Abstract

Hydrogen atom transfer (HAT) from a metal-hydride is a reliable and powerful method for functionalizing unsaturated C–C bonds in organic synthesis. Cobalt hydrides (Co–H) have garnered significant attention in this field, where the weak Co–H bonds are most commonly generated in a catalytic fashion through a mixture of stoichiometric amounts of peroxide oxidant and silane reductant. Here we show that the reverse process of HAT to an alkene, i.e. hydrogen atom abstraction of a C–H adjacent to a radical, can be leveraged to generate catalytically active Co–H species in an application of shuttle catalysis coined shuttle HAT. This method obviates the need for stoichiometric reductant/oxidant mixtures thereby greatly simplifying the generation of Co–H. To demonstrate the generality of this shuttle HAT platform, five different reaction manifolds are shown, and the reaction can easily be scaled up to 100 mmol.

Similar content being viewed by others

Introduction

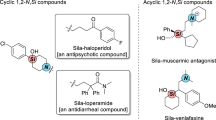

Carbon-centered radicals are versatile reactive intermediates which are widely used to produce polymers1, pharmaceuticals2, and other fine chemicals. In the context of complex molecule synthesis and drug discovery there is an increasing demand for C(sp3)-rich architectures which are often most readily accessible through radical based reactions3,4. To accelerate the discovery and synthesis of C(sp3)-rich molecules, a general methodology that can install readily diversifiable functional handles from simple olefin building blocks would be an ideal tool to access an array of different products. Currently, hydrogen atom transfer (HAT) from a metal-hydride to an alkene is among the most reliable methods for alkyl radical generation and can be used in a myriad of transformations5,6,7,8,9,10,11. However, the weak metal hydrides which undergo HAT have limited approaches to form under catalytic conditions (Fig. 1a). In these approaches, the cobalt(II) must be oxidized or reduced first before the hydride can be formed, and cannot be formed directly from cobalt(II). Initial pioneering work utilized a silane reductant and peroxide oxidant mixture where first, single-electron oxidation of the catalyst forms a M–X bond which is followed by transmetalation from the silane (Fig. 1a, top). The use of both oxidant and silane reductant in the same pot produces large amounts of unnecessary waste, is challenging to employ in large scale applications, and is less than ideal from a catalysis perspective. To overcome the problem of using the oxidant/silane mixture, photo- and electroreductive protocols have recently been developed by several groups as an emerging alternative to the classical oxidative conditions12,13,14,15,16,17,18. In these reactions, the catalytic metal-hydride is formed through reduction of a Co(II) center followed by protonation to form the Co(III)–H (Fig. 1a, bottom). While advantageous over the classical oxidative conditions as it avoids the use of silanes and oxidants, the reductive approach still requires acidic and reducing conditions to generate the Co–H from Co(II) sources (Fig. 1a, bottom). Norton and Chirik19,20,21 have also shown that metal hydrides that undergo HAT can be generated with H2, but these approaches are limited to hydrogenation and alkene isomerization and feature much stronger M–H species (BDE > 50 kcal/mol). While attractive in those contexts, they may not be applicable in hydrofunctionalization due to the fast rate of hydrogen atom transfer from M–H to alkyl radicals to produce the hydrogenated product22. Therefore, there is a clear demand for conceptually distinct strategies to access these catalytic manifolds under milder reaction conditions, ideally using neither reducing or oxidizing and pH neutral conditions to enable a broad substrate scope and allow the introduction of highly reactive functional handles that are crucial to synthetic endeavors (Fig. 1a, middle).

a Different approaches to generate unstable Co(III)–H from Co(II) sources. The most common or classical approach is shown on the top path where Co(II) is first oxidized to Co(III), then the hydride is introduced through transmetallation. The bottom path describes a more recent concept where the Co(III)–H is formed from reduction of Co(II) to Co(I) followed by protonation. The middle path describes this work where the Co(III)–H is formed directly from Co(II) by abstracting a hydrogen atom from a C–H bond adjacent to a radical. b The underlying reversibility of HAT and HAA that the shuttle HAT concept is based on. c A comparison of classical methods for HAT hydrofunctionalization of alkenes compared to the shuttle HAT strategy (d) The different synthetic applications explored in using this approach towards catalytic Co(III)–H.

Due to our lab’s interest in reversible catalysis23,24,25,26,27,28, we envisioned that a single-electron variation of the shuttle catalysis framework could form catalytically active Co–H by using the reverse process of hydrogen atom transfer to an alkene (Fig. 1b). In this way the Co–H would be formed directly from abstraction of a C–H bond adjacent to a radical29,30,31,32,33,34. Combining reversible Co–H formation with another reversible process could produce two interwoven catalytic cycles that allow for the net transfer of a hydrogen atom and functional group from one molecule (the donor) to another molecule containing an alkene (the acceptor). Crucially, the design of this shuttle HAT platform would not only be limited to a single functional group donor, but could be amenable to incorporating numerous different functional groups (Fig. 1d).

Results

Although there are numerous potential functional groups which could be applied in this methodology, we chose to initially focus on a hydroiodination reaction because of the synthetic versatility of alkyl iodides, and to demonstrate the mildness of our protocol by forming highly reactive C–I bonds under catalytic conditions. Indeed, alkyl iodides have historically been challenging to access using catalytic HAT protocols17,35,36,37. In this sense, the shuttle catalysis framework is advantageous over traditional approaches for forming highly reactive products, such as alkyl iodides38,39,40, because the catalyst is designed to reversibly react and reform the product, while traditional approaches are prone to irreversible degradation of the product by the catalyst or reagents. To intertwine with the reversible HAT cycle, we derived inspiration for a reversible halogen atom transfer (XAT) cycle from atom transfer radical polymerization (ATRP) where a halogen is reversibly cleaved and introduced in the propagation step of living polymerization (Fig. 2a, FG cycle)1.

a Reaction design for dual catalytic pathways (top). The reaction starts with cleavage of a single electron cleavage of a FG by a metal catalyst to generate a tert-butyl radical. A Co(II) species (Co-1) then abstracts a hydrogen atom to form isobutene and a Co–H. The Co–H undergoes HAT with an alkene to first form a radical cage pair followed by radical cage escape and trapping of the alkyl radical with the oxidized FG transfer catalyst M-1’ to generate the product and turn over the catalyst. b Model complexes of catalytically relevant species and their use in stoichiometric reactions to demonstrate the feasibility of the proposed mechanisms. The table shows how using model complex Cr-1’ or t-BuI can successfully form the product with decreasing amounts of side product as the amount of the t-BuI is increased. For synthesis of the model complexes, see Supplementary Information Section 4.

The use of cobalt salen complexes for reversible HAT in alkene isomerization and 1,5-HAT29,34, prompted us to focus on this ligand scaffold for our initial investigations. After considering numerous potential XAT catalysts, we chose to investigate the Cr(II/III) redox couple because of the high chemoselectivity for reversibly cleaving C(sp3)–I bonds41 and the excellent functional group tolerance of chromium in these oxidation states42. We preferred Cr over the more commonly used Cu ATRP catalysts because Cu is more prone than Cr to undergo undesired side reactivity such as coupling reactions43,44,45.

A concise set of experiments was initially designed to test the feasibility of the proposed reaction (Fig. 2b). It was unclear whether XAT to form the product (2a) could outcompete hydrogen atom abstraction (HAA) to form side products (1a’) considering that HAA is an inner sphere process while XAT is an intermolecular process, and that the C–H bond dissociation energy (BDE) is significantly lower than the C–I BDE of t-BuI (31–36 kcal/mol33 vs. 54 kcal/mol46). In a XAT vs. HAA competition experiment, a potentially catalytically relevant XAT species Cr-1’ and alkyl radical precursor Co-1’47 were heated together. To our gratification, the desired product 2a was formed in a 3:1 ratio with the internal olefin side product 1a’ (Fig. 2b, entry 1). While XAT from a catalytic M–X species was envisioned as one viable pathway to generate the product, another possible pathway for C–I bond formation is through direct XAT of tert-butyl iodide with an alkyl radical in a radical chain transfer pathway46. To test this, Co-1’ was heated with varying amounts of t-BuI. While 1 equivalent of t-BuI gave a 1:1 ratio of product 2a to side product 1a’ (Fig. 2b, entry 2), increasing the amount eventually resulted in only trace amount of the internal alkene side product (Fig. 2b, entry 4). These stoichiometric experiments with Co-1’, Cr-1’, and t-BuI suggest XAT from t-BuI is a selective method for C–I bond formation when t-BuI concentration is high, while an XAT pathway from catalytic Cr-1’ may also be selective at low concentrations (Fig. 2b). Implementing an XAT catalyst in combination with t-BuI would provide two potential pathways for C–I bond formation. Using an XAT catalyst with t-BuI could also be beneficial in case the radical chain is prematurely terminated. Then, the radical chain process could be reinitiated by small amounts of XAT catalyst and could prevent the reaction from dying in case of chain termination. Indeed, we observed premature termination of the radical chain only when no chromium catalyst was present (condition B) as evidenced by incomplete conversion of the alkene starting materials for many substrates in Fig. 3 (vide infra). Lastly, we demonstrated the catalytic relevance of Cr-1’ and Co-1’ by using them as pre-catalysts in place of Cr-1 and Co-1 to yield of the desired product (see Supplementary Fig. 4).

The reaction was run using 5 mol% of Co−1 and 10 mol% of Cr-1 (Condition A) or 10 mol% TBHP/PhSiH3 (condition B) with 1 equivalent of alkene and 3 equivalents of t-Bu–I in 1,4-dioxane ([0.1 M] Condition A; [1 M] condition B) in a sealed tube under argon. The data given reflects conditions A, [A], and conditions B, [B]. The yield is given as [A] 1H NMR yield (isolated yields are in parenthesis). In most cases, incomplete conversion of alkenyl starting material accounts for the remaining mass balance for lower yielding substrates. In more sterically hindered substrates, 1-position alkene isomerization is often also observed in low amounts, but hydrogenated alkene could never be detected. Abbreviations: TBDMS tert-butyl dimethylsilane, Bpin boronic pinacol ester, TMS trimethylsilane. a The reaction conditions were modified using 10 mol% of Co-1, and 20 mol% of Cr-1. Normal catalyst loading does not provide full conversion of the starting material which cannot be separated from the product, so high loadings of catalyst were required.

After establishing key reactivity for C–I bond formation, we began investigating catalytic conditions using unactivated alkene 1a and 3 equivalents of t-BuI with the commercial Co(II)–salen catalyst Co-1. We initially developed high yielding conditions with Cr-1 as an XAT co-catalyst (Fig. 3, Condition A). Because Cr-1 requires manipulation under inert atmosphere, we sought to develop a second set of conditions which could be more accessible for synthetic practitioners. Using a catalytic amount of initiators to form the Co–H in situ from Co-1, we reoptimized the reaction conditions to be advantageous from an accessibility point of view, because all of the principal components of the reaction are commercially available, air stable, and inexpensive (Fig. 3, condition B). Other known reversible XAT catalysts that require visible light irradiation, [Fe(Cp)(CO)2]248 and Mn2(CO)1049, were both competent in the reaction, although accompanied by formation of diiodinated product which cannot be easily separated from the hydroiodination product (See Supplementary Table 1)48. Other Cr(II) salts that are known to react with alkyl iodides proved inferior in terms of conversion and yield (See Supplementary Table 1)50. Although the reaction could be carried out at room temperature, mild heating to 65 °C drastically improved the yield, likely due to increased volatility of the byproduct isobutene which is more reactive towards the Co–H species than 1a5. Electron-donating substituents on the salen backbone performed slightly worse than Co-1, while electron-withdrawing groups completely shut down reactivity. This was anticipated based on previous reports which support electron-rich Co-salen complexes undergoing radical cage escape faster than electron-poor ones51,52.

Discussion

Using these two catalytic protocols we evaluated the generality of the reaction scope (Fig. 3). Protected amines (Phthalimide, 2b; Tosyl, 2c; Boc, 2d) performed with quantitative to high yields and 2c or 2d did not give the corresponding cyclized products. The Boc protected benzyl ester of allyl glycine (Boc-allyl-Gly-OBn) (±-1d), gave good yields despite offering little control over the diastereoselectivity (1.9:1 d.r.) in the product 2d. While alkene substrates containing terminal alkynes were not compatible with the reaction, alkene substrates containing silyl-aryl alkynes could be used to chemoselectively hydroiodinate the alkene to afford 2e. Esters and protected alcohols 2f-2i worked well in the reaction, including the acid-sensitive oxetane in 2 h. Free primary alcohol 1j also performed very well and cleanly forms 2j using conditions A despite potential nucleophilic attack on t-BuI or 6-exo-tet cyclization of the product. Conditions B gave a drastic decrease in yield (15%) likely due to side-reactivity of the free alcohol with the silane to form a silyl ether53. Functional groups that are prone to oxidation from peroxides formed the desired thioether-containing product 2k and boronic ester-containing product 2 l in good yields. Interestingly, conditions B significantly outperformed conditions A in forming 2k likely due to inhibition of the chromium catalyst from the sulfur in the thioether. The aryl aldehyde 1 m, gave the desired product 2 m in moderate yield with both sets of conditions. Nozaki-Hiyama-Kishi-type reactivity was not observed54, suggesting the tert-butyl substituents on the ligand shield the chromium center from forming nucleophilic alkyl-Cr(III) species. Allyl benzenes containing electron-withdrawing (2n) or -donating groups (2o) performed equally well, giving good yields with conditions A and slightly diminished yields when using conditions B.

We next investigated a range of N-heterocyclic compounds. Sulfonyl tetrazole product 2p was obtained in good yields and gave single crystals suitable for X-ray analysis to unambiguously assign the product structure. Chloropyrimidine 1q gave the product 2q in good yield. Two indole derivatives worked to varying degrees with N-allylated indole 2 s performing better than allyl ether 2r. In this case, a similarly low yield was obtained for another allyl ether 2 g, suggesting that this particular motif was the cause of the diminished yield and not the indole itself.

Due to the exquisite chemoselectivity exhibited by Cr-1 for the preferential activation of more highly substituted halides, we investigated substrates with primary (pseudo)halides that would otherwise react first with metals that undergo SN2 oxidative additions55. Tosylate 2t, chloride 2 u, and even iodide 2 v gave great to quantitative yields showing no undesired side reactions with the other halides. Due to the instability of aryl radicals, single-electron activation by Cr-1 occurs selectively on alkyl halides allowing aromatic iodide product 2w to be obtained in high yield. Lastly, the kinetic preference for Co-1 to undergo HAT to terminal or 1,1-disubstituted alkenes allowed us to chemoselectively functionalize a terminal alkene in good yield (2x)29, even in the presence of internal di- or tri-substituted alkenes (±-1x).

Similar to the HAT hydroiodination protocol of Ohmiya and Nagao17, styrenes, 1,1-disubstituted alkenes, and tri-substituted alkenes were among the low yielding and unsuccessful coupling partners. 1,1-disubstituted alkenes formed isomerized tri-substituted alkene side products as the major species showing that HAA outcompetes XAT for this type of substrate. We attribute the instability of benzyl iodides and tertiary iodides, and slower iodine atom transfer to the more stabilized benzylic or tertiary radicals as reasons for their poor reactivity. Such species are typically prepared and used in situ as they decompose in the absence of stabilizers, e.g. the tertiary iodide 2ad’ decomposed within 24 h, even at –40 °C (vide infra).

Next, we sought to demonstrate the broad synthetic applicability of this strategy in the late-stage functionalization of a structurally diverse set of FDA approved drugs. We challenged the method in the context of a highly functionalized and complex natural product, FK506. This natural product has multiple potential alkenes for functionalization, and numerous potentially reactive functional groups, but performed well to give the desired product 2 y in 48% yield. Methodologies which can chemoselectively modify the terminal alkene of FK506 are desirable for medicinal chemists as several known analogs contain modifications in this area of the molecule56,57. Using the progesterone receptor agonist allylestrenol, the desired product 2z was obtained in 23% yield with complete chemoselectivity for the terminal alkene to give the product without detectable amounts of cyclized oxirane. Lastly, the alkaloid natural product and malaria treatment drug quinine was hydroiodinated to give 2aa in 45% yield, showing the method can tolerate unprotected amines and pyridine-type heterocycles.

To expand the applications of this methodology, we envisioned cyclizations through either 2- or 1-electron pathways could give complementary approaches to compounds of different ring size. To form the small 4-membered ring, hydroiodination of an alkenyl secondary amine gave rise to a transiently formed alkyl iodide 2ab which underwent ring closure to form the azetidine 2ab’ as a single diastereomer. The possible reversibility of the ring closure, and C–I bond forming step appear to be crucial for achieving the high diastereoselectivity. Overall, this approach for intramolecular hydroamination provides complementary access to N-heterocycles with electron-rich amines compared to oxidative58 or reductive59 MHAT protocols which utilize electron-poor amines and have comparatively poor diastereoselectivity. Next, we were able to synthesize a 5-membered pyrrolidine ring through 5-exo-trig radical cyclization and trapping of the resulting methyl radical to give the primary iodinated product 2ac’. The d.r. in this case is close to the expected kinetic distribution for the cyclization step (~2:1, cis:trans)60 suggesting that formation of primary iodides occurs irreversibly as the thermodynamically favored trans product would be expected under fully reversible conditions. Interestingly, in both cases only conditions A were able to give the desired product while condition B failed to give any reaction.

The reversible nature of this catalytic process could allow us to run the reverse reaction for a single-electron variation of the E1 elimination reaction and selectively dehydroiodinate alkyl iodides to give alkene products31,61. Using the diene (±)-citronellene, an unselective global hydroiodination could first be done using MsOH and LiI to give 2ad’. Then, using norbornadiene as an HI acceptor, condition B gave clean formation of the secondary iodide product 2ad, accompanied by formation of iodonorbornene. Formation of the 1,1-disubstituted alkene regioisomer of 2ad was also observed as a minor (8:1) byproduct.

From the onset of this investigation, we envisioned that one of the main advantages of using shuttle HAT compared to classical methods is the ease of scalability. Traditional methods employ stoichiometric amounts of reductant and oxidant together in the same pot which is challenging to scale and causes excess waste as the two reagents inevitably quench each other to varying degrees62. Indeed, our protocol proved to be scalable as we were able to run the reaction from 0.1 mmol scale to 100 mmol scale, without changing the reaction conditions (Fig. 4d). One possible reason for the slight decrease in yield on 100 mmol scale is due to the decomposition of t-BuI as evidenced by the reagent progressively turning into a dark brown color during the longer time required for freeze-pump thaw on this scale. Using the scaled up 2a, we demonstrated a series of derivatizations that leverage a photoredox XAT strategy developed by Leonori63,64, as well as polar disconnections where the alkyl iodide is an electrophile for an SN2 reaction (see Supplementary Information, Section 5). The SN2 reaction can even be run with a mixture of 1a (40%) and 2a (60%) without significant change in yield, which obviates the need for separation of unreacted starting material in subsequent reactions.

a Hydroiodination followed by ring closure to form azetidine. b 5-exo-trig radical cyclization to form pyrrolidines. No ring open hydroiodinated products were observed. c An unselective acid-promoted global hydroiodination followed by selective transfer hydroiodination of the tertiary iodide to norbornadiene (nbd) as an acceptor. Alternatively, 2ad can be accessed from 1ad via condition B in lower yield. d Scalability of the procedure. The picture on the left shows 0.1 mmol reaction (vial) and 100 mmol reaction (Schlenk tube). The right picture shows isolated product from the 100 mmol reaction. e Applying this method to transfer hydrobromination using tert-butyl bromide. f Applying this method to transfer hydrothiolation using the tert-butyl Barton ester. a The yield was determined by 1H NMR using CH2Br2 as an internal standard. b The reaction conditions were modified using 10 mol% of Co-1, and 20 mol% of Cr-1. Normal catalyst loading does not provide full conversion of the starting material which cannot be separated from the product, so high loadings of catalyst were required.

To showcase the generality of the transfer HAT strategy for the installation of other functional groups, a hydrobromination and hydrothiolation were carried out using slightly modified conditions from the hydroiodination reaction (Fig. 4e, f). This illustrates the generality and possibility of combining the shuttle HAT reaction with other functional group transfer reactions to enable a broad range of hydrofunctionalization reactions. Both catalytic XAT and radical chain transfer pathways were shown to be operable in the installation of other functional groups (3a and 3b respectively), suggesting that new shuttle HAT reactions could be rationally designed based on both dual catalytic atom transfer cycles as well as through radical chain transfer pathways.

Leveraging the concept of shuttle catalysis, a strategy for generating HAT-active Co–H has been developed. This shuttle HAT protocol allows the most direct access to catalytic Co–H directly from Co(II) sources by abstraction of hydrogen atom from a C–H bond. In doing so, this approach avoids the oxidation–transmetalation sequence6, or reduction–protonation sequence of the cobalt center to generate catalytic Co–H14,15,16,17,18. The mildness of the shuttle HAT platform is exemplified in the ability to produce highly reactive alkyl iodides in a catalytic fashion using substrates that feature a range of unprotected functional groups as well as medicinally active scaffolds. The reaction proved to be scalable up to 100 mmol without modification to the procedure, and could be used in several different HAT reaction manifolds beyond hydroiodination. This lays the foundation for new HAT methodologies and radical trap reagents to be designed around this reversible catalytic process.

Methods

General procedure for catalytic condition A

Inside an argon-filled glovebox, to a 2-dram vial equipped with a magnetic stirring bar, Co-1 (3.0 mg, 5.0 µmol), Cr-1 (4.2 mg, 10 µmol), and the given substrate (0.100 mmol) were dissolved in 1,4-dioxane (1 mL). t-Butyl iodide (37 µL, 0.300 mmol) was added and the vial was sealed and removed from the glovebox. The reaction mixture was stirred at 55 °C for 0.25–1 h, then the solution was filtered through a silica plug and washed with pentanes (4 mL) and Et2O (4 mL). The solvent was removed in vacuo and the crude product was dissolved in CDCl3 and internal standard (CH2Br2) and the crude yield was calculated. The material was purified by flash silica column chromatography or preparative TLC.

General procedure for catalytic condition B

Inside an argon-filled glovebox, to a 2-dram vial equipped with a magnetic stirring bar, Co-1 (3.0 mg, 5.0 µmol), and the given substrate (0.100 mmol) were dissolved in 1,4-dioxane (0.1 mL). t-Butyl iodide (36.8 µL, 0.300 mmol) was added and the vial was sealed and removed from the glovebox. TBHP (1.8 µL, 0.0100 mmol, 6.6 M in hexane) was added by Hamilton syringe directly through a puncturable cap and the vial was shaken. This results immediately in a color change from a red to brown solution. ~ 30 s after adding TBHP, phenylsilane (1.2 µL, 0.0100 mmol) was added by Hamilton syringe directly through a puncturable cap. The reaction mixture was stirred at 55 °C for 0.25–1 h, then the solution was filtered through silica and washed with pentanes (4 mL) and diethyl Et2O (4 mL). The solvent was removed in vacuo and the crude product was dissolved in CDCl3 and internal standard (CH2Br2) and the crude yield was calculated. The material was purified by flash silica column chromatography or preparative TLC.

General procedure for catalytic condition B (large scale)

Using a modified procedure from General Procedure B, alkene (1.0 equivalent), tert-butyl iodide (3.0 equivalents), 1,4-dioxane [1 M] and Co-1 (5 mol%) were added under air to an appropriately sized Schlenk tube (>1/2 the volume of the reaction). The tube was closed and freeze-pumped-thawed under N2 three times. Then, through a septum, non-degassed t-BuOOH (6.6 M in hexanes) (10 mol%) was added resulting in a brown solution followed ~ 30 s later by non-degassed PhSiH3 (10 mol%). The reaction was heated to 55 °C under a continuous stream of N2 for 25 min then cooled to room temperature. The solvent was removed in vaccuo and the reaction diluted with pentanes and a saturated solution of sodium thiosulfate. The aqueous phase was extracted with pentanes (3x), dried over MgSO4 then solvent evaporated. The crude oil was purified by flash silica column chromatography.

Data availability

Details about the materials and methods, experimental procedures, mechanistic studies, characterization data, and NMR spectra are available in the Supplementary Information. The X-ray crystallographic coordinates for structures reported in this study have been deposited at the Cambridge Crystallographic Data Centre (CCDC), under deposition numbers 2306574, 2306575. These data can be obtained free of charge from The Cambridge Crystallographic Data Centre via www.ccdc.cam.ac.uk/data_request/cif. All data are available from the corresponding author upon request.

References

Braunecker, W. A. & Matyjaszewski, K. Controlled/living radical polymerization: features, developments, and perspectives. Prog. Polym. Sci. 32, 93–146 (2007).

Laudadio, G., Palkowitz, M. D., El-Hayek Ewing, T. & Baran, P. S. Decarboxylative cross-coupling: a radical tool in medicinal chemistry. ACS Med. Chem. Lett. 13, 1413–1420 (2022).

Smith, J. M., Harwood, S. J. & Baran, P. S. Radical retrosynthesis. Acc. Chem. Res. 51, 1807–1817 (2018).

Lovering, F., Bikker, J. & Humblet, C. Escape from flatland: increasing saturation as an approach to improving clinical success. J. Med. Chem. 52, 6752–6756 (2009).

Shevick, S. L. et al. Catalytic hydrogen atom transfer to alkenes: a roadmap for metal hydrides and radicals. Chem. Sci. 11, 12401–12422 (2020).

Crossley, S. W. M., Obradors, C., Martinez, R. M. & Shenvi, R. A. Mn-, Fe-, and Co-catalyzed radical hydrofunctionalizations of olefins. Chem. Rev. 116, 8912–9000 (2016).

Green, S. A. et al. The high chemofidelity of metal-catalyzed hydrogen atom transfer. Acc. Chem. Res. 51, 2628–2640 (2018).

Wu, J. & Ma, Z. Metal-hydride hydrogen atom transfer (MHAT) reactions in natural product synthesis. Org. Chem. Front. 8, 7050–7076 (2021).

Waser, J., Gaspar, B., Nambu, H. & Carreira, E. M. Hydrazines and azides via the metal-catalyzed hydrohydrazination and hydroazidation of olefins. J. Am. Chem. Soc. 128, 11693–11712 (2006).

Barker, T. J. & Boger, D. L. Fe(III)/NaBH4-mediated free radical hydrofluorination of unactivated alkenes. J. Am. Chem. Soc. 134, 13588–13591 (2012).

Isayama, S. & Mukaiyama, T. A new method for preparation of alcohols from olefins with molecular oxygen and phenylsilane by the use of bis(acetylacetonato)cobalt(II). Chem. Lett. 18, 1071–1074 (1989).

Kamei, Y. et al. Silane- and peroxide-free hydrogen atom transfer hydrogenation using ascorbic acid and cobalt-photoredox dual catalysis. Nat. Commun. 12, 966 (2021).

Bergamaschi, E., Mayerhofer, V. J. & Teskey, C. J. Light-driven cobalt hydride catalyzed hydroarylation of styrenes. ACS Catal. 12, 14806–14811 (2022).

Gnaim, S. et al. Cobalt-electrocatalytic HAT for functionalization of unsaturated C–C bonds. Nature 605, 687–695 (2022).

Wu, X. et al. Intercepting hydrogen evolution with hydrogen-atom transfer: electron-initiated hydrofunctionalization of alkenes. J. Am. Chem. Soc. 144, 17783–17791 (2022).

Jana, S., Mayerhofer, V. J. & Teskey, C. J. Photo- and electrochemical cobalt catalysed hydrogen atom transfer for the hydrofunctionalisation of alkenes. Angew. Chem. Int. Ed. 62, e202304882 (2023).

Shibutani, S., Nagao, K. & Ohmiya, H. A dual cobalt and photoredox catalysis for hydrohalogenation of alkenes. J. Am. Chem. Soc. 146, 4375–4379 (2024).

Liu, J. et. al. Co-catalyzed hydrofluorination of alkenes: photocatalytic method development and electroanalytical mechanistic investigation. J. Am. Chem. Soc. 146, 4380–4392 (2024).

Li, G. et al. Radical isomerization and cycloisomerization initiated by H• transfer. J. Am. Chem. Soc. 138, 7698–7704 (2016).

Mendelsohn, L. N. et al. Visible-light-enhanced cobalt-catalyzed hydrogenation: switchable catalysis enabled by divergence between thermal and photochemical pathways. ACS Catal. 11, 1351–1360 (2021).

Park, Y. et al. Visible light enables catalytic formation of weak chemical bonds with molecular hydrogen. Nat. Chem. 13, 969–976 (2021).

Bullock, R. M. & Samsel, E. G. Hydrogen atom transfer reactions of transition-metal hydrides. Kinetics and mechanism of the hydrogenation of α-cyclopropylstyrene by metal carbonyl hydrides. J. Am. Chem. Soc. 112, 6886–6898 (1990).

Dong, X., Roeckl, J. L., Waldvogel, S. R. & Morandi, B. Merging shuttle reactions and paired electrolysis for reversible vicinal dihalogenations. Science 371, 507–514 (2021).

Bhawal, B. N. & Morandi, B. Catalytic isofunctional reactions – expanding the repertoire of shuttle and metathesis reactions. Angew. Chem. Int. Ed. 58, 10074–10103 (2019).

Fang, X., Yu, P. & Morandi, B. Catalytic reversible alkene-nitrile interconversion through controllable transfer hydrocyanation. Science 351, 832–836 (2016).

Lutz, M. D. R., Gasser, V. C. M. & Morandi, B. Shuttle arylation by Rh(I) catalyzed reversible carbon–carbon bond activation of unstrained alcohols. Chem 7, 1108–1119 (2021).

Lian, Z., Bhawal, B. N., Yu, P. & Morandi, B. Palladium-catalyzed carbon-sulfur or carbon-phosphorus bond metathesis by reversible arylation. Science 356, 1059–1063 (2017).

Boehm, P., Kehl, N. & Morandi, B. Rhodium-catalyzed anti-markovnikov transfer hydroiodination of terminal alkynes. Angew. Chem. Int. Ed. 62, e202214071 (2023).

Crossley, S. W. M., Barabé, F. & Shenvi, R. A. Simple, chemoselective, catalytic olefin isomerization. J. Am. Chem. Soc. 136, 16788–16791 (2014).

Ye, K.-Y., McCallum, T. & Lin, S. Bimetallic radical redox-relay catalysis for the isomerization of epoxides to alylic alcohols. J. Am. Chem. Soc. 141, 9548–9554 (2019).

Zhao, H. et al. Merging halogen-atom transfer (XAT) and cobalt catalysis to override E2-selectivity in the elimination of alkyl halides: a mild route toward contra-thermodynamic olefins. J. Am. Chem. Soc. 143, 14806–14813 (2021).

Sun, X., Chen, J. & Ritter, T. Catalytic dehydrogenative decarboxyolefination of carboxylic acids. Nat. Chem. 10, 1229–1233 (2018).

Zhang, X.-M. Homolytic bond dissociation enthalpies of the C−H bonds adjacent to radical centers. J. Org. Chem. 63, 1872–1877 (1998).

Herbort, J. H., Bednar, T. N., Chen, A. D., RajanBabu, T. V. & Nagib, D. A. γ C−H functionalization of amines via triple H-atom transfer of a vinyl sulfonyl radical chaperone. J. Am. Chem. Soc. 144, 13366–13373 (2022).

Gaspar, B. & Carreira, E. M. Catalytic hydrochlorination of unactivated olefins with para-toluenesulfonyl chloride. Angew. Chem. Int. Ed. 47, 5758–5760 (2008).

Ma, X. & Herzon, S. B. Cobalt bis(acetylacetonate)–tert-butyl hydroperoxide–triethylsilane: a general reagent combination for the Markovnikov-selective hydrofunctionalization of alkenes by hydrogen atom transfer. Beilstein J. Org. Chem. 14, 2259–2265 (2018).

Yin, Y.-N. et. al. Modifying commodity-relevant unsaturated polymers via Co-catalyzed MHAT. Chem 10, 1–12 (2024).

Marchese, A. D., Mirabi, B., Johnson, C. E. & Lautens, M. Reversible C-C bond formation using palladium catalysis. Nat. Chem. 14, 398–406 (2022).

Marchese, A. D. et al. Pd(0)/blue light promoted carboiodination reaction – evidence for reversible C–I bond formation via a radical pathway. J. Am. Chem. Soc. 144, 20554–20560 (2022).

Lee, Y. H. & Morandi, B. Metathesis-active ligands enable a catalytic functional group metathesis between aroyl chlorides and aryl iodides. Nat. Chem. 10, 1016–1022 (2018).

Carney, M. J. & Smith, K. M. Chromium compounds without CO or isocyanide. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering. (ed. Reedijk, J.) (Elsevier, 2013).

Takai, K. Addition of organochromium reagents to carbonyl compounds. Org. React. https://doi.org/10.1002/0471264180.or064.03 (2004).

Evano, G., Blanchard, N. & Toumi, M. Copper-mediated coupling reactions and their applications in natural products and designed biomolecules synthesis. Chem. Rev. 108, 3054–3131 (2008).

Deshpande, N., Satani, P., Bharodiya, A. & Naveen, T. Recent advances in copper-catalyzed functionalization of unactivated C(sp3)−H bonds. Asian J. Org. Chem. 11, e202200532 (2022).

Li, Z.-L., Fang, G.-C., Gu, Q.-S. & Liu, X.-Y. Recent advances in copper-catalysed radical-involved asymmetric 1,2-difunctionalization of alkenes. Chem. Soc. Rev. 49, 32–48 (2020).

Zhang, Z., Zhu, Q., Pyle, D., Zhou, X. & Dong, G. Methyl ketones as alkyl halide surrogates: a deacylative halogenation approach for strategic functional group conversions. J. Am. Chem. Soc. 145, 21096–21103 (2023).

Shevick, S. L., Obradors, C. & Shenvi, R. A. Mechanistic interrogation of Co/Ni-dual catalyzed hydroarylation. J. Am. Chem. Soc. 140, 12056–12068 (2018).

Giese, B. & Thoma, G. Dimeric metal complexes as mediators for radical C–C bond-forming reactions. Helv. Chim. Acta. 74, 1135–1142 (1991).

Wang, L., Lear Jeremy, M., Rafferty Sean, M., Fosu Stacy, C. & Nagib David, A. Ketyl radical reactivity via atom transfer catalysis. Science 362, 225–229 (2018).

Zhou, W., Tang, L., Patrick, B. O. & Smith, K. M. Electronic effects in the oxidative addition of Iodomethane with mixed-Aryl β-diketiminate chromium complexes. Organometallics 30, 603–610 (2011).

Chiang, L. et al. Tuning ligand electronics and peripheral substitution on cobalt salen complexes: structure and polymerisation activity. Dalton Trans. 43, 4295–4304 (2014).

Dadashi-Silab, S. & Stache, E. E. A hydrometalation initiation mechanism via a discrete cobalt-hydride for a rapid and controlled radical polymerization. J. Am. Chem. Soc. 144, 13311–13318 (2022).

Obradors, C., Martinez, R. M. & Shenvi, R. A. Ph(i-PrO)SiH2: An exceptional reductant for metal-catalyzed hydrogen atom transfers. J. Am. Chem. Soc. 138, 4962–4971 (2016).

Matos, J. L. M., Vásquez-Céspedes, S., Gu, J., Oguma, T. & Shenvi, R. A. Branch-selective addition of unactivated olefins into imines and aldehydes. J. Am. Chem. Soc. 140, 16976–16981 (2018).

Hartwig, J. F. Organotransition Metal Chemistry: From Bonding to Catalysis 2010th edition, Vol. 1100 (University Science Books, 2010).

Brown, E. J. et al. A mammalian protein targeted by G1-arresting rapamycin–receptor complex. Nature 369, 756–758 (1994).

Hoy, M. J. et al. Structure-guided synthesis of FK506 and FK520 analogs with increased selectivity exhibit In vivo therapeutic efficacy against cryptococcus. mBio 13, e01049–01022 (2022).

Park, S. et al. Electrocatalytic access to azetidines via intramolecular allylic hydroamination: scrutinizing key oxidation steps through electrochemical kinetic analysis. J. Am. Chem. Soc. 145, 15360–15369 (2023).

Lindler, H. et. al. Photo- and cobalt-catalyzed synthesis of heterocycles via cycloisomerization of unactivated olefins. Angew. Chem. Int. 63, e202319515 (2024).

Spellmeyer, D. C. & Houk, K. N. Force-field model for intramolecular radical additions. J. Org. Chem. 52, 959–974 (1987).

Chen, W., Walker, J. C. L. & Oestreich, M. Metal-free transfer hydroiodination of C–C multiple bonds. J. Am. Chem. Soc. 141, 1135–1140 (2019).

Rayment, E. J., Mekareeya, A., Summerhill, N. & Anderson, E. A. Mechanistic study of arylsilane oxidation through 19F NMR spectroscopy. J. Am. Chem. Soc. 139, 6138–6145 (2017).

Constantin, T. et al. Aminoalkyl radicals as halogen-atom transfer agents for activation of alkyl and aryl halides. Science 367, 1021–1026 (2020).

Caiger, L., Zhao, H., Constantin, T., Douglas, J. J. & Leonori, D. The merger of aryl radical-mediated halogen-atom transfer (XAT) and copper catalysis for the modular cross-coupling-type functionalization of alkyl lodides. ACS Catal. 13, 4985–4991 (2023).

Acknowledgements

T.C.J. thanks the Swiss National Science Foundation (SNSF) for The Swiss Postdoctoral Fellowship (217192). The European Research Council (Shuttle Cat, Project ID: 757608), the Swiss National Science Foundation (213812 and R’Equip Project No. 206021_213224), and ETH are acknowledged for funding this work. We thank Ori Green for isolation of 2aa. We thank the Molecular and Biomolecular Analysis Service (MoBiAS), the X-ray structure service (SMoCC), and the LOC NMR Service at ETH Zürich for technical assistance. We further thank the whole Morandi group for critical proofreading of the manuscript. P.M.B. is grateful to the German Academic Scholarship Foundation and the Elite Network of Bavaria for Bachelor and Master degree fellowships.

Author information

Authors and Affiliations

Contributions

T.C.J. conceived of the project. T.C.J., P.M.B., A.B., P.B., F.A. conducted the experimental work and analyzed the data. B.M. supervised the research. T.C.J. and B.M. wrote the manuscript with input from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jankins, T.C., Blank, P.M., Brugnetti, A. et al. Shuttle HAT for mild alkene transfer hydrofunctionalization. Nat Commun 15, 9397 (2024). https://doi.org/10.1038/s41467-024-53281-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-53281-7