Abstract

A Copper-Carbon (Cu–Carbon) hybrid interconnect has been recently proposed for future VLSI applications, offering superior electrical performance compared to traditional interconnect structures. In the present era of high operating frequency, it is important to test this new structure for noise constrained applications specifically. In this work, ABCD parameter based analytical AC model of Cu–Carbon hybrid interconnects has been developed for efficient noise estimation in nanoscale systems. Several signal transmission parameters, noise parameters and frequency dependent complex conductivity and impedances of Cu–Carbon hybrid interconnects are estimated and compared with conventional copper (Cu) interconnects and emerging alternative copper-carbon nanotube (Cu-CNT) composite interconnects. The developed model is also verified with Advanced Design System (ADS) software. Cu–Carbon hybrid interconnects have the lowest impedance among other alternative configurations. Compared to copper, Cu–Carbon hybrid interconnect (with \(F_{cnt}\)=0.6) possesses \(\sim\)80% lower impedance at 100 GHz frequency. Cu–Carbon hybrid experiences lowest return loss and highest forward transmission gain as compared to Cu and Cu-CNT composite interconnects. It demonstrates \(\sim\)43% and \(\sim\)48% lower \(S_{11}\) and \(\sim\)30% and \(\sim\)38% higher \(S_{21}\) values than copper at 100 GHz for single and 2-line coupled interconnects, respectively. At lower frequencies, all interconnects have comparable crosstalk noise profiles. The percentage improvement in the noise figure (in dB) and noise factor of Cu–Carbon hybrid is \(\sim\)48% and \(\sim\)98% at 100 GHz, respectively as compared with Cu interconnect. These analysis strengthens the claim of Cu–Carbon hybrid interconnect to be a worthier possibility for high frequency noise constrained applications in next-generation nanoscale systems.

Similar content being viewed by others

Introduction

To satisfy modern technology requirements, device dimensions are being reduced. However, merely shrinking device sizes is insufficient to significantly reduce overall chip delay, as interconnect delay remains a major contributing factor1. Therefore, it is equally, if not more, crucial to scale down interconnect dimensions. Scaled-down copper interconnects exhibit significantly higher effective resistivity compared to bulk copper. Copper interconnects are increasingly unable to meet current technological demands due to issues like grain-boundary scattering and electro-migration degradation, which push them to their operational limits2. The IRDS 2021 roadmap3 indicates that with the rise in both operating frequency and transistor count, sustaining both simultaneously has become virtually unfeasible. To ensure ICs can function within practical thermal limits, it has become necessary to stabilize either the number of transistors or the operating frequency. This issue is targeted here by analyzing Cu–Carbon hybrid interconnects at GHz frequency range. Nowadays high performance mixed-signal systems tap into all the domains i.e. digital, analog, RF etc. For designs with lower supply voltages, higher clock frequencies, dynamic logic usage, analog and microwave requirements, noise effects become prominent since these applications have lower noise margin4,5. Specially, these noise effects needs to be studied for interconnects as they run in parallel and are prone to crosstalk and interference6. As a result, finding an alternative to the conventional interconnect system has become imperative. Carbon nanomaterials, such as carbon nanotubes (CNTs) and graphene nanoribbons, have been extensively studied and identified as promising candidates for next-generation interconnect applications7. Fundamental research on carbon-based nano interconnects, as reported in8,9,10,11, indicates that these materials offer higher ampacity, longer mean free path (MFP), and better thermal conductivity compared to copper interconnects.

Graphene nanoribbons have already been considered as a suitable candidate for RF interconnects12. Chen et. al. in13 experimentally demonstrated fully integrated carbon nanotube and graphene interconnects for high-speed CMOS electronics at gigahertz frequency range which is a crucial requirement in present on-chip technology. Copper carbon nanotube (Cu-CNT) composites, composed of CNT bundles and copper, are being considered as potential replacements for conventional interconnects in the near future14,15. The CNT bundles enhance performance due to their exceptional nanoscale properties. Additionally, their rectangular orientation allows for better alignment with contact pads compared to cylindrical CNTs, improving compatibility with CMOS fabrication processes. Sundaram et al. demonstrated in16 that the electro-deposition method can achieve a CNT volume fraction in the composite of more than 0.6.

Zhao et. al. conducted a high-frequency analysis of Cu-CNT through-silicon via (TSV) and Cu-graphene heterogeneous interconnects in17,18 and19, respectively. They found that co-depositing CNT with copper in the composite led to improvement in the electrical conductivity of the TSVs when compared to pure CNT TSVs and also that the resistive loss can be suppressed with multilayer graphene introduced in copper.

Cu–Carbon hybrid introduced as a novel structure in20, depicted in Fig. 1 is build upon the Cu-CNT composite interconnects explored in previous works, such as14,15. Our work introduces a graphene liner to this configuration, aiming to further reduce resistive losses and improve overall performance in high-frequency applications. This addition marks a significant advancement by addressing the limitations observed in earlier designs, such as increased impedance at high frequencies. We presented an electrical model for this Cu–Carbon hybrid and evaluated its electrical performance in terms of delay, noise, and power metrics, demonstrating its superior performance as an interconnect20. Recently, Park et al. fabricated this structure21 and confirmed that it exhibited excellent electrical, mechanical, and thermal properties, leading to overall performance improvements. However, to further validate its potential as an alternative to copper, other aspects of signal transmission need exploration. This paper introduces, for the first time, an ABCD parameter-based high-frequency model for Cu–Carbon hybrid interconnects, analyzing and comparing its transmission parameters with Cu-CNT composite and copper interconnects. The ABCD parameter-based22 analytical AC model is utilized to accurately estimating noise parameters in nanoscale systems. Figure 2 illustrates the configurational differences between the innovative Cu–Carbon hybrid and existing structures, including copper and Cu-CNT composites.

The remainder of the paper is organized as follows: “Results and discussion” section presents the simulation results. “Formulation and methodology” section proposes the high frequency model of Cu–Carbon hybrid interconnect structure. Finally, “Conclusion” section concludes this paper.

Results and discussion

The modeling and simulations were conducted using MATLAB software, version R2021b, on a standard desktop environment. The proposed model was verified with ADS software. This study assumes armchair CNT and zigzag graphene nanoribbon (GNR) configurations due to their metallic properties. The diameter of a single-walled carbon nanotube (SWCNT) in a bundle is set at 1 nm, with a CNT filling ratio (\(F_{cnt}\)) of 0.6 in the hybrid structure. For global-level interconnects, the line width and length are set at 15 nm and 1 mm, respectively. The thickness of the multi-layer graphene nanoribbon (MLGNR) barrier layer is considered to be 2.5 nm, equivalent to 6 layers of graphene. The parameters for the calculations in this paper were sourced from the IRDS 2017 roadmap1 for the 10 nm technology node.

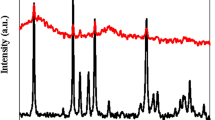

Figure 3 shows the AC magnitude vs frequency plot of Cu–Carbon hybrid, copper and Cu-CNT composite interconnects. Cu–Carbon hybrid interconnect has the highest Bandwidth (BW) due to its least resistance among other alternatives.

Figure 4 shows the frequency-dependent resistances and inductances of Cu–Carbon hybrid, copper and Cu-CNT composite metal lines, respectively. The resistances of the metals increases while inductances decreases with increasing frequency. Cu–Carbon hybrid interconnects have the lowest impedance among all. By incorporating CNT bundles in copper metal line, the impedance can be suppressed, resulting in improved performance in the composite as compared to copper interconnect. As expected, the resistance of Cu–Carbon hybrid increases with the decrease of \(F_{cnt}\).

The magnitudes (in dB) of return loss coefficient \(S_{11}\) for single and 2-line coupled interconnects made of Cu–Carbon hybrid, Cu-CNT composite and copper are plotted in Figs. 5 and 6, respectively. \(S_{11}\) value increases with increase in frequency. Cu–Carbon hybrid encounters lowest return loss when compared to other alternatives due to its lower impedance. Cu–Carbon hybrid interconnect has \(\sim\)68% lower \(S_{11}\) value than copper at lower frequencies but even at 100 GHz frequency, the improvement is \(\sim\)43% for single line and \(\sim\)48% for 2-line coupled interconnects. The observed lower return loss coefficient for Cu-CNT compared to Cu–Carbon hybrid interconnects in the low-frequency range can be attributed to the distinct impedance characteristics and material properties of CNTs. The Cu-CNT composite interconnect benefits from the unique quantum conductance and reduced scattering rates of CNTs, which contribute to a lower impedance profile at lower frequencies. In contrast, the Cu–Carbon hybrid, while possessing superior high-frequency characteristics due to the graphene liner, exhibits slightly higher impedance at lower frequencies, resulting in a higher return loss coefficient. This behavior reflects the trade-offs inherent in optimizing interconnect materials for different frequency regimes. Data points estimated from ADS simulator matches well with the plots obtained from our model as shown in the figures.

The magnitudes of forward transmission coefficient \(S_{21}\) of single line and 2-line coupled interconnects made of Cu–Carbon hybrid, copper and Cu-CNT composite are demonstrated in Figs. 7 and x 8, respectively. \(S_{21}\) value decreases with increase in frequency. Single line Cu–Carbon hybrid interconnect structure has higher bandwidth for gain below \(-3\) dB. Cu–Carbon hybrid interconnect has highest transmission coefficient because it exhibits least impedance. At 100 GHz, Cu–Carbon hybrid interconnect has \(\sim\)30% and \(\sim\)38% higher \(S_{21}\) values than copper for single line and 2-line coupled interconnects, respectively.

The effect of \(F_{cnt}\) on the noise parameter of Cu–Carbon hybrid interconnects is depicted in Fig. 9. This study tells us that a CNT fraction of 0.8 and 0.6 is a good choice for high frequency noise constrained applications. \(F_{cnt}\) = 0.6 is selected for further evaluations because it performs better at certain range of frequencies and also it has been experimentally demonstrated by Sundaram et. al. in16. The subsequent noise analysis is done for 2-line coupled interconnect systems to study the effects of crosstalk and interference in high frequency applications by applying input at port 1 of line 1 and observing output at port 4 of line 2.

Figure 10 gives an understanding of the noise figure in the 2-line coupled interconnect system. At lower frequencies, all interconnects have comparable noise profiles as observed in Fig. 10. Noise in copper remains almost constant with increasing frequency. Cu-CNT and Cu–Carbon hybrid interconnect experiences a steep dip in noise figure followed with a gradual rise. The percentage improvement (in dB) in the noise figure of Cu–Carbon hybrid interconnect as compared to copper is \(\sim\)48% at 100 GHz as a result of its lower mutual inductance. The noise factor corresponding to input at port 1 and output from port 4 for 2-line coupled interconnect lines is demonstrated in Fig. 11. As seen from the figure, the degradation in signal to noise ratio in Cu–Carbon hybrid interconnect is far better as compared to copper due to its lower coupling capacitance and mutual inductance, with an improvement of \(\sim\)98% at 100 GHz, which is zoomed and shown in the inset of the graph. The improvement is \(\sim\)44% when compared to Cu-CNT composite interconnect. Thus, both noise figure and noise factor parameters indicate that Cu–Carbon hybrid interconnect induces less noise as compared to copper especially at high frequencies.

Formulation and methodology

Figure 12 describes the electrical circuit model of a single-line Cu–Carbon hybrid interconnect structure. Here, \(R_{icon}\) denotes the imperfect contact resistance, here assumed to be 10 K\(\Omega\)23. The equivalent distributed per unit length (p.u.l) resistance of Cu–Carbon hybrid which is defined as,

where \(\sigma _\mathrm{{eff}}\) represents the conductivity of Cu–Carbon hybrid which can be defined as,

where is the CNT filling ratio in the hybrid structure which is defined as15,

\(\sigma _{{{\textrm{Cu}}}}\) is the conductivity of copper as described in24. The conductivity of single walled carbon nanotube (SWCNT) is expressed as25,

where, \(j = t,b,l,r\) denote the top, bottom, left and right sides of GNR barrier, respectively. \(Z_{\mathrm{{cnt}}}\) and \(Z_{\mathrm{{gnr}}}\) are intrinsic self-impedance of an isolated SWCNT and an isolated MLGNR, which are expressed as26,

where \(R_{quant}\) denotes the quantum resistance and \(L_K\) is the kinetic inductance calculated by utilizing the recursive method explained in27,28. \(N_{ch}^{c}\) and \(N_{ch}^{g}\) are the number of conducting channels in SWCNT and MLGNR, respectively. \(\lambda _{eff}^{c}\) and \(\lambda _{eff}^{g}\) are the effective electron mean free paths for the ith shell of SWCNT and jth layer of MLGNR which can be evaluated by the Matthiessen’s equation27,29.

The p.u.l equivalent capacitance of Cu–Carbon hybrid interconnect can be expressed as,

where the p.u.l equivalent capacitance contributed graphene barrier layers bordering Cu-CNT composite metal line is denoted by (\(C_{gnr}^t\), \(C_{gnr}^b\), \(C_{gnr}^l\), \(C_{gnr}^r\)) which can be evaluated using the recursive method provided in28. \({C_{cnt}}\) represents the p.u.l quantum capacitance of SWCNT bundle which can be calculated by utilizing the recursive method explained in27. The p.u.l electrostatic ground capacitance (\(C_{e}\)) is accessed from28.

The p.u.l equivalent inductance of Cu–Carbon hybrid interconnect consists of internal and external inductances which are described as,

Figure 13 demonstrates the electrical equivalent circuit of a 2-line coupled Cu–Carbon hybrid interconnect system. Here, \(C^c_{Cu-Carbon}\) and \(L^m_{Cu-Carbon}\) represent the p.u.l coupling capacitance and mutual inductance developed between the Cu–Carbon hybrid metal lines, respectively which are taken from30,31.

The effective complex conductivity of Cu–Carbon hybrid interconnect is calculated by substituting \(Z_{cnt} = R_{cnt} + j\omega L_{cnt}\), \(Z_{gnr} = R_{gnr} + j\omega L_{gnr}\) and (4) into (2), one can obtain,

and the ratio between Re(\(\sigma _{eff}\)) and Im(\(\sigma _{eff}\)) is described by (10).

Absolute magnitude of effective complex conductivity as a function of frequency as defined in (9).

Modulus of ratio of real and imaginary parts of effective complex conductivity as a function of frequency as defined in (10).

The results depicted in Figs. 14 and 15 provide critical insights into the frequency-dependent behavior of the effective complex conductivity of Cu–Carbon hybrid interconnects compared to Cu-CNT composite interconnects. In Fig. 14, the absolute magnitude of the effective complex conductivity \(|\sigma _{eff}|\) is shown to initially decrease with increasing frequency before reaching a saturation point at higher frequencies. This behavior is particularly pronounced in the Cu–Carbon hybrid interconnects with a CNT filling ratio (\(F_{cnt}\)) of 0.6, which exhibits the highest conductivity among the compared structures. The superior performance of the Cu–Carbon hybrid interconnect is attributable to the synergistic effects of the copper matrix and the embedded CNTs, which reduce scattering and enhance electron transport at nanoscale dimensions. Moreover, the reduced impedance in the Cu–Carbon hybrid interconnects due to the inclusion of graphene nanoribbons (GNRs) further contributes to the higher conductivity observed.

Figure 15 further elucidates the complex conductivity by presenting the modulus of the ratio between the real and imaginary components of the effective complex conductivity \(|Re(\sigma _{eff})/Im(\sigma _{eff})|\). This ratio highlights the dominance of the reactive component (imaginary part) in Cu-CNT composite interconnects at higher frequencies, contrasting with the Cu–Carbon hybrid interconnects where both real and imaginary parts contribute more evenly. The balanced contribution in the Cu–Carbon hybrid interconnects can be linked to the enhanced material properties of the graphene liner, which stabilizes the conductivity and reduces the reactive losses, making these interconnects more suitable for high-frequency applications. These findings are significant because they suggest that Cu–Carbon hybrid interconnects not only outperform traditional Cu and Cu-CNT interconnects in terms of real part conductivity but also maintain a lower and more stable reactive component at high frequencies. This characteristic is crucial for minimizing signal distortion and loss in high-speed, high-frequency nanoscale systems, thus reinforcing the potential of Cu–Carbon hybrids as a superior alternative for next-generation interconnect technology.

ABCD parameter based model

Single line interconnect model

The equivalent electrical model shown in Fig. 12 can be simplified as a transmission line whose transmission characteristics can be expressed by utilizing an ABCD matrix22. The total ABCD transmission parameter matrix of the configuration shown in Fig. 12 is defined by (11).

where \(Z_0\) and \(\varphi\) are the characteristic impedance and the propagation constant of single line interconnect. These parameters can be expressed as,

Coupled line interconnect model

Similarly, for a 2-line coupled interconnect system configuration as shown in Fig. 13, the total ABCD transmission parameter matrix can be expressed by (14).

where \(CC^n\) is the ABCD matrix representing a 2-line coupled system constructed using n number of cascaded infinitesimal sections and is given by,

Here, \(Z_1\) and \(Z_2\) are the characteristic impedances of the 2-line coupled interconnects. \(\varphi _1\) and \(\varphi _2\) are the propagation constants of the 2-line coupled interconnects. These parameters are defined as,

Here \(\alpha\)=(1-\(\eta _1\)-\(\eta _2\)), \(\beta\)=(1+\(\eta _1\)-\(\eta _2\)). Where \(\eta _1\)=\(\frac{b}{a^2-b^2}\), \(\eta _2\)=\(\frac{a}{a^2-b^2}\) with \(a=\frac{C_{Cu-Carbon}+C^c_{Cu-Carbon}+}{C_{Cu-Carbon}}\) and \(b=\frac{C^c_{Cu-Carbon}}{C_{Cu-Carbon}}\)

Conclusion

In this paper, for the first time, a high frequency electrical model of single and 2-line coupled Cu–Carbon hybrid metal lines is proposed and various transmission parameters are analyzed at 10 nm technology node. The high-frequency performance of Cu–Carbon hybrid is studied and compared with existing copper and Cu-CNT composite interconnects. The ABCD parameter model for single and 2-line coupled interconnects are developed which are utilized to obtain the scattering parameters. This model is also validated with ADS software. Here, Cu–Carbon hybrid interconnects have the lowest impedance among all which tends to increase with the decrease of \(F_{cnt}\). Compared with copper, Cu–Carbon hybrid interconnect (with \(F_{cnt}\)=0.6) possesses \(\sim\)80% lower impedance at 100 GHz frequency. The reactive part Cu-CNT composite interconnects is dominant at higher frequencies while that is not the case with Cu–Carbon hybrid interconnects where both real and imaginary parts contribute equally in the effective complex conductivity. Cu–Carbon hybrid interconnect experiences lowest return loss and highest forward transmission gain among all others. Compared to copper, Cu–Carbon hybrid interconnect has \(\sim\)43% and \(\sim\)48% lower \(S_{11}\) values and has \(\sim\)30% and \(\sim\)38% higher \(S_{21}\) values at 100 GHz for single and 2-line coupled interconnects, respectively. At lower frequencies, all interconnects have comparable noise profiles. Noise figure (in dB) and noise factor of Cu–Carbon hybrid interconnect when compared to copper shows \(\sim\)48% and \(\sim\)98% improvement at 100 GHz, respectively. The improvement in noise factor is \(\sim\)44% when compared to Cu-CNT composite interconnect. Although Cu–Carbon and Cu-CNT have comparable noise figures, still Cu–Carbon is recommended due to its lower AC impedances and better signal transmission. Cu–Carbon hybrid is an emerging interconnect structure with very promising performance metric and phenomenal advantages over copper interconnects. Therefore, it needs to be studied and analyzed extensively in theory and experiment for various aspects of VLSI applications.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

International Roadmap for Devices and Systems (IRDS-2017) Reports. https//irds.ieee.org/editions/2017.

Im, S., Srivastava, N., Banerjee, K. & Goodson, K. Scaling analysis of multilevel interconnect temperatures for high-performance ICS. IEEE Trans. Electron Dev. 52, 2710–2719 (2005).

International Roadmap for Devices and Systems (IRDS-2021) Reports. https//irds.ieee.org/editions/2021.

Secareanu, R., Banejee, S., Hartin, O., Fernandez, V. & Friedman, E. Managing substrate and interconnect noise from high performance repeater insertion in a mixed-signal environment. In 2005 IEEE International Symposium on Circuits and Systems (ISCAS). Vol. 1. 612–615 (2005).

Gong, J., Pan, D. & Srinivas, P. Improved crosstalk modeling for noise constrained interconnect optimization. In Proceedings of the ASP-DAC 2001. Asia and South Pacific Design Automation Conference 2001 (Cat. No. 01EX455). 373–378 (2001).

Sahoo, M. & Rahaman, H. Modeling of crosstalk induced effects in copper-based nanointerconnects: An abcd parameter matrix-based approach. J. Circuits Syst. Comput. 24, 1540007 (2015).

Li, H., Xu, C., Srivastava, N. & Banerjee, K. Carbon nanomaterials for next-generation interconnects and passives: Physics, status, and prospects. IEEE Trans. Electron Dev. 56, 1799–1821 (2009).

Sahoo, M. & Rahaman, H. Analysis of crosstalk-induced effects in multilayer graphene nanoribbon interconnects. J. Circuits Syst. Comput. 26, 1750102 (2017).

Liew, K. M., Wong, C. H., He, X. Q. & Tan, M. J. Thermal stability of single and multi-walled carbon nanotubes. Phys. Rev. B 71, 075424 (2005).

Sahoo, M., Ghosal, P. & Rahaman, H. An abcd parameter based modeling and analysis of crosstalk induced effects in multiwalled carbon nanotube bundle interconnects. In 2014 27th International Conference on VLSI Design and 2014 13th International Conference on Embedded Systems. 433–438 (2014).

Sahoo, M. & Rahaman, H. An abcd parameter based modeling and analysis of crosstalk induced effects in multilayer graphene nano ribbon interconnects. In 2014 IEEE International Symposium on Circuits and Systems (ISCAS). 1138–1142 (2014).

Meric, I., Baklitskaya, N., Kim, P. & Shepard, K. L. Rf performance of top-gated, zero-bandgap graphene field-effect transistors. In 2008 IEEE International Electron Devices Meeting. 1–4 (2008).

Chen, X. et al. Fully integrated graphene and carbon nanotube interconnects for gigahertz high-speed CMOS electronics. IEEE Trans. Electron Dev. 57, 3137–3143 (2010).

Singh, A., Ram Prabhu, T., Sanjay, A. & Koti, V. An overview of processing and properties of cu/cnt nano composites. Mater. Today Proc. 4, 3872–3881 (2017) (5th International Conference of Materials Processing and Characterization, ICMPC 2016).

Cheng, Z.-H. et al. Investigation of copper-carbon nanotube composites as global VLSI interconnects. IEEE Trans. Nanotechnol. 16, 891–900 (2017).

Sundaram, R. M., Sekiguchi, A., Sekiya, M., Yamada, T. & Hata, K. Copper/carbon nanotube composites: Research trends and outlook. R. Soc. Open Sci. 5, 180814 (2018).

Zhao, W.-S. et al. High-frequency analysis of Cu–Carbon nanotube composite through-silicon VIAS. IEEE Trans. Nanotechnol. 15, 506–511 (2016).

Zhao, W.-S. et al. High-frequency modeling of on-chip coupled carbon nanotube interconnects for millimeter-wave applications. IEEE Trans. Compon. Packag. Manuf. Technol. 6, 1226–1232 (2016).

Zhao, W.-S. et al. High-frequency modeling of cu-graphene heterogeneous interconnects. Int. J. Numer. Model. Electron. Netw. Dev. Fields 29, 157–165.

Kumari, B., Kumar, R., Sharma, R. & Sahoo, M. Design, modeling and analysis of Cu–Carbon hybrid interconnects. IEEE Access 9, 113577–113584 (2021).

Park, M. et al. Performance enhancement of graphene assisted CNT/Cu composites for lightweight electrical cables. Carbon 179, 53–59 (2021).

Fathi, D. & Forouzandeh, B. Time domain analysis of carbon nanotube interconnects based on distributed RLC model. Nano 04, 13–21 (2009).

Lee, J.-O. et al. Formation of low-resistance ohmic contacts between carbon nanotube and metal electrodes by a rapid thermal annealing method. J. Phys. D Appl. Phys. 33, 1953 (2000).

Ahmadloo, M. & Dounavis, A. Parameterized model order reduction of electromagnetic systems using multiorder Arnoldi. IEEE Trans. Adv. Packag. 33, 1012–1020 (2010).

Cheng, Z.-H. et al. Analysis of Cu-graphene interconnects. IEEE Access 6, 53499–53508 (2018).

Datta, S. Quantum Transport: Atom to Transistor (Cambridge University Press, 2005).

Sahoo, M., Ghosal, P. & Rahaman, H. Modeling and analysis of crosstalk induced effects in multiwalled carbon nanotube bundle interconnects: An abcd parameter-based approach. IEEE Trans. Nanotechnol. 14, 259–274 (2015).

Sahoo, M. & Rahaman, H. Modeling of crosstalk induced overshoot/undershoot effects in multilayer graphene nanoribbon interconnects. In 2015 2nd International Conference on Electrical Information and Communication Technologies (EICT). 416–421 (2015).

Brandbyge, M., Mozos, J.-L., Ordejón, P., Taylor, J. & Stokbro, K. Density-functional method for nonequilibrium electron transport. Phys. Rev. B 65, 165401 (2002).

Zhao, W. et al. Field-based capacitance modeling for sub-65-nm on-chip interconnect. IEEE Trans. Electron Dev. 56, 1862–1872 (2009).

Cui, J.-P., Zhao, W.-S., Yin, W.-Y. & Hu, J. Signal transmission analysis of multilayer graphene nano-ribbon (MLGNR) interconnects. IEEE Trans. Electromagnet. Compatibil. 54, 126–132 (2012).

Author information

Authors and Affiliations

Contributions

All authors contributed equally.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kumari, B., Sahoo, M. & Sharma, R. ABCD parameter based analytical AC modeling of novel Cu–carbon hybrid interconnects for noise constrained nanoscale systems. Sci Rep 15, 18440 (2025). https://doi.org/10.1038/s41598-024-81729-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-81729-9