Abstract

This study explores the impact of tractor drawbar height (520, 530 and 540 mm from the ground) on key performance indicators, including pulling force, fuel consumption, pulling power and overall tractor efficiency. Present experiments were conducted on a special pulling power test track under controlled conditions at the Directorate of Agricultural Equipment and Machinery Test Centre of the Ministry of Agriculture and Forestry. Data were collected at different tractor forward speeds and performance parameters were modeled and optimized using Response Surface Methodology (RSM), a statistical approach widely used for multi-factor optimization. Present findings revealed that a drawbar height of 520 mm yielded the highest pulling force (47.4 kN) at a speed of 5.48 km h−1, while the same height combined with a speed of 8.33 km h−1 produced the maximum pulling power (78.75 kW) and the lowest specific fuel consumption (267.03 g kWh−1). Statistical analysis confirmed that both drawbar height and tractor speed had significant effects on pulling force and fuel consumption (P < 0.05). However, for overall tractor efficiency, only tractor speed showed a significance. The developed RSM models demonstrated high predictive accuracy, with an R² value of 0.98 for pulling force and error metrics such as RMSE of 0.42% for efficiency, highlighting the reliability of the approach. The study concludes that optimizing the drawbar height and tractor speed not only improves pulling performance but also enhances fuel efficiency, offering a practical framework for achieving sustainable agricultural practices. Present findings emphasize the critical role of drawbar height adjustments in minimizing energy losses and maximizing operational efficiency during field operations.

Similar content being viewed by others

Introduction

Agricultural tractors are indispensable for modern farming, where tractive force is a critical performance indicator. Tractive force directly influences operational efficiency by ensuring effective power transfer between the tractor’s wheels and the ground. However, imbalances in this interaction can cause power losses due to rolling resistance and slippage, leading to increased fuel consumption and reduced overall tractor performance1,2,3.

Tractor efficiency plays a central role in determining agricultural productivity and resource utilization. Among the factors influencing efficiency, drawbar height is particularly critical due to its impact on traction, stability, and fuel efficiency. While lower drawbar heights improve stability by minimizing weight transfer to the rear axle, higher drawbar heights enhance traction but may increase the risk of rearward overturns on uneven terrain4. Previous studies have demonstrated the significant influence of hitch height and axle loads on tractor performance. WANG, et al.5 showed that these parameters affect drawbar pull, tractive efficiency, and motion resistance. Moinfar and Shahgholi6 emphasized the role of soil and operational parameters in modeling traction efficiency. Küçüksarıyıldız, et al.7 applied computational tools like artificial neural networks (ANN) to optimize fuel consumption based on drawbar force and axle loads. Tapang and Pal4 proposed a dynamic hitch system and achieved significant fuel savings and improved transport productivity. Additionally, Canli, et al.8 linked tractor geometry to fuel consumption and carbon emissions during high-speed transport. While these studies have advanced understanding, most focus on isolated conditions. Kovács and Szegedi9 stated in their study that the front axle suspension system changes the shock parameters of the tractor and this affects the traction parameters. The researchers aimed to find out how the traction parameters (drawbar force, speed, traction performance, wheel slippage) change due to the active front axle suspension. It was stated that the traction force exhibited a more stable behavior in tractors with front suspension systems and this had a positive effect on traction performance. This study addresses these gaps by using Response Surface Methodology (RSM) to analyze the combined effects of drawbar height and tractor speed on key performance indicators such as pulling force, fuel consumption, and overall efficiency. The study aims to provide a comprehensive framework for optimizing tractor operations under varying conditions.

Over the years, the net tractive force of driving wheels has garnered significant attention from researchers. Early studies by Forrest, et al.10 laid the groundwork for understanding tractive characteristics, and since then, numerous investigations have explored various factors influencing tractor pulling performance. Research indicates that parameters such as wheel slip, wheel size, dynamic weight, tire inflation pressure, tire type and surface conditions all have a direct impact on tractive effort11,12.

Recent advancements in agricultural engineering have introduced intelligent simulation systems and optimization techniques to enhance tractor performance. Among these, self-learning algorithms and Response Surface Methodology (RSM) stand out as effective tools for modeling and optimizing the interaction of multiple input and output parameters. Studies have successfully applied RSM to analyze experimental data related to various aspects of tractor performance. For instance, Bietresato, et al.13 employed RSM to evaluate the mechanical and environmental performance of an internal combustion engine (ICE) powering a farm tractor with different fuel blends. Similarly, Okoko and Akpankpuk14 and Okoko and Ajav15 applied RSM to model tillage operational parameters and to investigate the effects of tractor speed on tillage operations, respectively. Askari, et al.16 explored the estimation and optimization of the overall energy efficiency (OEE) of a tractor-tool system using RSM. Furthermore, Askari, et al.17 assessed the effectiveness of the RSM approach in predicting the traction performance of an agricultural tractor during semi-deep tillage operations. The main function of agricultural tractors is to develop traction power, therefore, important studies have been carried out in recent years to increase traction performance. High traction capacity is an important performance criterion in tractors operating under difficult conditions. In this sense, real-time tire pressure adjustment systems have been developed to reduce skidding and transfer the drive force to the ground better. Another important innovation encountered in tractor technologies in recent years is the front axle suspension systems. Front axle suspension systems are systems that can be adjusted automatically or manually according to tractor models and are generally designed as hydro-pneumatic. While these systems increase the performance of the front axle drive system, they also play an important role in damping the vibrations that come to the cabin due to road and field conditions. There are changes in the height of the rear drawbar in the rising and falling positions of the front axle suspension system, which affect the traction performance. The front suspension system of the experimental tractor used in this study can be adjusted manually. The study was planned according to 3 different positions of the suspension system. Three different drawbar heights were observed in three different suspension system settings.

Drawbar height is a critical parameter that directly influences the performance of agricultural tractors. The pulling force in tractors is generated by the interaction between the wheels and the ground. Efficient transfer of this force enhances the wheels’ traction ability, thereby minimizing the tractor’s energy loss. However, as the drawbar height changes, the distribution of this force across wheels also shifts, significantly affecting fuel consumption, pulling power and overall efficiency. Although many aspects of tractor performance have been examined in detail in previous studies, there is limited experimental data and systematic analysis specifically focused on drawbar height from the ground. Most research has concentrated on parameters such as wheel size, tire pressure, or dynamic weight, with fewer studies addressing the direct impact of drawbar height on tractor efficiency and fuel consumption. This study aims to bridge this gap in literature by analyzing the tangible effects of drawbar height variations on performance. Specifically, the determination of the optimal drawbar height using Response Surface Methodology (RSM) contributes significantly to filling this gap in the research.

The main objective of this study is to analyze the effects of different drawbar heights on tractor performance and to optimize these effects. Specifically, the study aims to provide clear answers to the following questions by the conclusion:

The study will thoroughly demonstrate how various performance parameters of the tractor, such as tractive effort, fuel consumption, wheel slip and overall efficiency are affected by changes in drawbar height.

It seeks to identify the optimal drawbar height that maximizes pulling force while minimizing fuel consumption in Case I, and minimizes pulling force while maximizing overall tractor efficiency in Case II. This information will serve as a valuable practical guide for enhancing tractor performance during agricultural operations.

The interaction between tractor speed and drawbar height will be examined to understand how these parameters collectively impact tractor performance. The optimization model obtained with the study can be used to adjust the system in real time with a controller to be developed later and to increase traction performance with automatic positioning under different operating conditions.

Materials and methods

Experimental setup

This research was conducted on the pulling power test track at the Directorate of Agricultural Equipment and Machinery Test Centre of the Ministry of Agriculture and Forestry. A tractor and a pulling test vehicle were used as the primary materials (Fig. 1a). The technical specifications of the tractor are presented in Table 1. The pulling power test track consists of a reinforced concrete structure, measuring 344 m in length and 4 m in width (Fig. 1b). The pulling test vehicle was utilized to perform the pulling performance tests in accordance with the OECD Standard Code 2 (Fig. 1a).

An air-cooled Eddy Current dynamometer was used for braking during the road test. The dynamometer has a maximum power capacity of 150 kW, a maximum torque capacity of 500 Nm and a standard operating speed of 8000 rpm (Fig. 1a). A Tuzeks PLU 401/108 measuring device was employed for fuel consumption measurement (Fig. 1c). The measuring capacity of this device is 60 l h−1 and the maximum pressure capacity is 10 bar. The equipment of the front pulling group in the pulling vehicle is shown in Fig. 2.

The front pulling system, the assembly to which the loadcell is connected and the test and driving positions are adjusted. (1. Height adjustment bolt, 2. T2 Connection, 3. T19 Connection, 4. Drawbar Lock Pin, 5. Load Cell Housing, 6. Drawbar, 7. Load Cell Stabilizer Shaft, 8. Worm Screw, 9. Fuel line connection Quick Coupling).

The speed sensor was connected to the test vehicle and adjustments were made using the adjustment bolts on the plates located at this point. The position was set by loosening two nuts on the plate, adjusting the sensor’s position and then securing it by tightening the nuts again. The sensor was positioned 300 mm above the ground (Fig. 1d). This device has speed range of 0.138–127 ms-1, distance resolution of 1.9 mm, measurement deviation of < ± 0.1%, working range of the sensor was 300 ± 60 mm.

Experimental procedure

The test conditions, measurements and calculations for the tractor used in this study were performed in accordance with OECD Standard Code 2.

The overall efficiency of the tractor was calculated using the following relationship, based on pulling power and fuel power18,19.

Where: η = Total tractor efficiency (%), Pd = Drawbar power (kW), Pf = Fuel power (kW), Be = Fuel consumption (kg h−1), H = Energy value of diesel fuel (41870 kJ kg−1).

The dynamometer in the experimental vehicle applies a braking force to stop the moving tractor. The force gauge in the front pulling system transmits the pulling force data to the computer via a load cell (Fig. 1e). Similarly, the tractor’s PTO speed is determined from the PTO ratio of the engine and the engine speed is calculated using the same ratio. The speed sensor measures the test vehicle’s speed and calculates the tractor’s theoretical speed from the engine-to-wheel ratio. The fuel delivered from the fuel tank to the tractor is measured using a fuel metering device equipped with a flow meter. All this data, including temperature readings from the temperature probe, is transferred to the Motest software display. The data can also be saved in Excel, if desired.

A tractor with a manually adjustable front axle suspension system was used in present experiments. The front suspension system was adjusted to 3 different positions and the drawbar heights, which changed depending on the suspension system, were measured. As a result, the drawbar height was determined as 520, 530 and 540 mm in 3 different positions of the suspension system. The experiments were conducted on a concrete floor with the tractor operating at four different gear settings under a fixed skid value of 15%. Tyre pressures were standardized at 160 kPa. The drawbar height was adjusted to three levels (540, 530 and 520 mm) and at each height, pulling force, tractor speed and fuel consumption were measured at a constant engine-to-skid ratio. Based on these measurements, key performance parameters, including pulling power, skidding rate, specific fuel consumption and tractor efficiency were calculated. Additionally, ground clearance and tractor velocity parameters were modeled and optimized using Response Surface Methodology (RSM). The study was conducted on two different optimization models. The first optimization scenario was determined by evaluating the working conditions where the traction requirement was high and taking the conditions where fuel consumption was minimum, and traction force was maximum (while working with plough) as reference. The second optimization scenario was determined by assuming that the tractors were used for transportation for a large part of their service life and taking the working conditions where the tractor efficiency was the highest and the traction force was minimum as reference. It has been emphasized in the literature that the tractor loadings in road conditions are 40% on average. Two optimization scenarios were considered: Case I - minimum fuel consumption and maximum pulling force; and Case II – minimum pulling force and maximum tractor efficiency.

Data analysis

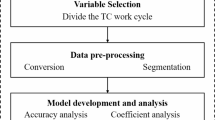

Response surface methodology (RSM)

RSM (Response Surface Methodology) has gained an important place in different engineering disciplines in recent years. It is widely used as a computer-based application in modelling and diversification of different processes20. The main purpose of this method is to determine and optimize the effects of various input factors on the response parameters. In this sense, RSM optimizes responses according to input factors by evaluating the relationship between input and output parameters. In particular, using the least squares technique, RSM evaluates the influential factors and optimizes the communication between variables so that the results achieve the desired responses21,22.

In this research, the main objective of the optimization is to determine the best tractor engine outcomes at tractor feed rate and drawbar ground clearance by maximizing pulling force and minimizing fuel consumption. The first step in RSM is to determine a suitable relationship between input and output parameters. In this study, Response Surface Methodology (RSM) was used to analyze the effects of drawbar height above ground (DHAG) and forward speed (S) on tractor performance. The quadratic model of RSM represents the relationship between dependent and independent variables as follows20:

where: y: The dependent variable (e.g., pulling force, fuel consumption or total overall efficiency), x1: Drawbar height above ground (DHAG), x2: Forward speed (S), β0: The intercept term, β1, β2: Coefficients for the linear effects, β12: Coefficient for the interaction term, β11,β22: Coefficients for the quadratic terms, ε: The residual error term.

The model was developed using experimental data and evaluated through an Analysis of Variance (ANOVA). The predictive capability of the model was confirmed by high R2 values, indicating its effectiveness in explaining variations in the dependent variables. Significance of the coefficients was assessed, with only those having P < 0.05 retained in the final model. Additionally, the model’s adequacy was validated through the lack-of-fit test and further supported by its R2 performance. An analysis of variance (ANOVA) was conducted to determine the significance of the relationships between input factors and responses. A higher F-value and a lower P-value indicate that the corresponding term has greater significance in the proposed model. Consequently, a P-value of less than 0.05 is considered as significant23. In this study, Central Composite Design (CCD) was applied to have relatively accurate results.

The effects of speed (independent variable) and DHAG (independent variable) on pulling force, fuel consumption and overall tractor efficiency (dependent variables) were evaluated using ANOVA. Interaction effects between speed and DHAG were also analyzed. The significance of each source of variation was determined using F-tests and P-values < 0.05 were considered as significant.

Model metrics

The predictive capability of the models was assessed using three key metrics: R2, Root Mean Square Error (RMSE) and Mean Absolute Percentage Error (MAPE). These metrics were computed using Eqs. (4), (5) and (6), respectively. The R2 value, representing the proportion of variance in the dependent variable explained by the independent variables, was used as an indicator of model performance, with higher values signifying stronger predictive accuracy. On the other hand, RMSE and MAPE were utilized to evaluate the magnitude of prediction errors, where smaller values reflect improved model reliability and precision24,25,26,27.

where; n is the number of experimental data points, opi is the predicted output value, oei is the experimental output value and om is the mean experimental output value.

Optimization process

In this optimization process, Response Surface Methodology (RSM) generates a three-dimensional surface to evaluate the interactions between factors and to derive optimal values based on the desired outcomes. The primary objective is to obtain the best possible outcomes by maximizing or minimizing specific factors within defined limits. RSM is a mathematical and statistical optimization technique that models input parameters and their effects on output parameters simultaneously22.

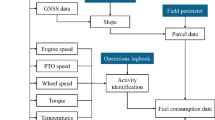

Two different optimization scenarios were conducted in this study. Case I aimed to optimize drawbar height and forward speed for maximum pulling force and minimum fuel consumption. Case II focused on optimizing drawbar height and forward speed for maximum overall tractor efficiency and minimum pulling force. These optimization scenarios were applied to evaluate whether adjustments in drawbar height and speed, based on the operator’s preferences, could be practically implemented. The general flow chart of the study is given in Fig. 3.

Results and discussions

Table 2 provides critical data regarding tractor performance at three drawbar heights (520 mm, 530 mm, and 540 mm) across various operational parameters, including drawbar power, drawbar force, engine-to-wheel ratio, speed, slippage, fuel consumption, specific fuel consumption, and overall efficiency. These metrics are examined under four gear settings (2-F-2, 2-F-3, 2-F-4, and 2-F-5) for each drawbar height, offering a comprehensive understanding of the interactions between drawbar height and operational parameters.

The highest drawbar power (78.75 kW) was recorded at a drawbar height of 520 mm under gear 2-F-5, corresponding to a speed of 8.33 km h−1 . However, drawbar force decreased with increasing speed, from 47.4 kN at 5.48 km h−1 /s to 34.73 kN at 8.33 km h−1 . A similar trend is observed at 530 mm and 540 mm, indicating a trade-off between drawbar power and force as speed increases. This aligns with the findings of Simikić et al. (2014), where increased speed reduces pulling force due to reduced traction28.

Engine speed remained relatively stable across drawbar heights but showed slight variations across gears. Slippage decreased significantly with higher speeds, falling from 15% at lower gears to as low as 3.3% under 2-F-5 at 540 mm drawbar height. Lower slippage at higher speeds contributes to better fuel efficiency and reduced tire wear, supporting the practical advantages of optimizing operational speeds29.

Specific fuel consumption (g/kWh) was lowest at 520 mm drawbar height and a speed of 8.33 km h−1 (267.03 g kWh−1), reflecting the optimal balance of power output and fuel input under these conditions. This indicates that the 520 mm height offers the best fuel efficiency at higher speeds.

Increased drawbar height resulted in higher specific fuel consumption values, with the highest being 322.33 g kWh−1 at 540 mm and 2-F-2. This trend suggests that lower drawbar heights minimize energy loss and improve energy transfer efficiency4. The highest overall efficiency (33.4%) was achieved at a drawbar height of 530 mm and a speed of 8.33 km h−1 under 2-F-5. This combination represents an optimal point for minimizing energy loss while maximizing traction and operational performance.

The data demonstrate that tractor performance is sensitive to both drawbar height and forward speed. Lower drawbar heights improve pulling force but can increase fuel consumption at lower speeds. Conversely, higher drawbar heights reduce pulling force but improve efficiency at higher speeds. Optimal performance for pulling force and fuel efficiency can be achieved at 520 mm drawbar height under higher speed settings (e.g., 8.33 km h−1 ). However, if overall efficiency is prioritized, 530 mm is preferable.

The highest drawbar force (47.4 kN) was recorded at a forward speed of 5.48 km h−1 and a drawbar height of 520 mm from the ground. The maximum drawbar power (78.75 kW) and the lowest specific fuel consumption (267.03 g kWh−1) were achieved at the same height (520 mm), with a forward speed of 8.33 km h−1 (Table 2). The highest overall tractor efficiency (33.4%) was observed at a drawbar height of 530 mm from the ground and a speed of 8.33 km h−1. An increase in the drawbar force also led to an increase in the percentage of tractor slippage. Studies by Shafaei, et al.29, Polcar, et al.30 reported a linear relationship between drawbar force and slippage.

Table 3 presents the design table containing the experimental data. In the established RSM model, drawbar height from the ground and forward speed were selected as the input parameters, while drawbar force, fuel consumption and overall tractor efficiency were chosen as the output parameters.

The linear effects of both DHAG and speed were statistically significant, with P-values < 0.05 (0.003 for DHAG and < 0.001 for speed). The high F-values (24.42 for DHAG and 281.85 for speed) further confirm the strong influence of these parameters on pulling force (Table 4).

Speed had the largest impact on pulling force, as evidenced by the substantially higher F-value compared to DHAG. This suggests that tractor speed plays a dominant role in determining the pulling force.

The quadratic terms for DHAG (P = 0.66) and speed (P = 0.427) were not significant, indicating that the relationship between pulling force and these variables is primarily linear within the tested range. Similarly, the interaction term (DHAG × speed) was not significant (P = 0.742), suggesting that the combined effect of DHAG and speed on pulling force does not deviate significantly from their independent contributions. The model explained 98.16% of the total variance in pulling force, as indicated by the total adjusted sum of squares (Adj SS) of the model relative to the total SS (326.657 vs. 332.798). This highlights the robustness of the model in capturing the primary factors affecting pulling force.

In the ANOVA for fuel consumption, the P-values for the linear coefficients of both drawbar height from the ground and tractor forward speed were found to be less than 0.05 (Table 5), indicating that these two input factors significantly affected fuel consumption. In contrast, the P-values for the quadratic coefficients of both parameters were greater than 0.05. Regarding overall tractor efficiency, the P-value for speed was less than 0.05, whereas the P-value for drawbar height was greater than 0.05 (Table 6). This suggests that tractor speed had a significant impact on overall efficiency. As speed increased, overall tractor efficiency and pulling power also increased. This indicates that tractor speed plays a key role in overall tractor efficiency, while the effect of drawbar height is less significant. Increased speed leads to greater pulling power and consequently, higher overall tractor efficiency.

The second-order equations for drawbar force, fuel consumption and overall tractor efficiency derived by the RSM model are shown in Eqs. (3), (4) and (5), respectively:

where, DHAG: Drawbar height above ground (mm), S: Speed (km h−1), ƞ: Total tractor efficiency (%).

The R² value for the drawbar force model was calculated to be 0.98, demonstrating a very high level of accuracy. The RMSE and MAPE values for this model were 1.57 kN and 3.57%, respectively. For the fuel consumption model, R² was 0.94, with RMSE and MAPE values of 1.24 kN and 5.08%, respectively (Table 7). The R² value for the overall tractor efficiency model was 0.95, with RMSE and MAPE values of 0.42 kN and 1.11%. The RSM model showed the best performance in terms of R² for drawbar force and in terms of error metrics for overall tractor efficiency.

Figure 4a shows the combined effect of drawbar height from the ground and tractor forward speed on pulling force. The figure indicates that as drawbar height decreases and forward speed increases, pulling force also increases. Simikić, et al.28 reported that reducing tractor speed from 2.1 km h−1 to 1.4 km h−1 led to a 58.7% increase in pulling force. Similarly, Abrahám, et al.31 found that lowering tractor speed resulted in an increase in pulling force. Therefore, decreasing the drawbar height enhances the tractor’s pulling force.

The combined effect of drawbar height and forward speed on fuel consumption is shown in Fig. 4b. At higher drawbar heights (530–540 mm), fuel consumption decreases as forward speed decreases. Increased drawbar height leads to reduced fuel consumption. Figure 4c illustrates the effect of forward speed on overall tractor efficiency. As forward speed increases, overall tractor efficiency also improves. However, the impact of drawbar height variations on total tractor efficiency is less evident. In such cases, optimizing both drawbar height and forward speed is necessary to achieve maximum tractor efficiency.

The optimized parameters from Case I are displayed in Fig. 5, while those from Case II are shown in Fig. 6. In each plot, the two vertical red lines indicate the optimal drawbar height and tractor speed for the respective output parameters.

For Case I, the optimal working parameters were determined as a drawbar height of 538.1 mm and a forward speed of 4.95 km h−1. Under these conditions, the best results were a fuel consumption of 23.45 Lh−1 and a pulling force of 45 kN. In Case II, the optimal parameters were a drawbar height of 529.3 mm and a forward speed of 8.39 km h−1, resulting in an overall tractor efficiency of 32.7% and a pulling force of 32.28 kN.

The combined desirability (D) value reflects how well the input factors were optimized to achieve the overall objectives. In optimization, a combined desirability value close to 1 indicates strong optimization performance32. In this study, the combined desirability was 0.9272 for the first scenario and 0.8735 for the second scenario, both of which are very close to 1. These results suggest that the RSM models can be effectively utilized to determine the optimal drawbar height and forward speed for achieving the best fuel consumption and pulling force parameters.

Conclusions

This study investigated the effects of drawbar height from the ground and tractor speed on pulling force, fuel consumption and overall tractor efficiency. Using Response Surface Methodology (RSM), these parameters were modeled and optimized. The key findings are summarized as follows:

ANOVA Results: According to the ANOVA results for pulling force and fuel consumption, both drawbar height and tractor forward speed had significant effects. However, for overall tractor efficiency, only tractor speed was found to have a significant impact.

RSM Model Performance: In terms of R² values, the best performance was achieved by the pulling force model, with an R² value of 0.98. Regarding error metrics, the best performance was shown by the model for overall tractor efficiency.

Effect of Drawbar Height and Speed: Lower drawbar heights resulted in higher pulling force and increased fuel consumption. Conversely, higher speeds improved overall tractor efficiency, though they also led to greater fuel consumption.

Optimization via RSM: The application of RSM enabled effective modeling and prediction of the optimal drawbar height and tractor speed settings. This approach successfully balanced fuel efficiency and pulling force.

The use of RSM and similar optimization techniques allows for the fine-tuning of operational parameters, facilitating better decision-making and enhancing performance outcomes. By continuously monitoring tractor performance metrics and making real-time adjustments, sustainable efficiency can be achieved. Training farmers and operators on the importance of adjusting drawbar height and speed is essential for promoting better management practices and improving agricultural productivity. Implementing these strategies will optimize tractor performance, resulting in more efficient and cost-effective agricultural operations.

In Case I, where the primary objective was to maximize pulling force while minimizing fuel consumption, the results indicate that a drawbar height of 538 mm at a speed of 4.95 km h−1 offers the best balance. This suggests that operators can achieve higher pulling power while conserving fuel, leading to more efficient operations and cost savings. In Case II, aimed at minimizing pulling force and maximizing overall tractor efficiency, a drawbar height of 530 mm at higher speeds was found to be optimal. This configuration reduces slippage and increases efficiency, which is particularly beneficial for minimizing wear on tires and machinery, ultimately extending the lifespan of the equipment.

However, it is important to acknowledge that the study was conducted under controlled conditions on a concrete floor. The results may vary depending on soil types (e.g., sandy, loamy, clay) and climate conditions (e.g., wet or dry soil), which significantly affect traction, skidding and fuel consumption. Future studies integrating these variables into experimental setups could further validate and refine these findings, ensuring their broader applicability to real-world agricultural scenarios. Present findings offer practical solutions to improve fuel efficiency and tractor performance, which directly contribute to agricultural sustainability by reducing carbon emissions and energy consumption. Moreover, these improvements present long-term economic benefits to farmers by lowering fuel and labor costs, ensuring more efficient and sustainable farming operations.

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

Farhadi, P., Golmohammadi, A., Malvajerdi, A. S. & Shahgholi, G. Tire and soil effects on power loss: measurement and comparison with finite element model results. J. Terrramech. 92, 13–22 (2020).

Shafaei, S., Loghavi, M. & Kamgar, S. On the reliability of intelligent fuzzy system for multivariate pattern scrutinization of power consumption efficiency of mechanical front wheel drive tractor. J. Biosystems Eng. 46, 1–15 (2021).

Shafaei, S., Loghavi, M. & Kamgar, S. Analytical description of power delivery efficiency of front wheel assist tractor in tillage works. J. Biosystems Eng. 46, 236–253 (2021).

Tapang, T. & Pal, A. Importance of automatic variable single hitch point for 2WD tractors a theoretical analysis. Eng. Agric. Environ. food. 8, 298–306 (2015).

Wang, G., Kushwaha, R. & Zoerb, G. Traction performance of a model 4VVD tractor. (1989).

Moinfar, A. M. & Shahgholi, G. Dimensional analysis of the tractor tractive efficiency parameters. Acta Technologica Agriculturae. 21, 94–99 (2018).

Küçüksarıyıldız, H., Çarman, K. & Sabancı, K. Prediction of specific fuel consumption of 60 HP 2WD tractor using artificial neural networks. Int. J. Automot. Sci. Technol. 5, 436–444 (2021).

Canli, E., Kucuksariyildiz, H. & Carman, K. Impact assessment of new generation high-speed agricultural tractor aerodynamics on transportation fuel consumption and related phenomena. Environ. Sci. Pollut. Res. 30, 6658–6680 (2023).

Kovács, Z. & Szegedi, A. Effect of front axle suspension on traction parameters of tractor with mechanical front wheel drive. Sci. Bull. Ser. C: Fascicle Mech. Tribology Mach. Manuf. Technol. 29, 57 (2015).

Forrest, P., Reed, I. F. & Constantakis, G. Tractive characteristics of radial-ply tires. (1962).

Wismer, R. & Luth, H. Off-road traction prediction for wheeled vehicles. J. Terrramech. 10, 49–61 (1973).

Wismer, R. & Luth, H. Off-road traction prediction for wheeled vehicles. Trans. ASAE. 17, 8–0010 (1974).

Bietresato, M., Caligiuri, C., Bolla, A., Renzi, M. & Mazzetto, F. Proposal of a predictive mixed experimental-numerical approach for assessing the performance of farm tractor engines fuelled with diesel-biodiesel-bioethanol blends. Energies 12, 2287 (2019).

Okoko, P. & Akpankpuk, S. N. Effects of tillage depth and tractor speed on implement speed for three tillage implements on a clay loam soil. Asian J. Adv. Agricultural Res. 22, 1–7 (2023).

Okoko, P. & Ajav, E. A. Modeling of tillage operation parameters for draft and power requirement for three tillage implements in a loamy soil. Agricultural Eng. 4, 10–29 (2021).

Askari, M. et al. Applying the response surface methodology (RSM) approach to predict the tractive performance of an agricultural tractor during semi-deep tillage. Agriculture 11, 1043 (2021).

Askari, M., Abbaspour-Gilandeh, Y., Taghinezhad, E., Hegazy, R. & Okasha, M. Prediction and optimizing the multiple responses of the overall energy efficiency (OEE) of a tractor-implement system using response surface methodology. J. Terrramech. 103, 11–17 (2022).

Özbayer, M. M. & Güner, M. Comparison of performance characteristics of agricultural tractors. J. Agricultural Fac. Gaziosmanpaşa Univ. (JAFAG). 39, 6–18 (2022).

De Souza, E., Lima, J. & Milanez, L. Overall efficiency of tractor operating in the field. Appl. Eng. Agric. 10, 771–775 (1994).

Uslu, S. & Celik, M. B. Performance and exhaust emission prediction of a SI engine fueled with I-amyl alcohol-gasoline blends: an ANN coupled RSM based optimization. Fuel 265, 116922 (2020).

Inayat, M., Sulaiman, S. A. & Kurnia, J. C. Catalytic co-gasification of coconut shells and oil palm fronds blends in the presence of cement, dolomite, and limestone: Parametric optimization via Box Behnken Design. J. Energy Inst. 92, 871–882 (2019).

Kumar, S. & Dinesha, P. Optimization of engine parameters in a bio diesel engine run with honge methyl ester using response surface methodology. Measurement 125, 224–231 (2018).

Dana, M., Sobati, M. A., Shahhosseini, S. & Ansari, A. Optimization of a continuous ultrasound assisted oxidative desulfurization (UAOD) process of diesel using response surface methodology (RSM) considering operating cost. Chin. J. Chem. Eng. 28, 1384–1396 (2020).

Gültepe, Y. A comparative assessment on air pollution estimation by machine learning algorithms. Eur. J. Sci. Technol. 8–15. https://doi.org/10.31590/ejosat.530347 (2019).

Wang, W. & Xu, Z. A heuristic training for support vector regression. Neurocomputing 61, 259–275. https://doi.org/10.1016/j.neucom.2003.11.012 (2004).

Silitonga, A. S., Hassan, M. H., Ong, H. C. & Kusumo, F. Analysis of the performance, emission and combustion characteristics of a turbocharged diesel engine fuelled with Jatropha curcas biodiesel-diesel blends using kernel-based extreme learning machine. Environ. Sci. Pollut. Res. 24, 25383–25405 (2017).

Shahhosseini, M., Martinez-Feria, R. A., Hu, G. & Archontoulis, S. V. Maize yield and nitrate loss prediction with machine learning algorithms. Environ. Res. Lett. 14, 124026. https://doi.org/10.1088/1748-9326/ab5268 (2019).

Simikić, M., Dedović, N., Savin, L., Tomić, M. & Ponjičan, O. Power delivery efficiency of a wheeled tractor at oblique drawbar force. Soil Tillage. Res. 141, 32–43 (2014).

Shafaei, S., Loghavi, M. & Kamgar, S. An experimental investigation of drawbar pull performance of front wheel assist tractors. Trans. Indian Natl. Acad. Eng. 7, 1369–1380 (2022).

Polcar, A., Renčín, L. & Votava, J. Drawbar pull and its effect on the weight distribution of a tractor. Acta Universitatis Agriculturae et Silviculturae Mendelianae Brunensis (2017).

Abrahám, R. et al. Frequency spectra analysis of drawbar pulls generated by special driving wheels improving tractive performance. Sensors 21, 2903 (2021).

Aydın, M., Uslu, S. & Çelik, M. B. Performance and emission prediction of a compression ignition engine fueled with biodiesel-diesel blends: a combined application of ANN and RSM based optimization. Fuel 269, 117472 (2020).

Acknowledgements

The authors would like to thank the Republic of Turkey Ministry of Agriculture and Forestry Directorate of Testing Centre for Agricultural Equipment and Machine (TAMTES) for providing important support in carrying out the study.

Author information

Authors and Affiliations

Contributions

Conceptualized the approach and formulated ideas, A.Y.Ş., N.O and M.Ö.; Designed methods and developed models A.Y.Ş., N.O and M.Ö; Performed formal analyses and curated data, A.Y.Ş. and N.O.; all authors contributed equally to the writing and revisions of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Şeflek, A.Y., Orhan, N. & Özkan, M. The impact of tractor drawbar height on performance and optimization using response surface methodology. Sci Rep 15, 5370 (2025). https://doi.org/10.1038/s41598-025-88821-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-88821-8