Abstract

This paper investigates the impact of High-Profile Promotions (HPPs), specifically luxury beauty and aroma booths, on environmental sustainability. While most prior research on similar pop-up installations has focused on their commercial value, this study approaches the topic from an environmental sustainability perspective. It quantifies the environmental impact of HPPs, transitioning from qualitative assessments to quantitative analysis, and explores potential environmental protection strategies for brands when planning HPP events, particularly regarding the selection of construction materials. The methodology employed in this study integrates Life Cycle Assessment, Eco-Indicator 99 (EI 99), and Comparative Study approaches. This comprehensive analysis, exemplified through a case study of an internationally renowned aroma brand, investigates the full life cycle of an HPP event booth. The study meticulously deconstructs the components and materials involved, quantifying their environmental impacts using the EI99 index. These environmental impact assessments are subsequently compared to those of conventional massive buildings, enabling a robust evaluation of the relative sustainability and resource efficiency of the HPP structures. Through calculation and analysis, this study reveals that the daily carbon emissions of different HPP options were found to range from 162 to 1308 times that of a conventional massive building, and varying material choices can potentially reduce HPPs’ daily carbon emissions by approximately 73%. This underscores the critical role of material selection in mitigating environmental impact within the context of pop-up retail. Notably, furniture components, particularly cabinets, emerge as pivotal areas where carbon footprint reduction efforts can be most effectively concentrated. Finally, this research offers valuable insights and practical guidance for environmentally conscious brands in the design and implementation of pop-up retail strategies. By incorporating these findings, brands can align their operations with principles of sustainability and social responsibility, promoting a more balanced and sustainable impact on society.

Similar content being viewed by others

Introduction

As e-commerce growth continues to outpace that of brick-and-mortar retail, temporary retail spaces, also known as pop-up shops, are becoming a crucial promotional strategy, especially for online retailers and service providers1. In this context, many brands are focusing on creating immersive experiences in offline spaces, with new retail pop-up stores becoming one of the most effective ways to engage young consumers. In 2020, the turnover of China’s pop-up store industry exceeded 80 billion yuan, with approximately 9.6 million pop-up events occurring2.

Pop-ups, defined as short-term, spontaneous business activities, involve brands renting smaller spaces for brief periods to quickly capture consumer interest in a product or service. In China, 65% of pop-up stores operate for less than 10 days3. This business model offers substantial benefits.

According to a report by Cushman and Wakefield4, pop-up store rents are typically 30–40% lower than those of traditional retail stores, while their sales are 20–30% higher. Furthermore, pop-up stores are generally rented for a few weeks to a few months, allowing them to adapt quickly to market conditions, unlike traditional retail stores, which are often leased for several years. A study by RET Reynolds found that pop-up stores are highly cost-effective for attracting foot traffic and generating sales revenue3. In the current Chinese market, pop-up stores match IP-based exhibitions in customer attraction and surpass them in revenue generation. Compared to general catering, fast fashion, and cinemas, pop-up stores excel in drawing customers as in Fig. 1.

Pop-ups offer freshness and experiential value to consumers and significant commercial benefits to brands. However, their short duration, thematic focus, and irregular venues raise several environmental and sustainability concerns. This study aims to assess the environmental impact of pop-up spaces quantitatively, identify design opportunities, and propose improvement strategies. The research focuses on High-Profile Promotions (HPPs), a specific type of pop-up. By collaborating with an internationally renowned perfumery brand, referred to as D Brand, field research was conducted at the brand’s processing plant and end-of-life facility for HPP event booths.

HPPs, used predominantly by high-end fashion and luxury brands (e.g., Prada, LVMH), are short-term promotional events designed to boost brand visibility and attract targeted customer groups during important occasions. Compared to pop-up activities of ordinary or start-up brands, HPPs as Fig. 2 showed are more temporary, require higher investment, and are geared toward maximizing commercial value.

For D Brand, HPPs are week-long events held hundreds of times a year across different regions, typically featuring aesthetically appealing, semi-open booths with strong circulation, measuring approximately 9 m × 15 m × 3 m. This study will analyze the materials used in constructing a typical HPP event booth from a product life cycle perspective to provide design insights and identify opportunities for sustainable improvement.

Materials and methods

Ethics statement

All protocols in this study were approved by the Tongji University Science and Technology Ethics Committee, Shanghai, China (permit number: TJDXSR021). All methods were carried out in strict accordance with relevant guidelines and regulations.

In addition, informed consent was obtained from all participants involved in the study and all participants signed informed consent forms. As all participants were over the age of 16, consent was provided directly by the participants.

Description of information sources

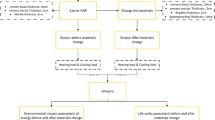

The project team employed non-participant observation and expert interviews for this study. Field research was conducted at the construction and scrapping facilities of the HPP booth to observe the production and processing activities in situ. Interviews were also conducted with brand managers and frontline manufacturing staff to gain a comprehensive understanding of the entire lifecycle of HPP production, processing, and deployment5 as in Fig. 3.

Life cycle assessment (LCA)

This study employs the Life Cycle Assessment (LCA) methodology, a quantitative approach that collects and analyzes data to quantify the environmental impacts of a product or system throughout its entire lifecycle, including resource consumption, energy use, and waste generation. LCA is extensively used in industrial processes to evaluate the environmental footprint of products6. In this study, LCA provides a scientific basis by quantifying the lifecycle impacts of the HPP booth and its components, identifying potential environmental impacts, and highlighting key opportunities for improvement.

Eco-Indicator 99 (EI 99)7

To enhance the specificity of the data, this study utilizes the Eco-Indicator 99 (EI99) method alongside LCA calculations. EI99 is a damage-oriented methodology that assesses the impact of emissions, extractions, and land use on human health, ecosystem quality, and resource depletion. These impacts are consolidated into a single score8. EI99 offers standard eco-indicator values for commonly used materials at various stages of production, transportation, use, and disposal, facilitating the assessment of the product system’s environmental performance. The calculation methodology for these standard eco-indicator values is detailed in the EI99 guidelines and is not elaborated upon in this study. In the EI99 method, the unit of all indicator values is the Point (Pt), where 1 Pt represents one-thousandth of the annual environmental load of an average European resident. Based on the latest data from the International Energy Agency (IEA)9, which reports per capita carbon dioxide emissions in Europe in 2021 as 5.37 t CO2e, 1 Pt is approximately equal to 5.37 tonnes of CO2eq. This study converts the results into an average daily carbon emissions value for more intuitive data analysis.

Comparative study

The main objective is to assess differences and impacts between variables comprehensively. In this research, we compare the environmental impact of different HPP material options. Given that different HPP events feature diverse design styles and that designers and engineers select varying materials and quantities during construction, the calculation process involves significant estimation, leading to inevitable errors. The research team identified the components and common material choices for a typical HPP. The specific estimation logic for each item is detailed in the accompanying table.

Comparative Studies help with providing insights into the effectiveness, efficiency, and sustainability of various options. By examining multiple scenarios or alternatives, we can inform decision-making processes, design processes and strategic planning aimed at minimizing environmental impact and maximizing resource efficiency.

Findings

Life cycle assessment of HPP for Brand D

The lifecycle of retail stores can be divided into three stages: Creation, Provision, and End-of-Life. The first stage encompasses activities such as locating specific premises, conceptualizing, designing, and constructing the store—essentially, all pre-service activities. The second stage involves the actual provision of the service. The third stage includes activities required to terminate the service, such as dismantling and waste treatment of redundant materials. Based on this framework, this study explores the lifecycle of HPPs in more detail, using Shanghai, China, as a case study. Following three offline field studies and direct communication with the brand, the research team identified the overall organizational process for an HPP as follows in Fig. 4.

-

Design Guideline Reception

The subsidiary first receives design guidelines from the parent company, which include the event theme, cycle, and design renderings for the HPP event. The subsidiary then discusses the feasibility of the HPP program in the Chinese market with senior management, proposes an execution plan, and produces renderings tailored to the Chinese market.

-

Feedback and Approval

The Chinese design team sends the design back to the parent company for approval. Once approved, the team collaborates with partner factories for production.

-

Booth Construction

Construction involves pre-assembly and final assembly. The factory first completes the entire HPP build-up on-site, confirms the design, dismantles the parts, and transports them to the event location for final assembly.

-

Event Execution

During the event, Brand D’s HPP showcases themed displays, offers experiential make-up trials, and organizes interactive sessions with consumers. These activities typically cause minimal wear and tear on the installations.

-

Booth Dismantling and Scrapping

After the event, the showroom enters the dismantling phase. The factory retains the dismantled components for a period, sorts reusable materials, and provides a scrapping recommendation for the remaining materials to Brand D. If authorized, the factory contacts a scrapping company to dispose of the materials.

Typical HPP components of Brand D

To identify design opportunities, the researchers categorized the components, materials, and furniture of a typical Brand D HPP booth into three categories: non-recyclable, recyclable until functionality is lost, and reusable. In Table 1, the team found that Brand D currently recycles only 14–34% of materials directly, with approximately 20% not entering the recycling process after a campaign lasting about 1 week.

The research team further analyzed the components, materials, and processes involved, summarizing their findings in Fig. 5. For example, PVC synthetic flooring is most commonly used due to its cost-effectiveness and ease of assembly, but it is typically discarded after the event. Some HPPs opt for floorless setups or solid wood flooring, which are also discarded post-event.

A typical HPP for Brand D consists of structures, furniture, and electrical equipment. Vanity chairs, tables, and light fixtures are often reused as they are not strongly theme-specific. However, walls, floors, art installations, and facing materials are usually discarded after a single event due to customization requirements, although most of these materials are recyclable. Brands often sacrifice material recycling to protect intellectual property rights.

Frames, especially metal ones, can ideally be recycled. Large frames made of unit frames or welded steel bars can be dismantled and reassembled for future events. Modularity is thus an effective and sustainable solution. However, recent HPP events by Brand D revealed that frames vary significantly, limiting their practical reuse. Consequently, frames are included in the recycling or end-of-life process alongside other materials.

Cabinets, being complex and material-intensive, are typically made from a combination of metal, glass, leather, chipboard, plywood, and pressboard. The variety of materials allows for selective recycling, but Brand D often prioritizes higher quality over recycling efficiency. Whether cabinets are reused depends on brand authorization, but field research indicates that time constraints usually prevent reuse. Therefore, cabinets are generally included in the end-of-life process in the subsequent calculations.

Typical HPP metric calculation for Brand D

To provide a clearer conclusion, the team estimated the quantities of various materials used in the HPP and calculated their environmental indices. First, the functional units for the main body of the calculation were defined according to the requirements of the EI99 methodology. Then, the specific indices for the materials involved in each part of the component were calculated individually. All the individual results were summed, and finally, the results were compared with the indicators for massive buildings of the same volume as provided in the EI99 manual.

The primary function of the HPP is to facilitate high-profile promotions for the brand. To achieve this, the team set the functional unit of Brand D’s HPP to be operational for 12 h a day (10 a.m.–10 p.m., which is the average opening time of shopping malls in Shanghai) continuously for 1 week. The estimated space size of a typical HPP is 9 m × 15 m × 3 m. Through researching several HPP events of Brand D from January 2023 to May 2024, it was found that the events were held in three shopping malls located in central Shanghai, with the construction and scrapping factories about 20 km away. Therefore, the material transportation distance was estimated to be 80 km, including two round trips with an empty truck for each trip.

It is important to note that the calculation process only considers the spatial materials needed to build the HPP event booth, excluding products for sale or giveaways, as well as environmental impacts generated by people during the building or operation process.

Based on the analysis of HPP’s constituent components, the research team focused on calculations for the floor, walls, frame (including off-wall and in-wall frames), cabinets, furniture, electrical equipment, art installations, and facing materials, with all decorative materials unified in the facing section. The specific calculation process is shown in Fig. 6, and more detailed calculations can be found in the Appendix (Table 2).

-

Floor

HPP mainly uses PVC material for flooring. PVC particles have an equal probability of entering the recycling and landfill processes, so the waste link calculates values for both disposal methods, each accounting for half of the total amount.

-

Wall

Given the high circulation characteristic of the HPP booth, it is preset to have only two vertical walls and a top surface, with the other two surfaces supported by frames.

-

Frame

The frame consists of two parts: the inside wall frame and the outside wall frame. The mainstream choice of materials for the outside wall frame includes stainless steel and aluminum alloy, which serve as substitutes for each other. For the in-wall frame, the choice is between lightweight steel keel and pine wood keel.

-

Furniture

Furniture includes cabinets (wood paneling), product displays (acrylic), and tables and chairs. Since tables and chairs are reused furniture with a longer lifecycle than the HPP, only the data generated from transportation are calculated.

-

Electrical equipment

Electrical equipment is included in the calculations as part of the total environmental impact.

-

Art installation

Art installations present the largest error margin due to varying inputs for each event. Therefore, the calculation uses the indicator for Metal construction building in the EI99 indicator and estimates the installation volume to be 4m3.

-

Facing material

Facing materials are challenging to estimate due to the wide variety of choices. The team averaged the EI99 indicators of materials such as paper, cardboard, wood panels, glass, PVC, PP, iron, aluminum, and copper, and estimated the total weight of all finishes to be 20 kg.

Discussion

Comparative analysis of HPP and permanent building carbon emissions

After the calculations, the research team gained a preliminary understanding of the environmental impacts of each component. To better visualize the data, they compared the results with the environmental impact of a massive building of the same volume (405 m3) from the EI99 methodology. A massive building of this volume would generate an environmental impact of around 607,500 Pt, equivalent to approximately 3,252,275 tons of CO2 emissions, assuming a lifespan of 10 years. The average daily carbon emissions for such a building are approximately 893.8 tons.

To provide a comprehensive comparison and better understand the potential environmental impacts of different material choices and configurations, the research team evaluated three distinct options for the HPP event booth. The EI99 guidelines do not specify whether a massive building includes multimedia, furniture, and fixtures in its environmental impact calculation. Therefore, these components are not included in Options 1 and 2 for the HPP but are added in Option 3.

The difference between Options 1 and 2 is that Option 1 uses stainless steel and lightweight steel keel for the off-wall and in-wall frames, while Option 2 uses aluminum and pine wood keel. This comparison allows us to see how the choice of materials with different environmental impacts influences the overall carbon footprint. Option 3 includes multimedia, furniture, and art installations, i.e., the maximum values for all calculations, to assess the comprehensive impact when all possible components are considered.

The environmental impact data for HPP, excluding electrical equipment, furniture, and art installations, ranges between 188,539 Pt and 689,353 Pt. Given that the impact for a massive building is 607,500 Pt, the calculation is relatively reasonable in Table 3.

This analysis led the research team to conclude the following findings.

Short lifespan increases huge environmental impact

Despite the material choices making HPPs appear environmentally friendly compared to conventional massive buildings, the short lifespan of HPPs (normally 7 days to half a month) results in a much higher average daily carbon emission index.

By calculating the average daily carbon emissions, we can compare the daily environmental impact of HPP with the regular emissions of permanent buildings, yielding intuitive data comparisons and insights for our study conclusions. Based on the data tracked from Brand D, the usage cycle of HPP ranges from 7 to 14 days; we use a median value of 10 days as the basis for our calculations. According to the previous calculations, the average daily carbon emissions for a permanent building are 893.8 tons. In contrast, the values for HPP are approximately 528,832.5 tons for Option 1, 144,637 tons for Option 2, and 1,169,520 tons for Option 3, which are 592 times, 162 times, and 1,308 times that of a conventional massive building, respectively. This clearly demonstrates the substantial environmental impact of HPP.

Material choices affect carbon footprint

The team observed that different material choices for the in-wall and off-wall frames significantly impact the overall environmental footprint. Stainless steel and lightweight steel keel have much higher environmental impacts than aluminum and pine wood keel.

When we applied the same calculation method and compared HPP option 1 and option 2 with different material choices, we found their daily carbon emissions differed by 3.65 times. This suggests that appropriate material selection could help HPP reduce its daily carbon emissions by approximately 73%.

Designers and engineers should consider materials with lower environmental impacts at the outset of the design process. The EI99 manual lists materials with low environmental impact indices, such as recycled aluminum, electrical steel, glass, cardboard, cement, sand, and wood panels. Using recycled materials can even result in negative environmental impact indices, contributing to carbon reduction (Fig. 7).

Findings on furniture-related carbon emissions

The analysis reveals that furniture, particularly cabinets, contributes significantly to carbon emissions among all HPP components. This notable impact may be attributed to the predominant use of wooden boards in cabinet construction. The research team posits that, for short-term activities like HPP, it is feasible to transition the storage function from wooden cabinets to lighter, more environmentally friendly materials such as recycled cardboard. Additionally, redesigning cabinets for reuse in multiple events could further mitigate their environmental footprint.

Through interviews and discussions, the research team discovered that Brand D has attempted to integrate sustainability into the entire HPP process and aims to reuse associated consumables. However, several challenges hinder the realization of this goal:

-

Conflicts between Premium Brand Positioning and Recycled Materials:

Brands often strive for high-quality texture and visual appeal, which recycled materials may not consistently provide. The high degree of customization in HPP booth materials further complicates the standardization of recycled components.

-

Lack of Motivation to Recycle Materials:

The current high costs of material recycling and reuse deter both factories and brands from prioritizing these practices. Partner factories, responsible for executing brand programs, also have limited influence in the decision-making process.

-

Insufficient Demonstration of Sustainable Value:

Commercial brands seek visible returns on their investment in sustainability, whether financial or in terms of brand recognition. Merely recycling materials can risk diminishing the brand’s perceived quality without clearly showcasing its commitment to sustainability, thus reducing the incentive for recycling initiatives.

System design opportunities in the HPP process

By examining Brand D’s HPP organizational structure, operation cycle, component materials, and recycling methods, the research team identified several design opportunities, confirmed through interviews and branding analyses:

-

Internal Component Recycling and Registry:

Brand D has adopted the practice of reusing certain components until they are completely unusable. Creating a registry to document material properties, reuse frequency, and application contexts could facilitate the selection and use of materials in future HPP campaigns.

-

External Component Recycling and Second-Hand Market Development:

To allow HPP components to enter the second-hand market, Brand D must ensure these items are unbranded to protect intellectual property. Thus, brands could design easily removable brand logos to promote external reuse and extend material lifecycles.

-

Digital Maintenance and Repair Instructions:

Brand D’s global operations require the decentralization of concepts and designs. Implementing an online smart warehouse management system with digital repair instructions from the parent company could empower local subsidiaries to maintain and reuse products more efficiently.

-

Redesign and Enhancement of Component Connectors:

Feedback indicates that the current HPP component connectors are difficult to dismantle and not cataloged. Investing in the redesign and enhancement of these connectors could increase the recycling rate and enhance user engagement through innovative design, providing consumers with new sustainability experiences.

Conclusion

In summary, HPP events, as ephemeral retail structures, serve as effective business tools that align with current market demands and offer substantial profitability opportunities for brands. However, their brief operational lifespan, focused thematic executions, and transient venue setups contribute to significant material waste and environmental impact. Through comprehensive field research, brand consultations, and rigorous analysis of environmental data concerning Brand D’s HPP events, it becomes evident that these events exert a markedly higher environmental footprint compared to conventional permanent buildings. Specifically, the daily carbon emissions of different HPP options were found to range from 162 to 1308 times that of a conventional massive building.

Furthermore, our investigation reveals that varying material choices can potentially reduce HPPs’ daily carbon emissions by approximately 73%. This underscores the critical role of material selection in mitigating environmental impact within the context of pop-up retail. Notably, furniture components, particularly cabinets, emerge as pivotal areas where carbon footprint reduction efforts can be most effectively concentrated.

To address these environmental challenges, our study proposes strategies such as internal and external component reuse to extend material lifecycles. Additionally, implementing advanced warehouse management systems, modular construction techniques, and incorporating easily reconfigurable furniture and wall coverings could offer viable solutions. However, obstacles remain, including safeguarding intellectual property rights, incentivizing the use of recycled materials, and reconciling premium brand positioning with sustainable material choices.

In conclusion, this research provides valuable insights and practical guidance for environmentally conscious brands navigating the design and implementation of pop-up retail strategies. By adopting these findings, brands can align their operations with principles of sustainability and social responsibility, fostering a more balanced and sustainable societal impact.

Change history

20 May 2025

The original online version of this Article was revised: The Acknowledgements section was incomplete in the original version. The correct Information now accompanies the original Article.

References

Yoder, C. R., Viswanathan, K. & Moore, W. L. Navigating the risks of rework in large development programs: A complex adaptive systems perspective. Calif. Manag. Rev. 63, 113–140. https://doi.org/10.1016/j.cmr.2020.07.009 (2021).

Huajing Industrial Research Institute. Chinese pop-up store industry market panoramic assessment and development strategy planning report, 2022–2027 (2023). (In Chinese).

RET. The Power of Immobility, A Study of China’s Pop-up Stores (2016) (In Chinese). https://www.ret.cn/in-sight/376.html.

Cushman & Wakefield. The Popularity of Pop-Up Shops (2015).

Hu, F. & Zhong, H. Environmental design methods and their multidimensional analysis. Packag. Eng. 41, 20–33 (2020).

Rebitzer, G. et al. Life cycle assessment: Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 30, 701–720. https://doi.org/10.1016/j.envint.2004.06.012 (2004).

Eco-indicator 99. (2014). https://pre-sustainability.com/articles/eco-indicator-99-manuals/.

Goedkoop, M., & Spriensma, R. The Eco-Indicator 99: A damage oriented method for life cycle impact assessment—Methodology report. Pré Consultants B.V., Amersfoort, The Netherlands (2001).

International Energy Agency. Europe Emissions (2021). https://www.iea.org/regions/europe/emissions.

Acknowledgements

This study was supported by the Ministry of Science and Technology (MOST) International cooperation project (2022YFE0197700) and Europe Horizon 2020 SC5-202019 (868887-2). The authors gratefully acknowledge Prof. Paola Trapani's invaluable assistance in implementing the research tools. Special thanks to researchers Ning Jin, Yating Ren, Yilin Li, Zinning Zhou, and Benyu Hu for their insightful contributions during initial discussions and for collecting materials. Also, the authors wish to express sincere appreciation to Brand D for generously sharing their materials and facilitating our field research.

Author information

Authors and Affiliations

Contributions

D.W. and S.Z. initiated and coordinated this collaborative research project. D.W. designed the research roadmap, methodologies, analytical approaches, and was responsible for the manuscript writing. Z.R. and H.L. conducted the field research and data collection. Z.R. performed data calculations, graphical analysis, and assisted with the manuscript writing.

Corresponding author

Ethics declarations

Competing interests

The corresponding author, Duan Wu, on behalf of all authors (Zixin Ren, Haoyue Lei, and Shijian Zhao), declares that there are no competing interests regarding the publication of this paper. This statement confirms that none of the authors have any financial, personal, or professional conflicts that could have influenced the work reported in the manuscript.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, D., Ren, Z., Lei, H. et al. Life cycle assessment of a luxury fashion brand’s HPP event booth in the context of circular economy. Sci Rep 15, 5153 (2025). https://doi.org/10.1038/s41598-024-84528-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-84528-4