Abstract

The integration of reclaimed asphalt pavement (RAP) in road construction offers substantial environmental and economic benefits, yet the performance degradation of recycled asphalt mixtures due to binder aging remains a critical challenge. This study addresses this issue by proposing a novel filler-to-asphalt (F/A) ratio optimization strategy for recycled asphalt mastic containing 50% aged binder. Recycled mastics with F/A ratios spanning 0.0 (pure binder control) to 1.5 were evaluated using dynamic shear rheometer (DSR) and bending beam rheometer (BBR) to assess rutting resistance, fatigue life, and low-temperature cracking performance. Results demonstrate that mineral filler amplifies the stiffening effects of aged binder, improving high-temperature stability but exacerbating low-temperature brittleness. Fatigue performance exhibited method-dependent behavior, with time sweep tests indicating extended fatigue life but fatigue factor analysis revealing accelerated damage accumulation. Additionally, strong exponential or linear relationships were established between performance indicators and the F/A ratio. Based on these relationships, an F/A ratio adjustment value of 0.3 to 0.5 was identified to achieve performance comparable to that of virgin asphalt mastic. These findings provide a viable approach for optimizing the mix design of recycled asphalt mixtures containing RAP.

Similar content being viewed by others

Introduction

The utilization of reclaimed asphalt pavement (RAP) in pavement construction has gained significant popularity worldwide due to its notable financial and environmental benefits1,2,3. The use of RAP not only conserves raw materials, such as virgin asphalt binder and mineral aggregates, but also reduces hazardous gas emissions and mitigates pollution issues4,5,6. Various recycling technologies have been proposed based on the processing temperature and site. Among these technologies, hot in-place recycling technique shows great advantages in reducing transport costs, simplifying construction process and decreasing traffic disruption, and it has been widely employed in asphalt pavement rehabilitation over the years7,8,9.

However, concerns have been raised regarding the road performance of hot-mix recycled asphalt mixtures with RAP incorporation. After several years of pavement service, the asphalt binder experiences severe aging due to the exposure to heat and sunlight10,11,12. Consequently, the binder in RAP exhibits increased stiffness and brittleness compared to virgin binder13,14,15. While the incorporation of RAP can enhance the rutting resistance of recycled asphalt mixtures to some extent16, it significantly degrades fatigue and low-temperature cracking resistance17,18,19,20, leading to premature pavement distress and a reduced service life. Additional challenges associated with hot-mix recycled asphalt mixtures include poor blending efficiency, elevated construction temperatures, and high variability in raw materials21,22,23. These limitations typically restrict the RAP content in recycled asphalt mixtures to below 30%2,24.

To address these challenges, strategies including rejuvenator additives and production process optimization have been explored21,25. Among these, rejuvenators—such as super-soft binders26, plant-derived oils27, waste oils28, and chemical agents29,30—are widely employed31. Although empirical evidence suggests their primary mechanism involves softening aged binders by reducing viscosity and replenishing lighter fractions lost during aging, the precise interactions between rejuvenators and oxidized asphalt components remain poorly understood27. This process is hypothesized to partially reverse oxidative and thermal aging effects, thereby restoring rheological and mechanical properties31. However, critical limitations hinder their effectiveness: (1) no universally accepted methodology exists for determining optimal rejuvenator dosages across diverse scenarios, and (2) rejuvenation mechanisms vary substantially depending on rejuvenator chemistry and aging severity, leading to inconsistent performance outcomes31. Consequently, further research is imperative to elucidate molecular-level interactions between rejuvenators and aged binders and to develop reliable, cost-effective protocols for enhancing the performance of high-RAP-content mixtures32.

Asphalt mastic, composed of asphalt binder and mineral filler, serves as a fundamental dispersed system within asphalt mixtures and plays a crucial role in determining road performance33,34,35,36. The particle size of mineral fillers is generally less than 0.075 mm, with commonly used fillers including limestone, granite, and fly ash37,38,39,40. In the mix design of asphalt mixture, filler/asphalt (F/A) ratio (by weight) is a critically important parameter, which generally ranges from 0.5 to 2.041,42,43. Optimizing the F/A ratio can significantly improve the adhesion between aggregates, moisture resistance, and resistance to permanent deformation in asphalt mixtures44.

At the mastic scale, mineral fillers exhibit modification effects on road performance similar to those of RAP binders. The addition of mineral filler can substantially enhance the stiffness of asphalt binder due to volume-filling stiffening effects, thereby improving rutting performance, although it may adversely affect fatigue and low-temperature cracking resistance45,46. Given the comparable effects of mineral fillers and RAP binders on the properties of asphalt mastic, reducing the F/A ratio in recycled asphalt mastic presents a potential strategy for mitigating the negative impacts of RAP binders and restoring the road performance of recycled asphalt mixtures. However, research on optimizing the mix design of hot-mix recycled asphalt mixtures at the mastic scale is currently lacking.

To address this research gap, the present study aims to restore the road performance of hot-mix recycled asphalt mastic by adjusting the F/A ratio. Recycled asphalt mastic was prepared by incorporating recycled asphalt binder with mineral filler, with the aged binder content set at 50% and the F/A ratio varying from 0.0 (representing pure asphalt binder) to 1.5. Virgin asphalt mastics were also prepared for comparative analysis. Subsequently, the rutting, fatigue, and low-temperature performance of the asphalt mastic were characterized by using a dynamic shear rheometer and a bending beam rheometer. Ultimately, the study seeks to determine the optimized F/A ratio for hot-mix recycled asphalt mastic that achieves comparable road performance to virgin asphalt mastic. This research is expected to provide valuable insights for optimizing the mix design of hot-mix recycled asphalt mixtures.

Materials and methods

Materials

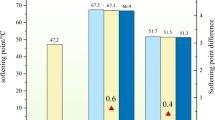

In this study, a base asphalt binder with a penetration grade of 80/100 and limestone mineral filler were utilized to prepare recycled asphalt mastic. Initially, recycled asphalt binder was produced by blending virgin binder with artificially aged asphalt binder using a high-shear mixer at 150 °C for 10 min. The artificially aged asphalt binder was generated through rolling thin film oven (RTFO) aging and pressurized aging vessel (PAV) aging treatments, with the aged asphalt binder constituting 50% of the total mass of the recycled binder. Subsequently, the recycled asphalt binder underwent further RTFO and PAV aging to simulate short-term and long-term aging processes that occur during service. Finally, recycled asphalt binders in various aging states (unaged, short-term aged, and long-term aged) were mixed with mineral filler to prepare the recycled asphalt mastic using a high-shear mixer at 150 °C for 20 min. The filler/asphalt (F/A) ratios selected for this study were 0.0, 0.5, 1.0, and 1.5. Additionally, virgin asphalt mastic was prepared for comparative analysis. It should be mentioned that aged asphalt mastics could also be prepared by aging the asphalt mastic directly. However, in this study, the aging of the asphalt binder was performed to simplify the preparation procedure and ensure consistency in the aged asphalt binder used across the various F/A ratios in the asphalt mastics.

Experimental methods

In this study, the test temperatures for characterizing the road performance of asphalt mastic were determined in accordance with the Superpave performance grading (PG) specifications. Specifically, temperatures of 64 °C were employed for the rutting factor (G*/sinδ) and multiple stress creep recovery (MSCR) test, 28 °C for the fatigue factor (G*sinδ), and − 12 °C for the bending beam rheometer (BBR) test. These temperatures were chosen as they represent the typical PG temperatures used to evaluate the high, medium, and low-temperature performance of asphalt materials, respectively. Furthermore, the test temperature for fatigue performance characterization is generally within the range of 15–25℃47,48. Therefore, a temperature of 20 °C was selected for the time sweep test.

Rutting performance characterization

Rutting factor

According to the Superpave specification, rutting factor is a fundamental parameter to characterize the rutting performance of a given binder or mastic. A higher rutting factor value suggests better performant deformation resistance. In this study, the rutting factor of virgin and recycled asphalt mastic at the unaged state was measured with the shear strain of 10% and the angular frequency of 10 rad/s.

Multiple stress creep recovery test

The MSCR test considers the creep and recovery behavior and shows great advantages in the rutting performance assessment of asphalt materials. It was conducted at two stress levels: 0.1 kPa and 3.2 kPa. At each stress level, the sample underwent ten successive creep and recovery cycles. Each creep and recovery cycle lasted for 1 s and 9 s, respectively. In this study, the non-recoverable creep compliance (Jnr) and percent recovery (R) were calculated based on the creep and recovery responses of asphalt mastic.

Fatigue performance characterization

Fatigue factor

Superpave specification also indicates that the fatigue factor can be utilized to evaluate the fatigue performance of asphalt materials at the intermediate temperature. A lower fatigue factor value indicates less dissipated energy will be accumulated after traffic loading, and fatigue cracks are less likely to occur during service. In this study, the fatigue factor of virgin and recycled asphalt mastic after PAV aging was determined with the shear strain of 1% and the angular frequency of 10 rad/s.

Time sweep test

As compared to fatigue factor, time sweep test better simulates the repeated vehicle loading in the field, offering a more accurate evaluation of the fatigue behavior. To characterize the fatigue performance of virgin and recycled asphalt mastic after PAV aging, time sweep test was performed under stress-controlled loading mode with the stress level of 0.5 MPa and the frequency of 10 Hz. In addition, 50% modulus reduction criterion was employed to calculate the fatigue life of asphalt mastic.

Low-temperature cracking performance characterization

BBR is commonly used to investigate the low-temperature cracking performance of asphalt materials. In this test, a static constant load was applied to the midpoint of the beam specimen, and the creep stiffness (S) and m-value can be obtained. Lower S values and higher m-values suggest better low-temperature cracking resistance. In this study, the BBR test was only conducted on the PAV-aged asphalt mastic.

Determination of the F/A ratio adjustment value for recycled asphalt mastic

The road performance of asphalt mastic is closely linked to the F/A ratio. In this study, robust fitting functions were developed to correlate road performance indicators with the F/A ratio. Utilizing these functions, the F/A ratio adjustment value for recycled asphalt mastic was determined to achieve road performance comparable to that of virgin asphalt mastic. This determination provides valuable insights for producing more durable recycled asphalt mixtures.

Results and discussion

Analysis of rutting factor

Figure 1 presents the rutting factor (G*/sinδ) of virgin and recycled asphalt mastic with different F/A ratio. As can be seen, recycled asphalt mastic has higher rutting factor values as compared to virgin asphalt mastic especially at higher F/A ratio. This suggests that RAP binder can significantly improve the permanent deformation resistance of asphalt materials due to the increased asphaltene content. Similarly, the rutting factor values are also apparently increased with the incorporation of mineral filler. As shown in the following equations, an exponential function can well describe the relationship between rutting factor and F/A ratio with the correlation coefficient (R²) higher than 0.99.

As aforementioned, both RAP binder and mineral filler contribute to the enhancement of rutting factor values in asphalt mastic, and robust fitting functions have been established between rutting factor and the F/A ratio. Based on these functions, the F/A ratio adjustment values necessary for recycled asphalt mastic to achieve equivalent rutting performance to virgin asphalt mastic were determined, as presented in Table 1. The F/A ratio adjustment value was calculated using Eq. (2), which identifies the F/A ratio at which recycled asphalt mastic attains the same rutting factor value as its virgin counterpart. This adjustment value typically ranges from 0.7 to 0.8 and represents the difference between the original and equivalent F/A ratios. For instance, when considering recycled asphalt mastic with an original F/A ratio of 1.5, it can achieve the same rutting factor value as virgin asphalt mastic at an equivalent F/A ratio of 0.71. Consequently, the F/A ratio adjustment value is determined to be 0.79. By adjusting the F/A ratio, the effects of RAP binder on rutting factor can be mitigated, allowing the recycled asphalt mastic to exhibit rutting performance comparable to that of virgin asphalt mastic. It is important to note that the equivalent F/A ratio becomes negative when the original F/A ratio is 0.5 or lower. This negative value is derived from the fitting equation used to determine the adjusted F/A ratio and holds no practical significance.

Analysis of MSCR test results

Figure 2 shows the non-recoverable creep compliance (Jnr) of virgin and recycled asphalt mastic with different F/A ratio at 3.2 kPa. Obviously, the addition of RAP binder leads to reduced Jnr values for recycled asphalt mastic regardless of F/A ratio. Less non-recoverable strain will be accumulated under vehicle loading in the field, beneficial for the anti-rutting performance of asphalt pavement. Additionally, the Jnr values exhibit a downward trend with the increase of F/A ratio and the exponential function well represents their relationship with the R² exceeding 0.98.

As shown in Table 2, the equivalent F/A ratio and F/A ratio adjustment value for recycled asphalt mastic to achieve the same Jnr value as virgin asphalt mastic were calculated. It can be found that the F/A ratio adjustment value for Jnr generally ranges from 0.4 to 0.6, which is lower than that for rutting factor.

The percent recovery (R) of virgin and recycled asphalt mastic with different F/A ratio at 3.2 kPa is shown in Fig. 3. It can be observed that the R value of virgin asphalt mastic is around zero as the F/A ratio is lower than 1.0, indicating the complete loss of elastic recovery under high-temperature conditions. As the F/A ratio rises to 1.5, the R value is slightly increased to around 1.5%. In contrast, for recycled asphalt mastic, the addition of RAP binder evidently enhances the elastic recovery even though at low F/A ratio. As shown in the following equation, the R values of recycled asphalt mastic also show a strong exponential relationship with the F/A ratio (R² > 0.98).

Analysis of fatigue factor

The results of fatigue factor (G*sinδ) of virgin and recycled asphalt mastic with different F/A ratio are shown in Fig. 4. As can be observed, both RAP binder and mineral filler prominently improve the fatigue factor values of asphalt mastic. The difference in fatigue factor values between virgin and recycled asphalt mastic also increases with the rise of F/A ratio. Therefore, RAP binder and mineral filler will lead to adverse effects on the fatigue performance of asphalt mastic judged from the fatigue factor. Furthermore, excellent exponential relationships can also be established between fatigue factor values and F/A ratio as follows:

The equivalent F/A ratio and F/A ratio adjustment value for recycled asphalt mastic to achieve the same fatigue factor value as virgin asphalt mastic were calculated and summarized in Table 3. The adjusted F/A ratio for fatigue factor is in the range of 0.3–0.5, which is evidently lower than that for rutting performance indicators.

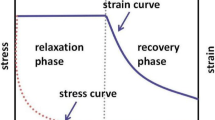

Analysis of time sweep test results

Figure 5 illustrates the complex shear modulus (G*) of virgin and recycled asphalt mastic as a function of loading cycles during the time sweep test. The G* curves exhibit three distinct stages. Initially, the G* curve experiences a sharp decline due to measurement instability. Following this, cyclic stress loading leads to the initiation of microcracks within the asphalt mastic, resulting in a steady decline in G* as the number of loading cycles increases. In the third stage, the microcracks progress to macrocracks due to the accumulation of fatigue damage, which is responsible for the final abrupt decrease in the G* curve. Notably, the presence of RAP binder and mineral filler contributes to increased G* values, and their effects persist even in the face of severe fatigue failure.

Analogous to G*, the phase angle (δ) of asphalt mastic also presents three-stage curves as shown in Fig. 6. During the time sweep test, the accumulation of fatigue damage causes the asphalt mastic to display more plastic behavior, resulting in an upward trend in δ values with increasing loading cycles. Furthermore, the inclusion of RAP binder and mineral filler leads to a noticeable decrease in δ values, regardless of the number of loading cycles.

Based on the 50% modulus reduction criterion, the fatigue life of virgin and recycled asphalt mastic was evaluated. As shown in Fig. 7, recycled asphalt mastic exhibits a longer fatigue life compared to virgin asphalt mastic. Additionally, fitting curves for both virgin and recycled asphalt mastics are presented. It is evident that the fatigue life of asphalt mastic increases linearly with the rise in F/A ratio. The corresponding equations are as follows, with R² values exceeding 0.98:

The complex modulus of asphalt mastic can be significantly enhanced by the addition of RAP binder and mineral filler. This improvement is attributed to the high modulus of the aged asphalt mastic. Under stress-controlled loading conditions, the aged asphalt mastic exhibits lower strain, resulting in reduced accumulation of fatigue damage during the time sweep test. Consequently, asphalt mastic containing RAP binder and a high F/A ratio demonstrates an increased fatigue life.

According to Eq. 9, The equivalent F/A ratio and F/A ratio adjustment value for recycled asphalt mastic to achieve the same fatigue life as virgin asphalt mastic were determined and summarized in Table 4. It can be observed that the F/A ratio adjustment value for fatigue life is in the range of 0.2–0.3, which is much lower than that for G*sinδ.

Analysis of BBR test results

The creep stiffness (S) and m-value of virgin and recycled asphalt mastic are shown Figs. 8 and 9, respectively. Figure 8 shows that the effects of RAP binder on S values are limited since virgin and recycled asphalt mastic have comparable S values regardless of F/A ratio. In contrast, RAP binder plays a more prominent role in the m-values. The addition of RAP binder results in the decreased m-values of recycled asphalt mastic, indicating the reduced relaxation capability.

In contrast, mineral filler leads to increased S values and decreased m-values and the low-temperature cracking resistance is dramatically deteriorated for both virgin and recycled asphalt mastic. Moreover, S values present good exponential relationships with F/A ratio (Eqs. (11), (12)), while linear relationships can be established between m-values and F/A ratio (Eqs. (13), (14)).

Tables 5 and 6 show the equivalent F/A ratio and F/A ratio adjustment value for recycled asphalt mastic to achieve the comparable S and m-value as virgin asphalt mastic. As can be seen, the F/A ratio adjustment value for S value (0-0.2) is significantly lower than that for m-value (0.3–0.5). As aforementioned, the S values are less affected by RAP binder than m-values, responsible for the decreased adjusted F/A ratio.

Recommendation of F/A ratio adjustment value for recycled asphalt mastic

Based on the data summarized in Tables 1, 2, 3, 4, 5 and 6, the F/A ratio adjustment value necessary for recycled asphalt mastic to achieve comparable road performance to virgin asphalt mastic is further illustrated in Fig. 10. It is evident that the adjustment value for rutting performance indicators is significantly higher than that for fatigue and low-temperature performance indicators. Considering the overall performance of asphalt mastic, the recommended adjustment value falls within the range of 0.3 to 0.5. This indicates that the F/A ratio for recycled asphalt mastic can be adjusted to be 0.3 to 0.5 lower than that of virgin asphalt mastic. Under these conditions, the rutting performance of recycled asphalt mastic remains notably superior to that of virgin asphalt mastic, while the fatigue and low-temperature performance of both materials are generally comparable. By adjusting the F/A ratio, the adverse effects of RAP binder on road performance can be mitigated, while retaining its beneficial effects, thereby restoring the road performance of hot-mix recycled asphalt mastic. This finding offers a promising approach to optimizing the mix design of hot-mix recycled asphalt mixtures. However, it is important to note that this study only determined the F/A ratio adjustment value for recycled asphalt mastic containing 50% RAP binder. Further research is needed to explore the adjustment values for recycled asphalt mastic with higher RAP binder content. Additionally, road performance tests on hot-mix recycled asphalt mixtures are required to validate the findings of this study.

Summary and conclusions

This study investigated the road performance of virgin and hot-mix recycled asphalt mastic with varying filler-to-asphalt (F/A) ratios. The relationships between road performance indicators and F/A ratio were established and the F/A ratio adjustment value for recycled asphalt mastic to achieve the equivalent road performance as virgin asphalt mastic was determined. Based on the findings of this study, the following conclusions can be drawn:

-

(1)

The incorporation of aged binder and mineral filler significantly enhances the rutting performance of asphalt mastic; however, the low-temperature cracking resistance may be compromised due to a reduction in relaxation capability.

-

(2)

The effects of RAP binder and mineral filler on fatigue performance vary depending on the testing methods employed. While they extend the fatigue life of asphalt mastic as determined by the time sweep test, they negatively impact fatigue performance as assessed by the fatigue factor.

-

(3)

Most road performance indicators exhibit strong exponential or linear relationships with the F/A ratio. These functions can be utilized to predict the road performance of asphalt mastic with a known F/A ratio.

-

(4)

The F/A ratio of recycled asphalt mastic containing 50% aged binder can be reduced by 0.3 to 0.5 compared to that of virgin asphalt mastic. Under these conditions, the rutting performance of recycled asphalt mastic remains superior to that of virgin asphalt mastic, while the fatigue and low-temperature cracking performances are comparable.

Overall, this work demonstrates that F/A ratio adjustment is a viable strategy for mitigating aging-induced deficiencies in recycled asphalt mastic. However, limitations exist: the study focused solely on 50% RAP binder and mastic-scale analysis. Future research should integrate rejuvenators (e.g., plant oils, waste-derived agents) with F/A optimization, validate findings through mixture-level tests, and explore alternative fillers such as recycled glass powder or industrial byproducts to enhance sustainability. By bridging mastic rheology and mix design, this approach supports the development of durable, high-RAP-content asphalt mixtures.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Ma, X., Leng, Z., Wang, L. & Zhou, P. Effect of reclaimed asphalt pavement heating temperature on the compactability of recycled hot mix asphalt. Materials (Basel) 13. https://doi.org/10.3390/ma13163621 (2020).

Xing, C. et al. A comprehensive review on the blending condition between Virgin and RAP asphalt binders in hot recycled asphalt mixtures: mechanisms, evaluation methods, and influencing factors. J. Clean. Prod. 398 https://doi.org/10.1016/j.jclepro.2023.136515 (2023).

Leng, Z., Sreeram, A., Padhan, R. K. & Tan, Z. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 196, 615–625 (2018).

Ma, Y. et al. Performance evaluation of temperature effect on hot in-place recycling asphalt mixtures. J. Clean. Prod. 277 https://doi.org/10.1016/j.jclepro.2020.124093 (2020).

Saltan, M. & Khaliqi, M. H. Effects of utilization of rejuvenator in asphalt mixtures containing recycled asphalt pavement at high ratios. Case Stud. Constr. Mater. 20 https://doi.org/10.1016/j.cscm.2024.e03095 (2024).

Zhao, S. et al. Effect mechanism of old asphalt on microstructure and mechanical properties of hot reclaimed pavement materials. Australian J. Civil Eng. 22, 108–123. https://doi.org/10.1080/14488353.2022.2132637 (2022).

Wang, T. et al. Hot In-Place recycled asphalt mixtures: RAP analysis, compaction characteristics and field evaluation. Sustainability 16 https://doi.org/10.3390/su16031064 (2024).

Chen, Y., Chen, Z., Xiang, Q., Qin, W. & Yi, J. Research on the influence of RAP and aged asphalt on the performance of plant-mixed hot recycled asphalt mixture and blended asphalt. Case Stud. Constr. Mater. 15 https://doi.org/10.1016/j.cscm.2021.e00722 (2021).

Liu, Y., Wang, H., Tighe, S. L., Zhao, G. & You, Z. Effects of preheating conditions on performance and workability of hot in-place recycled asphalt mixtures. Constr. Build. Mater. 226, 288–298. https://doi.org/10.1016/j.conbuildmat.2019.07.277 (2019).

Xu, Y. et al. Generation and evolution mechanisms of asphalt aging under the combined effects of intense UV radiation and large temperature variations. Constr. Build. Mater. 438 https://doi.org/10.1016/j.conbuildmat.2024.136786 (2024).

Zhang, K. & Shen, S. Numerical analysis of field aging in asphalt pavements via coupling of diffusion process and kinetics aging model. Road. Mater. Pavement Des. 1–15. https://doi.org/10.1080/14680629.2024.2320879 (2024).

Yu, J. et al. Long-term performance of recycled asphalt mixtures containing high Rap and reclaimed asphalt shingles. J. Road. Eng. (2024).

Ezzat, H. et al. Effect of Short- and Long-Term aging on the rheological and chemical properties of asphalt binders modified with different technologies. J. Mater. Civ. Eng. 36 https://doi.org/10.1061/jmcee7.Mteng-17095 (2024).

Ogbon, W. A. et al. Comparative analysis of several short-term aging simulation methods and their impact on long-term aging performance of asphalt binders. Constr. Build. Mater. 437 https://doi.org/10.1016/j.conbuildmat.2024.136969 (2024).

Zhang, J. et al. Investigating the role of sulfur stabilizer in modulating aging properties of SBS-modified asphalt. Constr. Build. Mater. 425 https://doi.org/10.1016/j.conbuildmat.2024.136045 (2024).

Zhang, Y. & Bahia, H. U. Effects of recycling agents (RAs) on rutting resistance and moisture susceptibility of mixtures with high RAP/RAS content. Constr. Build. Mater. 270, 121369 (2021).

Zhang, R., Sias, J. E. & Dave, E. V. Evaluation of the cracking and aging susceptibility of asphalt mixtures using viscoelastic properties and master curve parameters. J. Traffic Transp. Eng. (English Edition). 9, 106–119 (2022).

Zhan, Y., Wu, H., Song, W., Chen, X. & Liao, H. A novel approach to investigate the crack resistance of recycled asphalt mixture based on energy evolution. Eng. Fract. Mech. 307, 110284 (2024).

Fan, Y. et al. Fatigue performance evaluation of epoxy-recycling technology utilising 100% reclaimed asphalt pavement (RAP): binders and mixtures. Int. J. Pavement Eng. 25, 2409902 (2024).

Zhang, R., Sias, J. E., Dave, E. V. & Rahbar-Rastegar, R. Impact of aging on the viscoelastic properties and cracking behavior of asphalt mixtures. Transp. Res. Rec. 2673, 406–415 (2019).

Qu, L., Wang, Y., Wang, L., Li, X. & Xiao, Y. Experimental evaluation of fatigue performance of recycled asphalt mixture using refined separation recycled aggregates. Constr. Build. Mater. 411 https://doi.org/10.1016/j.conbuildmat.2023.134786 (2024).

Sreeram, A. et al. Fundamental investigation of the interaction mechanism between new and aged binders in binder blends. Int. J. Pavement Eng. 23, 1317–1327 (2022).

Sreeram, A., Leng, Z., Zhang, Y. & Padhan, R. K. Evaluation of RAP binder mobilisation and blending efficiency in bituminous mixtures: an approach using ATR-FTIR and artificial aggregate. Constr. Build. Mater. 179, 245–253 (2018).

Zhou, W. et al. Modulus of recycled hot mix asphalt: micromechanical modeling and experimental approaches. Constr. Build. Mater. 411 https://doi.org/10.1016/j.conbuildmat.2023.134697 (2024).

Hu, Y. et al. Atomic force microscopy (AFM) based microstructural and micromechanical analysis of bitumen during ageing and rejuvenation. Constr. Build. Mater. 467, 140387 (2025).

Pradhan, S. K. & Sahoo, U. C. Influence of softer binder and rejuvenator on bituminous mixtures containing reclaimed asphalt pavement (RAP) material. Int. J. Transp. Sci. Technol. 11, 46–59 (2022).

Yi, J., Wang, Y., Pei, Z., Xu, M. & Feng, D. Mechanisms and research progress on biological rejuvenators for regenerating aged asphalt: review and discussion. J. Clean. Prod. 422, 138622 (2023).

Yan, S. et al. Application of waste oil in asphalt rejuvenation and modification: A comprehensive review. Constr. Build. Mater. 340, 127784 (2022).

Abdelaziz, A. et al. Effects of ageing and recycling agents on the multiscale properties of binders with high RAP contents. Int. J. Pavement Eng. 23, 1248–1270 (2022).

Zhang, R. et al. Comprehensive laboratory evaluation of recycling agent treated plant-produced asphalt mixtures. Transp. Res. Rec. 2676, 620–634 (2022).

Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 231, 171–182 (2019).

Liu, J. et al. Molecular dynamics evaluation of activation mechanism of rejuvenator in reclaimed asphalt pavement (RAP) binder. Constr. Build. Mater. 298, 123898 (2021).

Bi, Y., Guo, F., Zhang, J., Pei, J. & Li, R. Correlation analysis between asphalt binder/asphalt mastic properties and dynamic modulus of asphalt mixture. Constr. Build. Mater. 276, 122256 (2021).

Cheng, Y. et al. Influence of the properties of filler on high and medium temperature performances of asphalt mastic. Constr. Build. Mater. 118, 268–275 (2016).

Cooper, I. I. I., Mohammad, S. B., Elseifi, M. A. & L. N. & Laboratory performance characteristics of sulfur-modified warm-mix asphalt. J. Mater. Civ. Eng. 23, 1338–1345 (2011).

Leng, Z., Tan, Z., Cao, P. & Zhang, Y. An efficient model for predicting the dynamic performance of fine aggregate matrix. Computer-Aided Civ. Infrastruct. Eng. 36, 1467–1479 (2021).

Lei, B. et al. Interfacial adhesion between recycled aggregate and asphalt mastic filled with recycled concrete powder. Case Stud. Constr. Mater. 20 https://doi.org/10.1016/j.cscm.2023.e02721 (2024).

Steineder, M. et al. Comparing different fatigue test methods at asphalt mastic level. Mater. Struct. 55 https://doi.org/10.1617/s11527-022-01970-4 (2022).

Tan, Z. et al. Multiscale characterization and modeling of aggregate contact effects on asphalt concrete’s tension–compression asymmetry. Mater. Design. 232, 112092 (2023).

Jin, D. et al. Waste cathode-ray-tube glass powder modified asphalt materials: Preparation and characterization. J. Clean. Prod. 314, 127949 (2021).

Ulutas, K. et al. Determination of optimum limestone filler content in asphalt mastic by dielectric spectroscopy. Road. Mater. Pavement Des. 1–16. https://doi.org/10.1080/14680629.2024.2331194 (2024).

Moon, K. H., Falchetto, A. C., Wang, D., Riccardi, C. & Wistuba, M. P. Mechanical performance of asphalt mortar containing hydrated lime and EAFSS at low and high temperatures. Materials (Basel) 10 https://doi.org/10.3390/ma10070743 (2017).

Ma, X., Chen, H., Gui, C., Xing, M. & Yang, P. Influence of the properties of an asphalt binder on the rheological performance of mastic. Constr. Build. Mater. 227 https://doi.org/10.1016/j.conbuildmat.2019.08.040 (2019).

Zhang, K., Min, Z., Hao, X., Huang, W. & Shao, K. Experimental investigation of the properties of epoxy asphalt mastic. Constr. Build. Mater. 435 https://doi.org/10.1016/j.conbuildmat.2024.136866 (2024).

Saberi Kerahroudi, F., Wang, Y. D. & Liu, J. Evaluation of thermal and rheological properties of phase change Material-Incorporated asphalt mastic with porous fillers. Transp. Res. Record: J. Transp. Res. Board. 2678, 835–845. https://doi.org/10.1177/03611981231172750 (2023).

Ren, H. et al. Correlation between high temperature performance of gussasphalt mixture for steel bridge decks and rheology of asphalt mastic. Case Stud. Constr. Mater. 20 https://doi.org/10.1016/j.cscm.2024.e03240 (2024).

Li, H. et al. Mechanistic modeling of fatigue crack growth in asphalt fine aggregate matrix under torsional shear Cyclic load. Int. J. Fatigue. 178, 107999 (2024).

Tan, Z. et al. Fatigue performance analysis of fine aggregate matrix using a newly designed experimental strategy and viscoelastic continuum damage theory. Mater. Struct. 57, 130 (2024).

Acknowledgements

The authors sincerely acknowledge fundings from the National Natural Science Foundation of China (Grant No.: 52408496) and Key Engineering Technology Project of Department of Transport of Jiangxi Province (Grant No.: 2023C0016).

Author information

Authors and Affiliations

Contributions

Z.T. and L.C. supervised the team activity. All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Y.C., L.C., J.G. and Z.T. The first draft of the manuscript was written by Y.C. and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cai, Y., Cao, L., Guo, J. et al. Restoring road performance of recycled asphalt mastic through filler asphalt ratio adjustment. Sci Rep 15, 17775 (2025). https://doi.org/10.1038/s41598-025-00709-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-00709-9