified the integration of MEMS and complementary metal-oxide-semiconductor (CMOS) by presenting a MEMS capacitive cantilever airflow sensor combined with a CMOS circuit, as shown in Fig. 4c. The monolithic integration of these systems offers a reduced footprint and decreased power consumption relative to traditional interfacing circuits. It exhibited a 10% variation in resonant frequency over airflow speeds ranging from 0 to 120 m/s, with a static power usage of ~1 µW139.

Diverse structures and technologies are being used to produce capacitive hair flow sensors. Saddeghi et al. presented a capacitive hair-like flow sensor array based on a micro-hydraulic structure. This sensor converts flow into hydraulic pressure, which is measured through capacitance incorporated within the micro-hydraulic system, as illustrated in Fig. 4d. The sensor exhibits a detection range of 0–10 m/s and a resolution of 1 cm/s. Furthermore, the micro-hydraulic system can serve as an innovative design element in other MEMS devices to enhance performance140. Subsequently, a two-dimensional (2D) directional hydraulic sensor was developed. This sensor exhibited a paramount sensitivity of 47.9 fF/(m/s), a tenfold increase compared with previous unidirectional sensors. Its dynamic range, minimal detection limit, and angular resolution were ~0–15 m/s, 2 mm/s, and 13°, respectively141. Rajasekaran et al. introduced a differential capacitive hair sensor fabricated via two-photon polymerization for detecting directional airflow. The sensor incorporates a high-aspect-ratio hair structure affixed to a thin, flexible membrane, as shown in Fig. 4e. This fabrication technique offers the potential to create sensors that closely mimic biological hairs, thereby advancing the development of future MAVs142.

Capacitive AHC flow sensors offer the advantages of simple structure, low power consumption, and less susceptibility to environmental temperature variations22,143,144. However, these sensors are more vulnerable to interference caused by variations in the dielectric properties of the medium, such as parasitic capacitance introduced by the measurement circuit or the pressure medium145. In addition, capacitive hair flow sensors with torsional plates may encounter challenges in underwater applications, as capillary forces could lead to the structural collapse of the narrow plates14.

Other hair and hair cell flow sensors

Researchers have explored alternative detection mechanisms for AHC flow sensors, including resonance, displacement, magnetic, optical, and contact resistance-based approaches. Resonant AHC flow sensors correlate flow field data with the output resonant frequency. Yang et al. developed a resonant hair sensor capable of quantifying multiple physical parameters, such as acceleration, angular velocity, and airflow. This sensor consists of a hair structure, a torsional frame, and a resonant signal transducer. Preliminary computational fluid dynamics and finite element analyses validated the structural feasibility of the design146. Subsequently, the design, simulation, fabrication, and experimental validation of a MEMS hair flow sensor incorporating a two-stage micro-leverage mechanism were presented, as depicted in Fig. 5a. Initial experimental findings revealed a maximum sensitivity of ~7.41 Hz/(m/s)2 at a resonant frequency of 22 kHz with a hair height of 9 mm. Notably, a 2.42-fold increase in sensitivity was observed when the hair height was extended from 3 to 9 mm. Furthermore, a detection threshold of 3.23 mm/s for airflow amplitude at 60 Hz was validated147. Using this two-stage micro-leverage flow sensor, an artificial lateral line system was developed to measure constant and oscillatory airflow. This system attains a minimum threshold of 0.785 mm/s for oscillatory airflow measurements and proficiently filters low-frequency disturbances, facilitating precise evaluation of high-frequency flow velocities148. Expanding on these advancements, Guo et al. further refined the sensor by employing an asymmetric structural configuration. Relative to the preceding iteration147, the sensor exhibited a sensitivity of 5.26 Hz/(m/s)2 at a resonant frequency of 22 kHz, with a hair height of 6 mm149. Furthermore, researchers introduced a mode-localized hair sensor, leveraging weakly coupled resonators to detect both oscillatory and dual-axis airflow150,151. In a similar vein, Li et al. devised a hair-like resonant sensor, employing a bridge-type flexible amplification mechanism to measure airflow rate. Experimental results demonstrated a sensitivity of up to 8.56 Hz/(m/s)2 in airflow rate measurement152. While MEMS-based resonant AHC flow sensors offer high sensitivity and low detection threshold, they are susceptible to external noise interference (such as vibration and sound waves), which can compromise signal-to-noise ratios.

a Resonant hair sensor designed for airflow measurement (reprinted and modified from ref. 147 with permission from AIP). b SEM image of a flexible hair flow sensor measuring local wall-shear stress via PDMS pillar deflection (reprinted and modified from ref. 153 with permission from Elsevier). c Schematic of a flexible, double-layer magnetic cilia-based airflow motion sensor (reprinted and modified from ref. 156 with permission from Springer Nature). d Schematic of a biomimetic AHC flow sensor using asymmetric optical fibers (reprinted and modified from ref. 159 with permission from IOP science). e Schematic of a hair cell sensor based on the contact resistance changes in vertically aligned CNT bundles (reprinted and modified from ref. 161 with permission from IOP science). f Soft airflow hair sensor using printed ionogel channels for wind gust detection in small uncrewed vehicles (reprinted and modified from ref. 167 with permission from IEEE)

Hair displacement measurement of AHC flow sensors is one technique for inferring flow field characteristics. Große et al. proposed a novel method to assess dynamic wall-shear stress in turbulent pipe flow using a flexible PDMS micro-pillar wall-shear stress sensor, as depicted in Fig. 5b. This approach leverages the deflection of the pillar tip in response to fluid forces as a surrogate for local wall-shear stress. Skin-friction experiments were performed in a controlled turbulent pipe flow regime at Reynolds numbers of 10,000–20,000. Experimental findings exhibited strong concordance with prior research, indicating the sensor’s ability to measure mean wall-shear stress with an error of approximately 0.0175 ustheo (mean friction velocity) at Reynolds numbers of 12,000–20,000 (ref. 153). Researchers at North Carolina State University and NASA Langley Research Center devised an elastic microfence structure for aerodynamic flow sensing. Fabricated through laser ablation patterning and soft lithography using a two-part silicone, the microfences’ response was captured using optical microscopy. Wind tunnel experiments conducted under diverse flow conditions demonstrated the microfences’ ability to discern critical aerodynamic flow characteristics, including stagnation points, separation points, laminar separation, and flow reattachment154. Nevertheless, in wind tunnel settings or real-world applications, vibrations may compromise the accuracy of displacement measurements.

Recent investigations have explored the use of magnetic and optical AHC flow sensors. Inspired by the intricate hair structure of spiders, Wu et al. introduced a self-powered, out-of-plane wind sensor employing flexible magnetoelectric materials. The sensor was fabricated via screen printing on a thin polyethylene terephthalate film, incorporating silver nanoparticle patterns on its surface. It exhibits the capacity to discriminate between forward and backward wind directions and can detect wind velocities as low as 1.2 m/s. These out-of-plane wind sensors show considerable promise for applications in outdoor sports, exploration, spatial perception, and positioning systems155. Similarly, Man et al. presented a tactile and airflow motion sensor using a flexible, bilayer magnetic cilia structure, as illustrated in Fig. 5c. The upper layer consists of a flexible material incorporating magnetic particles, while the lower layer comprises pure flexible material. Experimental findings indicated that this sensor possesses a sensitivity of 1.43 µT/(m/s) and shows potential for monitoring sleep apnea156. Xu et al. introduced an optical AHC flow rate sensor employing a U-shaped silica microfiber embedded in PDMS. In this configuration, PDMS film deflection in flowing liquid induces bending-dependent transmittance changes in the embedded microfiber, directly correlating with liquid flow rate. The sensor exhibits a low detection limit of less than 0.05 L/min, a high resolution of 0.005 L/min, and a rapid response time of 12 ms157. Furthermore, AHC flow sensors based on optically transmissive organic crystals158 and optical fibers, as shown in Fig. 5d, have been documented159,160. Unlike electrical AHC flow sensors, optical AHC flow sensors do not necessitate numerous electrodes. However, precise optical path design and alignment may present technical challenges.

Contact resistance variation serves as an additional sensing mechanism in AHC flow sensor design. Yilmazoglu et al. devised a hair cell sensor mimicking mammalian hair cells using vertically aligned CNT bundles, as presented in Fig. 5e. These topologically graded CNT bundles were produced through chemical vapor deposition. Deflection or compression of the central CNT bundle modifies its contact resistance with shorter adjacent bundles. The sensor exhibited an average sensitivity of 2100 ppm in the linear regime, quantified as the relative resistance change per micron (ppm/μm) of individual CNT bundle tip deflection161. Furthermore, researchers have developed AHC flow sensors that capitalize on variations in contact resistance within carbon fiber networks162 and high-aspect-ratio polycaprolactone/graphene cilia arrays163.

In a significant study, Devaraj et al. devised an economical, disposable airflow sensor designed to detect ON/OFF signals via a 3D-printed micro-hair made of the conductive polymer poly(3,4-ethylene dioxythiophene). The sensor generates ON/OFF signals when airflow meets specific thresholds. A thin platinum wire with a radius of 90 μm is positioned next to the micro-hair, acting as a reference point. Upon sufficient deflection of the conductive, flexible hair to make contact with the platinum wire, an electrical connection is established. With dimensions of 1000 μm in length and 6 μm in diameter, the sensor exhibited sensitivity between 0.66 and 0.97 m/s, rendering it ideal for detecting low-flow rates, such as those mandatory in neonatal resuscitators164. Furthermore, ionic polymer metal composites165,166 and conductive ionogels, as illustrated in Fig. 5f167, have been investigated for the fabrication of hair-like transducers and sensors. Wang et al. presented a cilia-like transducer that enables concurrent actuation and sensing. This work is applicable to small-scale soft robots operating in fluid environments168.

Table 1 provides an overview of AHC flow sensors employing diverse sensing mechanisms. The piezoresistive materials used in hair flow sensors can be classified into three main types: doped silicon, metal strain gauges, and polymer conductive composites. Doped silicon-based hair flow sensors typically exhibit higher sensitivity compared to those based on metal strain gauges. However, metal strain gauge-based sensors are easier to fabricate and more cost-effective. Polymer conductive composite-based sensors combine conductive materials, such as CNTs, CNFs, carbon paper, carbon black, and graphene, with flexible polymers like PDMS and PU. These sensors are highly flexible and stretchable, making them suitable for applications in electronic skin and soft robotics. Piezoelectric hair flow sensors are commonly based on materials such as BaTiO₃, PVDF, and PZT. They exhibit low sensitivity to static flow. Capacitive hair flow sensors have a simple structure, low power consumption, and are less susceptible to temperature variations. In addition, technologies such as resonance, displacement, optics, and magnetic principles have also been applied to the design of hair flow sensors.

Material, fabrication, and integration of artificial hairs

A primary challenge in manufacturing AHC flow sensors is the development of high-aspect-ratio artificial hairs. This involves material selection, appropriate fabrication techniques, and integration methods. Parameters including geometric shapes, flexibility, sizes, and verticality of the hairs significantly influence sensor performance. Table 2 summarizes the present state of artificial hairs, detailing their materials, processing methods, dimensions, and corresponding sensitivities.

The fabrication of AHC flow sensors, based on integration methods, can be classified into two categories. The first category involves the production of monolithic AHC flow sensors. For instance, out-of-plane microstructures using PDMA62 technology have been documented for the creation of artificial hairs. This technology employs plastic deformation to generate microstructures perpendicular to the substrate. Another method for fabricating artificial hairs involves creating self-bending structures through residual stress between multiple material layers71,74,103. However, this technique results in curved hairs that do not maintain a perpendicular orientation to the surface. In addition, monolithic AHC sensors have been fabricated using techniques such as laser cutting104, 3D printing, and casting169, 3D printing with replica molding105, sacrificial metal 3D printing106, and double molding of PDMS114.

The second category entails independently fabricating the hairs and subsequently integrating them with the sensor’s components. For instance, SU-8, a polymer material, can produce high-aspect-ratio 3D microstructures. Both SU-8 lithography and multi-layer SU-8 lithography have been documented to create artificial hairs ranging from hundreds of microns to over 1 mm in length60,128. Micron-scale hairs composed of SU-8 are highly suitable for applications involving microcantilever beams or micron-scale thin films. Three-dimensional printing technology is frequently used for the autonomous fabrication of hairs118,121, primarily using polymers. The 3D-printed artificial hair is manually incorporated with sensors using UV-curable adhesive. This method provides an efficient and cost-effective solution for producing hairs ranging from millimeters to centimeters in length. Independent hair fabrication techniques also include LIGA, hot embossing91, and replication from a wax mold99.

Between these two fabrication approaches for creating and integrating artificial hair, the former ensures the consistency of sensor units, enabling large-scale manufacturing of sensor arrays. Conversely, the latter involves secondary hair integration, predominantly manual, complicating large-area sensor array production. Therefore, developing more automated and efficient secondary integration techniques is imperative. Emerging fabrication methods offer new possibilities for producing high-aspect-ratio artificial hairs. Soft lithography, as a non-photolithographic fabrication technique, provides a complementary approach to traditional photolithography and enables the fabrication of high-aspect-ratio microstructures170,171,172. Nanoimprint lithography facilitates the fabrication of high-aspect-ratio artificial hairs at the nanoscale173. Metal-assisted chemical etching allows for the production of high-aspect-ratio silicon pillars at both micrometer and nanometer scales174,175. In addition, ultrafast laser processing176, nanosphere lithography177, and self-assembly178 provide alternative approaches for fabricating artificial hair structures.

Flow-sensing enhancement

Artificial cupula

The lateral line sensory mechanisms, prevalent in fish and certain amphibious aquatic organisms, detect water movement and pressure fluctuations. Neuromasts constitute the primary sensory architecture, with the cupula serving as a critical mechanotransductive component119. Research has advanced in replicating the cupula in the lateral line sensory system of fish. Inspired by the exceptional navigational abilities of blind cavefish in complex underwater environments, Peleshanko et al. pioneered an innovative hydrogel-encapsulated hair flow sensor to replicate SN functionality. The sensor’s design incorporates a dome-shaped hydrogel cupula to mimic the fish’s cupula. The hydrogel-encapsulated AHC sensors demonstrated a reduced flow detection threshold and an expanded dynamic range compared with conventional exposed sensors. Furthermore, the artificial hydrogel cupula showed increased resilience against elastic deformation from impacts, along with anti-corrosive and anti-biofouling properties, making it suitable for marine environments179. Contemporary research has demonstrated the utilization of electrospun fibers and hydrogel to create artificial cupula with customizable shapes and moduli180. Similarly, SMART developed a prolate spheroid-shaped artificial neuromast cupula using a nanofibril scaffold and a hydrogel, as depicted in Fig. 6a82. The sensitivity of this cupula-coated sensor increased by 3.5–5 times compared with the exposed sensor for steady-state flow detection. Rheological and nanoindentation analyses verified that the hyaluronic acid-based artificial cupula’s material properties closely mirrored those of biological cupula83. An optimized HA-MA hydrogel-based cupula was also designed to mimic the morphology, composition, and microstructure of natural cupula119. A hydrogel-infused CNT bundle hair flow sensor further confirmed the artificial cupula’s role in enhancing mechanical properties and sensitivity181,182. In addition, artificial neuromast cupula fabricated from materials including silicone (Fig. 6b)183, PDMS184, and PVA hydrogel102 have been documented.

a Electrospun fibers and hydrogel replicate the fish neuromast cupula structure (reprinted and modified from ref. 82 with permission from Springer Nature). b Capacitive hair sensor with artificial silicone cupula, depicted schematically and optically (reprinted and modified from ref. 183 with permission from MDPI). c Schematic of artificial CN system with PZT piezoelectric hair sensor arrays and PDMS canal (reprinted and modified from ref. 118 with permission from The Royal Society). d CN system with PVDF piezoelectric sensor arrays and PDMS canal, depicted schematically (reprinted and modified from ref. 186 with permission from MDPI). e AHC flow sensor coated with 2 μm-thick parylene conformal films (reprinted and modified from ref. 75 with permission from Elsevier). f Hair flow sensor mimicking the whisker function of harbor seals (reprinted and modified from ref. 191 with permission from IEEE)

Artificial CNs and SNs

In the sensory system of fish, SNs are situated on the epidermal surface, directly exposed to the external milieu. Conversely, CNs are housed within fluid-filled canals connected to the exterior via apertures38. SNs predominantly detect the velocity of the external hydrodynamic flow, whereas CNs exhibit heightened sensitivity to the acceleration of water induced by prey. These canals function as biomechanical filters, selecting signals at specific frequencies185. CNs have been documented as components of the fish’s lateral line system. The SMART has developed an artificial lateral line system incorporating both SNs and CNs. The artificial SNs are engineered to detect flow velocity, whereas PDMS-encapsulated CNs are used to sense flow acceleration. Figure 6c depicts the schematic of the PDMS CN system. Experimental studies evaluated the CN’s capability to filter steady-state flow signals118. Jiang et al. also unveiled a flexible artificial lateral line CN system using a piezoelectric sensor array and an artificial PDMS canal, as illustrated in Fig. 6d. Experimental evidence indicates that this canal system functions as a high-pass filter, suppressing low-frequency signals. It can detect pressure gradients as small as 11 Pa/m at a frequency of 115 ± 1 Hz186. Likewise, Herzog et al. developed an artificial lateral line CN system using hair sensor arrays integrated with PDMS lamellae. This system demonstrated robustness to underwater pressures up to 6 bar and the ability to estimate bulk flow velocity by analyzing the spatiotemporal propagation of flow fluctuations. This capability makes it suitable for flow rate measurement in industrial settings187. To augment the flow-sensing capabilities of autonomous aquatic and aerial robots, Abels et al. engineered an artificial lateral line system for multi-parameter freestream flow measurements. The system, based on a piezoresistive cantilever beam, underwent testing using a pulsed airflow generation setup to quantify freestream flow velocity and direction188.

Parylene coating for enhanced waterproofing

Recent advancements in parylene technology have established it as a prime material for sensor fabrication. Particularly, parylene c has garnered significant attention due to its compatibility with micromachining processes, biocompatibility, chemical inertness, optical transparency, flexibility, and mechanical robustness189,190. Furthermore, it serves as a protective encapsulation layer for AHC flow sensors. Illustratively, Li et al. engineered an AHC flow sensor encapsulated in a conformal parylene coating to augment its durability and electrical insulation64. Qualtieri employed a 2 μm-thick parylene conformal coating to render a hair cell sensor waterproof, as shown in Fig. 6e75. In addition, the parylene coating bolstered the sensor’s mechanical stability by augmenting its robustness and stiffness. Experimental results further indicated that the parylene conformal coating augmented sensor responsivity and overall sensing performance through adjustments in coating thickness76.

Artificial hair to mimic harbor seal whisker

Marine mammals, such as seals, navigate and detect prey in dark or turbid aquatic environments by relying on highly developed sensory systems. Seals exhibit a remarkable ability to detect and track hydrodynamic trails using their sensitive whiskers. Research suggests that the unique undulating structure of harbor seal whiskers plays a crucial role in suppressing VIV. This distinctive morphology significantly modulates the vortex street, attenuating the vibrations inherent in vortex shedding43,44. Drawing inspiration from the morphology of harbor seal whiskers, Kottapalli et al. constructed an artificial micro-whisker hair sensor comprising an artificial whisker and a PZT sensing membrane. The artificial whisker, fabricated via stereolithography, was designed to mimic the dimensions and structure of a natural seal whisker. Experimental results revealed that the VIV frequency peak of this bio-inspired sensor was significantly reduced, ~50 times lower than that of conventional circular cylinder hair flow sensors50. Figure 6f illustrates the schematic and optical images of the artificial harbor seal whisker sensor191. Zhang et al. developed a piezoelectric sensor modeled after harbor seal whiskers to detect underwater flow angles of attack and velocity. They used an oscillating sphere to generate oscillatory flow excitation, simulating underwater disturbances. Experimental data demonstrated that the sensor could distinguish between various flow angles of attack, achieving a sensitivity of 1.445 V/(m/s) in water122. Leveraging these breakthroughs, the study introduced a novel geometric framework to replicate artificial harbor seal whiskers and formulated modified whisker-like structures. Flow-structure interaction simulations were performed to evaluate the effect of morphological parameters on VIV suppression. Using the optimized whisker structure, they engineered a 3D-printed flow sensor integrated with graphene nanoplatelet-based piezoresistors107.

Several methodologies have been implemented to augment the performance of AHC flow sensors. One method entails fabricating an artificial cupula to shield the exposed hair, enhancing protection in engineering applications and bolstering sensor sensitivity. Another approach involves devising artificial lateral line systems to emulate the functionality of fish lateral lines. Parylene encapsulation enhances waterproofing and overall durability. Furthermore, mimicking the distinctive structure of seal whiskers aids in mitigating VIV. These enhancements target improved sensor performance in engineering applications. Future research will pursue further advancements in sensor performance and engineering adaptability.

Applications

Flow sensors are pivotal in various domains, including medical devices14,192,193, biomedical systems194, robotics technology195, harsh environment sensing34, automotive and aerospace engineering196,197, and industrial pipeline monitoring10. AHC flow sensors have gained notable attention for their versatile applications in bio-robotics, UAVs, UUVs, and biomedicine.

Bio-robotics

Bio-robotics harnesses nature’s inspiration to create robots emulating animals’ agility and adaptability. Its primary aims are to develop robots replicating animal movement and to study adaptive behaviors observed in nature. Progress in bio-robotics also propels advancements in fluid dynamics, biomechanics, neuroscience, and prosthetics198. Liu et al. developed a lamprey-inspired robot with a cupula receptor, augmenting the sensory functions of the soft, lamprey-like robot to mimic the movement mechanisms of living lampreys. The biomimetic hair-based cupula receptor exhibited a detection of 0.05–0.6 m/s in a flow environment199. Similarly, a joint initiative between Nanyang Technological University and the Massachusetts Institute of Technology introduced a biomimetic robotic stingray for underwater applications. The robot integrates two MEMS hair flow sensors: one gauges the stingray’s propagation velocity, while the other records the flapping dynamics of its fins, as shown in Fig. 7a. The predictive control system effectively directs the robotic stingray along a predetermined trajectory, showcasing promise for various unmanned robotic vehicles200. In addition, Abels et al. conducted a comprehensive review of stress-driven hair flow sensors for robotic flow-sensing applications201. Zhang et al. presented a robotic fish equipped with artificial lateral line sensors, as illustrated in Fig. 7b202. To mitigate turbulence noise near the sensors, they proposed a trio of flow control components: a fairing, a flow conditioner, and a flow collector. Computational fluid dynamics simulations indicated that these elements reduced turbulence intensity near the sensitive elements by 56.5%. Experimental findings further validated the robotic fish’s ability to achieve real-time flow speed measurements.

a Underwater biomimetic robotic stingray using two MEMS AHC flow sensors for flow-related control evaluation (reprinted and modified from ref. 200 with permission from IOP science). b Structural and physical representation of a biomimetic robotic shark with an artificial lateral line sensor (reprinted and modified from ref. 202 with permission from IEEE). c Flow sensing over an airfoil using flexible pillar sensors marked with LED light tips (reprinted and modified from ref. 210 with permission from MDPI). d MEMS piezoresistive cantilever volumetric flow sensor for biomedical IV system application (reprinted and modified from ref. 213 with permission from MDPI). e Multifunctional electronic hair sensor mimicking human skin structure and properties (reprinted and modified from ref. 95 with permission from the Royal Society of Chemistry). f Graphene-based AHC sensor replicating the hair cells of the vestibular system (reprinted and modified from ref. 220 with permission from IEEE)

Unmanned systems/vehicles

Recent technological advancements have significantly accelerated the development of unmanned systems and vehicles, which are now equipped with a diverse sensor suite to facilitate navigation and operation203. UAVs and MAVs have become highly ubiquitous in both military and civilian contexts, performing tasks including surveillance, reconnaissance, mapping, cartography, and border patrol204. Additionally, UUVs are gaining substantial interest from global navies and the offshore industry205,206.

A critical challenge in autonomous MAV operation is managing flow separation over airfoils. Closed-loop separation control systems offer a potential solution to improve autonomous control and stability. Dickinson et al. investigated the detection of flow separation in MAVs using bio-inspired flow sensors207. Building upon a bio-inspired multimodal artificial lateral line, DeVries et al. produced estimation and control strategies to assess flow properties over a UUV’s airfoil for feedback control208. Mohamed et al. demonstrated the use of biologically inspired hair flow sensors to maintain the attitude stability of fixed-wing MAVs in turbulent atmospheric conditions209. Selim et al. developed a novel approach using flexible pillar sensors to sense and characterize flow over an airfoil, as depicted in Fig. 7c. These sensors have the potential to enable “flying by feel” by detecting critical flow events on the airfoil210,211. Biomimetic artificial hair sensors offer a promising avenue for technological advancement in unmanned systems and vehicles. These sensors can identify specific flow characteristics, crucial for refining control models and improving the operational performance of unmanned systems.

Biomedicine

The biomedical field increasingly demands compact, adaptable flow sensors with minimal power requirements, driven by emerging applications such as health monitoring, human motion detection, and artificial electronic skin. Recent scientific investigations have demonstrated significant advancement in intravenous (IV) infusion monitoring technologies. Haghighi et al. developed a real-time IV infusion monitoring system using MEMS hair flow sensors, achieving a remarkable detection threshold of 5 mL/h, surpassing existing commercial IV sensors at low-flow rates212. Complementary research by Lansheng Zhang et al. introduced a bio-inspired volumetric flow sensor, as illustrated in Fig. 7d, with an expansive dynamic range, successfully detecting flow rates of 2–200 mL/h, representing a notable innovation in precision measurement technologies213.

Human skin, known for its flexibility and resilience, stands as the largest organ and serves as a protective barrier while sensing various external stimuli214. Electronic skin replicates these sensory functions by integrating advanced sensors, holding promise for applications in robotics, artificial intelligence, and human-machine interfaces215. At the Goddard Space Flight Center, researchers have fabricated flexible skins incorporating integrated sensors and circuitry. These sophisticated skins feature multimodal sensor nodes, including pressure sensors, shear stress sensors, surface-micromachined hot-wire anemometers, and hair cell sensors specially designed for measuring flow velocity in two dimensions across the skin’s surface216. Liu engineered an innovative electronic hair sensor using nylon fibers as artificial hair analogs, with PDMS serving as a biomimetic skin substrate, as shown in Fig. 7e. The nylon fibers and PDMS mimic the diameter and Young’s modulus of human hair and skin, respectively. This sensor can detect various stimuli, including pressure, surface roughness, airflow rate, and direction95.

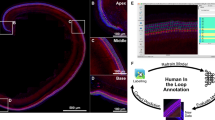

The vestibular system is critical for stabilizing gaze and postural control. Each inner ear comprises two otolithic organs and three semicircular canals, enabling the detection of 3D head rotations. Vestibular system damage, whether due to disease, injury, or aging, can lead to debilitating symptoms, such as nausea, vertigo, oscillopsia, dizziness, and imbalance217,218. Inspired by the success of cochlear implants, the development of artificial vestibular prostheses presents a promising avenue for restoring vestibular function. Raouf et al. have introduced a MEMS AHC flow sensor integrated within a 3D-printed semicircular canal, designed to mimic the human vestibular system. This biomechanical device has been evaluated under a range of angular accelerations within a frequency spectrum of 0.5–1.5 Hz. Experimental and computational investigations have provided valuable insights for the development of a commercially viable, cost-effective medical device219. In addition, Moshizi et al. have introduced a novel graphene-based flow sensor designed to emulate the hair cells of the vestibular system, as illustrated in Fig. 7f220. Their research also offers a comprehensive review of recent advancements in bioelectronic devices designed to interface with the peripheral vestibular system221.

Compared to conventional flow sensors, AHC flow sensors leverage unique hair structures to achieve precise flow measurements. These structures provide notable advantages in capturing fluid dynamics within 3D space. Furthermore, the incorporation of diverse sensing mechanisms facilitates the measurement of a broad of fluid parameters. Their exceptional sensitivity, compact design, and capability to detect multidirectional flow underscore their significant potential for applications across a wide range of fields.

While most applications of AHC flow sensors are currently in the research stage, their future potential across diverse fields is significant. In aerospace engineering, for instance, AHC flow sensors could be integrated into aircraft navigation systems for monitoring airflow over the wings and fuselage. This real-time data would improve flight control, stability, and overall operational efficiency31,222. In the field of robotics, AHC flow sensors could be incorporated into robotic skin to confer flow and tactile feedback, enabling the detection of subtle environmental changes223,224. In the biomedical sector, AHC flow sensors possess the potential to enhance advanced hearing aid technology, thereby enhancing sound detection for individuals with auditory impairments. Moreover, these sensors can be used in medical devices to detect bodily flow, including blood circulation or respiratory airflow, facilitating more accurate diagnostics. In microfluidics, they offer precise flow measurements in microfluidic devices, crucial for lab-on-a-chip systems used in diagnostics, drug delivery, and biochemical analysis225,226,227. In industrial applications, AHC sensors can monitor fluid flow in chemical processing, oil, and gas sectors, guaranteeing process efficiency and averting system failures. AHC sensors, when integrated into wearable devices, can provide real-time health metrics and environmental data during physical activity. These sensors can monitor airflow and other environmental conditions, making them valuable tools for both consumers and professionals. As materials science and fabrication techniques continue to evolve, AHC flow sensors are poised to become indispensable in a wide range of industries.

However, the long-term use of AHC flow sensors faces with several challenges, including environmental stability, material aging and durability, signal drift and calibration, contamination, maintenance, energy supply, and power consumption. AHC sensors may be affected by environmental factors such as temperature and humidity. Sensitive structures, including artificial hairs or cantilevers, are prone to mechanical fatigue or fracture under prolonged exposure to fluid shear and vibration. Furthermore, polymer components can degrade over time when subjected to harsh environments. Energy efficiency and power stability are essential to AHC flow sensors that require a continuous power supply.

Conclusion and future work

This review has provided a comprehensive analysis of recent developments in AHC flow sensor technology. We have described the extraordinary sensory capabilities of natural hair structures, specifically the hair cell’s capacity to detect flow and acoustic stimuli, and the intricate mechanisms that underpin these abilities. Subsequently, we have classified AHC flow sensors according to their sensing mechanisms, encompassing piezoresistive, piezoelectric, capacitive magnetic, resonant, and optical sensors. MEMS-based piezoresistive, piezoelectric, and capacitive AHC flow sensors commonly exhibit several key advantages:

-

1.

These sensors exhibit exceptional sensitivity and a remarkably low detection threshold, enabling the precise measurement of minute flow variations and vibrations, making them ideal for applications demanding high-precision flow measurement in low-flow environments.

-

2.

The sensors’ diminutive size and high degree of integration make them exceptionally well suited for applications with limited space constraints, including microchannels, biomedical devices, and microfluidic chips. Moreover, these sensors can be seamlessly integrated within intricate microsystems to facilitate multi-point flow monitoring.

-

3.

These sensors possess rapid response times, enabling the real-time capture of transient flow variations. This capability is essential for instantaneous feedback measurements in dynamic flow environments, for instance, airflow monitoring or underwater vortex detection.

-

4.

These sensors are well suited for long-term monitoring, particularly in energy-constrained environments such as wearable devices, Internet of Things (IoT) systems, drones, and implantable medical devices. Notably, MEMS piezoelectric AHC flow sensors are self-powered.

These sensors, while exhibiting high sensitivity in detecting dynamic flows, present limitations in measuring static flow and are susceptible to temperature variations, necessitating temperature compensation for high-precision measurements. AHC flow sensors using alternative sensing mechanisms possess unique characteristics. For instance, AHC flow sensors based on hair displacement detection are relatively simple to fabricate. These sensors are susceptible to external perturbations. In contrast to electrical AHC flow sensors, optical AHC flow sensors do not necessitate numerous electrodes but require precise optical path and alignment design. By developing AHC flow sensors grounded in varied principles, we can substantially advance sensing technologies and broaden their applications to better meet the evolving demands of the market.

A principal challenge in designing AHC flow sensors is the fabrication and integration of artificial hair structures. This necessitates selecting optimal materials, devising suitable processes, and formulating effective integration techniques. Two primary methodologies have been identified. The first entails fabricating monolithic AHC flow sensors using techniques such as PDMA and leveraging residual stress in various materials. The second methodology involves the independent creation of artificial hair, succeeded by secondary integration. The first approach ensures consistency across individual sensors and facilitates large-scale production of sensor arrays. Conversely, the manual nature of secondary incorporation in the second approach restricts scalability and consistency. Developing automated and accurate secondary incorporation techniques remains a significant challenge. Consequently, the fabrication and integration of artificial hair structures represent a critical limitation in AHC sensor development. Advancements in materials and fabrication technology will drive the evolution of this process.

Efforts to improve AHC flow sensor performance and broaden applications have been investigated. For instance, developing artificial neuromast cupulas with hydrogel materials has safeguarded exposed hair cells and heightened sensitivity. Parylene coatings bolster the robustness and waterproofing efficacy of AHC devices, ensuring durability in harsh environments. Artificial hairs inspired by seal whiskers effectively suppress VIV. Furthermore, artificial fish lateral line systems, derived from the CNs and SNs of biological lateral lines, can measure both steady-state flows and fluid movements at specific frequencies. These innovations augment the reliability and efficacy of AHC flow sensors in engineering contexts. Notably, AHC sensors have been deployed in diverse domains, encompassing bionic robotics (such as robotic fish), aircraft wings, IV systems, electronic skin, and vestibular hair cell models for the human inner ear. While many of these applications are still experimental, they offer valuable insights and possess significant potential for future commercialization and practical deployment.

Future work