Abstract

The fundamentally significant halogenation processes in organic synthesis heavily depend on the use of hazardous and toxic elemental halogens directly or indirectly, inevitably increasing environmental burden and leading to various production problems. Flavin-dependent halogenases (FDHs) in nature produce organic halides under benign conditions, yet their practical application remained elusive and difficult to scale up. Inspired by FDHs, here we develop a mild and eco-friendly biomimetic aerobic oxidative halogenation strategy that utilizes O2 from the air to oxidize non-toxic halide salts as a safer alternative. Using simple alloxan as catalyst and low-cost ascorbic acid as reductant, we successfully emulate the challenging flavoenzymatic aerobic halogenation cycle without requiring light activation. This approach yields various important monobromide and iodide products with high efficiency, excellent selectivity, and good functional group tolerance. Moreover, its successful application in late-stage bromination of complex bioactive molecules, operational ease at the gram scale, and use of cost-effective, unpurified primary raw materials all indicate significant potential for green industrial production.

Similar content being viewed by others

Introduction

Aryl halides are undoubtedly important chemicals due to their irreplaceable roles in various transformations1,2, and excellent performance in agrochemicals3, materials4, natural products5,6,7, and pharmaceuticals8 (Fig. 1A). Traditional chemical halogenation, however, is an environmentally hazardous process that requires the use of toxic and corrosive molecular halogens (X2)9, low atom-efficient organic halide reagents (e.g. N-halosuccinimides10, NXS), or stoichiometric amounts of strong oxidants (e.g. oxone11) to oxidize halide salts, often in combination with the generation of polluting wastes and may also lead to the formation of byproducts due to ambiguous regioselectivity (Fig. 1B).

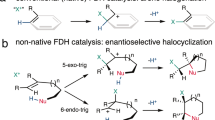

A Representative halide-containing drugs. B Current chemical halogenation method. C Aerobic oxidative halogenation in nature: Mechanistic proposal for FDH. D Non-enzymatic flavin-mediated photocatalytic oxidative halogenation reaction. E Alloxan-catalyzed biomimetic oxidations: our work. ADK (adenosine kinase), NXS (N-halosuccinimide), [O] (oxidant), FDH (flavin-dependent halogenase), NADH (reduced nicotinamide adenine dinucleotide), Lys (Lysine), pMBA (4-methoxybenzyl alcohol), ‘LutOx’ (2,6-lutidinium oxalate), FMO (flavin-dependent monooxygenase), HEH (Hantzsch ester), Asc (ascorbic acid).

Unlike the harsh and low regioselectivity of chemical halogenation, nature has developed a more elegant and efficient enzyme catalyzed oxidative halogenation strategy12. Flavin-dependent halogenases (FDHs), one of the most famous aerobic oxidative halogenases13,14,15,16,17, can regioselectively halogenate various electrorich arenes with benign halide ions as halogen source and molecular oxygen (O2) as oxidant. As members of the flavin-dependent monooxygenases (FMOs) superfamily, FDHs undergo a similar O2-activation mechanism to FMOs (Fig. 1C): Upon coenzyme flavin adenine dinucleotide (FAD) is converted into FADred by reduced nicotinamide adenine dinucleotide (NADH), they can activate O2 to give the shared highly activated reactive intermediate C4a-hydroperoxyflavin (FADOOH). Unlike FMOs, where FADOOH directly oxidizes the substrate, in FDHs, FADOOH tends to oxidize nearby halides X- rather than the electron-rich substrates (such as aromatic amines, indoles, and phenols). This is due to a roughly 10 Å long tunnel between the flavin binding site and the substrate binding site in FDHs, which separates the oxidation-prone substrates from the oxidative FADOOH18. The generated electrophilic halogen species (often considered as hypohalous acid, HOX) are then transferred to the substrate binding site with the help of the active site lysine residue, either through simple hydrogen bonding19,20 or by forming a haloamine intermediate21. Thus, the entire aerobic oxidative halogenation process consists of three steps: O2-activation, X--oxidation, and electrophilic halogenation (Fig. 1C). Although FDHs are promising biocatalysts for regioselective halogenation of aromatic substrates under benign conditions, their application is elusive and still limited to analytical and semi-preparative scales due to low expression yields, poor stability, narrow substrate scope, and the need for complex cofactor NADH regeneration systems12,22,23. Until recently, Sewald’s group24 developed a method to co-immobilize FDHs with other necessary auxiliary enzymes for halogenation, significantly improving the robustness and preparative efficiency of FDHs, enabling the gram-scale flavoenzymatic aerobic halogenation in vitro.

To address the limitations of enzymatic approach, König’s group25 pioneered the use of flavin photocatalysis to mimic the activity of FDHs and enabled the fully non-enzymatic flavin-mediated aerobic oxidative halogenation reaction. The key aspect of this reaction is the photoexcited tetraacetylriboflavin (Fl1) can be reduced by 4-methoxybenzyl alcohol (pMBA) and react with O2 to generate the peroxo species Fl1OOH. The subsequently released H2O2 is further activated by acetic acid (HOAc) to form highly oxidative peracetic acid (HOOAc) as the real active species leading to chloride oxidation. As a more general strategy, activation by HOOAc allows for a broader substrate scope but also results in poorer selectivity and incompatibility with oxidation-prone substrates (top of Fig. 1D). Building upon this, Storch’s group26 focused on flavin modification to improve this photocatalytic aerobic oxidative halogenation, and successfully prepared a series of C6 amino-modified flavins, potentially containing hydrogen bond donors. Utilizing stacked di(2-aminophenyl)thiazolium flavin (Fl2) as an optimized catalyst and 2,6-lutidinium oxalate (‘LutOx’, a 2:1 mixture of 2,6-dimethylpyridine and oxalic acid) as its reductant under light irradiation, they found the oxidation-prone phenol substrates were not quenched by formed Fl2OOH. This resulted in the desired aerobic bromination with low to moderate yields, requiring no additional HOAc as mediators (bottom of Fig. 1D). The above two methods initiated the functional simulation of FDHs, while both of them required combined photocatalysis to activate O2, successfully mimicking partial processes of the enzymatic halogenation cycle. However, the true flavoenzymatic aerobic oxidative halogenation cycle does not necessitate any photoactivation, and a complete chemical emulation of its entire cyclic process has not yet been achieved. Unlike the well-developed biomimetic catalysis research based on ordinary FMOs27,28, the functional simulation of FDHs is very challenging due to the difficulty in constructing a compatible biomimetic redox system for complex halogenation processes, which requires: (1) an appropriate catalyst play multiple functions of O2-activation and X+-transfer, and the formed active intermediate should selectively oxidize X- to OX- without affecting the oxidation-prone substrates and reductants; (2) the ideal reductants ([H]) only reduce the catalyst, not being quenched by other oxidative intermediates of the system (such as FADOOH, OX-, H2O2, O2). In 2015, Carbery’s group29 successfully simulated flavoenzyme monoamine oxidase by coupling synthetic flavin and alloxan as co-catalysts. Recently, we have utilized alloxan 1 alone as a biomimetic catalyst based on FMOs30,31,32, exhibiting remarkable efficiency in chemoselective and enantioselective oxidation of sulfides and amines, using environment-friendly H2O2 or O2 as the terminal oxidant. Mechanism studies have revealed this method undergoes a biomimetic process, that alloxan catalyst 1 can be reduced by Hantzsch ester (HEH) and then react with O2 to form the FADOOH-like reactive intermediate 1OOH, which could also be generated by 1 directly reacting with H2O230 (top of Fig. 1E). Given the shared mechanisms and coenzymes between FMOs and FDHs, as well as the advantages of alloxan, which has higher catalytic activity and a simpler structure than traditional flavins, we aim to explore the challenging biomimetic aerobic oxidative halogenation employing easily modified alloxan-[H] system as the light-free O2-activation step.

In this study, we demonstrate a biomimetic catalytic aerobic halogenation method using simple alloxan 1a as the catalyst and low-cost ascorbic acid (Asc) as the reductant, fully mimicking the natural process of FDHs (bottom of Fig. 1E). This biomimetic strategy can directly utilize oxygen from the air to oxidize benign halide ions, avoiding the use of harsh oxidative halogen sources, thus it offers better selectivity and functional group tolerance than traditional chemical halogenation. With this method, a variety of important brominated and iodinated (hetero)arenes can be produced at room temperature with very high yield and selectivity. Notably, the application explorations indicate that it suitable for the late-stage halogenation of complex bioactive molecules, scalable to a 10 gram scale, with simple post-processing, and capable of tolerating cost-effective unpurified raw materials.

Results

Initial optimization of the reaction conditions

We initiated our investigation by establishing an aerobic oxidative bromination model based on our previously reported biomimetic system. With N-benzylaniline (2-1) selected as the model substrate, the reaction was carried out at room temperature under O2 atmosphere with catalyst alloxan 1a, reductant Hantzsch ester 4a and different bromo sources (Table 1). After screening of common bromine anions and reaction solvents (Supplementary Table 1), we were pleased to find that in acetonitrile (MeCN) with LiBr as the selected bromo source, substrate 2-1 was smoothly transferred into the para-brominated product 3-1 in 18% yield, alongside a 99% yield of pyridine 4’a as the oxidative by-product of Hantzsch ester 4a (see Table 1, entry 1). Considering catalyst-reduction is the first crucial step in the aerobic flavoenzymatic halogenation cycle, we proceeded to explore other available reductants ([H]) for this alloxan-biomimetic aerobic system under the preliminary optimized conditions. Firstly, we examined various reducing organo-hydride sources, such as representative Hantzsch esters (4a ~ 4d), benzothiazolines (4e ~ 4f) and in-situ prepared benzimidazolines31 (4g ~ 4h). While altering their substituent types did not significantly affect the reaction or improve the halide yield; all tested reductants (except for 4b and 4c with poor solubility) were almost entirely consumed after 2 h of reaction (entries 1 ~ 8). Subsequently, we turned our attention to natural reductants. Common reduced coenzymes in vivo such as NADH (4i) and glutathione (4j), being almost insoluble in organic solvents, thus failed to initiate the expected redox cycle even with extended reaction time (entries 9 and 10). However, to our surprise, the widely used food antioxidant L-ascorbic acid (L-Asc, also known as vitamin C, 4k) could effectively reduce our catalyst alloxan to transform into dehydroascorbic acid (DHA, 4’k) (Supplementary Fig. 5). Notably, within 2 h, substrate 2-1 was almost quantitatively converted into the desired para-monobrominated product 3-1 (entry 11). Therefore, we chose to investigate various derivatives of ascorbic acid (entries 12 ~ 18). For this biomimetic aerobic oxidative bromination system, the free forms of ascorbic acid 4k and 4q provided excellent yields (L-form is faster than D-form) (entries 11 and 17), slightly superior to its 3-hydroxycalcium salt 4o (entry 15), and significantly better than other hydroxyl substituted derivatives (entries 12 ~ 14 and 16). As for the dihydro reduced state, 4r could not lead to the corresponding transformations (entry 18).

After identifying L-ascorbic acid 4k as an effective reductant for alloxan catalyst 1a, we continued to screen other key parameters and obtained the optimal biomimetic halogenation conditions as shown in entry 1 of Table 2. Control experiments revealed that both catalyst and reductant were essential for this reaction, as no desired bromination detected in the absence of alloxan 1a or L-ascorbic acid 4k (entries 1 ~ 3). When alloxan 1a was replaced by other catalysts, neither riboflavin 5a nor polycarbonyl compounds (such as ninhydrin 5b, electron-deficient pyruvate 5c and dehydroascorbic acid 4’k) catalyzed the reaction; however, all tested alloxans (1c ~ 1e, except 1b) performed well, though with slightly decreased efficiency, suggesting our reported alloxan active intermediate 1OOH might play a key role in this aerobic halogenation process (entries 4 ~ 11). Reducing the catalyst loading, 5 mol% 1a required an extended time of 6 h to complete the reaction (entry 12). Furthermore, the addition of a small amount of water did not affect the reaction yield (entries 13 and 14). Not limited to MeCN, other polar organic solvents such as N, N-dimethylformamide (DMF) and acetone have also been proven to be suitable solvents (entries 15 and 16). Changing the bromine source from LiBr to NaBr or NBu4Br also leaded to the same bromination, albeit with decreased yield, probably due to their alkalinity and solubility (entries 17 and 18). More importantly, even if the reaction was directly carried out in the open air instead of in O2 atmosphere, the high yield could be maintained by extending the reaction time (entry 19). It should be noted that in all aforementioned conditional screenings, our method only afforded para-brominated 3-1 as exclusive product, whereas other common chemical bromination strategies exhibited poor selectivity (entries 20 ~ 22). For example, both the Br2 and HBr/H2O2 systems resulted in only moderate yields of mono-bromination 3-1, along with uncontrolled di-brominated (3-1b, 15%) or imine (3-1c, 57%) products respectively (entries 20 and 21); as for the NBS method, it yielded complicated mixtures of mono-brominated (3-1/3-1a), di-brominated (3-1b), and imine products (3-1c) at room temperature (entry 22).

Substrate scope of aerobic oxidative halogenation

With the optimized reaction condition in hand (entry 1 and entry 19 of Table 2), we investigated the substrate scope for this aerobic oxidative bromination, summarized in Fig. 2A. Whether in O2 or air atmosphere, various electron-rich (hetero)aromatic substrates, including secondary (3-1 ~ 3-3) / tertiary (3-4 ~ 3-6) / primary (3-7 ~ 3-18) aromatic amines, phenols (3-19 ~ 3-20), aromatic ether (3-21), indoles (3-22 ~ 3-28), azaindole (3-29), benzimidazole (3-30), and julolidine (3-31), all smoothly provided the single mono-brominated products with high to excellent yields and regioselectivity. The methodology tolerated diverse functional groups, such as electron-donating (alkyl 3-7, alkoxy 3-8), electron-withdrawing (halogen 3-10 ~ 3-11, ester 3-16, nitro 3-26, carboxyl 3-28), and even oxidant-sensitive groups (e.g. unprotected NH2 3-7 ~ 3-18, sulfide 3-9, and phenolic hydroxyl 3-19 ~ 3-20). When aniline contains substituents at the 2- or/and 3-positions, the bromination selectively occurs at the para-position (3-7 ~ 3-11 and 3-14 ~ 3-16), while when the para-position is occupied, it yields the ortho-brominated product (3-12 ~ 3-13). For substrates bearing multiple reaction sites with slightly different chemical surroundings such as 3-14, the method effectively distinguishes to obtain single monobromination product in high yield. Phenols also smoothly convert into the corresponding mono-brominated products (3-19 ~ 3-20), with no poly-brominated or oxidized by-products observed. Notably, these brominated anilines obtained through this method often serve as key intermediates for pharmacoactive molecules. For example, bromoarylamines 3-10 and 3-18 can serve as starting materials for synthesizing the antitumor drug Vandetanib33 and ocular hypotensive agent Brimonidine34. Meanwhile, bromoaniline 3-16 and 3-bromo-7-azaindole 3-29 act as crucial intermediates for the herbicide triketone35 and the selective Janus kinase (JAK) 3 inhibitor VX-509 (Decernotinib)36,37, respectively (Fig. 2B). On account of the high efficiency and selectivity of this biomimetic method, we also applied this protocol for late-stage halogenation of various complicated compounds, which is of great significance for drug discovery and development. Drugs or natural products, such as indole alkaloid Vindoline (2-32)38, diagnostic reagent TOOS (2-33)39, photoswitchable compound spiropyran (2-34)40,41, DNA intercalator DAPP (2-35)42,43, anti-cancer agent Xanthotoxol (2-36)44, and laser dye 7-diethylamino-4-methylcoumarin DEAC (2-37)45, all successfully transformed into their monobrominated products with high yields (Fig. 2C). Building on this success, we proceeded to explore the compatibility of this biomimetic strategy for aerobic oxidative iodination, which has not been achieved before. By replacing LiBr with LiI and optimizing the conditions (Supplementary Table 2), we were pleased to find the expected iodination proceeded smoothly in open air (Fig. 2D). In addition to representative anilines (6a ~ 6 f), phenol (6 g) and aromatic ether (6 h) can also be smoothly transformed into the desired single monoiodized products with high to excellent yields, without any unexpected peroxidized hyperiodides or polyiodide byproducts. Conducting the reaction under the same conditions with NIS or I2 instead of our LiI systems resulted in black and messy products consisting of polyiodination and polymerization byproducts (taking 6a as an example). The less electron-donating arenes, such as simple anisole, diphenyl ether, styrene, or toluene, did not work in the present alloxan and ascorbic acid enabled oxidative halogenation system (see Supplementary Figs. 6 and 8).

A Oxidative bromination of (hetero)arenes. B Selected aryl halides as pharmaceutical intermediates. C Late-stage oxidative halogenation. D The synthesis of iodine-substituted products. a Bromination reaction conditions: 2 (0.1 mmol, 1.0 eq.), 1a (10 mol%), LiBr (0.5 mmol, 5.0 eq.), L-ascorbic acid 4k (0.2 mmol, 2.0 eq.), MeCN (4 mL), O2 balloon (1 atm), room temperature (25 °C ~ 30 °C), fully stirred 2 h; isolated yields; b 4 h instead of 2 h; c 4o instead of 4k, 1a (20 mol%), 12 h; d Iodination reaction conditions: 2 (0.1 mmol, 1 eq.), 1a (10 mol%), LiI (1.0 mmol, 10.0 eq.), L-ascorbic acid 4k (0.12 mmol, 1.2 eq.), MeCN (1 mL), open air, 28 °C, fully stirred 2 h, then quenched by water; e NIS method: 2a (0.1 mmol, 1.0 eq.), NIS (0.12 mmol, 1.2 eq.), MeCN (1 mL), 28 °C, 2 h; black messy products need additional purification. f I2 method: 2a (0.1 mmol, 1.0 eq.), I2 (0.12 mmol, 1.2 eq.), MeCN (1 mL), 28 °C, 2 h; black messy products need additional purification. TOOS (N-ethyl-N- (2-hydroxy-3-sulfopropyl)-m-toluidine sodium salt), DAPP (6-phenylphenanthridine-3,8-diamine), DEAC (7-diethylamino-4-methylcoumarin).

Application explorations

To expand the scope of applications of this halogenation method, we conducted the scale-up experiments (Fig. 3A–C). Using important anticancer precursor Vindoline 2-32 (the major alkaloid of Catharanthus roseus)38 as an example, the gram-scale halogenation proceeded effectively in open air without any decrease in yield or selectivity even within 1 h. Upon completion, the target bromide product 3-32 was precipitated by adding water, while LiBr, alloxan catalyst 1a, ascorbic acid 4k, and its oxidation byproduct 4’k were dissolved in the solution (Fig. 3A). Only by simple filtering, washing, and drying processes, over 99% HPLC purity was achieved without the need for additional silica gel chromatography purification (see Supplementary Fig. 12). Notably, this method has proven to be quite robust, capable of tolerating a low-cost primary unpurified bromine source and obtaining the bromine substituted 3-17 with high reaction mass efficiency, when replacing the analytical reagent LiBr with recovered LiBr aqueous solution from refrigerator46 (containing impurities such as Li2MoO4 and rust) (Fig. 3B). Not limited to bromination, this operationally simple scale-up procedure is also applicable for iodination process, and over 10 g of iodinated product 6a can be smoothly precipitated as white solid after adding water (Fig. 3C). Ascorbic acid, a well-known natural vitamin, is undoubtedly a safe and environmentally friendly sacrificial reductant, and has also been reported to serve as a mediator in organic reactions47. Up to date, a range of chemical synthesis methods and bacterial oxidation fermentation processes have been developed for the industrial-scale production of purified L-ascorbic acid48. Furthermore, due to its abundant natural reserves, ascorbic acid can also be directly extracted from various plants, fruits, vegetables, algae, and even food processing waste (such as fruit peels and seeds) using green extraction techniques49. Acerola cherry powder (ACP), a cheap, commercially available natural crude extract containing 17% vitamin C50, could be obtained from recycling of juice production waste. We investigated the oxidative halogenation results of using this crude extract ACP instead of pure L-ascorbic acid 4k. As shown in Fig. 3D, various representative substrates such as arylamines (3-2, 3-3, 3-4, 3-6, 3-15, 3-17, 6a, 6c, 6e, 6f), naphthol (6g), indole (3-25), julolidine (3-31), and even natural product (3-32) could be well tolerated by this crude extract. At room temperature, all test substrates can be smoothly converted into corresponding brominated and iodinated products with high yield and excellent selectivity within 2 h, in both O2 and air systems. Furthermore, this robust method can be successfully scaled up under air conditions without any decrease in yield or selectivity. And the highly purified product 3-17 could also be obtained by simply adding water, filtering, and drying, since all the components of ACP are water-soluble (right side of Fig. 3D, and Supplementary Fig. 15 for more details). These results indicate that our biomimetic aerobic oxidative halogenation method holds great potential for the industrial preparation of (hetero)aryl halides. This is due to the efficiency of the alloxan catalyst, the use of inexpensive and readily available green reagents, and their high water solubility, which facilitates the easy separation of low-polarity halogenated products.

A The scaled-up bromination modification of alkaloid Vindoline. B Bromination with cheap crude bromine source. C Operationally simple procedure for oxidative iodination. D Oxidative halogenation with acerola cherry powder (ACP). a 2–32 (2.2 mmol, 1.0 eq.), 1a (10 mol%), LiBr (22.0 mmol, 10.0 eq.), L-ascorbic acid 4k (8.8 mmol, 4.0 eq.), MeCN (40 mL), 28 °C, fully stirred 1 h in open air; added 500 mL water, stirred 10 min to precipitate 3–32. b 2–17 (10.0 mmol, 1.0 eq.), 1a (10 mol%), 55% LiBr aq. (containing 0.01% Li2MoO4, 8.0 g, 5.0 eq.), L-ascorbic acid 4k (20.0 mmol, 2.0 eq.), MeCN (400 mL), 29 °C, fully stirred 4 h in open air. c 2a (50 mmol, 1.0 eq.), 1a (10 mol%), LiI (500 mmol, 10.0 eq.), L-ascorbic acid 4k (60 mol, 1.2 eq.), MeCN (500 mL), 25 °C, fully stirred 2 h in open air; poured into 5 L water, stirred 30 min to precipitate 6a. d 2 (0.1 mmol, 1 eq.), 1a (10 mol%), LiBr (1.0 mmol, 10 eq.), ACP (containing 17% vitamin C, 0.1 g), MeCN (4 mL), O2 or open air, room temperature (25 °C ~ 30 °C), fully stirred 2 h; isolated yields. e 0.2 g ACP instead of 0.1 g. f 20 mmol-scale of 2–17 with ACP in open air, 25 °C, fully stirred 4 h. g 2 (0.1 mmol, 1 eq.), 1a (10 mol%), LiI (1.0 mmol, 10 eq.), ACP (containing 17% vitamin C, 0.1 g), MeCN (1 mL), O2 or open air, 28 °C, fully stirred 2 h, then quenched by water; isolated yields.

Mechanistic studies

Having explored the substrate scope and the utility of the reaction, we turned our attention to its mechanism (Fig. 4). Firstly, we conducted the radical trapping experiments as shown in Fig. 4A. With various radical scavengers added into the standard conditions, the radical inhibitors butylhydroxytoluene (BHT) and NaN3 almost had no effect on the reaction, while the 2 eq. of TEMPO significantly inhibited the required bromination, mainly caused by the oxidation of reductant L-ascorbic acid 4k by TEMPO51 (the reduced by-product TEMPOH was detected by NMR and HRMS in Supplementary information). Furthermore, 1,1-diphenylethylidene (DPE), known as common bromine radical trap52, was also added into the reaction, resulting in neither byproduct DPE-Br nor decreased bromination, thus excluding the Br· mechanism (right side of Fig. 4A, Supplementary Table 4 for more details). And since DPE can easily react with Br2 or I2 to form halogenated products, but does not react in our halogenation system, this further rule out the possibility of Br₂ or I₂ mechanisms being involved (Supplementary Fig. 18). These results exclude the possibility of this bromination proceeding through a radical reaction pathway or the Br2 mechanism, instead favoring the formation of OBr- being oxidized by Br-. To further explore the role of catalyst alloxan 1a, we designed the following two sets of simulation experiments (Fig. 4B, C). Firstly, given the fact that alloxan can react with H2O2 to form the active intermediate 1aOOH30, we replaced the oxidant O2 and the reductant 4k of the template reaction with H2O2. Performing the oxidative bromination of 2-1 with H2O2 and NaBr, with 20 mol% of alloxan 1a added as catalyst resulted in a 52% yield of the brominated product 3-1 after 4 h, while the blank control group (without 1a) showed no conversions (Fig. 4B, Supplementary Table 5 for more details). This result indicates that alloxan 1a significantly catalyzes the oxidative bromination of substrate 2-1 by forming intermediate 1aOOH to oxidize Br- into OBr- (bottom of Fig. 4B). In a second approach, we utilized NaOBr solution as a Br+-source and conducted catalytic experiments on template substrate 2-1 (Fig. 4C, Supplementary Table 6 for more details). At room temperature, the presence of 20 mol% alloxan 1a resulted in a 71% yield of the target brominated product 3-1 within 10 min, whereas the blank control group (without 1a) yielded only 25%, implying that alloxan also catalyzes the electrophilic halogenation process (this process is also supported by the in-situ NMR shown in Supplementary Fig. 19). On this basis, we also conducted experiments on NaOBr with different substrates, as shown in Supplementary Table 7 and Fig. 20: in the presence of alloxan catalyst 1a, both the template substrate N-benzyllaniline (2-1) and the N-unsubstituted substrate (2-7) selectively underwent the para-bromination with very high yields; while in the absence of alloxan catalyst, a mixture of bromination and oxidation by-products was observed. The above results further indicate that the alloxan catalyst can indeed significantly catalyze the electrophilic halogenation of NaOBr, with high regioselectivity and chemoselectivity.

A Radical experiments: exclude the Br· or Br2 mechanism. B Catalysis experiment 1: Br--oxidation. C Catalysis experiment 2: electrophilic halogenation. D Proposed mechanism. E Compare the reducibility of 4a and 4k. F Cyclic voltammetry experiments. TEMPO (2,2,6,6-tetramethylpiperidine-N-oxyl), BHT (butylated hydroxytoluene), DPE (1,1-diphenylethylene).

Therefore, a plausible biomimetic catalytic aerobic oxidative halogenation mechanism is proposed in Fig. 4D. Firstly, alloxan catalyst 1a is reduced by L-ascorbic acid 4k to give the reduced form 1ared, which then undergoes a reaction with O2 to generate the a relatively stable and mild reactive intermediate 1aOOH30 (more detailed explanation see Supplementary Information section 10.6). Subsequently, the formed 1aOOH can selectively convert Br- to OBr- through a possible transition state TS1, similar to the oxidation process of Br- by FADOOH in FDHs. Following this deoxygenation step, the generated alloxan hydrate 1aOH activates the resulting OBr- via a speculated transition state TS2 with hydrogen bonding, which simulates the role of lysine residues in FDHs20 and leads to the bromination of substrates. That is to say, alloxan catalyzes the entire aerobic bromination process and play multiple functions of O2-activation, X--oxidation, and electrophilic halogenation.

To further explain the critical role of L-ascorbic acid 4k in this biomimetic oxidative halogenation process, we designed a series of control experiments to compare it with common organic hydride source, Hantzsch ester 4a (Fig. 4E, Supplementary Table 9 for more details). In the aerobic oxidative bromination system the catalyst alloxan 1a present, 4k remained stable in the absence of substrate 2-1 (see top of Fig. 4E), while 4a was completely converted into its oxidation byproduct 4’a very rapidly (see bottom of Fig. 4E). We speculated the possible reason was 4a being oxidized and consumed by in situ generated OBr- (this hypothesis was also supported by Supplementary Table 10). Therefore, we conducted cyclic voltammetry experiments to compare their redox capabilities (Fig. 4F, Supplementary Figs. 24–27 for more details). The reduction potential of OBr- (Ep(OBr-/Br·) = 1.1 V vs Ag/AgCl, corresponding to the second oxidation potential of Br-53) is higher than the oxidation potential of Hantzsch ester 4a (Ep(4a/4’a) = 1.0 V), but lower than oxidation potential of L-ascorbic acid 4k (Ep(4k/4’k) = 1.2 V), suggesting OBr- only oxidizes 4a but does not affect 4k. Since L-ascorbic acid 4k is not oxidized or quenched by the oxidative intermediate OBr-, our biomimetic oxidative halogenation system does not require spatial isolation of enzyme proteins in FDHs to separate reductant from the generated strong oxidative species.

Discussion

In summary, we have achieved the biomimetic catalytic aerobic oxidative halogenation based on FDHs simulation by establishing a compatible alloxan redox system, requiring no light activation. Using L-ascorbic acid as the reductant, the catalyst alloxan can be efficiently reduced to activate O2, and catalyze the subsequent X--oxidation and electrophilic halogenation processes, which simulate the two functional domains FAD and lysine in FDH simultaneously. Mechanistic research further attributes this success into the unique reductant L-ascorbic acid, which can selectively reduce the catalyst without being quenched by any other oxidants existed in the system (especially HOX). By this mild biomimetic strategy, a wide range of significant aryl bromides and iodides were obtained with excellent yields, which only requires benign O2 and halide ions instead of harsh oxidative halogen sources, resulting in better selectivity and functional group tolerance than traditional chemical halogenation. Besides, compared to FDHs-catalyzed halogenations, this operationally simple organic catalytic method is quite robust and can be easily scaled up to gram level at room temperature under air conditions. Particularly, due to the high-water solubility of reagents involved in the reaction, such as alloxan catalyst, halide salts, and reductant ascorbic acid, it is easy to precipitate low-polarity halogenated products with high purity simply by adding water. And when replacing the pure L-ascorbic acid with more cost-efficient natural crude extracts containing only 17% vitamin C, the desired aerobic halogenation also occurred smoothly. This aerobic biomimetic strategy has proven efficient for bromination and iodination, the exploration of more challenging biomimetic aerobic oxidative chlorination is underway in our laboratory. We anticipate that this cheap and robust biomimetic approach could provide a mild and green option for halogenated industries. And since our alloxan catalyst is quite simple and easy to structurally modify, it provides a promising platform for designing catalysts to achieve precise site-selective aryl halogenation in the future.

Methods

General procedure for alloxan-catalyzed aerobic oxidative bromination

In a 40 mL test tube containing a magnetic stir bar were added substrate 2 (0.1 mmol, 1.0 eq.), L-ascorbic acid 4k (0.0352 g, 0.2 mmol, 2.0 eq.), and LiBr (0.0435 g, 0.5 mmol, 5.0 eq.). After adding the solvent MeCN (4 mL) and briefly stirring the mixture to dissolve the substrate, the alloxan catalyst 1a (0.0019 g, 0.01 mmol, 0.1 eq.) was added into the stirred reaction solution and kept the fully stirred at room temperature under an O2 atmosphere (balloon, 1 atm) or open air. After reaction, 20 mL of water was added to quench the reaction, followed by extraction using EtOAc (5 mL × 3). The combined organic layer was washed with saturated Na2S2O3 water and saturated brine orderly, dried over Na2SO4, filtered, and concentrated to give the crude product, which was purified by flash column chromatography on silica gel to afford the brominated product 3.

General procedure for alloxan-catalyzed aerobic oxidative iodination

In a 10 mL test tube containing a magnetic stir bar were added substrate 2 (0.1 mmol, 1.0 eq.), L-ascorbic acid 4k (0.0211 g, 0.12 mmol, 1.2 eq.), and LiI (0.134 g, 1.0 mmol, 10.0 eq.). After adding the solvent MeCN (1 mL) and briefly stirring the mixture to dissolve the substrate, the alloxan catalyst 1a (0.0019 g, 0.01 mmol, 0.1 eq.) was added into the stirred reaction solution and kept the fully stirred at room temperature under open air for another 2 h. After reaction, 10 mL of water was added and stirred for 30 min to quench the reaction, followed by extraction using EtOAc (5 mL×3). The combined organic layer was washed with saturated Na2S2O3 water and saturated brine orderly, dried over Na2SO4, filtered, and concentrated to give the crude product, which was purified by flash column chromatography on silica gel to afford the iodinated product 6.

Data availability

The data supporting the results of the article, including optimization studies, experimental procedures, compound characterization, mechanistic studies, and scale-up procedures are provided within the paper and its Supplementary information. All data are available from the corresponding author upon request.

References

Bellina, F. & Rossi, R. Transition metal-catalyzed direct arylation of substrates with activated sp3-hybridized C−H bonds and some of their synthetic equivalents with aryl halides and pseudohalides. Chem. Rev. 110, 1082–1146 (2010).

Samojłowicz, C., Bieniek, M. & Grela, K. Ruthenium-based olefin metathesis catalysts bearing N-heterocyclic carbene ligands. Chem. Rev. 109, 3708–3742 (2009).

Jeschke, P. Latest generation of halogen-containing pesticides. Pest Manage. Sci. 73, 1053–1066 (2017).

Tang, M. L. & Bao, Z. Halogenated materials as organic semiconductors. Chem. Mater. 23, 446–455 (2011).

Gribble, G. W. Naturally occurring organohalogen compounds. Acc. Chem. Res. 31, 141–152 (1998).

Gribble, G. W. Recently discovered naturally occurring heterocyclic organohalogen compounds. Heterocycles 84, 157–207 (2012).

Gribble, G. W. A survey of recently discovered naturally occurring organohalogen compounds. J. Nat. Prod. 87, 1285–1305 (2024).

Smith, B. R., Eastman, C. M. & Njardarson, J. T. Beyond C, H, O, and N! analysis of the elemental composition of U.S. FDA approved drug architectures. J. Med. Chem. 57, 9764–9773 (2014).

Saikia, I., Borah, A. J. & Phukan, P. Use of bromine and bromo-organic compounds in organic synthesis. Chem. Rev. 116, 6837–7042 (2016).

He, X., Wang, X., Tse, Y.-L., Ke, Z. & Yeung, Y.-Y. Applications of selenonium cations as Lewis acids in organocatalytic reactions. Angew. Chem. Int. Ed. 57, 12869–12873 (2018).

Wang, G.-W. & Gao, J. Solvent-free bromination reactions with sodium bromide and oxone promoted by mechanical milling. Green Chem. 14, 1125–1131 (2012).

Büchler, J., Papadopoulou, A. & Buller, R. Recent advances in flavin-dependent halogenase biocatalysis: sourcing, engineering, and application. Catalysts 9, 1030 (2019).

Payne, J. T., Andorfer, M. C. & Lewis, J. C. Regioselective arene halogenation using the FAD-dependent halogenase RebH. Angew. Chem. Int. Ed. 52, 5271–5274 (2013).

Shepherd, S. A. et al. Extending the biocatalytic scope of regiocomplementary flavin-dependent halogenase enzymes. Chem. Sci. 6, 3454–3460 (2015).

Gkotsi, D. S. et al. A marine viral halogenase that iodinates diverse substrates. Nat. Chem. 11, 1091–1097 (2019).

Kunitski, M. et al. Double-slit photoelectron interference in strong-field ionization of the neon dimer. Nat. Commun. 10, 1 (2019).

Menon, B. R. K. et al. RadH: A versatile halogenase for integration into synthetic pathways. Angew. Chem. Int. Ed. 56, 11841–11845 (2017).

Andorfer, M. C. & Lewis, J. C. Understanding and improving the activity of flavin-dependent halogenases via random and targeted mutagenesis. Annu. Rev. Biochem 87, 159–185 (2018).

Flecks, S. et al. New insights into the mechanism of enzymatic chlorination of tryptophan. Angew. Chem. Int. Ed. 47, 9533–9536 (2008).

Dong, C. et al. Tryptophan 7-halogenase (PrnA) structure suggests a mechanism for regioselective chlorination. Science 309, 2216–2219 (2005).

Yeh, E., Blasiak, L. C., Koglin, A., Drennan, C. L. & Walsh, C. T. Chlorination by a long-lived intermediate in the mechanism of flavin-dependent halogenases. Biochemistry 46, 1284–1292 (2007).

Latham, J., Brandenburger, E., Shepherd, S. A., Menon, B. R. K. & Micklefield, J. Development of halogenase enzymes for use in synthesis. Chem. Rev. 118, 232–269 (2018).

Minges, H. & Sewald, N. Recent advances in synthetic application and engineering of halogenases. ChemCatChem 12, 4450–4470 (2020).

Frese, M. & Sewald, N. Enzymatic halogenation of tryptophan on a gram scale. Angew. Chem. Int. Ed. 54, 298–301 (2015).

Hering, T., Muhldorf, B., Wolf, R. & Konig, B. Halogenase-inspired oxidative chlorination using flavin photocatalysis. Angew. Chem. Int. Ed. 55, 5342–5345 (2016).

Walter, A. & Storch, G. Synthetic C6-functionalized aminoflavin catalysts enable aerobic bromination of oxidation-prone substrates. Angew. Chem. Int. Ed. 59, 22505–22509 (2020).

Iida, H., Imada, Y. & Murahashi, S. I. Biomimetic flavin-catalysed reactions for organic synthesis. Org. Biomol. Chem. 13, 7599–7613 (2015).

Cibulka, R. Artificial flavin systems for chemoselective and stereoselective oxidations. Eur. J. Org. Chem. 2015, 915–932 (2015).

Murray, A. T. et al. Catalytic amine oxidation under ambient aerobic conditions: mimicry of monoamine oxidase B. Angew. Chem. Int. Ed. 54, 8997–9000 (2015).

Zhang, S. et al. Alloxan-catalyzed biomimetic oxidations with hydrogen peroxide or molecular oxygen. ACS Catal. 10, 245–252 (2020).

Zhang, S. et al. Biomimetic alloxan-catalyzed intramolecular redox reaction with O2: one-pot atom-economic synthesis of sulfinyl-functionalized benzimidazoles. Tetrahedron Lett. 62, 152688–152692 (2021).

Zhang, S. et al. Biomimetic dynamic kinetic asymmetric N-oxidation with H2O2 and O2. ACS Catal. 13, 11954–11962 (2023).

Wells, S. A. Jr et al. Vandetanib in patients with locally advanced or metastatic medullary thyroid cancer: a randomized, double-blind phase III trial. J. Clin. Oncol. 30, 134–141 (2012).

Aung, T. et al. Twice-daily brinzolamide/brimonidine fixed combination versus brinzolamide or brimonidine in open-angle glaucoma or ocular hypertension. Ophthalmology 121, 2348–2355 (2014).

Wang, D.-W. et al. Synthesis and herbicidal evaluation of triketone-containing quinazoline-2,4-diones. J. Agric. Food. Chem. 62, 11786–11796 (2014).

Farmer, L. J. et al. Discovery of VX-509 (decernotinib): a potent and selective janus kinase 3 inhibitor for the treatment of autoimmune diseases. J. Med. Chem. 58, 7195–7216 (2015).

Wang, S. et al. Synthesis and structure-activity optimization of 7-azaindoles containing aza-β-amino acids targeting the influenza PB2 subunit. Eur. J. Med. Chem 250, 115185 (2023).

Caputi, L. et al. Missing enzymes in the biosynthesis of the anticancer drug vinblastine in Madagascar periwinkle. Science 360, 1235–1239 (2018).

Lin, X. et al. Boosting the oxidase-like activity of platinum nanozyme in MBTH-TOOS chromogenic system for detection of trypsin and its inhibitor. Talanta 234, 122647 (2021).

Kohl-Landgraf, J. et al. Ultrafast dynamics of a spiropyran in water. J. Am. Chem. Soc. 134, 14070–14077 (2012).

Wagner, K. et al. A Multiswitchable poly(terthiophene) bearing a spiropyran functionality: understanding photo- and electrochemical control. J. Am. Chem. Soc. 133, 5453–5462 (2011).

Amann, N., Huber, R. & Wagenknecht, H.-A. Phenanthridinium as an artificial base and charge donor in DNA. Angew. Chem. Int. Ed. 43, 1845–1847 (2004).

Shi, X. & Macgregor, R. B. The effect of charge on the volume change of DNA binding with intercalator DAPP. J. Phys. Chem. B 111, 3321–3324 (2007).

Lin, X., Liu, J., Zou, Y., Tao, C. & Chen, J. Xanthotoxol suppresses non-small cell lung cancer progression and might improve patients’ prognosis. Phytomedicine 105, 154364 (2022).

El-Mossalamy, E. H., Obaid, A. Y. & El-Daly, S. A. Photophysical parameters and fluorescence quenching of 7-diethylaminocoumarin (DEAC) laser dye. Opt. Laser Technol. 43, 1078–1083 (2011).

Halpern, A. M. & Noll, R. J. That’s so cool. Using a flame to freeze water. The vapor-absorption refrigerator and how it works. J. Chem. Educ. 97, 726–735 (2020).

Rrapi, M. et al. Photochemical synthesis of lactones, cyclopropanes and ATRA products: revealing the role of sodium ascorbate. Chem. Eur. J. 30, e202400253 (2024).

See, X. Z., Yeo, W. S. & Saptoro, A. A comprehensive review and recent advances of vitamin C: Overview, functions, sources, applications, market survey and processes. Chem. Eng. Res. Des. 206, 108–129 (2024).

Susa, F. & Pisano, R. Advances in ascorbic acid (vitamin C) manufacturing: green extraction techniques from natural sources. Processes 11, 3167 (2023).

Xu, M. et al. Metabolomic analysis of acerola cherry (Malpighia emarginata) fruit during ripening development via UPLC-Q-TOF and contribution to the antioxidant activity. Food Res. Int. 130, 108915 (2020).

Warren, J. J. & Mayer, J. M. Tuning of the thermochemical and kinetic properties of ascorbate by its local environment: solution chemistry and biochemical implications. J. Am. Chem. Soc. 132, 7784–7793 (2010).

Lu, L., Li, Y. & Jiang, X. Visible-light-promoted oxidative halogenation of (hetero)arenes. Green Chem. 22, 5989–5994 (2020).

Zhang, P. et al. Electrochemical umpolung of bromide: transition-metal-free bromination of indole C–H bond. Molecules 24, 696 (2019).

Acknowledgements

This research was funded by the Natural Science Foundation of Sichuan Province (Grant No. 2024NSFSC1114 to S.Z.), and National Natural Science Foundation of China (Grant No. 22401275 to S.Z., Grant No. 22377124 to Z.T.).

Author information

Authors and Affiliations

Contributions

S.Z. conceived the project, performed the experiments, and wrote the paper. Z.T. directed the project and revised the paper. S.Z., G.L., D.F., X.Z., S.C., X.C. and Z.T. discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, S., Li, Gx., Fang, D. et al. Aerobic oxidative bromination and iodination enabled by alloxan and ascorbic acid to mimic flavin-dependent halogenases. Nat Commun 16, 3680 (2025). https://doi.org/10.1038/s41467-025-58904-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-58904-1