Abstract

Nanometal-based composite fibers have been widely explored in flexible sensors due to their outstanding optical and electrical properties. However, the weak binding force between metallic nanomaterial and fiber greatly limits the real application. In this work, nano silver (Ag) are strongly bonded with poly(3,4-ethylenedioxythiophene)-poly (styrene sulfonate) (PEDOT: PSS) fiber by the wet-spun process. Ag-S chemical bonds are formed by the interaction of Ag and PEDOT. The Ag/PEDOT: PSS composite fiber shows excellent surface-enhanced Raman scattering (SERS) sensitivity on Rhodamine 6G (R6G) molecules. The detection limit can reach 10–11 M and Raman enhancement factor (EF) is of 1.3 × 107. The high-sensitive SERS activity of Ag/PEDOT: PSS composite fiber mainly results from PEDOT: PSS, and the enhancement factor is 3 orders of magnitude better than that of other PEDOT: PSS based SERS substrates. Moreover, the composite fiber has metal-level conductivity of 1019 S/cm. This is 5 times higher than the conductivity of PEDOT: PSS fiber and a two-fold improvement over the reported values for nanometal/PEDOT: PSS based fabrics. The composite fiber has electric stability under bending test with bending speeds of 2 Hz indicating the composite fiber has good structural stability. In addition, the temperature of the composite fiber with 7 cm length can reach 76.5 °C at a voltage of 18 V. Additionally, the composite fiber shows anti-bacterial property and melting drop resistance, which pave the way for the integration of fiber-based optical and electrical sensors in the future multifunctional flexible devices.

Similar content being viewed by others

Introduction

High-performance optical sensors have been widely developed to detect traces of viruses, toxins and pesticide residue on human body or food, such as fluorescent sensor1,2, colorimetric sensor3,4, plasmonic sensors5,6,7 and surface-enhanced Raman scattering (SERS) sensors8,9,10. Among them, SERS sensors have been attracted much attentions due to the unique characteristics of low detection limit, label-free and high molecular specificity11. Currently, there are three kinds of SERS substrates: solution12, rigid13,14 and flexible substrates15,16,17. The development of colloidal and rigid SERS substrates are limited by the complicated sample pretreatment and weak scalability. Textile fibers with flexibility, good wearability and air permeability are promising substrates for in-situ and real-time monitor which extends the range of SERS applications18,19,20.

Noble metallic nanomaterials (gold, silver, etc.) are generally employed in fiber-based sensors, which are absorbed with fibers by immersion21, hot press22, dip-coating23,24, screen-printing25, dyeing26, or the combination of these methods. However, the weak bonding force between nanometals and textile fibers results in the poor performance of sensors. Currently, there are two methods to enhance the interaction between fiber and nanometals, containing blend spinning27,28 and in-situ growth29. In-situ growth of nanometals on cellulose fibers can introduce relatively strong absorption as cellulose can be used as stabilizing agent30. Carbon fiber cloth with oxygen defects introduced by the complicated hydrophilization treatment provides growth sites for the formation of silver nanoparticles31. For most types of fiber, metallic nanoparticles are in-situ grown on fiber surface through weak interaction32. Blend spinning is a promising way which adapts various fibers for wide applications. Metallic nanoparticles doped fiber-forming spinning solution have been reported to fabricate fiber-based SERS substrates, but the sensitivity still needs to be improved28,33. Semiconductors have been used with nanometals to improve fiber-based sensor sensitivity while the bond between semiconductor and nanometal is a weak electric attraction27,34. The way of strong chemical bonding between semiconductor fibers and nanometals needs to be further explored.

Organic semiconductor polymer poly(3,4-ethylenedioxythiophene)-poly(styrene sulfonate) (PEDOT: PSS) provides possible binding sites for metallic nanoparticles which can form the strong metal-sulfur bonds. PEDOT: PSS film with good biocompatibility has been used as a metal-free SERS substrate to detect 10− 3 M 4-mercaptobenzoic acid (4-MBA)35 and Raman enhancement factor (EF) is of 2.26 × 103 for methylene blue (MB) molecules36. However, there are few reports on nanometals/PEDOT: PSS composite fibers with high structural stability and high sensitivity for flexible SERS sensing. In addition, PEDOT: PSS shows excellent electrical properties. The electrical signals of PEDOT: PSS has been monitored to detect body temperature37 and strain38. High-conductive PEDOT: PSS has been used as an electrical conductor38,39,40. PEDOT: PSS is a promising candidate to integrate SERS and electrical sensors in future multi-functional fiber-based devices.

In this work, we fabricate Ag/PEDOT: PSS composite fiber by the wet spinning technology. The formation of Ag-S chemical bonds indicates the high structural stability of composite fiber. Under the combined effect of electromagnetic (EM) and charge transfer (CT) enhancements, the SERS detection limit of the composite fiber for Rhodamine 6G (R6G) reaches 10–11 M and Raman EF is of 1.3 × 107. In addition, the electric conductivity, electron-heat performance, antibacterial properties and melting drop resistance of composite fibers are also investigated. The Ag/PEDOT: PSS composite fiber is anticipated to pave the way towards the development of multifunctional fiber-based sensors.

Methods

Materials

PEDOT: PSS particles (Zhuhai Kaiwei Optoelectronics Technology Co., Ltd) and Ag NWs (XFJ95, XFNANO) were used as raw materials for wet spinning process (SEM image of Ag NWs can be seen from Supplementary Information Figure S1). The mixture of isopropanol (IPA, Sinopharm Chemical Reagent Co., Ltd) and dimethyl sulfoxide (DMSO, Sinopharm Chemical Reagent Co., Ltd) were used as coagulation bath. Rhodamine 6G (R6G) and ethanol were bought from Sinopharm Chemical Co., Ltd (Shaanxi, China). All chemicals and reagents used in this study were analytical grade and without further purification.

Characterization

The morphology, XPS spectra and Raman spectra of the fiber were characterized by the SEM (TESCAN MIRA LMS, Czech), X-ray photoelectron spectrometer (KRATOS, Axis UltraDLD) and Raman spectrometer (hr800, France HORIBA JobinYvon), respectively. The electrical property was investigated by obtaining the current–voltage (I–V) curve of the fiber using electrochemical workstation (CHI660e, China). The I-V curves of Ag/PEDOT: PSS composite fibers were measured at the length of 6, 9 and 12 cm respectively. The diameter of fiber can be obtained from SEM image, which is used to calculate the fiber conductivity through the following formula:

σ is the conductivity of fiber/(S/cm). ρ is the resistivity of fiber/(Ω · cm); I is the current of fiber/A. U is the voltage / V. S is the cross-sectional area of fiber/cm2. L is the length of fiber/cm.

The bending fatigue resistance of conductive fibers was tested in the three-point bending mode of fatigue test machine (FlexTest-TM-L, Hunan NanoUp Electronics Technology Co., LTD, China) by the electrochemical workstation, and the resistance change was detected in real time during the pressure test. The test was set to displacement loading with bending speeds of 2 Hz and bending degrees of 0 (initial state) and 125 (bend state). To verify the electric-heating performance, a voltage between 0 and 18 V was applied using the DC Power Supply (MP10010D, China). Thermal images were recorded by a thermal imaging cameras (Fluke PTi120, FLUKE, USA) with an infrared (IR) resolution of 120 × 90 (10,800 pixels). The antibacterial performance of composite fiber is test using the standard test method (GB/T 20944.1–2007, China). The Raman enhancement factors (EFs) of fiber-based SERS substrates were calculated by the formula of EF (EF = (ISERS · CNormal) / (INormal · CSERS), where ISERS and INormal are the Raman intensities of SERS and without SERS, CSERS and CNormal are molecular concentration to be measured during SERS detection and when there is no SERS)41. The laser wavelength of 532 nm, exposure time of 10 s and laser power of 0.5 mW were setted in Raman measurement.

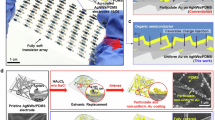

Preparation of Ag/PEDOT: PSS composite fibers

Ag/PEDOT: PSS composite fibers were fabricated by the wet spinning method as shown in Fig. 1a. For more details, aqueous PEDOT: PSS dispersion (0.0526 g/ml) and Ag NWs solution with concentration of 0.0667 g/ml were prepared and stirred at 500 r/min for 30 min respectively. Then 0.6 ml of Ag NWs solution was added into 1.4 ml of PEDOT: PSS dispersion and the mixture was used as the spinning solution. The mixture of IPA and DMSO (volume ratio of 3:1) was used as coagulation bath. The spinning solution was extruded into the coagulation bath at the speed of 5 ml/h. After 24 h immersion at room temperature, the composite fiber was dried at 60 °C for 30 min for further use. The reproducibility of the preparation method can be seen from the Supplementary Information Figure S2. The produced Ag/PEDOT: PSS composite fiber can be spirally twined on a finger, and carry a weight of 50 g without fracture (Fig. 1b).

Preparation and characterization of Ag/PEDOT: PSS composite fiber. (a) Schematic diagram of preparation of wet-spun composite fiber. (b) Optical images of composite fiber on a finger and carrying a weight of 50 g. (c) SEM images of composite fiber. (d) Magnified SEM images of composite fiber. The inset shows Ag nanoparticles on composite fibers. (e) EDS spectra of composite fiber. (f) SEM image of the cross-section of composite fiber. (g) XPS spectrum of composite fiber. The corresponding high-resolution Ag 3d (h) and S 2p (i) XPS spectra.

Results and discussion

Morphology of Ag/PEDOT: PSS composite fiber

The schematic diagram of preparation of wet-spun Ag/PEDOT: PSS composite fibers is displayed in Fig. 1a. From the SEM images in Fig. 1c, we can see the surface of Ag/PEDOT: PSS composite fiber with uniform diameter (~ 103 μm) has small grooves due to the fast diffusion between coagulation bath and solvent in spinning solution. The magnified SEM image of composite fiber in Fig. 1d shows Ag NWs are well dispersed and partially orientated in PEDOT: PSS, which can attribute to strong shear forces generated by the gradually narrowed spinning channel in the wet‑spinning process. It is found that many nanoparticles (NPs) appear at the surface of composite fiber, especially some NPs are oriented along the length direction of Ag NWs. The corresponding EDS spectra of composite fiber in Fig. 1e displays the existence of oxygen (O), carbon (C), sulphur (S) and silver (Ag) elements, indicating the composite fiber surface are decorated with Ag NPs. From the SEM image of cross section of composite fiber (Fig. 1f), we can see Ag NWs completely exist inside the fiber. Through tracing the fabrication process of composite fiber, it is found that Ag NPs are formed on composite fiber surface after the drying process (see Supplementary Information Figure S3). We infer that the fiber structure with Ag NWs inside and Ag NPs outside results from the interaction of Ag and PEDOT and the strong force applied to Ag NWs on fiber surface during drying. To further examine the attachment of Ag to PEDOT: PSS, XPS spectrum of composite fiber is displayed at Fig. 1g showing the different peaks of O, C, S and Ag elements. The high-resolution Ag 3d XPS spectrum is presented in Fig. 1h. Two peaks positioned at 368.4 eV and 374.4 eV are attributed to the binding energies of Ag 3d5/2 and Ag 3d3/2. The high-resolution S 2p XPS spectra of composite fiber and pure PEDOT: PSS fiber is shown in Fig. 1i, where two pairs of sub-peaks appear with S from PEDOT at low binding energy and PSS at high binding energy respectively42. Notably, after doping Ag an evident shift to higher energy is found for the S 2p peak assigned to PEDOT, while the S 2p peak position of PSS remains unchanged. The peak located at 162.4 eV results from the interaction of PEDOT and Ag forming the strong chemical bond of Ag-S43. The formation of such a chemical bond is able to link Ag strongly to PEDOT: PSS, resulting in a high structural-stable Ag/PEDOT: PSS composite fiber.

SERS performance of Ag/PEDOT: PSS composite fiber

Ag NPs bonded with PEDOT: PSS fiber through strong chemical Ag-S bonds give possibility to high-performance fiber-based SERS sensing. Here, different concentrations of R6G molecules are selected to evaluate SERS sensitivity of Ag/PEDOT: PSS composite fiber, as shown in Fig. 2a. This selection is motivated by the strong resonant Raman effect exhibited by R6G molecules within the visible spectrum. Distinctive peaks (611 cm–1, 771 cm–1 and 1503 cm−1) associated with R6G are marked. The decreased Raman intensity are visible with decreasing R6G concentration, and the detection limit can reach as low as 10− 11 M. The spectral feature located at 611 cm− 1 remains unobscured by the presence of PEDOT: PSS peaks, rendering it the most optimal selection for assessing the Raman EF of the composite fiber. The calculated Raman EF is 1.3 × 107, indicating an exceptionally high level of performance for the textile fiber-based SERS substrate. Figure 2b shows the intensity distribution histogram corresponding to R6G peak at 611 cm− 1 when R6G molecules with concentration of 10− 11 M are measured at 20 random points on composite fiber. The relative standard deviation (RSD) is calculated at 8.57%, which demonstrates the good homogeneity of composite fiber.

SERS performance of Ag/PEDOT: PSS composite fiber. (a) Raman spectra of 10− 11 − 10− 9 M R6G detected on composite fiber. (b) Raman spectra of 10− 11 M R6G on composite fiber from twenty collection points. (c) Raman spectra of pure PEDOT: PSS fiber and composite fiber with/without 10− 5 M R6G. The potential charge transfer processes in PEDOT: PSS/R6G (d) and PEDOT: PSS/Ag/R6G (e) systems under 532 nm laser excitation. (f) SERS detection limit of composite fiber and other reported flexible fiber-based substrate.

For comparison, neat PEDOT: PSS fiber is prepared by wet spinning of an aqueous PEDOT: PSS dispersion. Figure 2c displays the characteristic Raman peaks of pure PEDOT: PSS fiber and composite fiber with/without 10− 5 M R6G. Both pure PEDOT: PSS fiber and composite fiber with 10− 5 M R6G show obvious signals at 611 cm− 1, while the peak intensity of composite fiber is about 3 times higher than that of pure PEDOT: PSS fiber. From the finite-difference time-domain (FDTD) simulation results (see Supplementary Information Figure. S4), the SERS enhancement of composite fiber caused by the EM enhancement of Ag NPs is relatively weak, which is at least 2 orders of magnitude poorer than other dense metallic NPs with small gap21,44. The SERS enhancement of composite fiber can be mainly attributed to the EM enhancement of PEDOT: PSS36 and the photo-induced CT processes occurring in PEDOT: PSS/Ag/R6G. The possible CT in the PEDOT: PSS/R6G system and PEDOT: PSS/Ag/R6G system, induced by 532 nm laser excitation are illustrated in Fig. 2d,e. The energy levels of the highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO) levels for R6G are quantified at − 5.35 eV and − 3.28 eV respectively45. The energy levels corresponding to the HOMO and the LUMO of PEDOT: PSS are measured at − 6.20 eV and − 5.50 eV, respectively46. The Fermi level of Ag is determined to be at − 4.84 eV (vs. vacuum level)47. For the PEDOT: PSS/R6G system under 532 nm laser excitation, the electrons located in HOMO level will absorb the energy of photon and be excited to LUMO level of R6G. Moreover, the electrons located in HOMO level of R6G can relax to the LUMO level of PEDOT: PSS. On the other hand, the electrons located in HOMO level of PEDOT: PSS will absorb the energy of photon and are excited to LUMO level.

For the PEDOT: PSS/Ag/R6G system, when Ag and PEDOT: PSS are in contact, the equilibrium surface state is constructed as the Ag-S bond formed in the contact interface of composite fiber as proved in Fig. 1i and electron migration occurs from the metal to the organic semiconductor driven by the difference in work function. The electrons can be excited from the LUMO level of R6G to the LUMO level of resonance complex formed by the combination of Ag and PEDOT: PSS. Consequently, enhancements of Raman scattering from PEDOT: PSS mainly imparts high-sensitive SERS activity to the Ag/PEDOT: PSS composite fiber, which exhibits 3 orders of magnitude better than EF of other PEDOT: PSS based SERS substrates (see Table 1). In addition, the comparison of the SERS detection limit on R6G for different metal-fiber composites is shown in Fig. 2f21,28,32,34,48,49,50,51,52,53. The detection limit of R6G molecules on Ag/PEDOT: PSS composite fiber substrate is comparable with other metal-fiber substrates, and the structure of Ag/PEDOT: PSS composite fiber is more stable which can be prepared by a feasible and easy fabricated way.

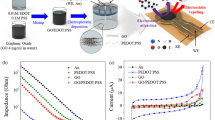

Electrical properties of Ag/PEDOT: PSS composite fiber

Both PEDOT: PSS and Ag have good electrical properties, indicating Ag/PEDOT: PSS composite fiber can be served as a conductive fiber. The I-V curves of Ag/PEDOT: PSS composite fiber with different lengths are shown in Fig. 3a. The resistance of composite fiber increases with the increased fiber length. Figure 3b displays the corresponding electrical conductivity of composite fiber, which reaches up to 1019 S/cm, 5 times higher than that of pure PEDOT: PSS fiber (~ 239 S/cm). This is, to the best of our knowledge, a two-fold improvement over the best previously reported value for nanometal-PEDOT: PSS based fabrics (426 S/cm)57. The bending stability of composite fiber with the highest conductivity is investigated in Fig. 3c. It can be seen that under 2 Hz bending the change of fiber resistance is increased to 0.5–1.5% at the initial stage and then kept almost unchanged even after 4000 times bending, which further indicates the composite fiber has good structural stability. In addition, the static contact angle of composite fiber is 44.9° (inset of Fig. 3d) indicating the surface of composite fiber is hydrophilic. We also check the influence of PU encapsulation on the electrical properties (Fig. 3d) and water washing performance of composite fiber (Fig. 3e). Although the fiber conductivity decreases from 1019 to 822 S/cm after PU package, the water-proof performance of encapsulated composite fiber is excellent. The electric conductivity of encapsulated composite fiber is kept at 700 S/cm after 10 min of water washing.

Electrical properties of Ag/PEDOT: PSS composite fiber. (a) I–V curves of composite fibers with different lengths. (b) Electrical conductivities of PEDOT: PSS fibers and composite fibers. (c) The electrical resistance stability of composite fiber under bending. (d) I–V curves of composite fibers before and after PU package. The inset shows the static contact angle of composite fiber. (e) Conductivity of PU encapsulated composite fiber during the water washing processes.

Multifunctionality of Ag/PEDOT: PSS composite fiber

Electrothermal performances of Ag/PEDOT: PSS composite fibers are shown in Fig. 4a–d. Figure 4a shows the electric heating property of composite fiber under varying driving voltages. The temperature of composite fiber at 3 V, 6 V, 9 V, 12 V, 15 V and 18 V can reach to 33.5 °C, 36.8 °C, 40.7 °C, 52.3 °C, 61.7 °C and 76.5 °C, respectively. As depicted in Fig. 4b, Ag/PEDOT: PSS composite fiber can be rapidly heated up to 76.5 °C in a short period of time (< 70 s) and maintain the surface temperature stable during a relative long time (> 1000 s), indicating the excellent heating reliability. At an applied voltage of 18 V, the composite fiber achieves a maximum surface temperature of approximately 76.5 °C, surpassing the threshold typically necessary for human thermal therapy, indicating the potential applications as wearable heater for human body. In addition, the composite fibers would be woven into fabrics as industrial electric heating blanket for de-icing, and surface heat sources to drive the complex, intelligent structures like shape memory alloy and polymer. When the Ag/PEDOT: PSS composite fiber is heated by increases and decreases of voltage, there is no obvious energy loss, exhibiting excellent stability and recyclability as illustrated in Fig. 4c. In Fig. 4d, the IR images further emphasize the uniformity of heat distribution within the composite fibers, which is important for electric heater. The antibacterial ability of composite fiber is explored using Escherichia coli (E. coli, gram negative) and Staphylococcus aureus (S. aureus, gram positive) as shown in Fig. 4e. Both bacteriostatic band diameters are above 1 mm indicating good antibacterial effect of composite fiber, as Ag can release silver ions to inhibit E. coli and S. aureus. In addition, the melting drop resistance of composite fiber is investigated in Fig. 4f. There is no appearance of melting drop throughout the entire combustion process. All these results indicate that the flexible, super‑tough Ag/PEDOT: PSS composite fibers with outstanding SERS performance and electrical conductivity are promising for development of textile fiber-based multifunctional flexible devices. Ag/PEDOT: PSS composite fibers can be woven into different parts of the same garment through the precise fabric design, such as the front chest for sweat SERS sensing, knee for electric heating, waist for electric conducting. Consequently, many Ag/PEDOT: PSS composite fibers can be integrated in intelligent clothing, which realizing the integration of flexible optical and electric devices.

Multifunctionality of Ag/PEDOT: PSS composite fiber. (a) Electric heating performance of composite fiber at different driving voltages. (b) Temperature stability of composite fibers at a constant voltage of 18 V. (c) Temperature change of composite fiber under increasing and decreasing voltage. (d) IR images showing the saturated temperature of composite fiber with length of 7 cm at different driving voltages. (e) Digital images of E. coli and S. aureus cultured on composite fibers. (f) Digital images showing the combustion process at varying times for composite fiber.

Conclusions

In this work, high-structural stability of Ag/PEDOT: PSS composite fibers with high-sensitive SERS sensing and high electrical conductivity are fabricated by wet spinning method via simply doping Ag NWs in the spinning solution. The interaction between Ag and PEDOT results in the formation of Ag-S bond which links Ag strongly to PEDOT: PSS. The composite fibers show low SERS detection limit (10− 11 M of R6G) and Raman EF (1.3 × 107), which results from the synergistic reaction of EM enhancement and CT enhancement of the PEDOT: PSS/Ag/R6G system. Moreover, Ag/PEDOT: PSS composite fiber has a metal-level electrical conductivity due to the incorporation of Ag/PEDOT: PSS conductive network. The conductivity of Ag/PEDOT: PSS composite fiber is 1019 S/cm which is 5 times higher than that of pure PEDOT: PSS fiber. In addition, the saturated temperature of composite fiber can reach to 76.5 °C within 70 s under 18 V and last for above 1000 s indicating the good electrothermal performances of composite fiber. Furthermore, the good antibacterial property and melting drops resistance make Ag/PEDOT: PSS composite fiber highly promising in textile fiber-based integrated multifunctional flexible devices.

Data availability

Data is provided within the manuscript or supplementary information files.

References

He, K. et al. Highly selective recognition and fluorescent detection of JEV via virus-imprinted magnetic silicon microspheres. Sens. Actuator B-Chem. 233, 607–614 (2016).

He, H. Y., Sun, D. W., Wu, Z. H., Pu, H. B. & Wei, Q. Y. On-off-on fluorescent nanosensing: materials, detection strategies and recent food applications. Trends Food Sci. Technol. 119, 243–256 (2022).

Yang, L. et al. Visual detection of aldehyde gases using a silver-loaded paper-based colorimetric sensor array. Talanta 280, 126716 (2024).

Mirzaei, Y., Gholami, A., Sheini, A. & Bordbar, M. M. An origami-based colorimetric sensor for detection of hydrogen peroxide and glucose using sericin capped silver nanoparticles. Sci. Rep. 13, 7064 (2023).

Wu, F. et al. Ultrasensitive and rapid detection of malaria using graphene-enhanced surface plasmon resonance. 2D Mater. 7, 045019 (2020).

Li, Y. et al. Flexible wearable plasmonic paper-based microfluidics with expandable channel and adjustable flow rate for portable surface-enhanced raman scattering sweat sensing. ACS Photonics. 11, 613–625 (2024).

Wu, F. et al. Layered material platform for surface plasmon resonance biosensing. Sci. Rep. 9, 20286 (2019).

Payne, T. D. et al. Catching COVID: Engineering peptide-modified surface-enhanced raman spectroscopy sensors for SARS-CoV-2. ACS Sens. 6, 3436–3444 (2021).

Zhang, X. et al. Surface-enhanced Raman spectroscopy for environmental monitoring using gold clusters anchored on reduced graphene oxide. Sci. Total Environ. 856, 158879 (2023).

Yang, J. et al. Application of serum SERS technology combined with deep learning algorithm in the rapid diagnosis of immune diseases and chronic kidney disease. Sci. Rep. 13, 15719 (2023).

Langer, J. et al. Present and future of surface-enhanced Raman scattering. ACS Nano. 14, 28–117 (2020).

Chen, Z. et al. Rapid detection of residual chlorpyrifos and pyrimethanil on fruit surface by surface-enhanced Raman spectroscopy integrated with deep learning approach. Sci. Rep. 13, 19855 (2023).

Luo, X. et al. Femtosecond laser micro-nano structured Ag SERS substrates with unique sensitivity, uniformity and stability for food safety evaluation. Opt. Laser Technol. 139, 106969 (2021).

Cui, S. F., Yang, H. L., Huang, X. & Wan, J. W. Identification and classification of ATS in oral fluid based on Ag nanoassemblies on Si surface doped with au nanobipyramids. Sci. Rep. 13, 14526 (2023).

Yang, K., Wang, Z. & Zhang, J. High sensitivity D-shaped fiber decorated with self-assembly ag nanoparticles for Raman enhancement via collecting backward and vertical direction scattering signals. Opt. Laser Technol. 164, 109533 (2023).

Yi, S. et al. Highly sensitive flexible SERS substrates with a sandwich structure for rapid detection of trace pesticide residues. Appl. Surf. Sci. 654, 159455 (2024).

Wu, F., Wang, W., Xu, Z. & Li, F. Bromide (Br) - based synthesis of Ag nanocubes with high-yield. Sci. Rep. 5, 10772 (2015).

Xu, K., Zhou, R., Takei, K. & Hong, M. Toward flexible surface-enhanced Raman scattering (SERS) sensors for point-of-care diagnostics. Adv. Sci. 6, 1900925 (2019).

Xie, L. et al. State of the art in flexible SERS sensors toward label-free and onsite detection: from design to applications. Nano Res. 15, 4374–4394 (2022).

Lee, K. P., Yip, J., Yick, K. L., Lu, C. & Lo, C. K. Textile-based fiber optic sensors for health monitoring: a systematic and citation network analysis review. Text. Res. J. 92, 2922–2934 (2021).

Wu, F. et al. Construction of dense plasmonic hotspots on coarse ag layer coated nylon fibers for ultrasensitive SERS sensing. Text. Res. J. 93, 664–673 (2023).

Zhou, B. et al. Flexible MXene/silver nanowire-based transparent conductive film with electromagnetic interference shielding and electro-photo-thermal performance. ACS Appl. Mater. Inter. 12, 40859–40869 (2020).

Zhao, X. et al. Smart Ti3C2Tx MXene fabric with fast humidity response and joule heating for healthcare and medical therapy applications. ACS Nano. 14, 8793–8805 (2020).

Zheng, Y. et al. Conductive MXene/cotton fabric based pressure sensor with both high sensitivity and wide sensing range for human motion detection and e-skin. Chem. Eng. J. 420, 127720 (2021).

Li, X. J. et al. A wearable screen-printed SERS array sensor on fire-retardant fibre gloves for on-site environmental emergency monitoring. Anal. Methods. 14, 781–788 (2022).

Ahmed, H. B., Emam, H. E., Mashaly, H. M. & Rehan, M. Nanosilver leverage on reactive dyeing of cellulose fibers: color shading, color fastness and biocidal potentials. Carbohydr. Polym. 186, 310–320 (2018).

Liu, X. et al. Large-scale fabrication of flexible macroscopic SERS substrates with high sensitivity and long-term stability by wet-spinning technique: uniform encapsulation of Plasmon in graphene oxide fibers. Appl. Surf. Sci. 654, 159513 (2024).

Zhang, Y., Zhou, J., He, Y., Ye, Y. & An, J. SERS active fibers from wet-spinning of alginate with gold nanoparticles for pH sensing. Spectroc Acta Pt A-Molec Biomolec Spectr. 271, 120848 (2022).

Sun, N. et al. UV-catalyzed TiO2-based optofluidic SERS chip for three online strategies: fabrication, detection, and self-cleaning. Anal. Chem. 96, 9104–9112 (2024).

Chen, J., Huang, M. & Kong, L. Flexible Ag/nanocellulose fibers SERS substrate and its applications for in-situ hazardous residues detection on food. Appl. Surf. Sci. 533, 147454 (2020).

Sun, N., Lv, Z., Zhu, Y. & Zhang, J. Raman enhancement properties of TiO2/Ag carbon fiber cloth using the ultraviolet-induced method: high sensitivity, flexible and reusable. Opt. Mater. Express. 13, 586–597 (2023).

Liu, X. et al. Plasmonic coupling of au nanoclusters on a flexible MXene/ graphene oxide fiber for ultrasensitive SERS sensing. ACS Sens. 8, 1287–1298 (2023).

Skwierczynska, M., Wozny, P., Runowski, M., Kulpinski, P. & Lis, S. Optically active plasmonic cellulose fibers based on au nanorods for SERS applications. Carbohydr. Polym. 279, 119010 (2022).

Liu, X. et al. Efficient multiplexed label-free detection by flexible MXene/graphene oxide fibers with enhanced charge transfer and hot spots effect. Sens. Actuator B-Chem. 390, 133888 (2023).

Han, B. et al. Probing the charge-transfer of Ag/PEDOT:PSS/4-MBA by surface-enhanced raman scattering. Spectroc Acta Pt A-Molec Biomolec Spectr. 239, 118451 (2020).

Zhang, X. Y. et al. Carrier dynamic monitoring of a π-conjugated polymer: a surface-enhanced Raman scattering method. Chem. Commun. 56, 2779–2782 (2020).

Fan, W. et al. An antisweat interference and highly sensitive temperature sensor based on poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) fiber coated with polyurethane/graphene for real-time monitoring of body temperature. ACS Nano. 17, 21073–21082 (2023).

Luo, R., Li, X., Li, H., Du, B. & Zhou, S. A stretchable and printable PEDOT:PSS/PDMS composite conductors and its application to wearable strain sensor. Prog Org. Coat. 162, 106593 (2022).

Cho, H. S., Jang, E., Liu, H. & Cho, G. Applicability of poly(3,4-ethylenedioxythiophene): poly(styrene sulfonate) impregnated polyurethane nanoweb as a transmission line for smart textiles. Text. Res. J. 91, 1253–1262 (2020).

Shi, W. et al. High-sensitivity and extreme environment-resistant sensors based on PEDOT:PSS@PVA hydrogel fibers for physiological monitoring. ACS Appl. Mater. Inter. 14, 35114–35125 (2022).

Le Ru, E. C., Blackie, E., Meyer, M. & Etchegoin, P. G. Surface enhanced Raman scattering enhancement factors: a comprehensive study. J. Phys. Chem. C. 111, 13794–13803 (2007).

Chen, Y. P. et al. Integrated ionic-additive assisted wet‐spinning of highly conductive and stretchable PEDOT:PSS fiber for fibrous organic electrochemical transistors. Adv. Electron. Mater. 7, 2100231 (2021).

Pan, X. F. et al. Strong and stiff ag nanowire-chitosan composite films reinforced by Ag-S covalent bonds. Nano Res. 11, 410–419 (2017).

Yang, C. et al. Synergistic effects of semiconductor substrate and noble metal nano-particles on SERS effect both theoretical and experimental aspects. Appl. Surf. Sci. 436, 367–372 (2018).

Zhao, Y. et al. Enhanced SERS stability of R6G molecules with monolayer graphene. J. Phys. Chem. C. 118, 11827–11832 (2014).

Iwan, A. et al. Electrochemical and photocurrent characterization of polymer solar cells with improved performance after GO addition to the PEDOT:PSS hole transporting layer. Sol Energy. 146, 230–242 (2017).

Zhang, X. et al. Charge-transfer effect on surface-enhanced Raman scattering (SERS) in an ordered ag NPs/4-mercaptobenzoic acid/TiO2 system. J. Phys. Chem. C. 119, 22439–22444 (2015).

Shao, F. et al. Preparation of hydrophobic film by electrospinning for rapid SERS detection of trace triazophos. Sensors 20, 4120 (2020).

Mondal, S., Rana, U. & Malik, S. Facile decoration of polyaniline fiber with Ag nanoparticles for recyclable SERS substrate. ACS Appl. Mater. Inter. 7, 10457–10465 (2015).

Ge, F., Chen, Y., Liu, A., Guang, S. & Cai, Z. Flexible and recyclable SERS substrate fabricated by decorated TiO2 film with ag NPs on the cotton fabric. Cellulose 26, 2689–2697 (2019).

Li, G. J. et al. Nanoporous Ag prepared from the melt-spun Cu-Ag alloys. Solid State Sci. 13, 1379–1384 (2011).

Turasan, H., Cakmak, M. & Kokini, J. Fabrication of zein-based electrospun nanofiber decorated with gold nanoparticles as a SERS platform. J. Mater. Sci. 54, 8872–8891 (2019).

Dang, A. et al. Electrospun gold nanoprism/poly(vinyl alcohol) nanofibers for flexible and free-standing surface-enhanced Raman scattering substrates. ACS Appl. Nano Mater. 5, 6650–6658 (2022).

Wang, X., Lu, A., Bai, Z. & Xu, T. A multilayer interlaced ag nanosheet film prepared by an electrodeposition method on a PPy@PEDOT:PSS film: a strategy to prepare sensitive surface-enhanced raman scattering substrates. ACS Omega. 7, 9380–9387 (2022).

Wang, X. Q., Jiang, J. G., Zhang, Q. Q. & Bai, Z. C. The high active SERs substrate prepared by self assembling Ag nanoparticles on PPy@PEDOT:PSS film to detect the sodium formaldehyde sulfoxylate molecules. Opt. Mater. 114, 110955 (2021).

Wang, K. S. et al. Electrochemical polymerization of PEDOT:PSS with graphene oxide and silver nanoparticles for antibacterial coating and SERS detection. Surf. Coat. Tech. 485, 130889 (2024).

Alamer, F. A. & Beyari, R. F. Overview of the influence of silver, gold, and titanium nanoparticles on the physical properties of PEDOT:PSS-coated cotton fabrics. Nanomaterials 12, 1609 (2022).

Acknowledgements

This work was supported by Shaanxi Fundamental Science Research Project for Mathematics and Physics (Grant No. 23JSQ020), Agricultural Technological Breakthroughs General Project of Xi’an Science and Technology Bureau (Grant No. 24NYGG0115), the Open Projects of State Key Laboratory for Manufacturing Systems Engineering, Xi’an Jiaotong University (Grant No. sklms2023011), National Natural Science Cultivation Project of Xi’an university of architecture and technology (Grant No. x20230039), National Natural Science Foundation of China Youth Fund (Grant No. 62305312). The author(s) would like to thank Ms. Zhang YuYao from Shiyanjia Lab (www.shiyanjia.com) for her assistance with the antibacterial experiments and Ms. Lin Cheng from Xi’an Polytechnic University (School of science) for her assistance in using the Laser Raman Spectrometer.

Author information

Authors and Affiliations

Contributions

F. W. conceived the experiment(s). F. W., H. S., Y. G., Z. C. and T. L. conducted the experiment(s). L. C. and T. G. did the simulations. F. W. and H. S. performed statistical analysis and figure generation. F. W. wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, F., Shi, H., Gao, Y. et al. Wet-spun Ag/PEDOT: PSS composite fibers for high-sensitive SERS sensing and high electrical conducting. Sci Rep 14, 29219 (2024). https://doi.org/10.1038/s41598-024-80655-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-80655-0