Abstract

The hydraulic system is crucial for the safety of the aircraft, which is the key to ensuring the safety of both the aircraft and passengers. It is necessary to study and analyze the normal and fault mode of the system to provide a way for evaluating the fault degree of the hydraulic system. Therefore an improved ResNet based fault degree evaluation method was proposed to evaluate the fault degree of the aircraft hydraulic system. First, the aircraft hydraulic system is constructed by the AMESim, one normal and five fault modes are simulated. Then the effects of the parametric variations for the five fault models are studied, in which pump oil leakage is chosen for analysis. After the analysis of the 5 kinds of faults, each of them is divided to 3 different fault degree, then 16 kinds of states are definition. Second, using the SE-ResNet based method to evaluate the system fault degree. The structure of the two improved ResNet blocks are designed, after that the whole structure of the SE-ResNet fault degree evaluation model is given. Then the parameters of the SE-ResNet are optimization by simulation. After that the evaluate results are given and analyzed, moreover the comparison between the SE-ResNet method with the other machine learning methods are given. The results show that the method in this paper has the best accuracy and shortest test time, therefore the method proposed in this paper has effective measures to improve the reliability of the aircraft hydraulic system.

Similar content being viewed by others

Introduction

The aircraft hydraulic system is an important part of an aircraft system. Hydraulic system performance is crucial for the safety of an aircraft, which is the key to ensuring the safety of both the aircraft and passengers. Research about a fault can only rely on experience and testing on the ground. Aircraft hydraulic systems account for a large proportion of aircraft maintenance work. The failures of aircraft hydraulic systems make up about 30% of total mechanical failures, and their maintenance accounts for one-third of the total mechanical maintenance1. The disadvantage of a hydraulic system is that it is difficult to find the cause of the failure2. The system is not intuitive compared with other devices. Therefore, the reliability of the hydraulic system has a crucial impact on the reliability of the whole aircraft system.

To ensure the flight safety and flying qualities of the aircraft, the hydraulic control system often has a backup system, the structure of the hydraulic control system is complex, and is essential to improve the reliability of the whole aircraft. Thus, the condition monitoring of fluid power systems is of great importance to both the academic and industrial fields3,4,5,6. To make progress towards this goal, it is desirable to develop fault diagnosis schemes that can report abnormal conditions in hydraulic systems. In order to ensure the safe and reliable operation of an aircraft hydraulic system, the fault diagnosis of the hydraulic system is of great significance7,8,9,10,11. Sun researched the failure mode and effect analysis for the all-flying tail control system of a light aircraft and the aileron control system of a new type of light aircraft12. Zhang studied the aircraft system safety assessment method at the aircraft level. A fault tree analysis and a failure mode and effect analysis were utilized to study the assessment methods and key technologies that met the requirements of the system safety assessment at the aircraft level13. P a Sa used a statistical method capable of independently monitoring a single sensor and thus enhancing overall system safety2. Yazdanpanah used a wavelet to detect the internal leakage in hydraulic actuators. The experimental tests showed the results for detecting internal leakage as low as 0.124 L/min, representing approximately 2.6% reduction of the flow rate available to move the actuator14. Dao H V designed an active fault-tolerant control (FTC) system for an n-degree-of-freedom (n-DOF) hydraulic manipulator with internal leakage faults and mismatched/matched lumped disturbances. His proposed active FTC guaranteed the position tracking performance in not only single-fault but also simultaneous-fault conditions15. Jin Y focused on piston seal wear in a hydraulic cylinder as one of the main factors that gave rise to internal leakage. Jin applied wavelet transform as a feature extractor to transform raw oil pressure data into a feature vector consisting of the wavelet packet sub-band energy, energy entropy, energy variance, and root mean square of the detailed wavelet coefficient. The proposed fault detection and identification (FDI) scheme was capable of effectively detecting the leakage experiment and simulation data16. Regarding the Hilbert-Huang transform approaches, in their recent study, multi-scale analysis (MA) technology, including measurements of the correlation entropy and wavelet detailed coefficients, was introduced for the internal leakage detection in electro hydrostatic actuators17. In a hydraulic system, many types of faults are actuator faults, including internal leakage, external leakage, a drop in the supply pressure, and sensor faults including pressure sensor faults and position sensor faults18,19,20,21.

ResNet (Deep residual network) is an improved algorithm of deep convolutional neural networks(CNN). The ResNet was proposed by the Microsoft Research Institute to solve the degradation in CNNs22. Now this method is widely used in the field of image generation, classification, feature extraction23,24,25,26. However, there are not so many applications in the field of signal processing and fault detection. Wen and their teem proposed a new ResNet with the depth of 51 convolutional layers for fault diagnosis, their method was tested on three datasets, The prediction accuracies all over 98%27. Amini et al proposed a deep network with LSTM and ResNet for the subsequent fault diagnosis step to avoid randomness imposed by the order of the input features. Their method combining fault detection and fault diagnosis networks is also presented without the assumption of having a perfect fault detection network28. Mishra et al focus was given to replace the complex time-frequency domain signal processing techniques by incorporating a simple time-domain based methodology. The vibration signature of different bearing faults was acquired at three different speeds and was directly converted into images by 2D-Vibration Imaging (2D-VI) technique using an overlapping-based moving window. The extracted images were fed into Res for automatic feature extraction, followed by classification using Support Vector Machine (SVM)29.

All these methods have a real good performance, but they did not consider the fault degree. From the perspective of the current literature, there are almost no researches in the field of fault degree evaluation of the aircraft hydraulic system. In this paper an improved ResNet based fault degree evaluation method of the aircraft hydraulic system was proposed to evaluate the fault degree of the aircraft hydraulic system. The main innovations of this paper are reflected in the following areas:

-

1.

The landing gear hydraulic system is constructed by the AMESim software, a normal state and five fault states are simulated. To analyze the faults and their effects to the whole hydraulic system, five kinds of the hydraulic faults are considered. Then pump oil leakage was chosen for analysis and the effects of the parametric variations for the fault model are studied based on the system stability condition. Then the analyzed faults are divided into 3 different failure degree, 16 kinds of different states are definition.

-

2.

The structure of the two SE-ResNet residual block was designed by adding SENet block to the ResNet,. Then using the two designed SE-ResNet residual block, the whole network structure of the SE-ResNet model was found, and giving the main parameters of the improved network.

-

3.

Using the SE-ResNet based method to evaluate the system fault degree. Considered different network structure and different number of convolution kernels are tested for the Se-ResNet model. The results show the SE-ResNet structure has the best performance in failure mode evaluation, and the kernel size is 64-64-64 has the best accuracy.

The remainder of this paper is organized as follows. Section II definite the aircraft hydraulic system and improve the ResNet algorithm, the SE-ResNet method is proposed. Section III the simulation system is built, the results of the normal mode and the fault mode are analysis, the range of parameter variations is proposed to definite the three fault degree and 16 different kinds of states are given. In Section IV the SE-ResNet fault degree evaluation method is proposed, the parameters of the network are optimization and the evaluation results are given. Finally, Section V concludes this research.

System model and ResNet algorithm

The landing gear hydraulic system is chosen for analysis. The stability of the hydraulic system is a precondition for the reliability of the landing gear control surface. For this reason, the failure mode effect analysis is carried out for the landing gear control surface system to improve the aircraft reliability.

System definition

The LG hydraulic system is the core of the flight control system, with the functions of driving and supporting the control surfaces. The structure layer classification of the landing gear system is shown in Fig. 1.

Figure 1 shows the relationship of each system. The hydraulic control surface is selected as the representative of the control surface systems. To highlight the research focus, this paper describes the study of the section from the oil tank to the landing gear system without the drive part or the transmission part. The normal operation of the system means that the input signal can be transformed into the stable operation of the control surfaces.

In general, a hydraulic system is divided into two parts, namely, the servo-actuation system and the oil supply system. These are the core components of a hydraulic control surface system. The hydraulic system in this research is models are created in LMS AMESim, as shown in Fig. 2.

In this hydraulic system, the controlling oil supply system is composed of three relatively independent systems: oil supply system 1, oil supply system 2, and oil supply system 3. Oil supply system 1 is powered by an engine drive pump (EDP,3). Oil supply system 2 is powered by an engine drive pump (EDP,11) and an electric pump (EMP,12). Oil supply system 3 is powered by an electric pump (EMP,13) and a ram air turbine (RAT,14) in emergencies when the left and right engines both fail. The servo-actuation system (9) is considered one modularization system, which can be taken as aircraft actuating parts, such as the landing gear, flap, aileron, etc. In this research, the landing gear is represented. Between system 1 and system 2 is a two-way PTU (Power Transfer Unit) system that works when the pressure difference between oil supply systems 1 and 2 is over 500 psi. The whole system from the oil tank to the service actuator is modeled and analyzed.

To analyze the effects of component failure on the system level, a model of the system is required that includes the considered failure at various extents. Different kinds of failure modes of the components should be modeled. The macroscopic failure behavior alters the performance of the component and affects the hydraulic system, but it is not easy to find when this happens, and it is difficult to find the level. When the system operation is normal, the EDP (in system 1) consists of an induction machine that drives an axial piston pump. The pump is controlled hydro-mechanically to maintain the system pressure for zero flow. With increasing flow, the maintained pressure decreases slightly. The EDP delivers flow from the oil tank (2) to a valve block that contains a high pressure (HP) filter (5) and a pressure relief valve (RV)(6). From the valve block, the hydraulic power is distributed to the consumers. A bladder accumulator (7) ensures the system pressure stability with sudden changes in the flow demands. The entire return flow passes the low pressure (LP) filter (8) towards the reservoir. The sensors measure the system flow (a), system pressure (b), and the return line fluid temperature (c).

Through the model described above, we can get 5 kinds of fault states and a normal state, each failure can be divided into three levels according to the degree of severity. Therefore, at last there are 16 kinds of different states of the aircraft hydraulic systems. And there are 8 kinds of different signals including the pressure (pump, filter, actuator), the flowrate (pump, filter, actuator), the displacement(actuator), and the velocity (actuator).

ResNet algorithm

ResNet was proposed by He et al22. It is an improved structure of CNN, by adding the residual block to solve the gradient dislocation problem of the deep network structure. In the ResNet network structure, convolutional layer (Conv) consists of multiple parallel convolution kernels, the convolution nucleus is used to calculate different feature diagrams. And select the ReLu activation function to introduce non -linear characteristics. Therefore, the calculation formula of convolutional layer is:

In this formula, \({x}_{j}^{m-1}\) and \({x}_{j}^{m}\) were presented the input and output of number m convolutional layer, j is the dimension of the system, n is the number of input feature vectors.\({k}_{ij}^{m}\) is the convolution kernel, and \({b}_{j}^{m}\) is the offset. F(.) is the active function. Convolution operation can be described as the Fig. 3.

The pooling layer is selected for the features extracted in the convolution layer. It can reduce the size of the model, improve the calculation speed. Common pooling operations include average pooling and maximum pooling. The calculation process is as follows:

In this formula, \({p}_{j}^{m}\) is the output of the pooling layer, l is the size of the pooling layer, \({x}_{j}^{m}(t)\) is the activation value of the t neurons output. Max pooling and average pooling can be described as Fig. 4.

Batch normalization (BN) layer is used to solve deep network training that may bring the problem gradients are scattered or gradient explosion. It is proposed as a normalized method. The calculation process of the BN is:

In this formula,\({x}_{i}\) and \({y}_{i}\) are the input feature and output of feature the BN, i represent the observation value. ε is a constant close to 0, \(\gamma\) and \(\beta\) are two training parameters, N is the number of each batch sample in the task.

The ResNet consists of multiple residual modules stacked. The residual module passes by shortcut connection, pass the input data directly to the output. The entire model only needs to learn different parts between input and output, while simplifying network learning tasks, improve the ability to judge the network. Its learning process is:

In this formula, x means the evergrande mapping, H(x) means the unknown mapping, and F(x) means the residual mapping. Dealing to the shortcut connection, the calculation properties of the ResNet change from multiplication to plus method, greatly alleviate the network degradation problem that has occurred with the network. Improve the stability of model training, The number of layers of the training network is greatly increased. The structure of ResNet residual block is in Figure 5.

Pros of Resnet:

-

1.

Ease of training deep networks: By introducing residual connections, the training of deep networks has become easier, enabling the training of deeper network structures than ever before.

-

2.

Avoid vanishing gradients and gradient explosions: The residual network alleviates the problems of vanishing gradients and gradient explosions to a certain extent.

-

3.

Improved performance: Residual networks have demonstrated superior performance across multiple computer vision tasks.

SE-ResNet structure design

According to the size of the model’s input and dataset, the input are 8 kinds of signals, including the hydraulic pressure (at pump, at filter, at actuator), the hydraulic flowrate (at pump, at filter, at actuator), and the displacement of the actuator, and the velocity of the actuator. The output are 16 kinds of states, including 5 different fault states and a normal state in the hydraulic system. Each kind of the faults have 3 kinds of fault degree, minor failures, ordinary failures, and serious failures.

In order to improve the accuracy of the fault degree, using the SENet30 structure to the ResNet, and construct a new structure SE-ResNet. There are two important processing in the SE-ResNet which called the squeeze and excitation, squeeze process is:

In the formula, xq represents the q feature diagram of the input size of H × W; \({F}_{sq}\left({x}_{q}\right)\) indicates the output value after the squeezing operation.

The excitation operation consists of two full connection layers and activation functions. The calculation process is as follows:

In the formula: ω1 is calculated by the first full connection layer; ω2 is the second full connection layer calculation; \(\delta\) is ReLu activation function; σ is the Sigmoid activation function.

SENet as a single subnet structure, can be embedded in the original network. Therefore, the degree of sensitivity to the useful characteristics of the network model is enhanced. Adding the SENet only needs to add a small amount of calculation to improve the classification accuracy of the model. This article embeds SENet to the ResNet, to improve the accuracy of different fault levels of the model. the following improvement of the structure of SE-ResNet residual block is shown in Fig. 6.

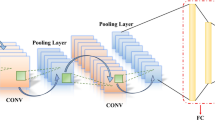

The parameters of each layer are presented in the Fig. 7 and Table 1. The whole structure of the SE-ResNet is shown in Fig. 7. In this work the input feature is 8 kinds of signals. One pairs of convolution and pooling layers was connected with two SE-ResNet block, then with a FC layers and one Softmax layer, as shown in Fig. 7. The convolution layer and the SE-ResNet block are responsible for feature extraction, whereas the pooling layer (where maximum pooling is used) is responsible for dimensionality reduction. The Softmax layer and the FC layer classify the feature maps extracted via convolution pooling. Typically, the size and step size of the convolution pooling are initially determined based on experience; thereafter, optimal values are determined using the parameters. The input layer is linked to a fully connected layer having 2500 nodes. The output of the fully connected layer is transformed into 16 class of states by the reshape function.

Table 1 lists the optimal values for the network parameters, where lr is the learning rate, and batch size refers to the number of batch samples. The dropout rate refers to the random resetting of the neuron output to zero with a certain probability during training, which can help reduce over-fitting. The optimal parameter is obtained by actual situation of aircraft hydraulic system and multiple experiments.

Aircraft hydraulic system simulation and fault degree analysis

Simulation method

The simulation model of LG hydraulic system is built based on LMS AMESim. Taking the aircraft landing gear hydraulic system as the research object. By the sketch model of AMESim, based on the working principle of the hydraulic cylinder and using the hydraulic library and the design library of the hydraulic components, the simulation model of the working loop of the landing gear hydraulic cylinder is shown in Fig. 2. In this section, the simulation result will give and analysis.

Taking the hydraulic system of A320 large passenger aircraft as the simulation object. The hydraulic system of A320 passenger plane is composed of three relatively independent systems: green system (system 1), blue system (system 3) and yellow system (system 2). The green system is powered by the left engine drive pump (EDP), the blue system by the electric pump (EMP), and the ram air turbine (RAT) in emergencies. The yellow system is powered by a right engine drive pump and an electric pump. The main parameters of the simulation are given in Table 2.

The fault model is built according to the normal model with consideration of five different common fault modes, including Pump Leakage (PL), Filter Block (FB), Actuator inner Leakage (AIL), Servo Valve Blockage (SVB), and Oil Pollution (OP). The fault mode parameters are listed in Table 3. The simulation values which was used in this paper can refer to the paper31.

The simulation model is built when system is stable. This simulation used oil supply system 1(Fig. 2) and actuator 9 (Fig. 2) to simulate the LG hydraulic system. When the system is working in normal, it will be considered as normal mode. All components and oil in the system work in a closed oil circuit.

The total simulation time is 25s, 0–5s actuator closed, 5–10s actuator opened and move left, 10–15s actuator closed, 15–20s actuator opened and move right, 20–25s actuator closed, simulation ended. Sample rate is 100hz, in each simulation a sample of 2500 number of time point will be collected.

Simulation results and analysis

The actuator inner leakage (AIL) model with oil leakage coefficient is simulated. The different value has been changed under the condition of keeping other parameters constant.

The normal value of AIL coefficient is 0.01L/min/bar, the failure value is 0.04L/min/bar, the simulation result is shown in Fig. 8. The four figs are: (1) the pressure at the pump outlet; (2) the pressure at filter outlet; (3) the pressure at actuator inlet; (4) the pressure at actuator outlet. The four Figures reflect the pressure variety in different place in the hydraulic system.

In Fig. 8, the normal mode and the AIL mode can work well in a stable state in the simulation. This shows that if the AIL value is not large enough, it will not have a significant impact on the system stability. Comparing with the normal mode, the AIL mode pressure drops and the response time is slow in the four figures. But the system can also work well, the AIL mode can get a stable state in the simulation. What is more, the system spends less time to get a stable state in the enlarged Fig. 1, which has a same result with the theory in section II. When the AIL coefficient becomes larger, the hydraulic system will be more stable. Compared the enlarged Fig. 1 with Fig. 2, the pressure signals become smoother and more stable after passing through the oil filter.

In order to analyses the impact of the AIL coefficient on the system stability. The AIL coefficient is changed under the condition of keeping other parameters constant. The normal coefficient is 0.01L/min/bar, and the failure coefficient value are 0.04 L/min/bar, 0.07 L/min/bar, and 0.10 L/min/bar. The simulation results are in Figs. 9 and 10.

The pressure at the pump outlet is shown in Fig. 9. If the AIL coefficient equal from 0.01 to 0.07 L/min/bar, the hydraulic system can work stable in the whole simulation. As the AIL coefficient become larger, the hydraulic system work pressure becomes lower, and the response time becomes longer. At the same time, the hydraulic system takes less time to go from an unstable state to a stable state. If the AIL coefficient is over 0.1 L/min/bar, the system cannot work well. The working pressure of the hydraulic system drops seriously, and the responding time is greatly delayed. During 5-10 sec, the hydraulic system cannot provide enough working pressure and cannot maintain a stable pressure value, the system is unstable. The displacement and acceleration of the hydraulic actuator is shown in Fig. 10.

As shown in Fig. 10 (1), if the AIL value is in the range from 0.01 to 0.07, the actuator can reach the right location (0.45 m), the system is stable. As the AIL value becomes larger, the hydraulic system spends more time to reach the target. If the AIL value is over 0.1, the actuator displacement can reach 4.246m. The hydraulic system is unable to reach the correct position, the system is unstable. In reality scenes, this condition may cause serious faults, like the hydraulic system unable to lower the landing gear to the right position. In particular, if the AIL is to large, the system will be unstable

The acceleration of the actuator is analyzed in Fig. 10(2) ~ (4). Fig. 2 is the acceleration of the actuator. When the AIL=0.1 the acceleration, the acceleration has a biggest fluctuation. It happened at the time 10-12sec. For the acceleration signal in the time domain have too many distractions, the Fig. 2 cannot react too much useful information. Fig. 3 is the spectrogram of the Fig. 2, using FFT (Fast Fourier Transform) method, the equation is:

In the acceleration vibration spectrum, the ordinate coordinate is the amplitude of the acceleration vibration, which reflects the height of the amplitude of the acceleration vibration and represents the frequency of shaking, such as determining whether the system is working or vibrating. When the AIL=0.1 the system vibrates severely in the low-frequency section.

Figure 4 is the decomposition of acceleration spectrum, in this figure, AIL=0.01-0.07 the acceleration frequency is in the high-frequency from 40 to 50Hz, AIL=0.1 the acceleration frequency is from 0 to 10 Hz and 30 to 40 Hz. The system reaches a steady state when the AIL value is 0.01–0.07. The time to reach the steady state is delayed with the increase of the AIL value. When the AIL value is over 0.1, the system enters a state of vibration instead of stability. Which proves that the result of the theoretical analysis is correct. Thus, if the leakage coefficient increases within a specified range, it does not have a big influence on the system stability. Furthermore, because oil is flammable, the oil leak will lead to fire and other devastating disasters. So when the values of the system changes, The eight-channel output signal of the system will change, and it can define the size of the faulty level by defining different simulation values.

Fault degree definition and data acquisition

From the analysis in 3.2, the different faults of pressure, flowrate and other signals have their own characteristics, which can be used to evaluate the degree of different failures. The 16 kinds of states are in Table 3.

In the Table 4, there are 6 kinds of states, one normal state and 5 kinds of fault states. Every fault state has three different failure degree. The sample number is the dataset will be used in the Se-ResNet to evaluate the different fault degree, the value is the simulation set of the 16 different state in the AMESim, the details can refer the 3.1. The samples can be collected by change the different values in the simulations.

SE-ResNet fault degree evaluation of the LG hydraulic system

The stability of the hydraulic system is a precondition for the reliability of an aircraft. For this reason, the SE-ResNet method was used for the LG hydraulic system to evaluate the failure degree. In this section, the oil supply system 1 and actuator 9 (Fig. 2) are selected as representative of the hydraulic systems. To highlight the research focus, the section studied is from tank 2 of oil supply system 1 to actuator 9 without the other parts, which work in the same way. The Se-ResNet training and testing set was collected in the last section.

SE-ResNet model built and failure level evaluation process

The SE-ResNet model of this article was built based on the TensorFlow2.0 GPU framework, computer matching place: Intel (R) Core (TM) i5-12400F CPU @ 4. 40 GHz + NVIDIA GEFORCE RTX 2070 super 8GB. Batch-Size is set to 64, The maximum number of iterations is 200 times. During the model training, the loss of the task is calculated with cross-entropy loss, and it is used as the total loss of the model. Due to the fast convergence speed of the Adam optimizer and less memory demand, it can reduce the performance of the device. Therefore, Adam algorithm was cheese as the optimizer, the learning rate is set to 0. 001, optimizing the model. And adjust the proportion of the task to the optimal training effect of the tasks. The SE-ResNet failure degree evaluate framework is shown in Fig. 11.

The specific steps of the failure level of the model mentioned in this article are as follows:

-

1.

Get the 8 channels signal in different working conditions during the operation of the aircraft hydraulic system.

-

2.

After analyzing the collected signals, the 5 kinds of faults are divided into different degrees of failure and labeled the data. Based on a certain proportion, the labeled dataset is randomly divided into training dataset and test dataset. The training dataset is 500 samples of each states, and test dataset 200 of each state.

-

3.

Establish the SE-ResNet model and initialize parameters.

-

4.

Enter the training data and calculate the model of the model cross-entropy loss function.

-

5.

Determine whether the training has reached the maximum batch. If it is reached, the test data is entered into the training model. Otherwise, turn to step 4.

-

6.

Output the SE-ResNet model fault degree evaluation results.

SE-ResNet parameter optimization

To evaluate the performance of the Se-ResNet model, this article comes from the network structure and the number of convolution kernels are tested for the Se-ResNet model. And in this paper used accuracy (account), recall rate, precision rate as the evaluation indicator:

In the three formula, TP represents the correct classification of the positive sample; FP represents a negative sample of error classification; FN represents the positive sample of error classification; TN represents the accurate classification negative sample; C represents the final output of the Se-ResNet model.

The structure of the network will affect the fault degree prediction. In order to prove the advantages of the Se-ResNet model mentioned in this article, choose three comparison class of different network structures, Res-Net, ResNet_1 and ResNet_2. To test the stability of each model, enter ten experiments, the results are shown in Table 5. The model size indicates the network of the model for hardware requirements. Train time and test time show the efficiency of the mode.

The ResNet is an improved method of CNN, here the structure of ResNet did not use any SENet model, the other parts are consistent with the model of this article. The ResNet_1 using just one SE-ResNet_b residual block, and did not use the The SE-ResNet_a residual block, the other parts are consistent with the model of this article. ResNet_2 using just one SE-ResNet_a residual block, and did not use the The SE-ResNet_b residual block, the other parts are consistent with the model of this article.

The original ResNet model has largest model size, making the running time longest, but the evaluation effect is the worst; ResNet_1 and ResNet_2 using the different SE-ResNet residual block, and the evaluation effect is better than ResNet, the mode size is become smaller. The SE-ResNet in this article has the best performance in failure mode evaluation, and not larger the mode size too much. Therefor this structure is suitable for the hydraulic failure degree evaluation.

Since the size of the convolution kernels will affect the final evaluation effect of the SE-ResNet model. This article uses accuracy as an evaluation indicator, and selects different convolution kernels combinations for 10 experiments. The experimental results are as shown in Tables 6 and 5.

When the number of convolution kernels is relatively small, the accuracy rate of failure classification and degree of assessment is relatively low, and the overall diagnosis of the model is not ideal; When the number of convolution kernels is too large, the two tasks have a serious overfitting phenomenon at the same time, and the accuracy rate of model testing has decreased sharply; When the convolution kernel combination is 64-64-64, the accuracy rate of failure classification and degree assessment is small and the highest accuracy after training and testing. Therefore, the SE-ResNet model finally selected the convolution kernel combination of 64-64-64 to study the failure classification and degree evaluation.

To avoid overfitting or underfitting, the learning rate and batch size are simulated below. When the learning rate value is set too large, it will cause the network parameters to swing back and forth on both sides of the optimal solution, and it is difficult to obtain the optimal solution, if the learning rate is too small, it may cause the gradient to fall too slowly and cause the gradient to disappear, so the learning rate attenuation term can be increased to prevent the gradient from disappearing.

Batch size is a method to divide input samples into batches to update network parameters in network training, which can avoid the problem of local optimization caused by the input of a single sample. Increasing the number of iterations can increase the accuracy of the network, but it will increase the network training time and fault detection time.

In Table 7, the smaller the learning rate set, the accuracy will increase, but if it is too small, it may lead to a large increase in the network training time, and the accuracy will decrease. To avoid overfitting the appropriate learning rate can be selected as 0.001.

The batch size will also affect the accuracy, when the batch size selection is small, because the data loading is slow, so the training time is relatively long, and it is not suitable for the fault diagnosis of the hydraulic system of large passenger aircraft, it can be seen from the table that the batch size set to 128 is appropriate.

SE-ResNet fault degree evaluate results

On the basis of the above research, in order to more intuitive analysis of the evaluation effect of the model in this article, use the trained model to identify the test data, and finally output in the form of confusion matrix, as shown in Fig. 12.

It can be seen from the fault type confusion matrix that only 8 samples of the faults are classified into the stage of normal. All of them are from minor situation, including 1 minor pump leakage sample, 1 Servo valve blockage sample and 6 minor pollution sample. The total accuracy is 98.39%. The accuracy of minor fault degree is 96.9%, ordinary is 98.3%, serious is 99.9%.

The accuracy of pump leakage (1~3) is 98.66%, only 1 sample was classified into the wrong state, and 7 samples are classified into different fault degree. The accuracy of filter blockage (4–6) is 99.5%, only 3 samples are classified into different fault degree, no samples are classified to normal state or other fault state. The accuracy of actuator inner leakage (7–9) is 98.8%, 7 samples are classified into different fault degree, the samples all comes from the minor leakage. The accuracy of servo valve blockage (10–12) is 98.83, 7 samples are classified into the wrong fault degree, 1 minor degree is classified into normal state, 3 into ordinary state. And 2 ordinary state is classified into minor and 1 into serious.

The accuracy of oil pollution (13–15) is the lowest, it is 96.1%. Especially in the case of minor pollution. The minor oil pollution is the state with the most classification errors, 6 of them was classified into the stage of normal, and 7 of them was classified into the different fault degree. It shows that the model of NE-ResNet can effectively classify the type of fault, at the same time, it can also accurately determine the severity of the failure.

Comparison between SE-ResNet with other machine learning algorithms

In order to prove the effectiveness and superiority of the method in this paper. Compare the SE-ResNet with CNN32, DBN33, BP, and SVM34. The structure of the model refers to the papers, Back Propagation (BP) network directly use eight-channel signals to simulate. The simulation results were shown in Table 6.

It can be seen from Table 8 that among the four network structures, the SVM and BP based on shallow networks has a gap in CNN and DBNs with deep learning methods in terms of accuracy, but the CNN with the highest recognition rate is used. Evaluation of the degree of the systems, which cannot fully reflect the information of the circuit breaker’s failure, so that the accuracy rate is lower than the model in this article. Compares the SE-ResNet algorithms with these four common machine learning algorithms. As can be seen, the test set precision of SE-ResNet is the highest; its training speed is only second to that of the BP neural network, with regard to algorithms that need to be trained. Furthermore, the model is smaller than most other models, with the exception of the linear SVM.

Conclusion

In this paper, an improved ResNet fault degree evaluation method was proposed to evaluate the fault degree of the landing gear hydraulic system.

First, by adding SENet block to the ResNet, the structure of the two SE-ResNet residual block was designed. Then using the two designed SE-ResNet residual block, the whole network structure of the SE-ResNet model was found, and giving the main parameters of the improved network.

Second, the landing gear hydraulic system is constructed by the AMESim, a normal state and five fault states are simulated. To analyze the faults and their effects to the whole hydraulic system, five kinds of the hydraulic faults are considered. Then pump oil leakage was chosen for analysis and the effects of the parametric variations for the fault model are studied based on the system stability condition. Then the analyzed faults are divided into 3 different failure degree, 16 kinds of different states are definition.

Third, using the SE-ResNet based method to evaluate the system fault degree. Considered different network structure and different number of convolution kernels are tested for the Se-ResNet model. The results show the SE-ResNet structure has the best performance in failure mode evaluation, and the kernel size is 64-64-64 has the best accuracy. Then give the confusion matrix of the method, the total accuracy is 98.39%. The accuracy of minor fault degree is 96.9%, ordinary degree is 98.3%, serious degree is 99.9%. It shows that the model of SE-ResNet can effectively classify the type of fault, at the same time, it can also accurately determine the severity of the failure. Then make a comparison with four different machine learning methods, the test precision of SE-ResNet is the highest; the training speed is only lower than that of the BP neural network. The method proposed in this paper has effective measures to improve the reliability of the aircraft hydraulic system.

In the future work, to solve the data imbalance in the fault diagnosis of the aircraft hydraulic system, GAN method may be considered.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Reveley, M. S., Briggs, J. L., Evans, J. K., et al. Causal factors and adverse conditions of aviation accidents and incidents related to integrated resilient aircraft control. US: NASA/TM-216967, 2011.

Samara, P. A., Fouskitakis, G. N., Sakellariou, J. S. & Fassois, S. A statistical method for the detection of sensor abrupt faults in aircraft control systems. IEEE Trans. Control Syst. Technol. 16(04), 789–798 (2008).

Antonio, C. B., De Andrea, M., Giovanni, J. & Sorli, M. A case study on the detection and prognosis of internal leakages in electro-hydraulic flight control. Actuators 10(09), 215–233 (2021).

Mehmood, Z., Hameed, A., Safdar, S., et al. Multiaxial stress mapping and fatigue failure prediction of aircraft hydraulic pipes. engineering failure analysis, 2021, vol. 121: 195–255.

Zheng, Z., Li, X. & Zhu, Y. Feature extraction of the hydraulic pump fault based on improved auto-gram. Measurement 163, 907–918 (2020).

León, P. G., García-Morales, J., Escobar-Jiménez, R. F., Gómez-Aguilar, J. F., López-López, G. and Torres, L. Implementation of a fault tolerant system for the internal combustion engine’s MAF sensor. Measurement 122: 91–99 (2018).

Li, L., Huang, Y., Tao, J., Liu, C. & Li, K. Featured temporal segmentation method and AdaBoost-BP detector for internal leakage evaluation of a hydraulic cylinder. Meas. J. Int. Meas. Confed. 130, 279–289 (2018).

Zhong, H. M. et al. Fault diagnosis of an intelligent hydraulic pump based on a nonlinear unknown input observer. Chin. J. Aeronaut. 31(02), 185–194 (2018).

Lu, C., Wang, S. & Maids, V. Fault severity recognition of aviation piston pump based on feature extraction of EEMD paving and optimized support vector regression model. Aerosp. Sci. Technol. 67(08), 105–117 (2017).

Zhou, X. et al. Reliability optimization design of hydraulic system considering oil contamination. J. Mech. Sci. Technol. 34, 5041–5051 (2020).

Sharifi, et al. Leakage fault detection in electro-hydraulic servo systems using a nonlinear representation learning approach. ISA Trans. 2018;73(02):154–164.

Sun, Y. C. et al. The FMEA for all-flying tail control system of a light aircraft. J. Mech. Transm. 24(04), 13–16 (2000).

Zhang, S. N., Wang, J. H. & Zhang, R. X. Study on aircraft system safety assessment method in aircraft level. China Saf. Sci. J. 24(10), 125–130 (2011).

Yazdanpanah Goharrizi, A. & Sepehri, N. A wavelet-based approach to internal seal damage diagnosis in hydraulic actuators. IEEE Trans. Ind. Electron. 57(05), 1755–1763 (2010).

Dao H V, Tran D T and Ahn K K, Active fault tolerant control system design for hydraulic manipulator with internal leakage faults based on disturbance observer and online adaptive identification, In IEEE Access, 2021, 9, 23850–23862.

Jin, Y. et al. Fault diagnosis of hydraulic seal wear and internal leakage using wavelets and wavelet neural network. IEEE Trans. Instrum. Meas. 68(04), 1026–1034 (2019).

Maddahi, A., Kinsner, W. & Sepehri, N. Internal leakage detection in electro-hydrostatic actuators using multiscale analysis of experimental data. IEEE Trans. Instrum. Meas. 65(12), 2734–2747 (2016).

Xu, Q. N., Lee, K. M., Zhou, H. & Yang, H. Y. Model-based fault detection and isolation scheme for a rudder servo system. IEEE Trans. Ind. Electron. 62(04), 2384–2396 (2015).

Muenchhof, M., Beck, M. & Isermann, R. Fault-tolerant actuators and drives structures, fault detection principles and applications. Annu. Rev. Control 33(02), 136–148. https://doi.org/10.1016/j.ar-control.2009.08.002 (2009).

Alsuwian, T., et al. Advanced fault-tolerant anti-surge control system of centrifugal compressors for sensor and actuator faults. 22(10), 10 2022. https://doi.org/10.3390/s22103864.

Yuan, Y., et al. Fault detection and location system for diagnosis of multiple faults in aeroengines. IEEE Access, 2017; 5, 17671–17677.

He, K., Zhang, X., Ren, S., et al. Deep residual learning for image recognition. Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition. 2016: 770–778.

Sarwinda, D. et al. Deep learning in image classification using residual network (ResNet) variants for detection of colorectal cancer. Procedia Comput. Sci. 179, 423–431 (2021).

Liu, Z. et al. Discrimination of the fruits of amomum tsao-ko according to geographical origin by 2DCOS image with RGB and Resnet image analysis techniques. Microchem. J. 169, 106545 (2021).

Zhang, L. et al. An infrared and visible image fusion algorithm based on ResNet-152. Multimedia Tools Appl. 81(7), 9277–9287 (2022).

Reddy, A. S. B., Juliet, D. S. Transfer learning with ResNet-50 for malaria cell-image classification. In 2019 International Conference on Communication and Signal Processing (ICCSP). IEEE, 2019: 0945–0949.

Wen, L., Li, X. & Gao, L. A transfer convolutional neural network for fault diagnosis based on ResNet-50. Neural Comput. Appl. 32(10), 6111–6124 (2020).

Amini, N. & Zhu, Q. Fault detection and diagnosis with a novel source-aware autoencoder and deep residual neural network. Neurocomputing 488, 618–633 (2022).

Mishra, R. K., Choudhary, A., Fatima, S., et al. A fault diagnosis approach based on 2D-vibration imaging for bearing faults. J. Vib. Eng. Technol. 2022: 1–14.

Hu, J., Shen, L., Sun, G. Squeeze-and-excitation networks. In 2018 IEEE/ CVF Conference on Computer Vision and Pattern Recognition, 2018: 7132–7141.

Hu, X. Q., Ma, C. B., and He, L., Modeling and fault simulation of the landing gear extension and retraction system. Comput. Eng. Sci. 2016, 38(06):1286–1293.

Guo, X. J., Chen, L. & Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 93, 490–502 (2016).

Gan, M. et al. Construction of hierarchical diagnosis network based on deep learning and its application in the fault pattern recognition of rolling element bearings. Mech. Syst. Signal Process. 72–73, 92–104 (2016).

Huang, N., Fang, L., Cai, G., et al. Mechanical fault diagnosis of high voltage circuit breakers with unknown fault type using hybrid classifier based on LMD and time segmentation energy entropy. Entropy, 2016; 18(9), 10. 3390/ e18090322.

Author information

Authors and Affiliations

Contributions

Methodology, S.K.; software, S.K.; validation, S.K.; writing—original draft preparation, S.K.; writ-ing—review and editing, S.K. and Z.D.; supervision, Z.D.; All authors have read andagreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shen, K., Zhao, D. Fault analysis and fault degree evaluation via an improved ResNet method for aircraft hydraulic system. Sci Rep 15, 4132 (2025). https://doi.org/10.1038/s41598-025-86634-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-86634-3