Abstract

Coal spontaneous combustion (CSC) constitutes a persistent threat to global mining safety, particularly through its impact on goaf environments. Understanding the evolutionary patterns of critical parameters (O2, CH4, CO, C2H4 concentrations, and temperature) within goaf areas holds crucial importance for effective CSC prevention and control. Similarity simulation experiments were conducted using a scaled-down experimental platform to replicate CSC processes. Through numerical simulation and field measurement data, the distribution ranges of the “three zones” in the goaf within the experimental platform were determined. Results revealed the formation of an ellipsoidal heating surface centered around the combustion source. The temperature gradient near the heat source increased linearly with coal temperature (1 °C/min), while the heating effect attenuated proportionally with distance. Notably, O2 and CH4 concentration fields exhibited minimal variation due to continuous air leakage and limited gas generation. In contrast, CO and C2H4 formed enrichment zones around the heat source, demonstrating a power-law growth trend. Air leakage significantly influenced gas distribution, with downwind CO concentrations 3.96 × higher than upwind. Vertically, gas concentrations decreased with height. These findings highlight the importance of multi-parameter monitoring for early warning systems in coal mines.

Similar content being viewed by others

Introduction

Coal spontaneous combustion (CSC) poses a severe threat to global mining safety, which is the predominant ignition source for coalmine fires across major coal-producing nations, like the United States, China, Australia, India, Germany, and South Africa1,2,3,4,5. In China, CSC burns 100–200 million tons of coal annually4. In Indian coal mines, 75% of coal fires are caused by spontaneous combustion2. CSC not only results in resource waste, but also causes air and water pollution, ground subsidence, and even mine explosion6,7,8,9,10.

In coal mines, a goaf, also referred to as a mined-out area, is characterized by the presence of numerous irregularly shaped collapsed rock masses with internal voids. These voids serve dual roles: they form air leakage channels and provide spaces for gas accumulation. When air leakage occurs, the residual coal in the goaf becomes particularly susceptible to spontaneous combustion11. To fully understand the development patterns of CSC, analysis of O2 concentration, CH4 concentration, and temperature evolution in the goaf is essential. The research strategies involve field testing, laboratory experiments, and numerical simulations12,13,14. Field testing involves embedding gas sampling tubes or temperature probes in the goaf, extracting internal gases through sampling pumps for analysis and testing, while the goaf temperature is directly read by data loggers. This approach is authentic and reliable, albeit with limited sampling points, typically placed along an intake or return roadway15,16. Nevertheless, this method can be affected by strata collapse risks. Thus, field testing is generally employed for model verification17,18,19.

Numerical simulations are crucial methods for understanding the gas and temperature distributions in the goaf20,21,22,23. Researchers have extensively investigated these issues. Wang et al. established a CFD model for Dingji Coal Mine and conducted simulation analysis on the distribution of CH4, O2 concentration fields, and temperature field under different gas drainage modes24. Yang et al. focused on Y type ventialtion caving face, and used COMSOL software to study the distribution law of gas concentration fields in the goaf under different ventilation conditions25. Li et al. studied the distribution characteristics of CH4 and O2 in the goaf through numerical simulation and found that the larger the airflow on the working face, the wider the oxidation zone and methane explosion zone26. Liu et al. investigated the distribution laws of O2 and temperature in the goaf during the suspension of mining activities through numerical simulation and found that increasing the advancing speed of the working face, reducing the thickness of coal left behind, and decreasing the airflow on the working face could reduce the risk of spontaneous combustion in the goaf27. Xu et al. simulated the emission law of CO during the spontaneous combustion process in the goaf and found that the area of coupled disaster risk between CSC and gas increases as an oblique strip, and increasing the airflow on the working face will move the risk area deeper into the goaf28.

In experimental investigations, Su et al. proposed a goaf model with adjustable inclination angles, examining the influence of airflow and coal seam inclination on oxygen concentration distribution in the goaf29,30. Li et al. established an experimental platform for CSC and gas coupling disaster in the goaf, observing gas accumulation near the coal combustion area31,32. Cheng et al. utilized a self-built three-dimensional similarity simulation experimental platform to assess gas concentration distribution in the goaf, revealing higher explosion risk near the goaf roof33. Zheng et al. built a full-scale 1:160 goaf model, researching CH4, O2, and temperature distributions under varying airflow conditions34,35. Ma et al. devised a specialized experimental platform for longwall goaf zones, substituting honeycomb briquettes for CSC area, and examined CH4, O2, and temperature distribution law during spontaneous combustion7,36. Hao et al. developed a physical simulation experimental platform for airflow leakage between the working face and surface, investigating the impact of ventilation amount and leakage rate on oxygen concentration distribution in shallow-buried goafs of coal seam group37.

While previous investigations have significantly advanced our understanding of airflow dynamics and thermal evolution in goaf environments, critical knowledge gaps persist in gas concentration analyses. Existing studies predominantly emphasize O2 and CH4 monitoring, while insufficiently addressing the evolutionary patterns of crucial CSC indicator gases-particularly CO and C2H4. These gases serve dual critical functions: as primary early-warning biomarkers for CSC initiation38,39,40 and as key modifiers of CH4 explosion limits41. This oversight fundamentally compromises safety assessments, underscoring the necessity for comprehensive analysis of multi-gas interactions in goaf environments. Current experimental methodologies frequently employ helium substitution for methane to mitigate explosion risks31,36. However, while this safety measure preserves general methane distribution trends, the distinct physicochemical properties of helium fundamentally alter CO and C2H4 generation kinetics and transport mechanisms.

To overcome these limitations, our study implements a novel approach using the established goaf simulation platform to recreate authentic gas compositions under programmed thermal activation42. In the goaf simulation experiment, the determination of the oxidation zone is critically important, as this zone serves as the primary region susceptible to CSC25. This zone is a key component of the “three zones” theory of goaf areas. Based on mine ventilation and safety theory, the spontaneous combustion risk zones of goaf areas can be divided into three characteristic zones: dissipation zone, oxidation zone, and suffocation zone43. In experimental platform research, it’s of great research value to scientifically define the spatial distribution of these three zones. The delineation of the “three zones” in the goaf relies on factors such as leak air velocity, O2 concentration, and temperature (rate of temperature increase), with O2 concentration serving as the predominant indicator29,44. Scholars employ various O2 concentration ranges for this division. In our study, an O2 concentration range of 18–6% was employed to classify the goaf into the “three zones”, which was aligned with empirical observations from the operational coal mine. When the oxygen volume fraction drops to 18%, it indicates the transition from the dissipation zone to the oxidation zone. When the oxygen concentration further decreases to 6%, it signifies the transition from the oxidation zone to the suffocation zone.

In the unique environment of goaf areas, oxygen concentration is typically lower than that of normal air, resulting in an oxygen-deficient state. The establishment of this hypoxic condition necessitates the controlled injection of methane (CH4) and nitrogen (N2). Consequently, determining the optimal injection ratio of methane to nitrogen becomes crucial for goaf similarity simulation experiments. The experimental protocol involves three key phases: First, numerical simulation techniques are employed to precisely quantify the required CH4/N2 injection volumes. Subsequently, the validated parameters are implemented in a geomechanically-scaled goaf simulation platform to systematically conduct coal spontaneous combustion experiments. Throughout the testing process, an integrated monitoring system enables comprehensive tracking of critical parameters including oxygen (O2) consumption rate, generation rates of methane (CH4), carbon monoxide (CO), and acetylene (C2H2), synchronized with three-dimensional thermal gradient mapping. This multidimensional analytical approach establishes a theoretical framework for developing predictive CSC monitoring systems.

Range of the “three zones” in the goaf

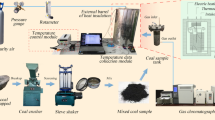

Experimental platform

In our preliminary research, we constructed an experimental platform to investigate thermal dynamics disasters in the goaf, based on the prototype of Dafosi Coal Mine in Shaanxi45. The Dafosi Coal Mine emerges as a paradigmatic case for investigating CSC hazards, attributable to its distinctive geological-structural configuration and well-documented historical combustion dynamics34. As a deep-mining operation in the Binchang coalfield, which is characterized by thick Jurassic coal seams with high volatile content and low metamorphic grades, the mine shows quintessential goaf conditions that are likely to lead to self-heating phenomena46. This platform mainly explores the coupling mechanism of CSC and gas disasters. Figure 1 illustrates the schematic diagram of the experimental platform, while Table 1 summarizes its key geometric parameters.

The experimental platform is equipped with the following functionalities:

-

1.

Accurate and adjustable roadway ventilation: Ventilation is controlled by fans, with fresh air entering the workface through the intake roadway to promote mine ventilation. Another setup connects the fan inlet to the high-level drainage roadway and upper corner extraction pipe, effectively extracting gases from the goaf. All fans are regulated by frequency converters for speed adjustment, and airflow measurement is precise with flow meters.

-

2.

Simulation of oxygen-poor and gas-rich environment in the goaf: Gas cylinders connected to the experimental platform inject CH4 and N2 into the goaf via pipelines, increasing gas concentration and reducing oxygen concentration. Gas flow is precisely controlled by flow controllers.

-

3.

Simulation of CSC process: Heating rods embedded in the goaf’s residual coal gradually heat the coal to simulate CSC, following a programmed temperature increase.

-

4.

Real-time temperature measurement in the goaf: K-type thermocouples measure the temperature of the coal-rock mass, with temperature data collected in real-time using a data acquisition system.

-

5.

Analysis of gases in the goaf: Gas samples are extracted layer by layer from the experimental platform using injectors, and gas composition is analyzed using gas chromatography to achieve layered testing of gases in the goaf.

Process for determining “three zones” boundaries in goaf areas

The precise delineation of “three zones” boundaries within the experimental platform serves as the critical foundation for conducting CSC simulations in goaf environments. This process follows a three-stage progressive methodology: Firstly, spatial parameters for the scaled “three zones” model are established using similarity criteria based on field-measured “three zones” distribution data from the Dafosi Mine prototype goaf. Subsequently, equivalent discrimination indices for the experimental platform are determined according to oxygen concentration threshold standards derived from field “three zones” classifications. Finally, multidimensional parameter mapping between experimental conditions and field environments is completed.

In the real goafs, oxygen concentration gradients arise from dual mechanisms: oxygen consumption through residual coal oxidation and gas accumulation from adjacent/current coal seams. Under laboratory conditions, however, spontaneous oxidation fails to replicate authentic oxygen depletion processes due to temporal constraints and reduced coal sample reactivity. To address this, an active control strategy is implemented: nitrogen injection artificially constructs equivalent oxygen concentration decay profiles, while introduced gas simulate methane accumulation effects.

Achieving spatial consistency between experimental “three zones” distributions and field prototypes requires precise nitrogen/methane injection rate regulation. This study employs computational fluid dynamics (CFD) to systematically investigate the regulatory effects of nitrogen/methane injection parameters on oxygen field distribution in goafs. The numerical simulation adopts a tri-level modeling approach: Initially, a 3D geometric model is constructed based on the experimental platform’s physical dimensions. Next, a porosity–permeability coupled porous medium model is developed according to particle size distributions of coal-rock mixtures within the filled media. Finally, flow parameters are defined based on experimental boundary conditions. Parametric simulations generate oxygen concentration field distribution profiles under varying nitrogen/methane injection rates. Spatial congruence analysis between these profiles and theoretical “three zones” thresholds identifies optimal nitrogen/methane injection parameters. These numerical solutions undergo dual physical validation: Nitrogen/methane injection experiments are conducted under identical boundary conditions to the CFD model. Experimental validity of nitrogen/methane injection parameters is confirmed when spatial congruence between measured oxygen concentration distributions and simulated predictions achieves ≥ 90% alignment threshold. This verification process successfully establishes a closed-loop validation mechanism between numerical simulations and physical experiments, creating a controlled experimental foundation for subsequent dynamic coal spontaneous combustion evolution studies. The “three zones” delineation process in goafs is illustrated in Fig. 2.

“Three zones” delineation in experimental platform

In our experiment, we adopted an O2 concentration range of 18–6% to delineate the goaf into “three zones”. The geometric similarity ratios of 1:180 provided the boundaries for the “three zones” on the experimental platform, as detailed in Table 2.

Numerical simulation of the “three zones” range

Boundary conditions

Simulations were conducted at nitrogen-methane flow ratio values of 1, 2, and 3. Consistent with the similarity criteria, the gas outflow velocity from the platform was set to 1 L/min, maintaining a constant velocity. Thus, the nitrogen release rates were chosen at 1 L/min, 2 L/min, and 3 L/min respectively. Based on the geometric dimensions of the goaf experimental platform, a physical model as shown in Fig. 3 is established. The boundary conditions of the model are set according to the experimental conditions and are specified in Table 3. The goaf model adopts a hexahedral grid with a total of 957,700 mesh elements. Porosity, viscous resistance coefficient, and inertial resistance coefficient were determined using theoretical models previously13,47. The numerical analysis utilizes the steady-state model and gas transport equation to simulate the migration and dispersion of N2 and CH4, accounting for gravity’s effects.

Numerical simulation results

The O2 concentration at 1 cm above the floor in the goaf under varying nitrogen injection scenarios is depicted in Fig. 4. As demonstrated, increasing nitrogen injection reduces the O2 concentration in the goaf, with the lowest O2 concentration occurring in the deeper parts of the goaf on the return roadway side. When N2:CH4 = 1, the O2 concentration exceeds 6%, suggesting no suffocation zone in the goaf. For N2:CH4 = 2, on the intake side, the 18% contour line of O2 concentration is 36 cm away from the working face, and the 6% contour line is 88 cm away from the working face; on the return side, the 18% contour line of O2 concentration is 6 cm away from the working face, and the 6% contour line is 58 cm away from the working face. With N2:CH4 = 3, on the intake side, the 18% contour line of O2 concentration is 31 cm away from the working face, and the 6% contour line is 69 cm away from the working face; on the return side, the 18% contour line of O2 concentration is 6 cm away from the working face, and the 6% contour line is 38 cm away from the working face. According to the measured results in the goaf of the Dafosi coalmine, when N2:CH4 = 2, the O2 concentration in the goaf is relatively consistent with the real site conditions. Therefore, an N2:CH4 intake ratio of 2 is chosen for the bottom intake gas flow in the experiment.

When N2:CH4 = 2, the methane concentration in the goaf is shown in Fig. 5. From the figure, it can be observed that methane accumulates in the deeper parts of the goaf on the return side. On the intake side, the 5% contour line of methane concentration is 37 cm away from the working face, and the 16% contour line is 63 cm away from the working face; on the return side, the 5% contour line of methane concentration is 6 cm away from the working face, and the 16% contour line is 27 cm away from the working face.

“Three zones” range experimental verification

Experimental conditions

The backfill materials in the goaf are arranged from bottom to top in the following sequence: coal, gravel, and refractory bricks, with coal at a height of 3 cm, gravel at a height of 17 cm, and refractory bricks at a height of 20 cm, respectively. During the backfilling process, the goaf is divided into three zones, namely A, B, and C, as illustrated in Fig. 6. In Zone A, the coal (gravel) is filled with a particle size of 2–2.5 cm; in Zone B, the coal (gravel) is filled with a particle size of 1-2 cm; in Zone C, the coal (gravel) is filled with a particle size of 0.5-1 cm.

During the experiment, the airflow rates were as follows: 43.2 L/min in the intake roadway, 6.2 L/min in the high-level drainage roadway, and 6.2 L/min in the upper corner extraction pipe. At the bottom of the platform, the intake rates were 1 L/min for CH4 and 2 L/min for N2. Once CH4 and N2 enter the goaf, they slowly diffuse internally. Additionally, some CH4 and N2 are carried out by leakage airflow in the goaf. It takes approximately 2 h for the concentrations of CH4 and N2 inside the goaf to stabilize, as indicated by previous studies45. Therefore, gas extraction from the middle-layer sampling pipes occurs after 2 h of gas injection, and the concentrations of CH4 and O2 in the gas are analyzed.

Experimental results

After the gas concentration field inside the goaf stabilizes, gas samples are extracted from the middle-layer sampling pipes for chromatographic analysis. Concentrations of O2 and CH4 at positions x = 10 cm, x = 50 cm, and x = 90 cm are presented in Fig. 7, alongside corresponding results from numerical simulations. The close alignment between experimental and numerical simulation results suggests that the numerical simulation’s “three zones” layout of the goaf can effectively guide the subsequent experimental placement of heating rods.

Experimental method

Arrangement of high-temperature heat source

Numerical simulations establish that the oxidation zone is between 36 and 88 cm in the intake side. Accordingly, during the experiment, the high-temperature heat source is placed 53 cm away from the working face and 5 cm away from the sidewall of the intake roadway, laid on the coal floor. As depicted in Fig. 6, it is positioned between measurement points P63 and P64. The experimental setup incorporated a cylindrical heating rod with critical dimensions of 2 cm in diameter and 5 cm in length, operating at a controlled heating capacity of 250 W. Constructed with a dual-material configuration, the device features a 304 stainless steel outer shell for structural integrity and corrosion resistance, encapsulating a high-thermal-conductivity magnesium alloy core optimized for efficient heat transfer. Electrical connectivity to the core was achieved through two thermally stable NiCr alloy wires, ensuring operational reliability under sustained high-temperature conditions.

Programmed heating and data acquisition

According to existing research findings48, CSC enters an extremely dangerous stage when the coal temperature exceeds 285℃. To ensure operational safety while replicating near-ignition conditions (coal ignition typically occurs at > 340°C49,50,51), the programmed heating protocol was capped at 320 °C—a temperature sufficient to drive advanced oxidation reactions without triggering open combustion.

After 2 h of ventilation, the gas concentration field in the goaf reaches a steady state. The programming of the heating rod is initiated at a heating rate of 1℃/min. The initiation of heating marks the starting point in time. Concurrent temperature monitoring within the goaf is conducted at one-minute intervals. With an average laboratory temperature of 20℃, a CSC experiment in the goaf lasts approximately 7 h.

During the CSC process, the gas composition inside the goaf undergoes real-time changes. To quantify spatial–temporal gas distributions, a multi-level sampling protocol was implemented: gas specimens were systematically collected from the bottom, middle, and top measurement points using hermetically sealed gastight syringes. Compositional analysis was performed via gas chromatograph equipped with flame ionization and thermal conductivity detectors. Gas sampling maintains a 30-min cycle until the thermal source attains 320 °C.

Results and discussion

Evolution law of temperature field in the goaf

During the heating process of the high-temperature heat source, the evolution of the temperature field in the goaf is depicted in Fig. 8. This figure illustrates little heat transfer from the heating source to the adjacent coal mass. After a heating period of 5 h, the peak temperature at a distance of 5 cm above the coal seam floor is approximately 25℃, while there is almost no change in temperature at distances of 10 cm and 15 cm above the coal seam floor. This suggests that during the coal oxidation stage, the CSC source, confined within a localized region around the ignition point, faces significant challenges in transferring heat to its surroundings. This is attributed to the low thermal conductivity of coal-rock34, resulting in low heat transfer efficiency. Moreover, the goaf being a porous medium further diminishes the heat transfer effect of air. Additionally, air leakage takes away a portion of the heat, making it difficult for heat to accumulate effectively. These factors highlight the difficulty in detecting the spontaneous combustion status of coal in the goaf through temperature detection, especially during the early stages of CSC.

In the presence of a high-temperature heat source, the downwind bottom measurement point P64B is the earliest point to detect temperature changes. The distance between this point and the center of the high-temperature heat source is 6.4 cm. The ratio of the temperature difference between the measurement point and the high-temperature heat source to the distance difference is referred to as the temperature gradient in the goaf. Based on the obtained temperature measurements, the variation of the temperature gradient in the goaf over time is shown in Fig. 9. From the graph, it is evident that as the temperature of the high-temperature heat source increases, the temperature gradient and the temperature difference between them also increase linearly. This further indicates that the effective heating area of the high-temperature heat source is limited to the vicinity of the heat source, and the heating effect diminishes linearly with increasing distance. This phenomenon occurs because the high-temperature heat source forms an ellipsoidal heating surface around it, with the heat source being the core of the ellipsoid, and the energy weakening as it moves away from the core52.

Scholars have conducted experimental investigations on temperature fields during coal spontaneous combustion in goaf environments. When a high-temperature heat source (120 °C) was applied, the measured temperature gradients were as high as 4.3 °C/cm on the upwind side and 3.2 °C/cm on the downwind side32. However, as can be seen from Fig. 9, the downwind temperature gradient in our study reached a peak of 12 °C/cm, which is far higher than the 3.2 °C/cm reported in the literature. This significant difference can be attributed to the composition of the backfill material. The studies referred to used non-reactive gravel-sand mixtures in goaf simulation, which could not undergo oxidation and heat up under the influence of a heat source. In contrast, in our experiment, coal was backfilled in the platform, and it has distinct thermal-oxidative properties.

Evolution law of O2 concentration field

During the heating process, the evolution of O2 concentration field in the goaf is shown in Fig. 10. It can be observed that at positions equidistant from the working face, O2 concentration on the intake side is higher than that on the return side. Furthermore, O2 concentration in the deep part of the goaf has dropped to 3%, forming an oxygen-poor zone. Throughout the CSC process, O2 concentration in the goaf at the same position does not change significantly. This is attributed to continuous air leakage from the working face into the goaf, which supplies ample O2 for CSC. Additionally, the high-temperature heat source acts as a point heat source, with a limited disturbance range on the coal, and thus consumes little oxygen.

In the vertical direction, the overall difference in O2 concentration in the goaf is not significant. However, near the upper corner, as height increases, the oxygen concentration tends to decrease. This phenomenon occurs because when airflow passes through the working face into the return roadway, vortexes form near the upper corner. Some airflow enters the upper corner, increasing the oxygen concentration near the bottom measuring point. Additionally, the extraction pipe at the upper corner extracts gas from near the upper corner, leading to air replenishment and further increasing the oxygen concentration near the bottom measuring point. Furthermore, the high-level drainage roadway extracts gas from the interior of the goaf, causing high-concentration gas to flow towards the vicinity of the high-level drainage roadway. This flow increases gas concentration above the upper corner, consequently reducing the oxygen concentration near the upper measuring point.

The oxygen concentration in the goaf is significantly affected by the ventilation speed. Relevant research indicates that as the air speed increases, the difference in oxygen concentration in the goaf between the cases of coal spontaneous combustion and no combustion gradually decreases34. When the ventilation speed reaches 1 m/s, the distribution law of oxygen concentration in the goaf is basically similar under both conditions. In this study, the ventilation speed was 1.2 m/s, and under this condition, the impact of the high-temperature heat source on the distribution of oxygen concentration was very weak.

Evolution law of CH4 concentration field

The evolution of CH4 concentration field in the goaf is illustrated in Fig. 11. It can be observed that the highest CH4 concentration occurs in the deep area of the return side of the goaf. This phenomenon arises from CH4 migrating towards the deep return side under the influence of airflow, resulting in internal CH4 accumulation. Despite the passage of time, CH4 concentration at the same measurement point does not change significantly. This stability is due to the relatively high initial CH4 concentration in the goaf at the beginning of heating, coupled with little amount of CH4 generated by CSC, making it challenging to alter the initial CH4 concentration field. In the vertical direction, the overall difference in CH4 concentration in the goaf is not significant. However, near the upper corner, there is an upward trend in CH4 concentration with increasing height, contrary to the observed trend in oxygen concentration.

As a combustible gas accumulated in goaf areas, methane concentration exhibits significant sensitivity to ventilation velocity. Studies have demonstrated an inverse relationship between airflow speed and methane concentration differentials under spontaneous combustion versus non-combustion conditions7. Notably, when ventilation velocity reaches 1.4 m/s, the methane distribution law in the goaf become virtually identical regardless of combustion status. The experimental conditions in this investigation employed a controlled ventilation speed of 1.2 m/s, at which thermal effects from high-temperature sources exerted negligible influence on methane dispersion characteristics.

Evolution law of CSC indicator gases

CO concentration field

During the heating process of the high-temperature heat source, the evolution of CO concentration field in the goaf is depicted in Fig. 12. It is evident from the figure that with the increase in heating time, CO concentration in the goaf gradually increases, forming an enrichment zone around the heating source. As the distance from the high-temperature heat source increases, CO concentration shows a decreasing trend. After 5 h of heating, the highest CO concentrations at distances of 5 cm, 10 cm, and 15 cm from the coal seam floor are 1311 ppm, 1158 ppm, and 957 ppm, respectively. On the return side, as the airflow approaches the working face, there is a decreasing trend in CO concentration. This decrease is attributed to air leakage bringing CO from the deep parts of the goaf, which then mixes with surrounding gases, resulting in a decrease in concentration.

According to the experimental results, it was found that the maximum CO concentration occurs at measurement point P64, downwind of the high-temperature heat source. The variation of CO concentration over time at different heights of point P64 is depicted in Fig. 13, where P64B represents the bottom-level measurement point, P64M represents the middle-level measurement point, and P64T represents the top-level measurement point. From the figure, it can be observed that with increasing height, there is a decreasing trend in CO concentration. This decrease is attributed to the maximum CO concentration being generated at the CSC source, and the diffusion process of CO obeying Fick’s law. As the airflow moves away from heating rod, CO concentration decreases.

Measurement points P63 and P64 are the two closest positions to the CSC source, one located upwind and the other downwind. The variation of CO concentration over time at the bottom-level measurement points (P63B, P64B) is illustrated in Fig. 14. It is evident from the figure that although both P63B and P64B are at the same distance from the high-temperature heat source, they exhibit different CO concentrations. Specifically, CO concentration measured at the downwind side is higher. After 5 h of heating, CO concentration measured at P64B is 3.96 times higher than that at P63B. This discrepancy is attributed to the airflow entering the goaf through the intake roadway, resulting in air leakage at the working face. As the airflow passes over the high-temperature heat source, it disperses the CO generated by CSC, leading to a lower CO concentration on the upwind side compared to the downwind side. Additionally, through data fitting, it was found that CO concentration at the measurement points varies over time according to a power function relationship. This is because as the temperature of the coal increases, the rate of decomposition of coal macromolecules sharply increases, leading to a significant increase in the rate of CO generation. This variation law is consistent with previous findings from low-temperature oxidation experiments on coal53,54.

In conventional programmed temperature-increase experiments, CO gas typically begins to be released before the temperature reaches 60℃55. However, in the goaf simulation experiment, when the temperature of the heating rod reached 110℃, CO gas was not detected until 90 min later (with an initial concentration of 2.92 ppm), which is about 30 min later than under conventional conditions. Through multi-dimensional mechanism analysis, it was found that this abnormal phenomenon is due to the following four-fold coupled mechanisms:

-

1.

Coal did not have an insulation layer, leading to continuous heat dissipation from the coal body. The heat supply for the coal oxidation process mainly relies on the external heating device, forming a non-steady-state heat transfer mode, which significantly slows down the temperature rise rate inside the coal body.

-

2.

The open boundary conditions of the goaf cause the CO gas to exhibit anisotropic diffusion characteristics, and the concentration gradient at the monitoring point is weakened by the three-dimensional spatial dilution effect.

-

3.

In an oxygen-rich environment, the activation energy threshold for coal-oxygen composite reactions increases, prompting the reaction to preferentially proceed along the path of CO2 generation, suppressing the formation of CO intermediate products.

-

4.

There is a certain spatial distance between the monitoring point and the oxidation center, and the gas diffusion is slow, resulting in a dynamic detection delay.

Comparative studies show that there are essential differences in key parameters between laboratory standard conditions (closed system, steady-state heat transfer) and actual goaf environment (open system, non-steady-state heat transfer). The research results provide a theoretical breakthrough direction for precise monitoring of underground coal spontaneous combustion from the perspective of heat and mass transfer coupling mechanisms.

C2H4 concentration field

During the heating process of the high-temperature heat source in the goaf, C2H4 concentration field is depicted in Fig. 15. It can be observed from the figure that, similar to CO, the evolution of C2H4 concentration in the goaf forms an enrichment zone around the heating point as heating time increases. After 5 h of heating, the highest concentrations of C2H4 at distances of 5 cm, 10 cm, and 15 cm above the coal seam floor are 6.10 ppm, 7.20 ppm, and 7.85 ppm, respectively.

The maximum C2H4 concentration occurs at the bottom measurement point downwind of the high-temperature heat source, and the temporal variation of C2H4 concentration at this point is depicted in Fig. 16. Through data fitting, it was found that C2H4 concentration varies over time according to a power function relationship. C2H4 was first detected after heating for 150 min, with a concentration of 0.74 ppm. In comparison to CO, when the CSC source temperature reaches 320 °C, the internal C2H4 concentration in the goaf remains relatively low. However, the detection of C2H4 inside the goaf indicates a severe CSC accident has occurred. According to related studies56, when C2H4 concentration inside the goaf exceeds 1 ppm, it suggests that the CSC source temperature has exceeded 200 °C, indicating a more serious state of CSC.

Ucertainties and errors in the experiment

The experimental platform is equipped with a comprehensive three-level array of measurement points, with 36 points per level, resulting in a total of 108 measurement points. The sampling procedure involves three experimenters working collaboratively to collect samples from all points, requiring approximately 5 min to complete. However, the substantial number of measurement points introduces inherent temporal discrepancies during sampling across different locations. These temporal variations may potentially induce experimental errors due to slight fluctuations in sampling conditions over time.

To mitigate such errors, we implemented a systematic approach by labeling measurement points. This labeling ensures that sampling intervals for points on the same side remain as consistent as possible, thereby reducing the impact of time-dependent variations. Additionally, gas sample analysis using a gas chromatograph constitutes a time-intensive process, requiring approximately 5 min per sample. During this period, gas samples are stored in syringes. Despite employing syringes with excellent sealing properties, achieving 100% airtightness remains unattainable. This limitation introduces potential gas leakage or atmospheric ingress, which may compromise the accuracy of measured gas concentrations.

Field measurement serves as an ideal validation approach for verifying the effectiveness of similarity simulation experiments, yet faces unique challenges in coal spontaneous combustion research within goaf areas. Under current engineering technical conditions, precise localization of spontaneous ignition sources within goaf remains an industry-wide challenge57,58,59. This technical bottleneck directly leads to spatial alignment discrepancies between simulated oxidation heating zones in experiments and actual ignition points in field conditions. Nevertheless, the scientific value of laboratory similarity simulation methodology has gained widespread academic recognition: By controlling key parameters (working face ventilation rate, coal seam dip angle, etc.), this method has successfully replicated thermodynamic evolution characteristics of coal spontaneous combustion processes29,31,36. Extensive studies demonstrate that in special scenarios where in-situ validation is infeasible, scaled-down experimental systems constructed based on similarity criteria remain the most scientifically rigorous research methodology7,32,34.

In conclusion, while the experimental design demonstrates methodological robustness, the combination of extensive measurement requirements and time-sensitive analytical procedures introduces potential error propagation. Through standardized labeling protocols ensuring temporal consistency and explicit recognition of inherent sealing limitations, we systematically mitigate these error sources to enhance experimental reliability and data integrity.

Conclusions

Through integrated numerical simulations and experimental validation, the spatial distribution of the “three zones” within a goaf was systematically characterized. To replicate the oxygen-depleted and methane-enriched environment typical of goafs, nitrogen was injected to suppress oxygen levels while methane supplementation elevated background gas concentrations. Coal spontaneous combustion (CSC) dynamics were simulated using controlled heating rods to induce oxidation processes at a laboratory scale, enabling detailed analysis of temperature evolution and gas transport mechanisms. The key findings are summarized as follows:

-

1.

An ellipsoidal heat propagation pattern centered on the CSC source was observed, reflecting anisotropic heat diffusion within the heterogeneous goaf structure. The thermal gradient exhibited a linear correlation with the CSC source temperature, while heat dissipation followed an inverse proportionality to the distance from the high-temperature zone. These results underscore the utility of temperature monitoring as a supplementary early-warning criterion during incipient CSC stages, particularly in proximity to potential ignition loci.

-

2.

Minimal perturbations were detected in both O2 and CH4 concentration fields during CSC progression. The equilibrium in O2 levels arose from a dual mechanism: continuous oxygen replenishment via air leakage from adjacent working faces counterbalanced limited oxidative consumption at low-temperature CSC phases. Similarly, CH4 concentrations remained static due to the overwhelming dominance of preexisting methane within the goaf, rendering the marginal CH4 release from CSC thermochemically negligible. This stability disqualifies O2 and CH4 as standalone diagnostic markers for CSC detection in high-gas goafs.

-

3.

CO and C2H4 formed distinct enrichment halos around the CSC source, with concentrations adhering to a power-law growth trend as coal temperatures escalated. Air leakage critically modulated gas distribution, creating an asymmetric concentration profile: downwind regions exhibited higher CO/C2H4 levels than upwind zones due to advective transport. Vertical stratification further revealed a monotonic decline in gas concentrations with levation, likely attributable to buoyancy-driven dispersion and ventilation effects. These findings position CO and C2H4 as primary indicators for advanced CSC detection, with optimal sensor placement recommended at downwind, near-floor positions to maximize sensitivity.

Our research systematically analyzed the temporal and spatial evolution patterns of key indicator gases such as CO and C2H4 during coal spontaneous combustion in the goaf through experiments. This approach compensates for the limitation of traditional research, which primarily concentrated on O2 and CH4. Consequently, it offers a novel theoretical foundation for the early warning of coal spontaneous combustion. The experimental platform employed a geometric similarity ratio of 1:180. However, the actual geological conditions of goafs are more intricate, potentially impacting the extrapolation applicability of the model. In the experiment, nitrogen injection was utilized to simulate the oxygen consumption of residual coal. The oxidation reaction rate of real coal spontaneous combustion is influenced by a variety of factors, such as moisture and coal quality, which were not fully replicated in the experiment. In future research endeavors, we intend to systematically conduct goaf experiments under varying wind velocities, diverse fire source locations, and multiple ventilation configurations. The primary goal of these experiments is to refine and enhance the theoretical framework for early detection and monitoring systems pertaining to CSC.

Data availability

The data that support the finding of this study are contained in the Article and available in the Supplementary File.

References

Liu, X. et al. Thermodynamic characterization and spontaneous combustion mechanism of coal in continuous hot-humid air flow. Energy 317, 134702 (2025).

Vikram, M., Madhab Bhattacharjee, R., Sarathi Paul, P. & Sai Vinay, L. Determinants of prioritised influencing factors on coal spontaneous combustion propensity—a fuzzy-delphi-geometric mean analytic hierarchy process. Fuel 356, 129541 (2024).

Ulyanova, E. V., Malinnikova, O. N., Dokuchaeva, A. I. & Pashichev, B. N. Effect of structural nonuniformity on spontaneous combustion liability of coal. Solid Fuel Chem. 56, 426–431 (2022).

Plakunov, M. M., Yavuzturk, C. C. & Chiasson, A. D. on the effects of temperature-dependent diffusion of carbon dioxide from underground coal fires. Geothermics 85, 101768 (2020).

Lawal, A. I. et al. On the performance assessment of ANN and spotted hyena optimized ANN to predict the spontaneous combustion liability of coal. Combust. Sci. Technol. 194, 1408–1432 (2022).

Liang, Y. & Wang, S. Prediction of coal mine goaf self-heating with fluid dynamics in porous media. Fire Saf. J. 87, 49–56 (2017).

Ma, D., Qin, B., Li, L., Gao, A. & Gao, Y. Study on the methane explosion regions induced by spontaneous combustion of coal in longwall gobs using a scaled-down experiment set-up. Fuel 254, 115547 (2019).

Shukla, U. S., Mishra, D. P. & Mishra, A. Prediction of spontaneous combustion susceptibility of coal seams based on coal intrinsic properties using various machine learning tools. Environ. Sci. Pollut. Res. 30, 69564–69579 (2023).

Said, K. O., Onifade, M., Lawal, A. I. & Githiria, J. M. An artificial intelligence-based model for the prediction of spontaneous combustion liability of coal based on its proximate analysis. Combust. Sci. Technol. 193, 2350–2367 (2021).

Gbadamosi, A. R., Onifade, M., Genc, B. & Rupprecht, S. Analysis of spontaneous combustion liability indices and coal recording standards/basis. Int. J. Min. Sci. Technol. 30, 723–736 (2020).

Liu, Q., Lin, B., Zhou, Y. & Li, Y. Constitutive relation and particle size distribution model of rock fragments in the goaf. Environ. Sci. Pollut. Res. 30, 39142–39153 (2023).

Liang, Y., Zhang, J., Wang, L., Luo, H. & Ren, T. Forecasting spontaneous combustion of coal in underground coal mines by index gases: A review. J. Loss Prev. Process Ind. 57, 208–222 (2019).

Liu, Q., Lin, B., Zhou, Y. & Li, Y. Permeability and inertial resistance coefficient correction model of broken rocks in coal mine goaf. Powder Technol. 384, 247–257 (2021).

Onifade, M. & Genc, B. A review of research on spontaneous combustion of coal. Int. J. Min. Sci. Technol. 30, 303–311 (2020).

Cheng, J., Ma, Y., Lu, W., Liu, G. & Cai, F. Using inverting CO critical value to predict coal spontaneous combustion severity in mine gobs with considering air leakages—a case study. Process Saf. Environ. Protect. 167, 45–55 (2022).

Liu, W., Zhang, F., Gao, T., Chu, X. & Qin, Y. Efficient prevention of coal spontaneous combustion using cooling nitrogen injection in a longwall gob: An application case. Energy 281, 128214 (2023).

Li, Z. et al. Intermittent Injection of carbon dioxide to control the risk of coal spontaneous combustion and methane explosion: A case study in U-type ventilation. Process Saf. Environ. Protect. 177, 795–806 (2023).

Zhuo, H., Qin, B. & Qin, Q. The impact of surface air leakage on coal spontaneous combustion hazardous zone in gob of shallow coal seams: A case study of Bulianta mine, China. Fuel 295, 120636 (2021).

Zhuo, H., Qin, B., Qin, Q. & Su, Z. Modeling and simulation of coal spontaneous combustion in a gob of shallow buried coal seams. Process Saf. Environ. Protect. 131, 246–254 (2019).

Ma, L. et al. Determination on the hazard zone of spontaneous coal combustion in the adjacent gob of different mining stages. Process Saf. Environ. Protect. 142, 370–379 (2020).

Ren, T., Wang, Z., Liang, Y. & Zhang, J. Numerical investigation of CO2 fringe behaviour on a longwall face and its control. Int. J. Coal Geol. 186, 80–96 (2018).

Wang, Z., Ren, T. & Cheng, Y. Numerical investigations of methane flow characteristics on a longwall face part II: Parametric studies. J. Nat. Gas Sci. Eng. 43, 254–267 (2017).

Xia, T. et al. Controlling factors of symbiotic disaster between coal gas and spontaneous combustion in longwall mining gobs. Fuel 182, 886–896 (2016).

Wang, C., Yang, S. & Li, X. Simulation of the hazard arising from the coupling of gas explosions and spontaneously combustible coal due to the gas drainage of a gob. Process Saf. Environ. Protect. 118, 296–306 (2018).

Yang, S., Zhou, B. & Wang, C. Investigation on coal spontaneous combustion in the gob of Y type ventialtion caving face: A case study. Process Saf. Environ. Protect. 148, 590–603 (2021).

Li, Z. et al. Numerical analysis on the potential danger zone of compound hazard in gob under mining condition. Process Saf. Environ. Protect. 147, 1125–1134 (2021).

Liu, W., Qin, Y., Shi, C. & Guo, D. Dynamic evolution of spontaneous combustion of coal in longwall gobs during mining-stopped period. Process Saf. Environ. Protect. 132, 11–21 (2019).

Xu, Y. et al. A model for assessing the compound risk represented by spontaneous coal combustion and methane emission in a gob. J. Clean. Prod. 273, 122925 (2020).

Su, H., Zhou, F., Song, X. & Qiang, Z. Risk analysis of spontaneous coal combustion in steeply inclined longwall gobs using a scaled-down experimental set-up. Process Saf. Environ. Protect. 111, 1–12 (2017).

Hetao, S., Fubao, Z., Xiaolin, S., Bobo, S. & Shaohua, S. Risk analysis of coal self-ignition in longwall gob: A modeling study on three-dimensional hazard zones. Fire Saf. J. 83, 54–65 (2016).

Li, L., Qin, B., Liu, J. & Leong, Y. Integrated experimentation and modeling of the formation processes underlying coal combustion-triggered methane explosions in a mined-out area. Energy 203, 117855 (2020).

Li, L. et al. Unique spatial methane distribution caused by spontaneous coal combustion in coal mine goafs: An experimental study. Process Saf. Environ. Protect. 116, 199–207 (2018).

Cheng, J., Qi, C. & Li, S. Modelling mine gas explosive pattern in underground mine gob and overlying strata. Int. J. Oil, Gas Coal Technology. 4, 554–577 (2019).

Zheng, Y. et al. Study on the coupling evolution of air and temperature field in coal mine goafs based on the similarity simulation experiments. Fuel 283, 118905 (2021).

Zheng, Y. et al. Study on the evolution characteristics of coal spontaneous combustion and gas coupling disaster region in goaf. Fuel 349, 128505 (2023).

Ma, D., Qin, B., Gao, Y., Jiang, J. & Feng, B. An experimental study on the methane migration induced by spontaneous combustion of coal in longwall gobs. Process Saf. Environ. Protect. 147, 292–299 (2021).

Hao, M. et al. Hazardous areas determination of coal spontaneous combustion in shallow-buried gobs of coal seam group: A physical simulation experimental study. Environ. Earth Sci. 78, 1–11 (2019).

Li, H. et al. Effects of oxygen concentration on the macroscopic characteristic indexes of high-temperature oxidation of coal. J. Energy Inst. 92, 554–566 (2019).

Liu, H., Wang, F., Ren, T., Qiao, M. & Yan, J. Influence of methane on the prediction index gases of coal spontaneous combustion: A case study in Xishan coalfield. China. Fuel. 289, 119852 (2021).

Wang, C. et al. Coal oxidation characteristics and index gases of spontaneous combustion during the heating and cooling processes. Fuel 307, 121806 (2022).

Cheng, J., Mei, J., Peng, S., Qi, C. & Shi, Y. Comprehensive consultation model for explosion risk in mine atmosphere-CCMER. Saf. Sci. 120, 798–812 (2019).

Liu, Q., Lin, B., Zhou, Y., Li, Y. & Ting, L. Experimental verification of permeability and inertial resistance coefficient model in the goaf. Energy Sources Part a-Recovery Util. Environ. Eff. 11, 1–20 (2022).

Ma, H., Ren, W., Wang, Y., Deng, H. & Zhang, D. Prediction model of spontaneous combustion “three zones” in goaf. Fuel 397, 135402 (2025).

Zhang, X. & Zou, J. Research on collaborative control technology of coal spontaneous combustion and gas coupling disaster in goaf based on dynamic isolation. Fuel 321, 124123 (2022).

Liu, Q., Lin, B., Zhou, Y., Li, Y. & Liu, T. Experimental verification of permeability and inertial resistance coefficient model in the goaf. Energy Sources Part a-Recovery Util. Environ. Eff. 11, 1–20 (2022).

Lei, C. et al. A Comparison of random forest and support vector machine approaches to predict coal spontaneous combustion in gob. Fuel 239, 297–311 (2019).

Liu, Q., Lin, B., Zhou, Y. & Li, Y. Porosity model of the goaf based on overlying strata movement and deformation. Environ. Earth Sci. 81, 214 (2022).

Qing, G., Wanxing, R. & Wei, L. Risk evaluation of coal spontaneous combustion from the statistical characteristics of index gases. Thermochim. Acta 715, 179287 (2022).

Miroshnichenko, D. A., Kaftan, Y. S., Desna, N. A., Nazarov, V. N. & Nikolaichuk, Y. V. Ignition temperature of coal. 1. Influence of the coal’s composition, structure, and properties. Coke Chem. 59, 277–282 (2016).

Miroshnichenko, D. V., Shulga, I. V., Kaftan, Y. S., Desna, N. A. & Nikolaichuk, Y. V. Ignition temperature of coal. 2. Binary coal mixtures. Coke Chem. 60, 219–225 (2017).

Miroshnichenko, D. V., Shulga, I. V., Kaftan, Y. S., Desna, N. A. & Nikolaichuk, Y. V. Ignition temperature of coal 3. Multicomponent coal mixtures. Coke Chem. 60, 343–347 (2017).

Qing, G., Wanxing, R., Xianliang, M., Hongchun, X. & Jingtai, S. An investigation into the morphological distribution of the temperature field in loose media and its underlying principles of evolution. Process Saf. Environ. Protect. 180, 639–647 (2023).

Meng, X. et al. Effect of active functional groups in coal on the release behavior of small molecule gases during low-temperature oxidation. Energy 273, 127290 (2023).

Wang, K., Huang, H., Deng, J., Zhang, Y. & Wang, Q. A spatio-temporal temperature prediction model for coal spontaneous combustion based on back propagation neural network. Energy 294, 130824 (2024).

Zheng, Y. et al. Real-time analysis of the changing trends of functional groups and corresponding gas generated law during coal spontaneous combustion. Fuel Process. Technol. 199, 106237 (2020).

Ren, W., Guo, Q., Shi, J., Lu, W. & Sun, Y. Construction of early warning indicators for coal spontaneous combustion based on statistical characteristics of index gases. J. China Coal Soc. 46, 1747–1758 (2021).

Ma, Z. et al. The location analysis and efficient control of hidden coal spontaneous combustion disaster in coal mine goaf: A case study. Process Saf. Environ. Protect. 184, 66–78 (2024).

Ren, S. et al. Detection of signal of fire source for coal spontaneous combustion applied with acoustic wave. Nat. Resour. Res. 32, 2243–2256 (2023).

Wang, C. et al. Study on the dynamic evolution law of spontaneous coal combustion in high-temperature regions. Fuel 314, 123036 (2022).

Acknowledgements

This work was funded by the open research fund of State Key Laboratory for Fine Exploration and Intelligent Development of Coal Resources, CUMT (SKLCRSM23KF017), Longyan City Wuping County Qimai Science and Technology Innovation Fund Project (2022LYQM007), Scientific Research Foundation of Longyan University (LB2022004).

Author information

Authors and Affiliations

Contributions

Q.L.: Methodology, Investigation, Writing—original draft. C.Z.: Supervision, Writing—review & editing. T.L.: Investigation, Writing—review & editing. D.M.: Writing—review & editing. Y.L.: Data curation, Visualization.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, Q., Zhu, C., Liu, T. et al. Experimental study on temperature and gas concentration evolution law during coal spontaneous combustion in the goaf. Sci Rep 15, 17428 (2025). https://doi.org/10.1038/s41598-025-01688-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-01688-7