Abstract

The development of new urban areas necessitates building on increasingly scarce land, often overlaid on weak soil layers. Furthermore, climate change has exacerbated the extent of global arid lands, making it imperative to find sustainable soil stabilization and erosion mitigation methods. Thus, scientists have strived to find a plant-based biopolymer that favors several agricultural waste sources and provides high strength and durability for sustainable soil stabilization. This contribution is one of the first studies assessing the feasibility of using inulin to stabilize soil and mitigate erosion. Inulin has several agricultural waste sources, making it a sustainable alternative to traditional additives. Soil samples susceptible to wind erosion were collected from a dust-prone area in southwest Iran and treated with inulin at 0%, 0.5%, 1%, and 2% by weight. Their mechanical strength was evaluated using unconfined compressive strength tests and a penetrometer. In addition, wind tunnel tests (at 16 m/s) were performed to investigate inulin’s wind erosion mitigation potential. The durability of treated samples was evaluated after ten wetting–drying cycles to assess the effect of environmental stressors. The results indicated a 40-fold increase in the unconfined compressive strength (up to 8 MPa) of the samples treated with 2% inulin and only 0.22% weight loss after ten wetting–drying cycles. SEM images revealed the formation of biopolymer-induced particle-to-particle bonds. Moreover, Raman spectroscopy indicated molecular (hydrogen) bonding of the biopolymer hydrogel-soil particles facilitated by the hydroxyl groups of inulin. The deterioration in stiffness and strength of treated samples was less noticeable after 3rd dry–wet cycle, indicating the durability of the samples. The durability of samples against wet–dry cycles was attributed to molecular bonding of soil-biopolymer hydrogel, as revealed by FTIR analysis.

Similar content being viewed by others

Introduction

Fostered by advancements in health and sanitation, the world population is expected to surpass 9 billion in 2050 and experience an approximate peak of 10 billion in the mid-2080s1. This unprecedented population growth would demand ample use of limited land resources for agriculture and construction2,3,4. However, the earth’s surface in several geographical regions is covered by soils susceptible to erosion, making the built environment and infrastructures in their vicinity difficult to develop and maintain. The issue is particularly severe in arid regions, home to one-sixth of the global population, contributing to one-third of the Earth’s surface5.

Soil erosion is a global socioeconomic concern resulting in soil degradation, water quality loss and air pollution6,7. Airborne particles mobilized by erosion can potentially lead to health issues and diseases such as Covid 19, meningococcal meningitis, coccidioidomycosis, respiratory inflammation and cardiovascular disease7,8,9,10,11,12,13. The annual and global financial loss due to wind erosion is multifaceted, affecting the agricultural sector and the aviation industry14.

To address financial and health concerns of soil erosion, solutions mitigating these effects and maintaining soil productivity are crucial. To combat wind erosion and improve soil mechanical strength and surface resistance, methods like frequent soil watering and physical and chemical stabilizers have been utilized15. The high costs associated with mechanical stabilization techniques often limit their use. Chemical stabilization techniques, relying on pozzolanic reactions and cementitious binders, are effective but face environmental and human health concerns. Cement, a common stabilizer since the 1960s16, can alter the alkalinity of the groundwater and surrounding soil, influencing the indigenous soil ecosystem and the quality of water resources. Additionally, the cement industry contributes significantly to global warming, accounting for 5–8% of CO2 emissions17,18,19. Most notably, producing 1 ton of cement emits 1 ton of CO220.

In response to this environmental challenge, scientists have recently strived to examine eco-friendly soil improvement approaches microbially induced carbonate precipitation (MICP)21,22,23,24,25,26,27,28,29, extracellular polymeric substance (EPS)-induced stabilization through microalgae such as Cholera Vulgaris, enzymatically induced carbonate precipitation (EICP)30,31,32, as well as biopolymer soil treatment3,18,33,34. MICP enhances soil properties by precipitating calcium carbonate through bacterial activity. Still, it suffers from reduced efficiency in fine-grained soils due to the large size of bacteria relative to soil pores, difficulties in cultivating and transporting bacterial solutions, issues with ammonium by-products from ureolytic MICP, and challenges in achieving uniform soil stabilization in field applications35,36. EICP employs enzymes to facilitate biomineralization without the need for living microorganisms18,30,31,32,37. However, EICP also faces challenges, including the lack of nucleation sites for crystallization and precipitation of calcium carbonates38 and the high costs associated with enzyme production and application at an industrial scale. Biopolymers, which can be extracted from various plants and agricultural wastes, have emerged as a promising biogeotechnical method for soil stabilization15,17,18,34,39,40,41,42,43,44,45,46. Biopolymers are derived from biological materials, including polysaccharides, proteins, silk, and marine prokaryotes or alternatively through microbial activity or chemical synthesis (from bio-derived monomers). The relatively straightforward exo-cultivation and application processes for biopolymers allow for greater control over their efficacy and quality compared to other biological treatments18.

The use of biopolymers for soil stabilization and wind erosion mitigation has been investigated in recent years18,42,43,44,45,46,47,48,49. For instance, Chang et al.40 investigated biopolymer treatment to enhance soil erosion resistance. For this purpose, they used two microbial biopolymers: β-glucan and xanthan gum. Soil erosion response to severe precipitation (i.e., rainfall intensity: 8000 mm/h; duration: 5 s) was evaluated. The erosion tendency of biopolymer-treated soils remained relatively low (i.e., below 1%). Later, Im et al.50 applied Gellan gum and xanthan gums on typical Korean sand and observed the soil’s mechanical strength enhancement. Chang and Cho51 performed vane shear and direct shear experiments on sand-clay mixtures with another microbial biopolymer, the gellan gum. Their findings indicated a significant improvement in soil strength and cohesion. The gellan gum treatment, 4% gellan–gum treatment of clay samples, enhanced the cohesion from 18.5 kPa to 127.3 kPa and the internal friction angle was improved from 18.7° to 30.7°, only 12 h after treatment, as compared to 5% cement treatment, which needed 28 days of curing time to achieve the same improvement. Fatehi et al.52 utilized casein and sodium caseinate salt biopolymers to improve the compressive strength of sand. Soil samples treated with 1% casein and 1% sodium caseinate could achieve an unconfined compressive strength of around 600 kPa. Dehghan et al.53 employed xanthan gum and guar gum to stabilize collapsible soil. Compaction, consolidation, permeability, and unconsolidated-undrained triaxial tests were performed, and the results showed a reduction in the maximum dry density and permeability53. Xanthan gum performed better than guar gum in reducing soil permeability at lower weight percentages (i.e., 1%), while by increasing the biopolymer of both to 2%, they had almost the same influence. Xanthan gum-treated samples also favored higher strength in triaxial tests. Dehghan et al.53 attributed the better performance of xanthan gum to its carbocyclic acid groups. Ghasemzadeh and Modiri54 performed a series of macro- and micro-scale tests on the soil samples treated with different Persian gums. The experiments included unconfined compression strength, direct shear test, and microfabric studies. Compared to common hydrocolloids, Persian gum performed much better at binding soil particles, filling pores, maintaining thermal stability, and resulting in soil aggregation54. A maximum unconfined compressive strength of almost 800 kPa was achieved by treating low-plasticity clay (industrial white kaolinite) samples with 2.5% Persian gum. It was noteworthy that increasing the curing time from 28 to 90 days did not considerably alter the treated samples’ mechanical performance. Kumar and Sujatha55 studied the hydro-mechanical behavior of sand-clay soil. They used three biopolymers (xanthan gum, Guar gum (GG), and β-glucan (BG)) to treat the soil for one year. The purpose was to examine the potential of biopolymer-treated sand-clay mixtures for landfill applications as a liner material. The polysaccharides improved the heavy metal adsorption capacity and the strength of the soil. Xanthan gum-amended soil had the lowest permeability, the highest strength, and thus the best performance55. Xanthan gum amended soil samples could achieve unconfined compressive strength up to 1697 kPa for the samples treated with 2% xanthan gum.

These studies demonstrate that carbohydrate biopolymers have significant promise for revolutionizing soil erosion mitigation, improving soil fertility, and advancing the construction and building sectors by offering sustainable and cost-effective substitutes for conventional materials56,57. Using biopolymers aligns well with the United Nations’ Sustainable Development Goals (SDGs)58, as presented in Fig. 1.

Although biopolymers can be obtained from different sources, most notably from plant sources, the presented literature review indicates most studies have been devoted to biopolymers from microbial and animal sources (such as xanthan gum and β-glucan (BG)). Finding a biopolymer that can be obtained from plant sources and results in high strength and durability can facilitate the gradual and industrial replacement of traditional additives such as cement with biopolymers. Among different biopolymers commonly used in the food and sanitation industry and rarely employed in civil, environmental and geotechnical engineering, particularly for soil improvement and wind erosion mitigation, one can cite Inulin (IN). Inulin is widely used in the pharmaceutics and food industry as a thickener, dietary fiber, fat replacement, sweetener, and water-retaining agent70,71.

This paper examines the application of IN as an eco-friendly and new material for wind erosion mitigation and soil stabilization for the first time, indicating its potential to provide reasonable mechanical strength, surface resistance, and adequate durability. The reason to select inulin roots is the following characteristics: (1) Inulin cannot be digested by the human digestion system71; in other words, it is durable in harsh (acidic) conditions human digestion system, potentially indicating its durability against severe environmental conditions, that stabilized soils may experience. (2) Inulin is used in applications such as drug delivery due to its several hydroxyl groups providing sites to anchor to other functional groups72,73. Its chemical structure results in a high potential for creating hydrogen bonds with the soil matrix. (3) Moreover, numerous agricultural waste sources70,71,74,75,76,77,78,79,80, from which it can be extracted, make it an excellent candidate for sustainable soil stabilization.

For this purpose, a comprehensive experimental program has been followed. As measuring surface resistance provides a reliable method to analyze the efficacy of this biopolymer for improving soil surface strength, soil penetration tests were applied on the treated soils. It is of utmost importance in applications such as improving the outer layer of soil dams, waste dams, and soil roads. Furthermore, to study its durability and efficiency against atmospheric factors (sunlight, rain, and rising underground water levels), a careful durability examination against sunshine and wetting–drying cycles has been conducted. After that, another set of penetration tests was performed. Unconfined compression experiments determined the treated soil’s uniaxial compressive strength and stress–strain behavior. The samples’ weight loss was measured after wind tunnel tests to investigate wind erosion resistance. Furthermore, micro-fabric studies such as scanning electron microscopy, Raman spectroscopy and X-ray diffraction analysis of the samples have been performed.

Material and methods

Soil samples susceptible to wind erosion

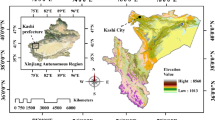

According to Cao et al.81, the main dust sources in Iran are Hawizeh Marsh (Azim Marsh), Shadgan Marsh, Sistan Basin81 and Jazmourian Basin (Fig. 2).

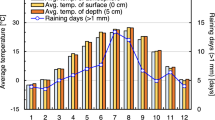

Therefore, in this study, the required soil samples were collected from Hawizeh Marsh, which is one of the main sources of fine dust. The reason for choosing this area for sampling was its substantial susceptibility to erosion. In recent years, when this area has dried up, both the intensity and frequency of dust production have increased considerably. Moreover, more than 90% of fine dust is related to the Iran-Iraq border region, which includes the Hawizeh Marsh82. The mean and max monthly temperature, relative humidity, and UV level of the dust source region have been presented in Fig. 3.

Maximum monthly temperature, relative humidity and UV level of the dust source region in 202383.

As the goal was to improve surface soil properties in a region susceptible to wind erosion, the soil samples were collected from a depth of 0–30 cm. For this purpose, the relatively undisturbed samples taken by Shelby tube (ASTM D 1587) were used to determine the in-situ density and moisture content. The rest of the soil samples were obtained from the topsoil layer following the procedure suggested by ASTM D 7015. All samples were transported to the laboratory in closed boxes following instructions of ASTM D 4220. Some preliminary tests were performed to determine the physical and mechanical characteristics of the soil. Soil properties are reported in the following sections.

Soil classification

Grading and hydrometric tests were conducted to establish the grain size distribution and classify the soil according to the ASTM D 2487-93 standard. The soil grading curve is depicted in Fig. 4. The uniformity coefficient is 8.6 (CU = 8.6), while the curvature (conformity) coefficient is recorded (CC) as 0.64. Liquid and plastic limits, as well as the plasticity index of the soil, were determined following the ASTM D 4318-93 standard method. Based on the grain size distribution and plasticity index obtained, the soil sample is identified as silty clay (SC) soil according to the USDA classification. It is classified as CL in the unified soil classification system (USCS). The specific gravity of soil particles, determined by ASTM C 127-88, is 2.63. The maximum dry density and optimum water content were determined by the Standard Proctor energy following ASTM D698. Additionally, the in-situ density of the soil, determined by ASTM D 1556, is 1.43 g/cm3. To assess the concentration and composition of elements in the soil of the identified dust source, with a specific focus on primary oxides and heavy components, three samples underwent XRF analysis. The XRF machine was equipped with an Rh-tube with an accuracy of at least 0.01 weight percent. Table 1 presents the soil’s physical characteristics, and Table 2 shows the compositions of the main soil elements.

Inulin biopolymer

Inulin (IN) is a plant-derived polysaccharide (allowing its extraction from several agricultural waste sources); it is characterized by hydroxyl rings. These rings enable it to form hydrogen bonds with soil. Main IN plant sources include chicory, artichoke, agave, asparagus, daffodil root, elecampane, and dandelion. Extensive research has demonstrated the diverse biological activities of IN, leading to its widespread use in the health sector. Its roles encompass acting as a prebiotic to enhance the gut microbiota environment, regulating blood sugar and lipid levels, and exhibiting antioxidant, anticancer, and immune system-modulating properties. Additionally, IN finds utility in the food industry as a thickener, fat substitute, sweetener, and preservative for water. In the pharmaceutical sector, it is a stabilizer, drug carrier, and adjunctive therapeutic agent for conditions like constipation and diabetes71. The average polymerization degree (DP) and size distribution of inulin from various sources determine its solubility, thermal behavior, crystal morphology, rheological properties, and stability70,73,84. Despite its broad application in biological and life sciences, its potential in construction technology and geotechnical engineering has not been explored.

Inulin (IN), characterized by a linear fructan structure, consists of β-D-fructosyl residues linked by glycosidic bonds, with a terminal glucose connected through an α-D-glucopyranosyl or α-(1 → 2) bond71,79. These fructose units, forming the inulin backbone, are linked by glycosidic bonds β-2,1. Consequently, each fructose chain begins with two fructose units, followed by one glucose unit at the end. The presence of β-2,1 bond is a distinguishing feature of inulin’s structure70,85. Inulin molecules bind large amounts of water through hydrogen bonds, but this ability varies with the molecular weight of inulin. Inulin exhibits high water-binding ability due to numerous external hydroxyl groups and the presence of small sugars such as glucose, fructose, and sucrose70,72,73.

In this study, we utilize inulin Orafti®GR, manufactured by Beneo. It is extracted through hot water processing of chicory root and has an average polymerization degree (DP) 10. The degree of polymerization (DP) characterizes the number of monomer units comprising a singular strand of inulin polymer.

Experimental program

Specimen preparation and testing scenarios

The samples were prepared using aluminum molds measuring 235 × 235 × 64 mm. Each sample contained 2.5 kg of soil treated with a specific concentration of the biopolymer solution and was subsequently air-dried for 24 h. Each mold was filled with soil and compacted to achieve a target (wet) density of 1.43 g/cm3 in moisture content 8%, with meticulous control of soil height in the molds. This specific density was chosen to match the in-situ density of the topsoil layer.

Next, 130 ml of biopolymer solution, with predetermined concentrations as outlined below, was sprayed onto the soil sample surfaces. This application resulted in an equivalent rate of 1.9 l/m2, determined based on specifications for treating road soil and trash dams86. The quantities of water and biopolymer were calculated to ensure consistency with previous studies assessing other biopolymers for soil treatment86. The study utilized inulin concentrations of 0.5%, 1%, 1.5%, and 2% by solution weight. To ensure control and enable comparison of results, samples prepared with deionized water (without biopolymer) were used as a reference. The specimens selected for wind tunnel, durability, and moisture retention tests underwent a similar preparation process, but the mold dimensions were 235 × 295 × 64 mm.

There were two categories of the experiments. The first category included experiments aimed at investigating the mechanical properties of the soil improved by biopolymer, which were performed under lab conditions (temperature (25 °C), and the moisture content of samples was preserved by plastic bags. The second category of experiments addressed the durability of improved soil samples, which was carried out by exposing the treated samples to cycles of wetting and drying as well as sunlight with the maximum and minimum environmental factors presented in Table 3. The selected conditions during durability tests were considered such that the temperature and UV index closely simulate the dust source critical conditions. Most importantly, as the biopolymers could potentially be impacted by UV15, days of high UV indices have been considered for the durability cycles. In durability tests, the duration of each test was considered 15 consecutive days (one day for wetting and fourteen days for drying of the soil sample exposed to the climate conditions depicted in Table 3).

To ensure the reproducibility of results, three trials for each experiment were considered. Care was also practiced to prepare similar soil samples of identical density and moisture content. Furthermore, during the curing period of the biopolymer-treated samples, they were kept in plastic bags to ensure they kept their initial moisture content and to control the reducibility of the results. Finally, to assess the reliability and repeatability of the results, a statistical analysis was performed on the results of each test, which is provided in Appendix A (Supplementary Material). Detailed explanation of the experiments is presented in subsequent sections.

Soil surface resistance test

Surface resistance can be measured through different methods, including the rupture method, the needle penetrometer method, the fall cone or cone penetrometer method, and the torvane test87,88,89,90,91,92,93.

The needle penetrometer method suggested by Rice et al.92 was used in this research. First, a flat-ended cylindrical steel needle with a 6-mm diameter tip was prepared. This needle was attached to the loading piston of the uniaxial loading device. Next, the force-penetration curve was obtained by applying a constant strain rate of 0.1 mm/min. This strain rate was selected based on the penetration rate considered by previous studies such as Rice et al.92, Chen et al.86 and Lemboye et al.68 so that the results could be comparable with the previous studies. Furthermore, such a slow strain rate commonly allows to better capture the crust strength formed by the studied additive. For each sample, nine penetrometer tests were conducted at nine different points on the sample, and each test was carried out until a 4 mm penetration of the needle was achieved.

Moisture retention capacity

Moisture retention tests were conducted to assess the biopolymer’s impact on the soil surface. This experiment aimed to evaluate the water retention capabilities of soils when exposed to different environmental conditions, such as sunlight and rain. Enhanced moisture retention indicates a healthier and more stable soil structure, potentially facilitating water accessibility for plant growth as well.

For this purpose, after preparing the biopolymer-treated samples by spraying the soil samples with biopolymer solutions of different concentrations, the samples were kept at 25 °C for 24 h to facilitate interactions between the soil and the biopolymer. Then, the drying-wetting cycles were started by adding water. The first measurement point was obtained when the samples were dried by sunlight and weighed after 24 h. Treated specimens were tested after exposure to sunlight for two-week periods. The climate factors during the durability tests are reported in Table 3. The weight of each sample was monitored daily during the wet–dry cycle to assess moisture retention capacity. The end of each wet–dry cycle was defined by consistent weight observations over several consecutive days, marking the initiation of a new wet–dry cycle following the wetting of the sample to its initial moisture content. Normalized weights relative to the initial weight (i.e., the first measurement point) were used to compare moisture retention capacity. The same procedure has been followed in previous studies86. Finally, after conducting the wet–dry cycles, surface resistance and wind tunnel tests were performed on the samples to examine their performance after wet–dry cycles.

Wind tunnel test

The Armfield Subsonic Wind Tunnel was used for the wind tunnel test. The working section of the wind tunnel possesses dimensions of 304 mm in width, 304 mm in height, and 457 mm long (octagonal cross-section), as illustrated in Fig. 5. A variable-speed motor-driven fan downstream of the working section enables seamless airspeed control within the 0 to 26 m/s range. The airspeed was accurately measured using a calibrated manometer.

Having investigated the average monthly dust discharge of Hawr-al-Azim wetland (our selected dust source to collect soil samples) for 20 years since 1995, it was observed that the three consecutive months of May, June, and July have the maximum recorded dust discharge. Furthermore, in these months, the mean value of maximum monthly wind speed is 14.62, 14.69, and 14.31 m/s, respectively, as reported by Adib et al.94. In another study, G. Zhang et al.95 showed that in regions prone to dust emission, an increase in the wind speed from 6 m/s to 14 m/s resulted in an almost seven-fold increase in PM 2.5 concentration and a ten-fold increase in PM 10 concentration in Northwest China. Abbasi et al.96 investigated various dust sources in Iran, inclusive of sand dunes, flood plains, lowlands, pediment plains, and alluvial plains, and concluded that the threshold (detachment) wind velocity varied between 5.5 and 16 m/s96. Therefore, in this study, a wind speed of 16 m/s was selected to investigate the wind erodibility of the treated soil samples for the perceived critical conditions. Following the moisture retention tests mentioned earlier and after the wet–dry cycles (i.e., when the soil weight remained constant for several consecutive days, highlighting the end of dry cycle), each sample was also placed in the wind tunnel test section and exposed to a wind speed of 16 m/s for 10 min. Precise measurements of the sample weight were taken and documented before and after the wind tunnel test. The resulting weight loss served as the basis for evaluating the wind erosion resistance of each sample.

Unconfined compressive strength (UCS) tests

In the unconfined compression (UC) tests, inulin powder at different weight percentages of dry soil, namely, 0.5%, 1%, 1.5%, and 2%, was added to the soil sample. Samples were then mixed for 5 min to ensure uniform distribution of inulin among the soil grains. Eventually, water was added to bring the soil gravimetric water content to its optimum value obtained from the standard proctor test (15.8% of soil weight) to facilitate the formation of bonds between biopolymers and soil grains. After adding water, the soil was remixed for 5 min. The final mixture of soil and biopolymer solution was then placed in cylindrical molds with dimensions of 38 mm in diameter and 76 mm in height and compacted in three layers to achieve the maximum dry density (i.e., 1.66 g/cm3 according to the compaction curve). The samples were then removed from the mold and allowed to cure for 7 and 28 days at 25 °C. This preparation procedure aligns with the methodologies employed in prior studies, such as that of Latifi et al.97, facilitating comparability with earlier works.

Finally, strain-controlled unconfined compression tests following the ASTM D 2166-87 procedure were carried out using an ELE uniaxial device. The prepared samples were subjected to uniaxial loading under a strain rate of 1 mm/min, and the loading process continued until failure occurred in the specimens. This strain rate was selected based on the suggestion by ASTM D 1633 and following the previous studies in the literature, such as Latifi et al.97, Losini et al.98, and Fatehi et al.99.

Atterberg limits (wL and wP) measurements

The Atterberg limits, comprising the plastic limit (wP), liquid limit (wL), and plasticity index (IP), signify the interplay between soil and water on particle surfaces, along with the chemical environment within pore spaces100. These tests were conducted to study the effect of inulin content on liquid and plastic limits. The tests were performed on the soil passed through a No. 40 sieve (0.425 mm) following the procedure outlined in ASTM D 4318-93. As explained earlier in UCS tests, the soil was mixed with a specified mass percentage of inulin (0%, 0.5%, 1.5%, 2%) per dry soil before the Atterberg limits tests.

Microfabric and physicochemical analysis

Microfabric analysis of soil grains treated with biopolymers provides insights into the performance of biopolymers at the grain scale. The induced alterations in particle roughness and shape, as well as the particle-to-particle bonding, can be examined through this analysis. Consequently, to scrutinize the microstructure of the samples, scanning electron microscopy (SEM) and Raman spectroscopy, as well as Fourier transform infrared (FTIR) spectroscopy, were employed. SEM was conducted using the TESCAN-Vega3 (TESCAN, Czech Republic), and Raman and FTIR spectroscopy were performed through confocal Raman spectroscopy (Lab Ram HR, Horiba, Japan), and FTIR spectroscopy (Tensor II, Bruker, Germany), respectively, at the central laboratory of Shiraz University. While Raman spectroscopy was conducted to reveal the structure of the hydrogel-soil matrix and induced bonds, FTIR imaging was employed to investigate the changes in the microfabric during wet–dry cycles as a complementary tool, owing to its higher signal to noise ratio and more significant potential in detecting changes in microfabric101,102.

Results and discussion

Soil surface resistance and durability

Figure 6 illustrates the penetration resistance over penetration depth for the control and biopolymer-treated samples after the first and fifth wet–dry cycles. The penetration force reaches its maximum at depths of 2 to 3 mm. In contrast, the sample treated only with water did not exhibit a peak during the test. This observed trend is attributed to crust formation in the biopolymer-treated samples. As depicted in Fig. 6a, the treatment with the biopolymer solution of 2% concentration consistently yielded a higher penetration resistance at a higher penetration depth. As evident from this figure, there is a sharp and remarkable difference between the surface resistance of treated and untreated samples. While the surface resistance of the control sample treated with deionized water was about 63.3 N, the surface strength for the sample treated with only 1% of the biopolymer solution resulted in an almost sixfold increase in the maximum penetration resistance, namely, 414 N, and with 2% biopolymer treatment, it surpassed 714.8 N.

Figure 6b illustrates the impact of wet–dry cycles and sunlight exposure on the strength induced by the biopolymer. This figure shows a reduction of about 20% in the maximum penetration resistance after exposing the treated samples to sunlight and wet–dry cycles (i.e., five cycles, and each cycle takes a minimum of 14 days before the sample weight remains unchanged). It is crucial to note that the decrease was acceptable and economical, considering the low percentage of biopolymers employed. The biopolymer-treated samples exhibit a relatively intact and undamaged surface, signifying the integrity of the crust formed by the biopolymer, and the samples treated with even a small amount of biopolymer (0.5%) did not experience any surface crack. This sharp contrast in the observed behavior underscores the substantial increase in surface resistance induced by the biopolymer, achieved through the bonding of soil grains, thereby preventing detachment and shear failure by enhancing the tensile strength of the soil as well.

Figure 7 illustrates the changes in maximum penetration force for samples treated with 0.5%, 1%, and 2% inulin after undergoing the first to fifth wet–dry cycles. The maximum penetration force values for all samples exhibited a consistent decline as the number of wet–dry cycles increased. Nevertheless, beyond 3rd cycle, the observed changes became less pronounced. Consequently, it is expected that the biopolymer-treated samples to endure more wet–dry cycles.

Moisture retention capacity

Moisture retention capacity or water holding capacity is defined by the variation of water content during exposure of the soil sample to sunlight. This definition is a proxy of the effect of evaporation on the moisture retained in the soil samples. Figure 8 shows the results for soils treated with 0.5 and 2% biopolymer during the first and tenth wet–dry cycles, respectively. These figures show that the moisture retention capacity is improved compared to the control sample, and the sample treated with higher inulin content indicated better moisture retention over time. This fact is justified since samples with higher biopolymer content produce thicker crusts with many smaller pores (higher capillary action), thereby enabling significant capacity for water storage.

Wind tunnel test

Figure 9 illustrates the weight loss of treated and untreated soil samples in the wind tunnel test for different wet–dry cycles. As revealed from this figure, the control samples (those treated with water only) experienced the highest weight loss, whereas the samples improved with the biopolymer solution showed a significant reduction in weight loss. It is also clear that the higher the biopolymer concentration, the more significant the weight loss reduction induced by wind erosion would be. For all the improved and control samples, the weight loss after the tenth wet–dry cycle is higher than the first wet–dry cycle. This weight loss may indicate damage to the microstructure of the crust produced by the biopolymer, the formation of cracks, or the destruction of large biopolymer molecules due to sunlight and wet–dry cycles. However, at high concentrations, for example, 2%, the increase in weight loss after the tenth wet–dry cycle is negligible. This shows the adequate durability of biopolymer-treated soil under harsh environmental conditions, where 2% biopolymer concentration provides adequate durability against wet–dry cycles and exposure to site conditions, such as sunlight and rain.

Figure 10 demonstrates the weight loss of treated and untreated soil samples concerning each sample’s initial weight after the wind tunnel test for different wet–dry cycles. As illustrated in Fig. 10, an increase in wet–dry cycles results in significant weight loss. Samples stabilized solely with deionized water exhibit a much more pronounced (steeper) trend in weight loss. The steeper slope of weight loss and, consequently, the reduced effectiveness of stabilization occurs after seven cycles in biopolymer-treated samples. The figure shows that the stabilization remains effective with 0.5% and 2% biopolymer solution treatment after ten cycles. Even then, the corresponding weight loss is less than that of the control (untreated) sample in the first cycle. After ten cycles and approximately five months, the combined effects of sunlight exposure and wet–dry cycles caused biopolymer degradation, damaged the treated soil’s microstructure, formed cracks, and decreased the effectiveness of the biopolymer more perceptible.

The results indicate that inulin effectively reduces soil erosion and demonstrates significant erosion resistance. After the first wet–dry cycle, the accumulated erosion ratios were approximately 0.08% for soil treated with 2% inulin solution concentration and 0.15% for soil treated with 0.5% inulin solution concentration. These ratios increased with each subsequent wet–dry cycle. After ten cycles, the erosion ratios were 0.32% for soil treated with 0.5% inulin and 0.22% for soil treated with 2% inulin. Inulin-treated samples performed better than untreated samples even after ten cycles and sunlight exposure, highlighting inulin’s durability against environmental stresses.

To assess the suitability of the biopolymer treatment based on the standard codes, a further assessment was performed based on the Portland Cement Association (PCA) and the United States Army Corps of Engineers (USACE) standards. Figure 11 shows the cumulative soil loss during the wet–dry process. By the end of the tenth wet–dry cycle, the samples treated with 2% inulin showed the least cumulative weight loss of 1.5%, whereas samples treated with 0.5% showed a total loss of 2%. However, all inulin-treated soils demonstrated an allowable amount of soil loss based on criteria from PCA103,104 (i.e., maximum allowable mass loss of 10% for CL soils) and USACE104,105 (i.e., loss less than 6% for CL soils).

Unconfined compression tests

Figure 12 presents compressive stress versus axial strain obtained for soil stabilized at different percentages of inulin after 7 and 28 days.

Figure 12 shows an increase in the peak strength with the increase in the percentage of biopolymer. The peak strength of the untreated soil was 220 kPa, while the strength of the soil treated with only 0.5% inulin reached 1657 kPa—approximately eight times that of the untreated soil. A further increase in inulin concentration to 2% of the soil weight resulted in a peak strength of 8098 kPa, demonstrating a remarkable 40-fold increase over the initial strength.

Consequently, the peak strength in samples treated with the biopolymer significantly surpassed that treated solely with water. Moreover, a direct correlation was observed between biopolymer concentration and peak soil resistance; higher biopolymer concentrations yielded increased peak strength. Additionally, the increased absorbed energy, represented by the area under the stress–strain curve until failure, signifies a notable improvement. This enhanced energy absorption underscores the suitability of inulin for soil stabilization in various engineering applications. However, the brittle failure observed at high inulin contents is a drawback for applications involving significant deformation, as evident from the stress–strain curves ending at lower strains (cf. Fig. 12, compare stress strains curves of inulin-treated samples of 1% and 2%, cured for 28 days).

Figure 13 presents the unconfined compressive strength (qu) and stiffness (E50) of the 2% inulin-treated samples after the first to fifth wet–dry cycle. The qu values of all specimens showed a gradual decrease with the number of wet–dry cycles (Fig. 13). However, beyond the 3rd cycle, the changes in stiffness and strength are less noticeable. Therefore, the biopolymer-treated samples are also expected to resist a higher number of wet–dry cycles.

Atterberg limits (wL and wP) tests

Figure 14 depicts the changes in the liquid limit (wL) and plastic limit (wP) with increasing mass percentage of inulin. As illustrated, the liquid limit (wL) increases with the percentage of inulin. This increase is attributed to the formation of a hydrogel by inulin within the inter-particle voids of the soil. This hydrogel strongly favors water absorption, which increases the soil’s water retention capacity and raises its liquid limit. It is believed that the change in consistency limits of biopolymer-treated soils is controlled by two competing mechanisms, both taking place in biopolymer-treated soils. The first one is soil aggregation, which reduces the liquid limit, and the second mechanism is the formation of hydrogels, leading to an increase in the liquid limit. At lower biopolymer content, the dominant mechanism is hydrogel formation. The more prevalent formation of hydrogel in soil pores tends to increase water absorption and consistency limits (i.e., an increase in liquid limit and a much less pronounced increase in plasticity limit for the studied low-plasticity soil). However, as the biopolymer content increases, soil aggregation augments; consequently, the competition of the two mechanisms mentioned above results in a less steep increase in consistency limits. This observation aligns well with previous experiments on biopolymer-treated soils reported by Chang et al.106; however, this behavior varies depending on soil type and biopolymers due to the competition of the above mechanisms106. The variation of soil aggregation by biopolymer content is further studied through scanning electron microscopy (SEM) micrographs, presented in the next section.

Micro-scale characteristics

A typical SEM image of the treated sample is shown in Fig. 15. This SEM micrograph reveals that higher inulin content for soil stabilization leads to more aggregation. The image shows less aggregation in the soil samples treated with 0.5% inulin solution. Subsequently, this biopolymer concentration does not enhance the particle-to-particle cohesion considerably, thereby not resulting in a substantial increase in the surface resistance, as reported in the previous sections. As shown in Fig. 15c, by increasing the amount of inulin to 1%, the soil aggregation, particle-to-particle bonding, and the biopolymer coverage of the particles’ surface are augmented. As a result, the resistance of the soil crust increases. By increasing the biopolymer amount to 1.5%, the aggregation intensifies. However, there are still uncovered parts of biopolymer detectable on the soil surface, indicating that the biopolymer-treated soil could achieve even higher strength. Finally, by increasing the amount of inulin to 2%, almost all the visible soil pores are covered, and the soil becomes completely aggregated and compact; thus, higher soil surface resistance could be expected, which is consistent with the results of surface and uniaxial strength tests presented earlier.

As evident from the scanning electron microscope images, voids and large pores are identifiable in the natural soil samples and soils treated with a lower percentage of inulin. By increasing the inulin content, the sample microfabric exhibits a relatively denser structure than untreated samples. The soil structure becomes significantly coarser, and the size of the soil pores becomes finer. Increasing the percentage of the additive leads to the proximity of the flakes and the formation of a flocculated structure. Essentially, the hydrogen bonding of the biopolymer with water leads to forming a hydrogel, which binds soil particles together. This hydrogel fills soil voids and pores, resulting in a denser soil structure with fewer visible pores.

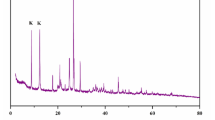

Raman spectroscopy was employed to further investigate the formation of these bonds in the samples. Figure 16a presents the spectra corresponding to the source soil and stabilized samples. The source soil’s Raman spectrum contains peaks corresponding to quartz and kaolinite minerals. However, upon adding the inulin biopolymer to the soil, the Raman spectrum reveals the emergence of new peaks, indicating the formation of new bonds within the soil.

(a) The Raman spectra of the untreated soil specified by (1) and three points inside the carbohydrate biopolymer-treated soil specified by (2, 3 and 4). (b) The Raman image of the point (4) in the soil sample, where the Raman shift range of 3400–3700 (cm−1) is colored in green, and the Raman shift range of 2800–3000 (cm−1) is depicted in red.

According to previous studies107,108,109,110, Raman spectrum peaks corresponding to hydrogen bonds within the soil fall within the Raman shift range of 3400–3700 (cm-1). These peaks are observed between 3400 and 3700 in our three samples, indicating direct hydrogen bonds between the biopolymer and the soil. Additionally, a peak in the range of 3800 indicates an ionic bond with silica oxide, which is still visible to a lesser extent. Furthermore, peaks in the range of 900–1100 and 2800–3000 (cm−1) are observed, corresponding to carbohydrate bonds associated with biopolymers, effectively demonstrating the impact of biopolymers on the bonds.

Raman spectral images (maps) were used to identify bonds in stabilized soil samples, and the results are displayed in Fig. 16b. As shown, the prominent spectra within the 2800–3000 (cm-1) range are abundantly observed at the soil surface, indicating the presence of polymer. The green color represents hydrogen bonding, suggesting that the soil has formed hydrogen bonds with the biopolymer. The Raman spectral image of the biopolymer-treated soil, where regions having the Raman shift range of 3400–3700 (cm-1) are shown in green, indicating the presence of biopolymer, and those with the Raman shift range of 2800–3000 (cm-1) are depicted in red. The Raman shift range specifies the formation of hydrogen bonds between inulin and soil matrix.

The three functional groups, hydroxyls (OH groups), amides (NH groups), and amines (CO–NH, CO–NH2 groups), contribute to polymers’ hydrophilic properties, water absorption, and hydrogel formation111. The biopolymer inulin possesses numerous hydroxyl groups, which facilitate hydrogel formation. In arid conditions or dry soils with limited water availability, biopolymers can interact with clay particles through direct hydrogen bonds or indirect ionic bonds mediated by intermediate ions, such as earth-metal ions in the soil. These interactions create a sturdy biopolymer-soil matrix, significantly enhancing soil cohesion17.

Figure 17 illustrates the formation of bonds within the hydrogel through the interaction of water molecules and biopolymer and, eventually, the development of the hydrogel-soil matrix, where the formation of chemical bonds with prevalent oxides in the soil matrix occurs. For illustration, and to avoid complexity, the bonds between SiO2 (constituting more than one-third of studied soil chemical composition (Table 2) and hydrogel have been presented. To better convey the mechanisms involved, in Fig. 17a, hydrogel formation is solely demonstrated, where the hydrogen bonding between the hydroxyl groups of inulin powder and the added water is showcased. Upon introducing this hydrogel to the soil sample, as depicted in Fig. 17b, hydrogen bonding between the hydrogel and the soil matrix occurs. Furthermore, the ionic bonding between the oxides in soil elements (such as the silicate sheets in the clayey portion of the soil) with the hydrogel (through the hydroxyl groups) is anticipated. These bonds are depicted in the schematic.

(a) The bonds between inulin and water and hydrogel formation. (b) Development of the bonds within soil matrix (inulin, water and soil elements) )one of the most prevalent chemical constituents of the studied soil, namely, SiO2, has been presented in the soil along with its associated bonds with the considered biopolymer, namely, inulin).

The effect of drying-wetting cycles on biopolymer treatment: From micro fabric to macroscopic properties

As discussed earlier in Sect “Unconfined compression tests” (Fig. 13b, c), and surpassing the third cycle, the change in macroscopic properties with the number of cycles is less pronounced, pointing to the durability of the treated samples against environmental stressors. To interpret the variations in the macroscopic properties in light of the microfabric changes induced by the biopolymer treatment, FTIR analysis and SEM micrographs of the treated samples (treated with 2% inulin) after 3rd and 5th wet–dry cycles were compared with those not exposed to the durability test conditions.

As discussed earlier in Sect “Micro-scale characteristics”, the effects of biopolymer treatment on soil fabric are two-sided. Firstly, the biopolymer treatment forms inter-particle bonds and, thereby, aggregation of soil particles. Secondly, the hydroxyl groups of inulin facilitate hydrogel formation through interaction with soil particles. As can be seen in Figs. 18a–d, some of the inter-particle bonds are weathered due to wet–dry cycles, resulting in a deterioration of the strength (as previously shown in Figs. 13b, c). However, the molecular bonds formed via functional groups of biopolymer with soil particles are kept relatively unchanged. The absorption peaks around 1427 cm-1 and within the range 3386–3616 cm-1 in Fig. 19 indicate the O–H bending vibrations112, detectable before and after cycles. Moreover, the stretching vibrations of CH2–OH groups are identified by absorption peak around 1000 cm-1, confirming the potential durability of the molecular bonds within the soil-hydrogel matrix.

Practical applications, economic efficiency and environmental impact

Practical applications and economic aspects

In this section, an analysis was performed to compare different biopolymers used for wind erosion mitigation against inulin, as proposed in this study (Table 4).

As clear from Table 4, inulin exhibits the highest penetration force of 714.8 N, followed by guar gum at 428N, xanthan gum at 340.6N, and Acacia gum at less than 160N. In terms of application rate and concentration, inulin and the other biopolymers (guar gum and xanthan gum) have been examined at similar application rates of 1.9 L/m2 but different concentrations, with inulin used at 2%, guar gum, as well as xanthan gum at 1.6%, and Acacia gum at a higher rate of 3.52 L/m2 (5% in terms of solution concentration). However, the latter has shown a lower penetration force. Since inulin achieves the highest penetration force with a moderate concentration (2%), it can be deduced that inulin is the most effective biopolymer for soil erosion mitigation. Given the similar application rates, inulin’s superior performance at a slightly higher concentration indicates better cost-effectiveness than the other biopolymers. Inulin is competitively priced at 2 to 5 USD/kg, making it the most cost-effective biopolymer for soil erosion mitigation. Guar gum and xanthan gum are less effective in penetration force and have comparable or higher prices.

Furthermore, the experimental findings demonstrated that inulin significantly enhances the unconfined compressive strength (UCS) and water-retention capacity and decreases soil erosion under adverse environmental conditions. These results underscore the potential of inulin as a valuable agent for wind erosion mitigation, reinforcing load-bearing layers, enhancing the structural integrity of pavement subgrades, and serving as a water-retentive stratum within pavements and landfill liners. This investigation advocates using dry mixing techniques to incorporate the additive into the soil. Industrial inulin is priced at 5 USD/kg, while cement can be acquired for as little as 0.2 USD/kg. Employing a similar mixing methodology, the cost of treating 1 m3 of soil with 0.5% inulin is the same as achieving stabilization with 10% cement used by Chang and Cho60. Nevertheless, the adoption of biopolymers in practical field applications, coupled with evolving market dynamics, is anticipated to drive down production costs significantly, thus promoting increased utilization of biopolymers.

Figure 20 compares various biopolymers and Portland cement for enhancing soil compressive strength. This figure illustrates that inulin exhibits the highest uniaxial compressive strength next to gellan gum. Despite the superior performance of Gellan gum, it requires heating to trigger the thermoregulation process, which is challenging for field-scale applications. Therefore, inulin can serve as a substitute with significant strength improvement. To address economic aspects, a comparison between inulin and other binding materials (i.e., traditional ones and different biopolymers) is provided in Table 5. According to this table, inulin ranks second in cost after cement, with its price being approximately equivalent to carboxymethyl cellulose and starch. However, the demonstrated increase in strength in fine-grained soils is significantly higher than that of carboxymethyl cellulose and starch, indicating an economic advantage over other biopolymers. The cheaper Portland cement is environmentally unsuitable due to its high carbon dioxide emissions. Cement produces approximately ten times more carbon dioxide than the cited biopolymers60in Table 5, highlighting their use as the emerging eco-friendly and sustainable binding materials. Thus, inulin offers the best combination of performance and cost, making it the optimal choice for soil stabilization and erosion control.

Viability, sustainability and environmental considerations: traditional additives versus inulin

It has been estimated that the production of 1 metric ton of cement emits 0.73 to 0.99 tons of CO2120, and the production of 1 metric ton of lime results in 1.19 to 1.5 tons of CO2121,122. However, biopolymers commonly have a low CO2 footprint (as low as one-tenth of traditional additives, depending on processing technique, sources, and types)123. What makes inulin more environmentally appealing is the different agricultural wastes from which it can be extracted. Inulin, a fructan polysaccharide that is naturally abundant in all species of plant, can be obtained from a variety of plants, including chicory, dahlia, and Jerusalem artichoke, derived from various fruits, vegetables, and grains, for instance, garlic, leeks, bananas, onions, and wheat73,111,124. Natural sources of inulin can be found in more than 36,000 plant species comprising 1200 genera from 10 families worldwide125.

Extraction of inulin from agricultural wastes not only helps its viability of production but can also help save the CO2 footprint associated with different agricultural wastes, aiming for carbon neutrality. As described earlier, there are plenty of agricultural wastes from which inulin can be extracted. Table 6 presents four waste sources, their estimated amount of production, and inulin content. The statistics point to an estimated 1.847 million tons of inulin, potentially to be obtained from the proposed four agricultural waste sources. It should be noted that 1 kg of non-recycled waste generates roughly 700 g of CO2126. Furthermore, as indicated in the current study (Table 5) and previous ones, only a small amount of biopolymer (2%), such as inulin, could increase soil strength markedly higher than (and comparable to) samples treated with 10% cement.

According to Chang et al.127, CO2 emissions related to cement usage in geotechnical applications (soil stabilization, grouting, etc.) account for 2% of the total cement-related CO2 emissions17 (4.1 G tons as of 2023, estimated based on the global cement production 128). Thus, cutting only 8% of cement usage globally in ground improvement works solely would lead to an emission reduction equivalent to more than 5.7 M tons of CO2 annually (i.e., 85% annual CO2 emission from countries such as Latvia and around 9.3% of Austria’s annual emission)129. The CO2 saving due to waste recycling would also be another plus for replacing cement used in ground improvement works with low carbon producing agents such as inulin.

Scope of the study, limitations and future perspective

The following remarks regarding the scope of applications of the results and potential future studies can be made:

-

This study investigated the effect of inulin treatment on the mechanical properties as well as erosion susceptibility of soil samples collected from a specific region (southwest of Iran). This region is known for its severe susceptibility to wind erosion. The studied soil type is known to be prevalent in most arid lands, ephemeral lakes, and continental shelves found in several countries and geographical regions such as North America, China, the Middle East, and North and South Africa138,139,140,141,142. It is noteworthy that arid and semi-arid regions contribute to one-third of the Earth’s surface, which indicates the potential for direct implementation of the results. Besides, to examine the durability of the treated samples, the exposure to sunlight, rainfall as well as wind erosion susceptibility of the samples were studied, which provides a basis for assessing the durability of the samples in arid to semi-arid regions. However, to expand the application of the results to other regions with different climates, the effects of freezing and thawing, as well as intense rainfall, have to be investigated. Furthermore, the studied soil type is classified as A4 by the American Association of State Highway and Transportation Officials (AASHTO) standard, which indicates the fair to poor rating of this soil type for road applications. Particularly, its fine content can intensify frost heave under pavements. There are limited studies in the literature investigating freezing–thawing effects on biopolymers other than inulin143. Although this study demonstrated that considerable strength increase could be achieved by the inulin treatment of this soil type, thereby enhancing its applicability for subgrade and subbase applications, in the regions prone to freezing, the effect of biopolymer treatment on post-freezing soil deformation in cold and wet regions needs further investigations and future studies in this direction are encouraged.

-

This study has addressed the mechanical performance of inulin-treated samples in the laboratory. To extend these results to field scale applications, pilot studies and field tests should be conducted to investigate the performance of the treatment in real-world condition and assess the effectiveness of the method on a larger scale.

-

The previous studies by Zhang et al.144, and Sheikh et al.145 suggest rate dependent behavior of soil response. This study did not focus on the rate effects, and for the purpose of comparison, loading rates in penetrometer and unconfined compression tests were in accordance with the previous studies and standard codes. It is recommended to investigate rate effects on the mechanical performance of inulin-treated soils in future studies.

-

It is noteworthy that ageing effects for soils treated with traditional additives such as gypsum and cement have been observed to last longer than 28 days (Kongsukprasert et al.146; Maqsood et al.147). However, studies on biopolymer-treated soils (other than inulin) in the literature have shown little change in the achieved strength beyond 28 days (Fatehi et al.52; Ghasemzadeh and Modiri54), which led this study to focus on the curing interval up to 28 days in UCS tests. It is, therefore, recommended that longer-term curing effects on the inulin-treated soils be investigated to further current knowledge.

-

The current study demonstrated a decline in strength deterioration with the number of cycles indicating adequate durability of the treated samples under considered environmental conditions. Future studies are encouraged to envision the performance of inulin-treated samples under a higher number of wet–dry cycles and other environmental conditions.

Conclusions

Inulin, a biopolymer favoring several agricultural waste sources and widely used in pharmaceutics and in the food industry, has not yet been utilized in construction technology. This study has addressed this knowledge gap by conducting a feasibility assessment of soil improvement and wind erosion mitigation using inulin. For this purpose, unconfined compressive strength tests, penetrometer as well as wind tunnel tests were performed on soil samples susceptible to wind erosion that were treated with inulin. In addition, the durability of the samples was investigated by exposing them to wet–dry cycles and sunlight. Notable findings include:

-

Surface penetration resistance tests indicated a significant increase, with values as high as tenfold higher than those of untreated soil samples.

-

Higher biopolymer concentrations led to more durable samples against environmental conditions such as wet–dry cycles and sunlight exposure, promising durability for combating environmental stresses.

-

Inulin effectively reduced soil erosion, with erosion ratios of 0.08% for soil treated with 2% inulin and 0.15% for soil treated with 0.5% inulin after the first wet–dry cycle. These ratios increased to 0.32% and 0.22% after ten cycles. Inulin-treated samples consistently outperformed untreated samples, even after ten cycles and sunlight exposure.

-

Untreated soil had a peak strength of 220 kPa, while soil with 0.5% inulin reached 1657 kPa. With 2% inulin, the strength surpasses 8 MPa, a 40-fold increase. Higher biopolymer concentrations correlated with greater peak strength and energy absorption. However, high inulin contents led to brittle failure, limiting its use in applications requiring significant deformation.

-

A 40-fold increase in unconfined compressive strength (UCS) surpassing 8 MPa makes treated soil samples suitable for mitigating erosion and supporting construction as subgrade and foundation materials.

-

Microfabric studies and consistency experiments revealed that increasing biopolymer content intensified aggregation, enhancing mechanical strength and erosion resistance.

-

Spectral analysis highlighted the formation of a robust biopolymer-soil matrix through hydrogen bonds, significantly enhancing soil cohesion. These interactions are crucial for improving soil stability and cohesion, especially in arid conditions.

-

The deterioration in stiffness and strength of treated samples was less pronounced after 3rd dry–wet cycle, pointing to the durability of the samples. The durability of the samples was attributed to the molecular bonding of soil-biopolymer hydrogel, which was found to withstand wet–dry cycles, as revealed by FTIR analysis.

In summary, inulin presents an economical and feasible choice for improving soil erosion resistance and soil strength. This newly introduced biopolymer resulted in a multi-fold increase in the treated samples’ erosion resistance, durability, and mechanical strength. More research is recommended for its use as a novel and eco-friendly soil stabilizer. Particularly, further studies are required to investigate its effects on other soil types and its durability against freezing–thawing cycles and under different environmental conditions. Given the significant improvements in soil strength and durability observed, particularly with the 2% inulin treatment, inulin shows promising results potentially suitable for improving base, subbase and subgrade materials and providing an eco-friendly wind erosion suppressant for regions prone to severe wind erosion (e.g., arid lands, dried lakes) as well as mine tailings. Compared to other biopolymers, inulin can be extracted from a spectrum of different waste resources, commonly agricultural waste, making it a green and sustainable solution for soil erosion mitigation and stabilization and one of the most economical alternatives to date.

Data availability

Data would be available upon request from the corresponding author.

References

Bongaarts, J. & O’Neill, B. C. Global warming policy: Is population left out in the cold?. Science 361, 650–652. https://doi.org/10.1126/science.aat8680 (2018).

Chu, J. & Guo, W. Land reclamation using clay slurry or in deep water: challenges and solutions. Jpn. Geotech. Soc. Spec. Publ. 2, 1790–1793. https://doi.org/10.3208/jgssp.tc217-02 (2016).

Hopkins, C., Cameron, D. & Rahman, M. M. Field trials of unbound granular pavements treated with an insoluble dry powdered polymer. Transp. Geotech. 41, 101037. https://doi.org/10.1016/j.trgeo.2023.101037 (2023).

Manzoor, S. O., Yousuf, A., University of Mohammed Premier Oujda Morocco. Stabilisation of soils with lime: A review. J. Mater. Environ. Sci. 11, 1538–1551 (2020).

Noin D, Clarke JI. Population and environment in arid regions: Paris, Pearl River, N.Y. UNESCO, Parthenon Publication Group. https://nla.gov.au/nla.cat-vn241731. (1998).

Liu, B. et al. Bio-mediated method for improving surface erosion resistance of clayey soils. Eng. Geol. 293, 106295. https://doi.org/10.1016/j.enggeo.2021.106295 (2021).

Owji, R., Habibagahi, G., Nikooee, E. & Afzali, S. F. Wind erosion control using carboxymethyl cellulose: From sand bombardment performance to microfabric analysis. Aeolian Res. 50, 100696. https://doi.org/10.1016/j.aeolia.2021.100696 (2021).

Broomandi, P. et al. Assessment of the association between dust storms and COVID-19 infection rate in southwest Iran. Environ. Sci. Pollut. Res. 29, 36392–36411. https://doi.org/10.1007/s11356-021-18195-7 (2022).

Fongsodsri, K. et al. Particulate matter 2.5 and hematological disorders from dust to diseases: A systematic review of available evidence. Front. Med. https://doi.org/10.3389/fmed.2021.692008 (2021).

Government of Canada, Canadian Centre for Occupational Health and Safety. What are the Effects of Dust on the Lungs?. https://www.ccohs.ca/oshanswers/chemicals/lungs_dust.html. (Accessed 17 Feb 2024). (2024).

Leung, N. H. L. Transmissibility and transmission of respiratory viruses. Nat. Rev. Microbiol. 19, 528–545. https://doi.org/10.1038/s41579-021-00535-6 (2021).

Particulate Matter (PM) Basics | US EPA. US EPA (2024). https://www.epa.gov/pm-pollution/particulate-matter-pm-basics. (Accessed 17 Feb 2024). (2024).

Scheuch, G. Breathing is enough: for the spread of influenza virus and SARS-COV-2 by breathing only. J. Aerosol Med. Pulm. Drug Deliv. 33, 230–234. https://doi.org/10.1089/jamp.2020.1616 (2020).

Kang, K. K., Chu, J. M., Jeong, H. S., Han, W. J. & Yu, N. M. A study on the analysis of damages of Northeast Asian dust and sand storm and of the regional cooperation strategies. Korea Environ. Inst. 2(1), 112–118 (2004).

Kavazanjian E, Iglesias E, Karatas I. Biopolymer soil stabilization for wind erosion control. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering. 881–884. https://doi.org/10.3233/978-1-60750-031-5-881 (2009).

Chu J, Varaksin S, Klotz U, Mengé P. Construction processes. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering. IOS Press, 3006–3135. (2009).

Chang, I., Im, J. & Cho, G.-C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability 8, 251. https://doi.org/10.3390/su8030251 (2016).

Chang, I. et al. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 24, 100385. https://doi.org/10.1016/j.trgeo.2020.100385 (2020).

Metz, B., Davidson, O., De Coninck, H., Loos, M. & Meyer, L. Carbon dioxide capture and storage (IPCC 2005): summary for policymakers. Cambridge University Press, UK. https://www.ipcc.ch/site/assets/uploads/2018/03/srccs_summaryforpolicymakers-1.pdf (Accessed 8 Dec 2024) (2005).

Worrell, E., Price, L., Martin, N., Hendriks, C. & Meida, L. O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 26, 303–329. https://doi.org/10.1146/annurev.energy.26.1.303 (2001).

Wang, X., Silbermann, C. B., Nagel, T. & Nackenhorst, U. Modelling of the elastoplastic behaviour of the bio-cemented soils using an extended modified Cam clay model. J. Rock Mech. Geotech. Eng. https://doi.org/10.1016/j.jrmge.2023.09.015 (2023).

Saffari, R., Nikooee, E., Habibagahi, G. & van Genuchten, M. T. Effects of biological stabilization on the water retention properties of unsaturated soils. J. Geotech. Geoenviron. Eng. https://doi.org/10.1061/(asce)gt.1943-5606.0002053 (2019).

Moravej, S., Nikooee, E., Habibagahi, G., & Niazi, A. Bio-stabilisation of dispersive soils, (2015).

Moravej, S., Habibagahi, G., Nikooee, E. & Niazi, A. Stabilization of dispersive soils by means of biological calcite precipitation. Geoderma 315, 130–137. https://doi.org/10.1016/j.geoderma.2017.11.037 (2018).

Sadjadi, M., Nikooee, E. & Habibagahi, G. Biological treatment of swelling soils using microbial calcite precipitation. Unsatur. Soils Res. Appl. https://doi.org/10.1201/b17034-132 (2014).

Talebbeydokhti, N., Nikooee, E., Kazemi, M.M., Habibagahi, G. & Ghasemi, Y. Biological Stabilization of the Fine-Grained Soils Using Microalgae: Evaluation of the Effective Parameters, Proceedings of the U.S.-Iran (Academies of Sciences) Symposium on Air Pollution in Megacities, American Association for the Advancement of Science (AAAS), Beckman Center, Irvine, California, 52-65. https://www.researchgate.net/profile/Meeghat-Habibian/publication/318983681_Assessing_the_Role_of_Transportation_Demand_Management_Policies_on_Urban_Air_Pollution_A_Case_Study_of_Mashad_Iran/links/59898af9a6fdcc756263574c/Assessing-the-Role-of-Transportation-Demand-Management-Policies-on-Urban-Air-Pollution-A-Case-Study-of-Mashad-Iran.pdf (Accessed 8 Dec 2024) (2013).

Van Paassen, L. A. Biogrout, ground improvement by microbial induced carbonate precipitation. Doctoral thesis, TU Delft. https://resolver.tudelft.nl/uuid:5f3384c4-33bd-4f2a-8641-7c665433b57b (Accessed 8 Dec 2024) (2009).

Tiwari, N., Satyam, N. & Sharma, M. Micro-mechanical performance evaluation of expansive soil biotreated with indigenous bacteria using MICP method. Sci. Rep. 11, 10324. https://doi.org/10.1038/s41598-021-89687-2 (2021).

Moqsud, M. A. & Gochi, T. Evaluation of biocementation of slope soil for erosion control with low-cost materials. Sci. Rep 14, 16065. https://doi.org/10.1038/s41598-024-67185-5 (2024).

Arab MG. Soil Stabilization using Calcium Carbonate Precipitation via Urea Hydrolysis. Proceedings of the World Congress on Civil, Structural, and Environmental Engineering. https://doi.org/10.11159/icgre19.149. (2019).

Arab, M. G. et al. State-of-the-art review of enzyme-induced calcite precipitation (EICP) for ground improvement: Applications and prospects. Geosciences 11, 492. https://doi.org/10.3390/geosciences11120492 (2021).

Hamdan, N. & Kavazanjian, E. Enzyme-induced carbonate mineral precipitation for fugitive dust control. Géotechnique 66, 546–555. https://doi.org/10.1680/jgeot.15.p.168 (2016).

Gedela, R., Indraratna, B., Nguyen, T. T. & Medawela, S. The effect of biopolymer treatment on the potential instability of a soft soil under cyclic loading. Transp. Geotech. 42, 101102. https://doi.org/10.1016/j.trgeo.2023.101102 (2023).

Lee, M., Chang, I., Park, D.-Y. & Cho, G.-C. Strengthening and permeability control in sand using Cr3+-crosslinked xanthan gum biopolymer treatment. Transp. Geotech. 43, 101122. https://doi.org/10.1016/j.trgeo.2023.101122 (2023).

Dejong, J. T. et al. Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Géotechnique 63, 287–301. https://doi.org/10.1680/geot.sip13.p.017 (2013).

Afzali, S. F., Hemayati, M., Niazi, A. & Nikooee, E. Toward industrialization of microbially induced carbonate precipitation for wind erosion suppression: Novel methodology, challenges, and opportunities. Iran. J. Sci. Technol. Trans. Civil Eng. 48, 1143–1149. https://doi.org/10.1007/s40996-023-01190-y (2023).

Alotaibi, E., Arab, M. G., Abdallah, M., Nassif, N. & Omar, M. Life cycle assessment of biocemented sands using enzyme induced carbonate precipitation (EICP) for soil stabilization applications. Sci. Rep. https://doi.org/10.1038/s41598-022-09723-7 (2022).

Hemayati, M., Nikooee, E., Habibagahi, G., Niazi, A. & Afzali, S. F. New non-ureolytic heterotrophic microbial induced carbonate precipitation for suppression of sand dune wind erosion. Sci. Rep. https://doi.org/10.1038/s41598-023-33070-w (2023).

Zhang, Y. M., Wang, H. L., Wang, X. Q., Yang, W. K. & Zhang, D. Y. The microstructure of microbiotic crust and its influence on wind erosion for a sandy soil surface in the Gurbantunggut Desert of Northwestern China. Geoderma 132, 441–449. https://doi.org/10.1016/j.geoderma.2005.06.008 (2006).

Chang, I., Prasidhi, A. K., Im, J., Shin, H.-D. & Cho, G.-C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 253–254, 39–47. https://doi.org/10.1016/j.geoderma.2015.04.006 (2015).

Maleki, M., Ebrahimi, S., Asadzadeh, F. & Tabrizi, M. E. Performance of microbial-induced carbonate precipitation on wind erosion control of sandy soil. Int. J.Environ. Sci. Technol. 13, 937–944. https://doi.org/10.1007/s13762-015-0921-z (2016).

Jiang, T., Zhao, J.-D. & Zhang, J.-R. Splitting tensile strength and microstructure of xanthan gum-treated loess. Sci. Rep. https://doi.org/10.1038/s41598-022-14058-4 (2022).

Zhang, X., Cao, W. & Zhang, X. Experimental study on mechanical and hydraulic properties of xanthan gum improved low liquid limit silty soil. Sci. Rep. https://doi.org/10.1038/s41598-024-61875-w (2024).

Soldo, A., Miletić, M. & Auad, M. L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. https://doi.org/10.1038/s41598-019-57135-x (2020).

Kwon, Y.-M., Chang, I. & Cho, G.-C. Xanthan biopolymer-based soil treatment effect on kaolinite clay fabric and structure using XRD analysis. Sci. Rep. https://doi.org/10.1038/s41598-023-38844-w (2023).

Armistead, S. J., Smith, C. C. & Staniland, S. S. Sustainable biopolymer soil stabilization in saline rich, arid conditions: a ‘micro to macro’ approach. Sci. Rep. https://doi.org/10.1038/s41598-022-06374-6 (2022).

Cabalar, A. F., Awraheem, M. H. & Khalaf, M. M. Geotechnical properties of a low-plasticity clay with biopolymer. J. Mater. Civil Eng. 30(8), 04018170. https://doi.org/10.1061/(ASCE)MT.19435533.0002380 (2018).

Lentz, R. D. Polyacrylamide and biopolymer effects on flocculation, aggregate stability, and water seepage in a silt loam. Geoderma 241–242, 289–294. https://doi.org/10.1016/j.geoderma.2014.11.019 (2015).

Orts, W. J., Sojka, R. E. & Glenn, G. M. Biopolymer additives to reduce erosion-induced soil losses during irrigation. Ind. Crops Prod. 11(1), 19–29. https://doi.org/10.1016/S09266690(99)00030-8 (2000).

Im, J., Tran, A. T. P., Chang, I. & Cho, G.-C. Dynamic properties of gel-type biopolymer-treated sands evaluated by resonant column (RC) tests. Geomech. Eng. 12, 815–830. https://doi.org/10.12989/gae.2017.12.5.815 (2017).

Chang, I. & Cho, G.-C. Shear strength behavior and parameters of microbial gellan gum-treated soils: from sand to clay. Acta Geotech. 14, 361–375. https://doi.org/10.1007/s11440-018-0641-x (2018).

Fatehi, H., Abtahi, S. M., Hashemolhosseini, H. & Hejazi, S. M. A novel study on using protein based biopolymers in soil strengthening. Constr. Build. Mater. 167, 813–821. https://doi.org/10.1016/j.conbuildmat.2018.02.028 (2018).

Dehghan, H., Tabarsa, A., Latifi, N. & Bagheri, Y. Use of xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 21, 155–165. https://doi.org/10.1007/s10098-018-1625-0 (2018).

Ghasemzadeh, H. & Modiri, F. Application of novel Persian gum hydrocolloid in soil stabilization. Carbohydr. Polym. 246, 116639. https://doi.org/10.1016/j.carbpol.2020.116639 (2020).

Kumar, S. A. & Sujatha, E. R. An appraisal of the hydro-mechanical behaviour of polysaccharides, xanthan gum, guar gum and β-glucan amended soil. Carbohydr. Polym. 265, 118083. https://doi.org/10.1016/j.carbpol.2021.118083 (2021).

Brodin, M., Vallejos, M., Opedal, M. T., Area, M. C. & Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Clean. Prod. 162, 646–664. https://doi.org/10.1016/j.jclepro.2017.05.209 (2017).

Kabir, E., Kaur, R., Lee, J., Kim, K.-H. & Kwon, E. E. Prospects of biopolymer technology as an alternative option for non-degradable plastics and sustainable management of plastic wastes. J. Clean. Prod. 258, 120536. https://doi.org/10.1016/j.jclepro.2020.120536 (2020).

United Nations. The sustainable development goals report 2023: special edition. https://unstats.un.org/sdgs/report/2023. (Accessed 8 Dec 2024) (2023).

Cappai, M. et al. Thermal properties of eco-friendly earthen materials stabilized with bio-based polymers: Experimental data and modeling procedure for improving mix-design. Materials 17, 1035. https://doi.org/10.3390/ma17051035 (2024).

Chang, I. & Cho, G.-C. Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Constr. Build. Mater. 30, 30–35. https://doi.org/10.1016/j.conbuildmat.2011.11.030 (2012).

Gera, R. et al. A narrative review on use of biomaterials in achieving SDG 9: Build resilient infrastructure, promote sustainable industrialization and foster innovation. E3S Web Conf. 391, 01180. https://doi.org/10.1051/e3sconf/202339101180 (2023).

Ghosh, E., Fahim, S., Shahariar, Md. N. K. & Alam, T. Prospect of biopolymer application for sustainable and durable earthen structures in context of Bangladesh: A brief review. AIP Conf. Proc. https://doi.org/10.1063/5.0129893 (2023).

Khaleghi, M. & Heidarvand, M. A novel study on hydro-mechanical characteristics of biopolymer-stabilized dune sand. J. Clean. Prod. 398, 136518. https://doi.org/10.1016/j.jclepro.2023.136518 (2023).

Rajvanshi, J., Sogani, M., Kumar, A. & Arora, S. Biomaterials: A sustainable solution for a circular economy. Eng. Proc. 59, 133 (2023).

Zhang, K. et al. Microbial-induced carbonate precipitation (MICP) technology: a review on the fundamentals and engineering applications. Environ. Earth Sci. https://doi.org/10.1007/s12665-023-10899-y (2023).

Lee, M., Kwon, Y.-M., Park, D.-Y., Chang, I. & Cho, G.-C. Durability and strength degradation of xanthan gum based biopolymer treated soil subjected to severe weathering cycles. Sci. Rep. https://doi.org/10.1038/s41598-022-23823-4 (2022).

Pritchard, O. G., Hallett, S. H. & Farewell, T. S. Soil impacts on UK infrastructure: current and future climate. Proc. Inst. Civil Eng. Eng. Sustain. 167, 170–184. https://doi.org/10.1680/ensu.13.00035 (2014).

Lemboye, K., Almajed, A., Alnuaim, A., Arab, M. & Alshibli, K. Improving sand wind erosion resistance using renewable agriculturally derived biopolymers. Aeolian Res. 49, 100663. https://doi.org/10.1016/j.aeolia.2020.100663 (2021).

Ashwin, P. B., Ananthan, S., Rakesh, K., Bharath, P. & Padmapriya, M. Potential of natural bio-polymers in stabilization of soil. Int. Res. J. Eng. Technol. (IRJET) 6(4), 5106–5117 (2019).

Ni, D. et al. Inulin and its enzymatic production by inulosucrase: Characteristics, structural features, molecular modifications and applications. Biotechnol. Adv. 37, 306–318. https://doi.org/10.1016/j.biotechadv.2019.01.002 (2019).

Wan, X. et al. The physiological functions and pharmaceutical applications of inulin: A review. Carbohydr. Polym. 246, 116589. https://doi.org/10.1016/j.carbpol.2020.116589 (2020).

Liang, X. et al. Progress in the preparation and application of inulin-based hydrogels. Polymers 16, 1492. https://doi.org/10.3390/polym16111492 (2024).

Mensink, M. A., Frijlink, H. W., Van Der Voort, M. K. & Hinrichs, W. L. J. Inulin, a flexible oligosaccharide I: Review of its physicochemical characteristics. Carbohydr. Polym. 130, 405–419. https://doi.org/10.1016/j.carbpol.2015.05.026 (2015).

Escobar-Ledesma, F. R. et al. Extraction of inulin from Andean plants: An approach to non-traditional crops of Ecuador. Molecules 25, 5067. https://doi.org/10.3390/molecules25215067 (2020).

Mangguali, M., Meta, M. & Syarifuddin, A. Study of inulin content and extractions methods in several types of tubers: review paper. Bio Web Conf. 96, 01031. https://doi.org/10.1051/bioconf/20249601031 (2024).