Abstract

5-Hydroxymethylfurfural (HMF), a product of the Maillard reaction and caramelization in honey, serves as a crucial marker of food quality and thermal processing, underscoring the importance of regulatory surveillance for consumer safety. This study introduces a method for rapid, high throughput and eco-friendly detection of HMF, using derivatization in matrix-assisted laser desorption/ionization mass spectrometry (MALDI-MS). 5,10,15,20-Tetrakis-(4-aminophenyl)-porphyrin was employed for in-situ derivatization of aldehydes after extraction by ethyl acetate, enhancing detection sensitivity by shifting low-molecular-weight aldehydes to higher regions. The calibration curves for HMF determination exhibited outstanding linearity. The detection limit reached 0.347 mg/kg with good accuracy and precision. Variations in the content of HMF in honey during heating were also assessed, revealing the increased formation of HMF under high temperature and prolonged heating. The method’s proficiency was evidenced through the detection of various aldehydes. This method represents an advance in rapid analysis for food safety, aligning with green chemistry principles.

Similar content being viewed by others

Introduction

5-Hydroxymethylfurfural (HMF), a byproduct of Maillard and caramelization reactions in sugar-rich foods1,2,3, has garnered attention due to its association with potential health hazards, including mucosal toxicity, cytotoxicity4, neurotoxic effects5 and DNA damage6,7. Its presence in foods serves as a critical indicator for evaluating the extent of heat treatment, deterioration, and storage conditions8. Recognizing its significance, regulatory authorities like the Codex Alimentarius Commission and the European Union have established maximum permissible levels of HMF in honey and apple juice, set at 40 mg/kg and 50 mg/kg, respectively6. This underscores the necessity for precise quantification of HMF to uphold food safety and quality standards.

A wide range of analytical techniques for the quantification of HMF, including spectrometric, sensor-based, enzyme-linked immunosorbent assays, and chromatographic/mass spectrometric methods, have been established9,10. Among these, mass spectrometry is particularly valued for its exceptional sensitivity and specificity11. In particular, some strategies applied green solvents or green materials to extract analytes before mass spectrometry analysis, achieving strong analytical performance and enhancing sustainability12,13. Nonetheless, conventional mass spectrometric techniques for HMF analysis, such as a optimized QuEChERS method followed by liquid chromatography-mass spectrometry (LC-MS)14 and an analytical miniaturized methodology based on solid-phase-microextraction followed by gas chromatography-mass spectrometry (GC-MS)15, tend to be laborious and time-consuming, not meeting the fast and high-throughput needs critical for stringent food industry quality control16.

Our prior research has developed an innovative method that combines stable isotope labeling with flow injection analysis-mass spectrometry (FIA-MS) for the rapid detection of HMF in beverages17. While this technique demonstrates efficiency, its dependence on organic solvents as carrier fluids presents environmental challenges, diverging from principles of green chemistry18. Consequently, the development of rapid, high-throughput, and environmentally sustainable mass spectrometric analytical methods for the monitoring of HMF in food products is both meaningful and essential.

Matrix-assisted laser desorption/ionization mass spectrometry (MALDI-MS) is highly valued for its sensitivity, speed, efficiency, and low sample needs19,20, yet struggles with low-molecular-weight compounds like HMF due to matrix interference and poor ionization21,22,23. Chemical derivatization24,25, tagging small molecules for higher mass detection, circumvents these issues, enabling clear spectra with standard matrices26. Innovations in derivatization reagents, such as Feng’s C60-based tags for amino acids27 and thiols28, enhance detection by shifting analyte mass above m/z 800, thus boosting sensitivity and selectivity.

In this study, for precise quantification of HMF to uphold food safety and quality standards, we established a rapid and high-throughput analysis method in MALDI-MS based on in-situ derivatization using 5,10,15,20-tetrakis (4-aminophenyl) porphyrin (TAPP) as derivatization agents. To achieve the highest detection sensitivity for HMF, the concentrations of TAPP and formic acid were optimized. The method’s efficacy was validated through the detection of various aldehydes, such as p-coumaraldehyde, perilla aldehyde, citral, and citronellal. The method’s quantification effect was evaluated by quantifying HMF in honey samples. This approach was also applied to track HMF level changes in heated honey, showcasing its applicability for wider analytical purposes. The performance of this integrated method for HMF determination was assessed by comparing it with existing methodologies in terms of sensitivity, sample usage, and analysis duration.

Results

General principle of TAPP-based in-situ derivatization

For MALDI MS, the direct detection of small molecules remains a challenge29. This is primarily due to low desorption/ionization efficiency and interference from matrix-related signals, as noted in previous studies21,30,31. Specifically, small molecule aldehyde compounds are often undetectable or weakly detected using conventional MALDI techniques32,33,34,35.

In this study, inspired by the extensive conjugated systems of porphyrins that efficiently absorb the laser energy used in MALDI-MS (355-nm Nd:YAG laser) and their molecular weights exceeding 600 Da, TAPP was selected as the derivatization reagent due to its ability to specifically react with aldehyde groups under slightly acidic conditions. The formation of TAPP-aldehyde derivatives may significantly enhance the detection sensitivity of aldehydes, thanks to the TAPP tag’s favorable response in MALDI-MS detection. Notably, the derivatization increases the molecular weight of the aldehydes above 600 Da. This shift moves the aldehyde signals from the interference-heavy low m/z range to a higher, interference-free m/z region in MALDI-MS analysis, thus greatly improving the selectivity of detection. Furthermore, the four amino groups of TAPP provide increased reactivity with aldehydes, potentially facilitating in-situ derivatization. This advancement has the potential to considerably streamline the sample preparation process. Figure 1 illustrates the analytical workflow for TAPP-based in-situ derivatization, followed by the MALDI-MS detection of aldehydes.

Feasibility and performance study

In the initial experimental phase, we found that the reactions between TAPP and HMF can all be carried out quickly at room temperature and other temperatures (Fig. 2A), or at different derivatization times (Fig. 2B). And no differences were found in the signal intensity of the TAPP-HMF derivative for different derivatization temperatures and times. Hence, for the sake of greater convenience, the reaction was carried out by mixing directly at room temperature. In this work, it was achieved on the MALDI target plate in an in-situ manner and there was no significant difference in the signal intensity of the TAPP-HMF derivative for the derivatizations in an in-situ manner or mixing solvents before spotting (Supplementary Fig. S1). So, the standard HMF solution (400 μg/mL) was directly mixed with the TAPP solution and the catalyst FA on the MALDI plate spot to perform in-situ chemical derivatization. Additionally, a HMF-free blank solution underwent the same treatment to determine the presence of any interferences.

The MALDI mass spectra presented in Fig. 3 demonstrated that the HMF was not detected and the CHCA matrix generated an abundance of signals in the low m/z range, originating from fragment ions, adduct ions, and ion clusters. In contrast, the high m/z region exhibited notably fewer interference signals. Comparatively, the TAPP-HMF derivative was successfully detected at m/z 782.68 without any interfering signals within the same m/z values. Furthermore, the derivative was situated in the high mass region against a clear background, effectively eliminating interference from the organic matrix, CHCA. Similarly, the applicability of this method for analyzing isotopically labeled HMF, particularly HMF-13C6, was examined. HMF-13C6 is vital for quantitative analysis, acting as an internal standard to compensate for signal variations during MALDI-MS detection36. Comparable results were observed. As depicted in Supplementary Fig. S2, HMF-13C6 could not be directly detected (Supplementary Fig. S2A). The signal for the TAPP-HMF-13C6 derivative was successfully identified at m/z 788.16, while no interfering signals were observed in the HMF-13C6-free blank solution after derivatization. This underscores the potential ability of the TAPP-based in-situ derivatization strategy for the quantitative MALDI-MS analysis of aldehyde compounds.

Optimization of derivatization conditions

To achieve the highest detection sensitivity for HMF, two primary factors were optimized: the concentration of TAPP and the concentration of FA. The optimization process was conducted in triplicate, and the average signal intensities were used as the metric for comparison to determine the optimal conditions.

For the chemical derivatization, sufficient amounts of the derivatization reagents are necessary to ensure high yields of the reaction16,27. However, an excess of derivatization reagent could also lead to competitive effects during the desorption/ionization process. Therefore, the impact of TAPP concentration on the signal intensity was assessed within the 0.1–5.0 mg/mL range. As depicted in Fig. 2C, the signal intensity of the TAPP-HMF derivative initially increased significantly and peaked at a concentration of 1.0 mg/mL. Beyond this concentration, a slight reduction in signal intensity was noted, likely due to competition during the desorption/ionization stage caused by an excess of the derivatization reagent. Consequently, the optimal concentration of TAPP was determined to be 1.0 mg/mL.

Typically, a weakly acidic condition promotes the reaction between aldehyde group and amino group37. In this context, FA was chosen to catalyze the derivatization reaction38, and the effect of its concentration on signal intensity was assessed across a range of 0–5%. Interestingly, the in-situ derivatization proceeded successfully even in the absence of FA (Fig. 2D). This could be attributed to TAPP, which contains four amino groups, possessing high reactivity towards HMF. Therefore, for the sake of experimental simplicity, subsequent experiments were conducted without the addition of FA.

Method validation

To evaluate the analytical figures of merit of the TAPP-based in-situ derivatization strategy, a series of experiments were designed to validate the method’s accuracy, precision, and overall reliability, etc. This included the establishment of a calibration curve for HMF, assessing the linearity over a wide concentration range. The sensitivity of the method was determined by calculating the limit of detection (LOD) and limit of quantification (LOQ) for HMF. Inter-day and intra-day relative standard deviation (RSD), and recoveries were assessed to evaluate the method’s precision and accuracy. Specificity was investigated by comparison of MALDI-MS spectra of a blank honey sample, a blank honey sample spiked with TAPP, and a blank honey sample spiked with HMF and internal standard and derivatized by TAPP. To assess the method’s robustness, minor changes in the method conditions (Laser Pulse Energy and Sample Rate) were made and the effects of these changes on the method recovery and precision were checked. The ruggedness of the method was evaluated by analyzing the same sample by two different analysts using the same instrument on different days.

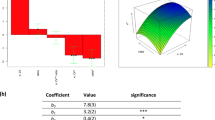

As shown in Supplementary Fig. S3, no apparent interfering signals of endogenous substances of honey and TAPP were found at the m/z of HMF (782.60) and internal standard (788.52), which demonstrates the high specificity of the method. To further validate this approach, honey samples spiked with a fixed amount of IS (40.0 mg/kg) and a series of HMF standards ranging from 1.0 to 150.0 mg/kg were analyzed by the TAPP-based in-situ derivatization MALDI-MS method. The calibration curve was constructed by plotting mean peak intensity ratios of TAPP-HMF derivative/TAPP-HMF-13C6 derivative (analyte/IS) against the HMF concentrations. As shown in Table 1, satisfied linearity was obtained with the correlation coefficients being 0.997 (R2 = 0.997). The LOD defined as the amount of analytes at a signal-to-noise ratio of 3 was 0.347 mg/kg for HMF. The LOQ defined as the amount of analytes at a signal-to-noise ratio of 10 was 1.145 mg/kg for HMF. Given that the maximum allowable HMF level in honey is set at 40.0 mg/kg by international standards, such as those outlined by the Codex Alimentarius9,14,17,39,40, the detection limit established in this study effectively satisfies the regulatory requirements for HMF monitoring in honey. Therefore, it is suitable for routine analysis, ensuring both the quality and safety of honey intended for consumption.

The inter-day and intra-day relative recoveries and RSDs were used to assess the precision and accuracy by analyzing honey samples spiked with the IS at 40.0 mg/kg and HMF at varying concentrations: low (5.0 mg/kg), medium (40.0 mg/kg), and high (120.0 mg/kg). The “precision” refers to the reproducibility of measurements, as determined by the RSD of repeated analyses under the same conditions, with an RSD of less than 12% considered acceptable for this study.Accuracy refers to the degree of consistency between the measured result and the true value, with recoveries between 80 and 120% considered acceptable for this study. The intra-day and inter-day RSD values and relative recoveries for HMF were presented in Fig. 4, showcasing the validated method’s satisfied precision and accuracy. As shown in Supplementary Table S1, the minor changes in the operating conditions of the Laser Pulse Energy and Sample Rate did not alter the accuracy and precision of the method as revealed from the recovery values (96.19–102.93%) and the RSD did not exceed 5.06%. In ruggedness evaluation, the recovery values were in the range of 97.93–103.42% and the RSD values did not exceed 4.12%, indicating the high ruggedness and reproducibility of the method. These results confirm the method’s adequacy for the quantitative analysis of HMF in honey samples.

Real sample analysis

The validated quantification method was employed to ascertain the levels of HMF in various honey samples acquired from supermarkets. Each sample was analyzed in triplicate to calculate the average concentration based on the calibration curve. Results presented in Supplementary Table S2 indicated that the endogenous HMF content ranged from 6.125 to 16.194 mg/kg, complying with the regulatory limit of 40.0 mg/kg.

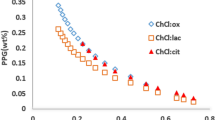

Some studies have indicated that heating can lead to an increase in HMF levels in sugar-containing samples41,42. Therefore, a further examination was conducted to evaluate the impact of heat treatment on HMF content in honey. The results depicted in Fig. 5 confirm that the HMF content in honey increases with prolonged heating time and temperature. Specifically, at 60 °C, the HMF content remains relatively stable with only a slight increase over 5 h. However, at higher temperatures of 80 °C, 100 °C, 150 °C, and 200 °C, there is a clear upward trend in HMF levels. The most significant rise occurs at 200 °C, where the HMF content escalates sharply, surpassing 800.0 mg/kg after 5 h of heating, suggesting a substantial thermal effect on HMF formation in honey.

Crucially, HMF concentrations surpass the internationally recognized safe limit of 40.0 mg/kg when the temperature exceeds 100 °C for more than 3 h, underscoring the imperative to monitor and control heating conditions in honey processing to prevent excessive HMF formation. These findings not only offer guidance on safe processing temperatures for honey but also suggest that prolonged exposure to high temperatures should be avoided. The measurement of HMF can serve as a direct method for assessing honey’s preparation and storage conditions, signaling potential overheating or improper treatment.

The applicability of the derivatization strategy

Food contains diverse low-molecular-weight aldehydes43. For instance, citral, abundant in lemongrass, imparts a zesty lemon flavor to Asian cuisine44. p-Coumaraldehyde, prevalent in garlic and herbs, lends a distinctive taste and may offer health benefits45. Perilla aldehyde, found in perilla leaves, enriches Japanese and Korean dishes46. Citronellal, derived from citronella grass, infuses teas and pastries with a revitalizing citrus scent.

Therefore, the potential applicability of the TAPP-based in-situ derivatization strategy was explored by detecting above small molecule aldehyde compounds. The results shown in Fig. 6 demonstrated that the TAPP-based in-situ derivatization strategy markedly enhanced the MALDI-MS detection of various small molecule aldehyde compounds. Notably, p-coumaraldehyde, perilla aldehyde, citral, and citronellal, which were previously undetectable using conventional MALDI-MS techniques35,47,48, yielded distinct peaks post-derivatization. For instance, the perilla aldehyde derivative was identified at m/z 808.36 (Fig. 6A), the citral derivative at m/z 808.51 (Fig. 6B), the citronellal derivative at m/z 810.50 (Fig. 6C), and the p-coumaraldehyde derivative at m/z 804.30 (Fig. 6D). These findings validate the efficacy of the TAPP derivatization strategy in enhancing sensitivity and selectivity for the MALDI-MS analysis of aldehyde compounds. Of course, this only validates the application of the present method to other low-molecular-weight aldehydes using standard solutions, providing ideas and references for establishing quantitative methods for other aldehydes. Further optimization of this strategy for the precise quantification of specific aldehydes in various complex samples requires additional validation.

MALDI-MS spectra of A Perilla aldehyde standard solution (200.0 μg/mL), B Citral standard solution (200.0 μg/mL), C Citronellal standard solution (200.0 μg/mL), and D p-Coumaraldehyde standard solution (200.0 μg/mL), all following in-situ derivatization with TAPP. CHCA was utilized as the MALDI matrix.

The method greenness evaluation

In order to assess the greenness of the developed method, some greenness assessment tools were utilized in this section, which will reflect the impact of method on environment, safety and health. GAPI (Green Analytical Procedure Index) can evaluate the green character of an entire analytical methodology, from sample collection to final determination49. In the specific symbol with five pentagrams in GAPI, the environmental impact involved in each step of an analytical methodology can be showed by different colors, mainly from green through yellow to red depicting low, medium to high impact, respectively. In Fig. 7A, the pictogram contained four red areas, three yellow and eight green, which reflected the method’s overall excellent greenness.

For the Analytical GREEnness (AGREE) calculator, its assessment criteria are based on the 12 principles of green analytical chemistry (SIGNIFICANCE). The overall score is shown in the middle of the pictogram with values close to 1 and dark green color indicating that the assessed procedure is greener50. In Fig. 7B, this method scored 0.66, exceeding 0.6, indicating that the developed method was green.

The AGREE metric specifically for sample preparation (AGREEprep) was based on 10 categories of impact, including the choice and use of solvents, materials and reagents, waste generation, energy consumption, sample size, and throughput51. In Fig. 7C, the assessment result was a circular pictogram with a total score (0.62) in the center, the outer 10 sections represented the low-moderate-high degree of greenness, and the colors of the inner circle was green.

Blue applicability grade index (BAGI) focus on evaluating the practicality of an analytical method, such as the type of analysis, the number of analytes that are simultaneously determined, the number of samples that can be analyzed per hour, the type of reagents and materials used in the analytical method, the required instrumentation, the number of samples that can be simultaneously treated, the requirement for preconcentration, the automation degree, the type of sample preparation, and the amount of sample52. In Fig. 7D, the color of the pictogram and the total score (67.5) showed the compliance of the method with the greenness.

Sample Preparation Metric of Sustainability (SPMS) can explicitly and exclusively evaluate the sample preparation without considering aspects related to sampling and the final instrumentation53. In Fig. 7E, the colors can signify performance levels, ranging from green for “successful” to red for “inadequate”. And the total score was 6.42. Collectively, the method employed in this study was green based on the above greenness assessment tools.

Discussion

In this study, each MALDI-MS sample analysis was completed within one minute, offering rapid and high-throughput capabilities. In terms of determining HMF in complex samples, this method holds distinct advantages. It bypasses the extended chromatographic separation procedures and the high consumption of organic solvents often associated with traditional chromatographic methods. While the steps of solvent extraction and evaporation-resolubilization are somewhat time-intensive, the capability to process multiple samples concurrently significantly reduces the average pre-treatment time to less than one minute per sample. Such efficiency does not impede the speed of the overall analysis. When analyzing large batches of samples, the average analysis time per sample is approximately 2 min. TAPP is a common porphyrin compound and is generally considered to be relatively safe under laboratory conditions. Although there is no sufficient evidence indicating that it is necessarily harmful to the environment, as an organic compound, we should still pay attention to the potential environmental risks associated with TAPP. In the method greenness evaluation, we also considered its impact. Nevertheless, related research has shown TAPP and its derivatives may play a role in environment protection. For example, the copper and iron complexes of TAPP can catalyze the oxidation of phenol and chlorophenols into harmless short-chained carboxylic acids under neutral conditions, and might find practical applications in environment protection54. Similarly, manganese (III) chloride TAPP, conjugated with graphene quantum dots composite holds great potential in environmental remediation by visible-light-driven photocatalytic applications55. In addition, TAPP derivatives and their analogs are widely used in research fields such as catalysis, solar energy conversion, the primary process of photosynthesis and the development of advanced functional organic materials56. Notably, TAPP is commercially available, which greatly reduces the time required for synthesizing some derivatization reagents. Furthermore, in this work, 1 mL TAPP (5 mg/mL) can be used for the in-situ derivatization reaction of 1000 samples, with an average cost of only 0.0014 $ per sample. The above studies further demonstrate the feasibility, rationality and environmental friendliness of selecting TAPP as a derivatization reagent.

A comparative analysis assessed the proposed method against those documented in previous studies, detailed in Table 2. The proposed MALDI-MS method, with a detection limit of 0.347 mg/kg and an analysis time of about 2 min, stands out. UV/Vis spectroscopy relies only on absorption wavelength for detection, with poor selectivity and is not suitable for complex sample analysis, despite its advantages such as small size, low cost, high sensitivity, and simple operation57. For NMR, on the one hand, it is nondestructive, has a high flux and short analysis time, but on the other hand, it encounters difficulties due to overlapping chemical shifts that complicate spectrum interpretation when applied to complex matrices58. Chromatographic methods, including GC-MS, HPLC-FLD, HPTLC-UV, and LC-MS/MS, boast lower detection limits but suffer from longer analysis times, reduced throughput, and higher consumption of organic solvents59. It is important to note that while the detection sensitivity of the proposed MALDI-MS method may not rival that of chromatographic techniques, its robustness is adequate for routine screening. This is particularly beneficial for the analysis of high-volume samples, where the method’s satisfactory sensitivity and significantly shortened analysis time are advantageous60.

The present study has successfully developed a rapid, high-throughput, and environmentally friendly mass spectrometric method for analyzing aldehydes, especially HMF. It showcases the efficacy of porphyrin derivatives, particularly TAPP, as potent derivatization agents in MALDI-MS, enhancing the analysis of low-molecular-weight aldehydes. By employing TAPP for in-situ derivatization, detection sensitivity and selectivity for aldehydes were significantly improved by shifting their mass to a higher range, thereby reducing low mass interferences and improving ionization efficiency. The method exhibited remarkable effectiveness, evident from its ability to detect various aldehydes and establish precise and robust quantification methods for HMF in honey. With satisfactory linearity and sensitivity, coupled with good accuracy and precision, as well as rapid, high-throughput capabilities, the method is ideally suited for routine analysis, especially for monitoring HMF levels in honey. The method’s efficacy was further illustrated by observing the increase in HMF levels with heating, underscoring its potential in food quality control. Nevertheless, this method also has certain limitations. For example, it is necessary to optimize the selection and concentration of the matrix. Only derivatization reagents with larger molecular weights can shift the signal of HMF to the high m/z region, thereby eliminating interference from matrix signals. For some compounds with similar structures and small mass differences, it may be difficult to achieve good separation and identification. Additionally, compared to LC-MS, MALDI-MS is less commonly available in most laboratories and is generally less sensitive and precise. Despite its limitations, this method still represents a significant advancement in rapid food safety analysis, aligning with the principles of green chemistry.

Methods

Materials and reagents

Formic acid (FA, >99%) and HMF (>99%) were purchased from Aladdin Co., Ltd. (Shanghai, China). TAPP (>97%) was purchased from Yanshen Technology Co., Ltd. (Jilin, China). Perilla aldehyde (>92%), p-coumaraldehyde (>97%), citral (>98%) and citronellal (>96%) were purchased from Macklin Biochemical Technology Co., Ltd. (Shanghai, China). The internal standard (IS) 5-hydroxymethylfurfural-13C6 (HMF-13C6, ≥98%) was purchased from Panphy Chemicals Co., Ltd. (Los Angeles, USA). a-Cyano-4-hydroxycinnamic acid (CHCA, >98%) was purchased from TCI Chemical Trading Co., Ltd. (Shanghai, China). Honeys were purchased from a local supermarket (Zhengzhou, China): honey 1 was from Brassica napus L., Robinia pseudoacacia L. and Vitex negundo L., and date of manufacture was March 29, 2023; honey 2 was comvita multiflora honey and date of manufacture was March 6, 2023; honey 3 was from Tilia tuan Szyszyl. and date of manufacture was November 5, 2021; honey 4 was from Brassica napus L. and Ziziphus jujuba Mill., and date of manufacture was September 20, 2022. LC-MS grade ethyl acetate, methanol (MeOH), and acetonitrile (ACN) were purchased from Thermo Fisher Scientific (Fair Lawn, NJ, USA). Pure water was purchased from Wahaha Group Co., Ltd. (Hangzhou, China).

Sample preparations

The stock solutions of HMF and HMF-13C6 were prepared in ethyl acetate at the concentrations of 3.0 mg/mL. These were subsequently diluted using ethyl acetate to achieve the desired concentrations for use. The TAPP solution was prepared in MeOH at a concentration of 5.0 mg/mL, and further dilutions were made to obtain various concentrations ranging from 0.1 mg/mL to 5.0 mg/mL. For the CHCA matrix, a solution of 10.0 mg/mL was prepared in 50% ACN. All solutions were stored in a light-shielded environment within a refrigerator set at 4 °C and were freshly prepared on a weekly basis.

For the analysis of HMF in honey, a solvent extraction method was employed using ethyl acetate to extract HMF. In this process, 100 mg of honey was thoroughly mixed with 1 mL of ethyl acetate and then vortexed for 5 min. After centrifugation at 10,000 × g for 2 min, the supernatant was collected and evaporated to dryness. The resulting dried residue was re-dissolved in 50 μL of methanol, preparing it for the following in-situ derivatization. To explore the variations in HMF content in response to heat, honey samples were subjected to a range of heating conditions. These samples were heated at various temperatures—60 °C, 80 °C, 100 °C, 150 °C, and 200 °C—for different time intervals, specifically 1, 2, 3, 4, and 5 h. This approach was designed to systematically investigate the effects of heating on HMF levels in honey.

In-situ derivatization process

The derivatization reaction was carried out directly on the MALDI target plate in an in-situ manner. For this process, 1 μL of the pre-treated sample solution was first applied to the target plate. Following this, 1 μL of TAPP solution (1.0 mg/mL in MeOH) and 1 μL of FA were sequentially added to the same spot on the plate. The plate was then left to dry at room temperature. After drying, 2 μL of CHCA solution (10.0 mg/mL in 50% ACN) was carefully deposited onto the stainless-steel target plate, followed by a second drying phase. This completed the sample preparation for analysis, priming it for subsequent MALDI-MS detection.

Derivatization mode: mixing before spotting

The derivatization reaction was carried out directly in Eppendorf® tube by mixing derivatization solutions. For this process, 25 μL of the pre-treated sample solution was mixed with 25 μL of TAPP solution (1.0 mg/mL in MeOH) in 0.5 mL Eppendorf® tube, and 1 μL of FA was sequentially added. The solution in the tube was vortex mixed evenly at room temperature and was spotted on the MALDI target plate. After drying, 2 μL of CHCA solution (10.0 mg/mL in 50% ACN) was carefully deposited onto the stainless-steel target plate, followed by a second drying phase. This completed the sample preparation for analysis, priming it for subsequent MALDI-MS detection.

Optimization temperatures of TAPP-based derivatization by directly mixing derivatization solutions

The standard HMF solution (25 μL, 400.0 μg/mL) was mixed with the 25 μL TAPP solution (1.0 mg/mL in MeOH) in 0.5 mL Eppendorf® tube, and 1 μL catalyst FA was added. The mixed solution was shaken at a constant temperature of 25 °C, 30 °C, 40 °C, 50 °C and 60 °C for 30 min, respectively. Then the solution was spotted on the MALDI target plate, and air-dried before detection. The signal intensities of the TAPP-HMF derivative under different derivatization temperatures were compared.

Optimization times of TAPP-based derivatization by directly mixing derivatization solutions

The standard HMF solution (25 μL, 400.0 μg/mL) was mixed with the 25 μL TAPP solution (1.0 mg/mL in MeOH) in 0.5 mL Eppendorf® tube, and 1 μL catalyst FA was added. The mixed solution was shaken at a constant temperature of 25 °C for 0, 5, 10, 30 and 60 min, respectively (0: only mixing directly). Then the solution was spotted on the MALDI target plate, and air-dried before detection. The signal intensities of the TAPP-HMF derivative under different derivatization times were compared. The optimization process was conducted in triplicate, and the average signal intensities were used as the metric for comparison to determine the optimal conditions.

MALDI-TOF MS analysis

The MALDI-MS detection was performed on a MALDI-TOF MS system (QuanTOF II) equipped with a 355-nm Nd:YAG laser (IntelliBio, Qingdao, China). A stainless-steel target plate, also from IntelliBio, was utilized for the analysis. Mass spectra were acquired in positive-ion reflector mode with a m/z scan range of 50–1000. The m/z values were calibrated using the exact adduct peaks of CHCA. Other parameters were set as follows: Pulse Frequency: 3000 Hz; Laser Pulse Energy: 5.5 μJ; Detector Voltage: −0.55 kV; Source Voltage: 10 kV; Laser Pulse Current: 2.06 Amps; Motion Scanning Speed: 3.00 mm/sec; Sample Rate: 800 ps. For each spectrum, data were accumulated from 1000 laser shots. Subsequent data processing and analysis were carried out using the ProteoWizard3.0.4472 software.

Data availability

No datasets were generated or analyzed during the current study.

Code availability

No custom code or mathematical algorithm was developed for this study. Details regarding the specific codes used can be found in the references cited. Any access restrictions or licensing information associated with the codes used can be obtained from the respective sources as indicated in the references.

References

Deshavath, N. N. et al. Pitfalls in the 3, 5-dinitrosalicylic acid (DNS) assay for the reducing sugars: Interference of furfural and 5-hydroxymethylfurfural. Int. J. Biol. Macromol. 156, 180–185 (2020).

Qiu, Y. et al. Efficient production of xylooligosaccharides from Camellia oleifera shells pretreated by pyruvic acid at lower temperature. Int. J. Biol. Macromol. 259, 129262 (2024).

Shen, T. et al. Recent advances in processes and technologies for production of 5-hydroxymethylfurfural and 2,5-furandicarboylic acid from carbohydrates. Chem. Eng. J. 500, 156470 (2024).

Qiu, Y. et al. 5-Hydroxymethylfurfural Exerts Negative Effects on Gastric Mucosal Epithelial Cells by Inducing Oxidative Stress, Apoptosis, and Tight Junction Disruption. J. Agric. Food Chem. 70, 3852–3861 (2022).

Wang, C. et al. Potential neurotoxicity of 5-hydroxymethylfurfural and its oligomers: widespread substances in carbohydrate-containing foods. Food Funct. 11, 4216–4223 (2020).

Choudhary, A. et al. 5-Hydroxymethylfurfural (HMF) formation, occurrence and potential health concerns: recent developments. Toxin Rev. 40, 545–561 (2021).

Ou, J. Y. et al. Interaction of Acrylamide, Acrolein, and 5-Hydroxymethylfurfural with Amino Acids and DNA. J. Agric. Food Chem. 68, 5039–5048 (2020).

Lee, C. H. et al. Recent advances in processing technology to reduce 5-hydroxymethylfurfural in foods. Trends Food Sci. Tech. 93, 271–280 (2019).

Gan, Y. M. et al. Current sample preparation strategies for the chromatographic and mass spectrometric determination of furfural compounds. Microchem. J. 191, 108797 (2023).

Martins, F. C. O. L. et al. The role of 5-hydroxymethylfurfural in food and recent advances in analytical methods. Food Chem. 395, 133539–133548 (2022).

Cao, G. D. et al. Mass Spectrometry for Analysis of Changes during Food Storage and Processing. J. Agric. Food Chem. 68, 6956–6966 (2020).

Silva, A. R. et al. Green solvents in dispersive liquid-liquid microextraction for the determination of carbonyl compounds in coffee extracts. J. Chromatogr. A 1745, 465743 (2025).

Karimi, S. & Shekaari, H. Application of acidic deep eutectic solvents in green extraction of 5-hydroxymethylfurfural. Sci. Rep. 12, 13113 (2022).

Tomasini, D. et al. Simultaneous determination of pesticides and 5-hydroxymethylfurfural in honey by the modified QuEChERS method and liquid chromatography coupled to tandem mass spectrometry. Talanta 99, 380–386 (2012).

Vazquez, L. et al. Optimization of a miniaturized solid-phase microextraction method followed by gas chromatography mass spectrometry for the determination of twenty four volatile and semivolatile compounds in honey from Galicia (NW Spain) and foreign countries. Sustain. Chem. Pharm. 21, 100451–100460 (2021).

Chen, D. et al. High throughput and very specific screening of anabolic-androgenic steroid adulterants in healthy foods based on stable isotope labelling and flow injection analysis-tandem mass spectrometry with simultaneous monitoring proton adduct ions and chloride adduct ions. J. Chromatogr. A 1667, 462891 (2022).

Wang, Z.-H. et al. Stable isotope labelling-flow injection analysis-mass spectrometry for rapid and high throughput quantitative analysis of 5-hydroxymethylfurfural in drinks. Food Control 130, 108386–108392 (2021).

Voukkali, I. et al. Fashioning the Future: Green chemistry and engineering innovations in biofashion. Chem. Eng. J. 497, 155039 (2024).

Huang, Y. et al. The crucial quality marker of Panax ginseng: Glycosylated modified ribonuclease-like storage protein. Int. J. Biol. Macromol. 282, 136894 (2024).

Zeng, X. et al. Application of Matrix-Assisted Laser Desorption Ionization Time-of-Flight Mass Spectrometry for Identification of Foodborne Pathogens: Current Developments and Future Trends. J. Agric. Food Chem. 72, 22001–22014 (2024).

He, H. et al. Recent advances in nanostructure/nanomaterial-assisted laser desorption/ionization mass spectrometry of low molecular mass compounds. Anal. Chim. Acta 1090, 1–22 (2019).

Hong, M. et al. Recent advances in the chemical-catalytic approaches for the production of 5-(halomethyl)furfurals from cellulose and its derivatives: A review. Int. J. Biol. Macromol. 282, 137194 (2024).

Li, X. et al. Plasmonic array assisted mass spectrometry for preferential metabolite detection. Chem. Eng. J. 486, 150224 (2024).

Zaikin, V. G. & Borisov, R. S. Options of the Main Derivatization Approaches for Analytical ESI and MALDI Mass Spectrometry. Crit. Rev. Anal. Chem. 52, 1287–1342 (2022).

Li, S. Q. et al. A new chemical derivatization reagent sulfonyl piperazinyl for the quantification of fatty acids using LC-MS/MS. Talanta 277, 126378 (2024).

Bergman, N. et al. Approaches for the analysis of low molecular weight compounds with laser desorption/ionization techniques and mass spectrometry. Anal. Bioanal. Chem. 406, 49–61 (2014).

Wu, P. et al. Development of C60-based labeling reagents for the determination of low-molecular-weight compounds by matrix assisted laser desorption ionization mass (I): Determination of amino acids in microliter biofluids. Anal. Chim. Acta 960, 90–100 (2017).

Qin, Z. N. et al. Development of C60-based labeling reagents for the determination of low-molecular-weight compounds by matrix assisted laser desorption ionization mass spectrometry (II): Determination of thiols in human serum. Anal. Chim. Acta 1105, 112–119 (2020).

Yin, S. J. et al. A metal-organic framework@hydrogen-bond framework as a matrix for MALDI-TOF-MS analysis of small molecules. Chem. Commun. 58, 6701–6704 (2022).

Wang, X. N. & Li, B. Monolithic Gold Nanoparticles/Thiol-beta-cyclodextrin-Functionalized TiO(2) Nanowires for Enhanced SALDI MS Detection and Imaging of Natural Products. Anal. Chem. 94, 952–959 (2022).

Fridjonsdottir, E. et al. Region-Specific and Age-Dependent Multitarget Effects of Acetylcholinesterase Inhibitor Tacrine on Comprehensive Neurotransmitter Systems. ACS Chem. Biol. 17, 147–158 (2022).

Zheng, R. et al. NH2NH-MOF: a reaction matrix for the specific determination of small aldehydes by MALDI-MS. Microchim. Acta 189, 51 (2022).

Sejalon-Cipolla, M. et al. Targeting out of range biomolecules: Chemical labeling strategies for qualitative and quantitative MALDI MS-based detection. TrAC Trends Anal. Chem. 143, 116399 (2021).

Horatz, K. et al. Polymerization as a Strategy to Improve Small Organic Matrices for Low-Molecular-Weight Compound Analytics with MALDI MS and MALDI MS Imaging. ACS Appl. Polym. Mater. 3, 4234–4244 (2021).

Xie, J. et al. Extraction and derivatization in single drop coupled to MALDI-FTICR-MS for selective determination of small molecule aldehydes in single puff smoke. Anal. Chim. Acta 638, 198–201 (2009).

Bu, X. M. et al. Matrix-assisted laser desorption/ionization high-resolution mass spectrometry for high-throughput analysis of androgenic steroid adulteration in traditional Chinese medicine based on d0/d5-Girard’s reagent P labeling. Talanta 253, 124006–124014 (2023).

Zang, Q. et al. Enhanced On-Tissue Chemical Derivatization with Hydrogel Assistance for Mass Spectrometry Imaging. Anal. Chem. 93, 15373–15380 (2021).

Chen, D. et al. One-pot derivatization/extraction coupled with liquid chromatography-tandem mass spectrometry for furfurals determination. Food Chem. 428, 136839–136845 (2023).

Zhang, A. et al. Nitrone formation: A new strategy for the derivatization of aldehydes and its application on the determination of furfurals in foods by high performance liquid chromatography with fluorescence detection. Talanta 178, 834–841 (2018).

Verissimo, M. I. et al. Determination of 5-hydroxymethylfurfural in honey, using headspace-solid-phase microextraction coupled with a polyoxometalate-coated piezoelectric quartz crystal. Food Chem. 220, 420–426 (2017).

Wang, X. et al. Novel class of aldehyde reductases identified from Scheffersomyces stipitis for detoxification processes in cellulosic ethanol production industry. Int. J. Biol. Macromol. 282, 136882 (2024).

Pereira, T. C. et al. Ultrasonication for honey processing and preservation: A brief overview. Food Res. Int. 174, 113579 (2023).

Guichard, E. Interactions between flavor compounds and food ingredients and their influence on flavor perception. Food Rev. Int. 18, 49–70 (2002).

Muala, W. C. B. et al. Optimization of extraction conditions of phenolic compounds from Cymbopogon citratus and evaluation of phenolics and aroma profiles of extract. Heliyon 7, e06744 (2021).

Xiong, Z. Q. et al. Functional characterization of a Colchicum autumnale L. double-bond reductase (DBR1) in colchicine biosynthesis. Planta 256, 95 (2022).

Sa, K. J. et al. Characterization of volatile compounds of crop (Perilla frutescens L.) in South Korea. Appl. Biol. Chem. 66, 41 (2023).

Ding, J. et al. A matrix-assisted laser desorption/ionization mass spectrometry method for the analysis of small molecules by integrating chemical labeling with the supramolecular chemistry of cucurbituril. Anal. Chim. Acta 1026, 77–86 (2018).

He, X. M. et al. Black phosphorus-assisted laser desorption ionization mass spectrometry for the determination of low-molecular-weight compounds in biofluids. Anal. Bioanal. Chem. 408, 6223–6233 (2016).

Plotka-Wasylka, J. A new tool for the evaluation of the analytical procedure: Green Analytical Procedure Index. Talanta 181, 204–209 (2018).

Pena-Pereira, F. et al. AGREE-Analytical GREEnness Metric Approach and Software. Anal. Chem. 92, 10076–10082 (2020).

Wojnowski, W. et al. AGREEprep - Analytical greenness metric for sample preparation. Trac-Trend Anal. Chem. 149, 116553 (2022).

Manousi, N. et al. Blue applicability grade index (BAGI) and software: a new tool for the evaluation of method practicality. Green Chem. 25, 7598–7604 (2023).

González-Martín, R. et al. A tool to assess analytical sample preparation procedures: Sample preparation metric of sustainability. J. Chromatogr. A 1707, 464291 (2023).

Győri, E. et al. Environment-Friendly Catalytic Mineralization of Phenol and Chlorophenols with Cu- and Fe- Tetrakis(4-aminophenyl)-porphyrin—Silica Hybrid Aerogels. Gels 8, 202 (2022).

Jokazi, M. et al. Photocatalytic activity of MnCl and Cu 5,10,15,20-Tetrakis(4-aminophenyl) porphyrins conjugated to graphene quantum dots against Rhodamine B dye using visible light. J. Water Process Eng. 71, 107188 (2025).

Prashanthi, S. et al. Reductive Fluorescence Quenching of the Photoexcited Free Base meso-Tetrakis (Pentafluorophenyl) Porphyrin by Amines. J. Fluoresc. 20, 571–580 (2010).

Chen, X. et al. A new method for the rapid identification of external water types in rainwater pipeline networks using UV–Vis absorption spectroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 324, 124968 (2025).

Wang, Z. F. et al. Research Progress of NMR in Natural Product Quantification. Molecules 26, 6308 (2021).

Kishikawa, N. et al. Chromatographic methods and sample pretreatment techniques for aldehydes determination in biological, food, and environmental samples. J. Pharm. Biomed. Anal. 175, 112782 (2019).

Song, D. et al. Research advances in detection of food adulteration and application of MALDI-TOF MS: A review. Food Chem. 456, 140070 (2024).

He, C. et al. Compositional identification and authentication of Chinese honeys by (1)H NMR combined with multivariate analysis. Food Res. Int. 130, 108936–108944 (2020).

Teixido, E. et al. Analysis of 5-hydroxymethylfurfural in foods by gas chromatography-mass spectrometry. J. Chromatogr. A 1135, 85–90 (2006).

Tu, X. et al. A Simple High-Throughput Field Sample Preparation Method Based on Matrix-Induced Sugaring-Out for the Simultaneous Determination of 5-Hydroxymethylfurfural and Phenolic Compounds in Honey. Molecules 27, 8373–8383 (2022).

Chernetsova, E. S. et al. Fast quantitation of 5-hydroxymethylfurfural in honey using planar chromatography. Anal. Bioanal. Chem. 401, 325–332 (2011).

Acknowledgements

We would like to thank the financial support from the National Key R&D Program of China (2021YFC2401105), National Natural Science Foundation of China (No. 82374018, No. 82003921), China Postdoctoral Science Foundation (2021M702937, 2023M733256), and the Henan Provincial Science and Technology Research Project (242102311184).

Author information

Authors and Affiliations

Contributions

Zhi Sun: writing of the original draft and funding acquisition. Fangfang Wang: writing of the original draft, and methodology. Peipei Zhou: methodology. Di Chen: writing-review & editing, funding acquisition, methodology, conceptualization. Lihua Zuo: writing-review & editing, funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, Z., Wang, F., Zhou, P. et al. Rapid and high-throughput analysis of 5-hydroxymethylfurfural in honey by MALDI-MS with in-situ tetra (4-aminophenyl)-porphyrin derivatization. npj Sci Food 9, 66 (2025). https://doi.org/10.1038/s41538-025-00431-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41538-025-00431-w