Abstract

This study investigates free convective within an octagonal cavity, which is partitioned into two compartments by a flexible separator. One of the left walls is maintained at a high temperature, while a lower temperature is applied to one of the right walls. The position of these active walls is adjustable, and the separator can be oriented vertically or inclined with either a positive or negative slope. The deformation of the flexible separator is modeled using the Arbitrary Lagrangian–Eulerian method. The outcomes indicate that locating the hotter wall near the top and moving the colder wall downwards hinders free convection and reduces the stress in the separator. Moreover, upward movement of both active walls leads to a decrease in the average temperature. An inclined separator with a positive slope enhances the heat transfer rate and experiences the lowest stress levels compared to vertical and negatively sloped separators. Raising Rayleigh number enhances the flow intensity and the stress in the flexible separator. Furthermore, it is found that a decrease in the elasticity modules of the separator from 1014 to 5 × 1011 results in a 5% increase in the average Nusselt number.

Similar content being viewed by others

Introduction

Natural convection is important to everyday and engineering tasks, including heat dissipation away from a source, water circulation in a pot, and natural cooling of electronic devices. Its comprehension is essential in defining effective cooling systems, anticipating energy, and heat distribution usage. The case of natural convection in differentially heated cavities has been reported to be the benchmark problem in a great number of investigations1,2,3,4. In practical applications, the arrangement usually differs quite a lot from the geometrically elementary cavity model. For instance, some electronic units may be encased in metallic covers for ensuring sufficient thermal protection, or chemical reactors are split into chambers occupied by various species, in which thermal contact still exists. Similarly, in solar heat collectors, glazing creates air layers that influence heat transfer. Such practical designs of dividers in the interior of enclosures have aroused some interest in the study of their impact on convective heat transfer5,6,7.

Tatsuo et al.8 examined the impact of a partition on the thermal and hydrodynamic behavior of free convection within a rectangular enclosure, where the sidewalls exhibit varying temperatures. In a numerical investigation by Kahveci9, the focus was on examining laminar free convection within a partitioned chamber featuring a partition of limited thermal conductivity and thickness. The findings showed that the average Nusselt number reduced as the gap between the heated wall and the partition widened. Intriguingly, a significant increase in the average Nusselt number was observed as the thermal resistance of the partition reduced, ultimately culminating in the identification of a distinct peak point. Both experimental and numerical approaches were employed to investigate laminar-free convection within rectangular cavities that were partitioned by multiple vertical barriers10. In the context of the boundary layer regime, a distinct linear progression of partition temperature along the vertical axis was established. The derived solution revealed an inverse proportionality between the Nusselt number and the quantity (\(1+\text{N}\)), where \(\text{N}\) denotes the count of partitions. This intriguing correlation was subsequently validated through experimental observations.

In a numerical investigation, Ciofalo and Karayiannis11 examined the effectiveness of partitions extending from the vertical or horizontal boundaries to enhance heat exchange within a rectangular cavity. Their findings underscored the significant influence of the partition, which was found to be intricately linked to both the Rayleigh number and the aspect ratio of the cavity. Khatamifar et al.12 performed a computational analysis, delving into the intricacies of conjugate free convection flow and heat transfer. Their focus was set on a square enclosure subjected to differential heating, where a partition with both finite thickness and thermal conductivity played a pivotal role in dividing the cavity. Rabhi et al.13 explored the influence of the number of partitions and surface radiation on heat transfer and flow configuration within a tilted rectangular enclosure. The enclosure was tilted at an angle of \(\upgamma =45^\circ\) with respect to the horizontal plane. In this enclosure, two vertical walls had an aspect ratio of 4 and were maintained at uniform temperatures, albeit with differences, while the remaining walls were thermally insulated.

Fluid–structure interaction (FSI) is a ubiquitous phenomenon wherein pliable structures engage in interactions either with the encompassing fluid or internal flows. These occurrences also hold significant importance in various engineering contexts. Recently, several investigations have delved into examining FSI in conjunction with natural convection within diverse enclosure geometries14,15,16,17,18,19. Yaseen et al.14 explored the use of deformable walls as a potential solution to mitigate flow disturbances and improve heat transfer. In their work, the influence of varying wall properties such as thickness, length, and elasticity, on the circulation patterns within the cavity were studied. Moreover, the results demonstrated that varying the aspect ratios of the cavity provides valuable insights into how geometry influences flow behavior and thermal performance.

In various applications, a remarkably slender and flexible barrier is employed to segregate two distinct fluids or containment gases. In the context of building insulation, the practice involves introducing a polyethylene layer into wall cavities, effectively countering heat loss. In situations where an exceedingly thin divider is utilized, it exhibits complete flexibility, allowing it to experience deflection due to its interaction with the free convection flow. The enclosures, featuring a flexible separator, have diverse applications across multiple fields. In thermal management and energy efficiency, it can optimize building climate control and electronic cooling by dynamically adjusting heat distribution. For fluid dynamics and heat transfer studies, it serves as an ideal setup to investigate natural convection, thermal stratification, and fluid flow patterns. Industrial applications include designing advanced heat exchangers and maintaining precise temperature control in chemical reactors. The system also finds use in environmental and geophysical modeling, such as simulating atmospheric or oceanic convection and studying geothermal systems. In material science, it aids in testing the thermal properties of insulation or conductive materials. Additionally, it serves as an educational tool for demonstrating heat transfer principles and has potential aerospace applications, such as thermal control in spacecraft. This versatile system provides a robust platform for both research and practical implementations in thermal and fluid sciences.

Jamesahar et al.15 investigated the heat transfer through natural convection within a partitioned chamber. The chamber was partitioned into two sub-zones by a flexible and extremely thin wall, and this complex interaction was effectively captured through an Arbitrary Lagrangian–Eulerian (ALE) formulation. ALE method is often employed in problems involving fluid–structure interaction, where the motion of the solid structure and the fluid flow affect each other. In the study of Jamesahar et al.15, the intricate interplay between the fluid and the flexible partition was carefully examined through the incorporation of forces equilibrium and the preservation of continuity for both fluid and structure at the partition interface.

Ghalambaz et al.16 investigated the dynamic interplay between fluid and structure in a square chamber. A flexible and extremely thin wall separated the chamber, and sinusoidal temperature variations were applied to the left wall. Their study focused on free convection and explored how the flexible separator influences the fluid flow patterns and heat transfer within the chamber. Moreover, this study contributed to the understanding of FSI under varying thermal conditions and provided insights into the complex behavior of the system. Mehryan et al.17 employed the FSI methodology to simulate the movement of a pliable partition within a trapezoidal chamber arising from its interaction with the internal free convection flow. The internal angle of the trapezoidal chamber had a negligible impact on the applied stresses to the partition, but it affected heat transfer. Specifically, the heat exchange rate from the hot wall of a square chamber surpasses that of a trapezoidal chamber with 30°-inclined side walls by 15%.

To the best of our knowledge, no previous studies have explored the influence of active wall location and flexible partition positioning on the thermal and hydrodynamic characteristics of natural convection within an enclosed medium, under both steady-state and unsteady-state conditions. Therefore, the focus of this study is to analyze the effects of positioning a highly conductive flexible partition and the location of active walls on the heat transfer dynamics linked with free convection within an octagonal cavity. Additionally, we aim to investigate the dynamic response of the flexible partition. The octagonal enclosure features flexible thin partitions oriented vertically or inclined partitions at positive and negative slopes.

Problem description

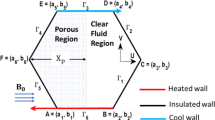

Figure 1 illustrates the schematic representation of the physical models utilized in the current study. As depicted, the enclosure takes on an octagonal shape with a height of \({\text{L}}^{*}\), and is partitioned into two sub-domains by a flexible, thin separator. The flexible, impenetrable separator can be positioned vertically or inclined at a positive or negative slope. On either the left or right side of the flexible separator, there exists a hot (\(\text{T}={\text{T}}_{\text{h}}^{*}\)) and cold (\(\text{T}={\text{T}}_{\text{c}}^{*}\)) surface, respectively. The remaining walls of the enclosure are thermally insulated. It is important to highlight that, in all the cases examined, the cold surface is never positioned lower than the hot surface. However, both the hot and cold surfaces can be at the same height.

A Newtonian fluid is present within both compartments of the enclosure and the buoyancy-driven flow in these compartments is laminar. The Boussinesq linear approximation is used to simulate density variations in the buoyancy force term. Initially, the temperature of the fluid inside both subdomains is \({\text{T}}_{\text{c}}^{*}\). In the context of the convection of a fluid in an enclosure, the hot and cold wall’s location plays a crucial role in determining the flow patterns and heat distribution within the enclosure. Therefore, Fig. 2 shows twenty-five different configurations characterized by different positions for the active walls and the flexible separator. This study investigates these configurations and analyze their impacts on the flow and heat transfer within the enclosure.

Fluid–structure interaction (FSI) model

Considering the specified assumptions and incorporating the Arbitrary Lagrangian–Eulerian (ALE) technique, we can represent the governing equations for fluid flow and heat transfer in the following manner20:

Continuity equation:

where \({\nabla }^{*}\) is the gradient operator, and \({\mathbf{V}}^{*}\) is the velocity vector of the fluid. It is worth noting that the star superscript indicates that the parameters are dimensional. Therefore, when referring to these parameters, their dimensional representation should be considered.

Momentum equations:

\({\uprho }_{\text{f}}^{*}\) is the density of the fluid, \({\text{t}}^{*}\) is time, \({\mathbf{W}}^{*}\) is the mesh vector velocity, \({\text{p}}^{*}\) is the pressure of the fluid, \({\upmu }_{\text{f}}^{*}\) is the dynamic viscosity of the fluid, \({\upbeta }_{\text{f}}^{*}\) is the volumetric thermal expansion coefficient, \({\text{g}}^{*}\) is the gravity acceleration, \({\text{T}}^{*}\) is the temperature. The subscript c refers to the cold wall, and the index j shows that the buoyancy term is applied only along the y-axis direction.

Energy equation:

\({\text{c}}_{\text{p},\text{f}}^{*}\) and \({\text{k}}_{\text{f}}^{*}\) are, respectively, the sensible heat capacity and the thermal conductivity of the fluid. Furthermore, the deformation of the flexible separator can be accurately characterized by employing a nonlinear elastodynamic equation as follows21:

where

The vector of \({\mathbf{D}}_{\text{s}}^{*}\) indicates the displacement of the flexible separator, \({{\varvec{\upsigma}}}^{*}\) is the solid stress tensor, \({\mathbf{F}}_{\text{v}}^{*}\) is the volume force that is applied to the flexible separator, which equals \(\left({\uprho }_{\text{f}}^{*}-{\uprho }_{\text{s}}^{*}\right){\text{g}}^{*}\). The variable \({{\varvec{\upsigma}}}^{*}\) in Eq. 4 is derived using the Neo-Hookean solid model. The Neo-Hookean model is widely used because it accurately captures the large deformations that occur in soft structures. It is particularly suitable for materials that have large strain levels and are nearly incompressible, meaning their volume remains almost constant during deformation.

in which

\({\text{I}}^{*}\) is the identity matrix. The mathematical formulation of the Neo-Hookean solid model involves defining a strain energy density function (\({\text{G}}_{\text{s}}^{*}\)) which describes the energy stored in the material as it undergoes deformation. For isotropic materials—those with properties that are independent of the direction of deformation—the Neo-Hookean strain energy density function can be expressed as:

where

and

Boundary and initial conditions

The given assumptions lead to the representation of boundary conditions for the computational domain in mathematical form as follows:

By applying the conservation of energy to the flexible separator, we can derive the following equation:

The subscripts of \(\text{ls}\) and \(\text{rs}\) refer to the left and right sides of the separator. The fluid-wall interaction assumes a no-slip boundary condition, implying that the fluid velocity at the stationary walls is zero. Additionally, the fluid velocity at the solid–fluid interface equals the velocity of the flexible separator.

At the interface of the separator and fluid:

Non-dimensional governing equations

The governing Eqs. (1)–(4) are rendered into dimensionless form by utilizing the below set of scaled variables:

By applying the dimensionless variables to the dimensional equations, the resulting set of dimensionless equations is as follows:

where

Boundary and initial conditions in non-dimensional coordinates

The boundary and initial conditions in the dimensionless coordinates are:

At the interface of the separator and fluid:

Post-processing equations

For post-processing purposes, this section defines four quantities. The first is the Nusselt number, which signifies the rate of heat transfer. The second is the maximum von Mises stress experienced by the flexible separator. The third is the peak value of streamlines observed in the simulation. Lastly, the fourth quantity is the mean temperature of the domain for each case. Considering the control surface on the hot wall, we then have:

By applying the variable parameters defined in Eq. (16), the above equation is:

where \({\text{Nu}}_{\text{l}}\) is the local Nusselt number. Moreover, the average Nusselt number at the heated boundary is:

in which \(\text{dl}\) denotes a segment along the direction where \({\text{Nu}}_{\text{l}}\) is evaluated and, \({\text{S}}_{1}\) is the total length over which the averaging is performed, corresponding to the heated boundary. The total Nusselt number during the natural convection process is defined as follows:

The stream function \(\uppsi\) is employed to depict the fluid flow patterns in the chamber and is characterized as:

To solve this equation, Dirichlet boundary conditions are set on the chamber’s rigid surfaces. Lastly, the mean average temperature is calculated as follows:

where \(\Gamma\) is the surface area of the enclosure.

Numerical method, mesh sensitivity analysis, and verification

The Finite Element Method (FEM) is employed in this work due to its unique advantages in addressing the challenges of the problem. FEM excels in handling complex geometries, such as an octagonal cavity with a flexible separator, by discretizing irregular domains using unstructured meshes, ensuring an accurate representation of the domain and boundary conditions. Its integration with the Arbitrary Lagrangian–Eulerian (ALE) technique allows for dynamic mesh updates, making it well-suited for problems involving deforming boundaries, such as the flexible separator’s interaction with fluid flow. FEM’s reliance on the weak formulation of partial differential equations (PDEs) reduces continuity requirements, enhancing its robustness for handling complex boundary conditions and material properties. Additionally, FEM efficiently handles coupled physics, such as FSI and heat transfer, within a unified framework.

The Galerkin method, a key approach within FEM, is used to approximate solutions to the governing PDEs. The first step in FEM is to transform the PDE from its strong form into its weak form. This involves multiplying the equation by a test function \(\upxi\) (often chosen from the same function space as the solution) and integrating over the domain \(\Omega\). For example, the weak form of a generic PDE \(\mathcal{L}\left(\text{z}\right)\) is given by22:

where \(\mathcal{L}\left(\text{z}\right)\) represents the differential operator applied to the unknown solution z. The unknown solution \(\text{z}\) is approximated using a finite-dimensional function space:

where \({\text{z}}_{\text{h}}\) is the approximate solution, \({\text{z}}_{\text{i}}\) are the nodal values, and \({\upphi }_{\text{i}}\) are the basis functions. The test function \(\xi\) is also approximated using the same basis functions. The Galerkin method enforces that the residual of the weak form is orthogonal to the space of test functions, ensuring that the error introduced by the approximation is minimized in a weighted sense. This results in a system of algebraic equations22:

where \(\mathbf{K}\) is the stiffness matrix, \(\mathbf{z}\) is the vector of unknown nodal values, and \(\mathbf{F}\) is the force vector.

Quadratic basis functions are used to achieve a higher order accuracy in the solution, as they provide a better approximation of nonlinear behavior and smoother gradients compared to linear basis functions. A three-point Gaussian quadrature is employed for numerical integration, which provides exact integration of polynomials up to fifth order, ensuring precise evaluation of the integrals in the weak form. The nonlinear system of equations arising from the weak formulation is solved iteratively using the Newton–Raphson method. This method linearizes the system at each iteration, facilitating rapid convergence. The iterations are terminated when the residual error falls below 1E-5, ensuring that the numerical solution converges to a high level of accuracy.

In the numerical study, we utilize the Backward Differentiation Formula (BDF) for temporal discretization within COMSOL Multiphysics. The BDF method is an implicit time-stepping scheme, which is well-suited for handling stiff systems and ensuring numerical stability. The specific order of the BDF scheme and the time step size are chosen based on the stability and accuracy requirements of the problem.

Mesh sensitivity analysis is an essential part of the simulation process, helping engineers and researchers balance accuracy and computational efficiency in their numerical models. It ensures that the simulation captures the important features of the problem being analyzed while keeping the computational effort manageable. This study uses a non-uniform and irregular grid, along with the boundary layer grids, to discretize the computational domain. By combining the nonuniformity and unstructured nature of the grid and incorporating boundary layer grids, simulations can more accurately capture complex flow phenomena near solid boundaries, where the majority of flow effects are concentrated. This approach improves the accuracy of the simulation results while reducing computational costs compared to using a uniformly fine grid throughout the entire domain. To select an appropriate grid size, we analyze five meshes with varying numbers of elements, as tabulated in Table 1. In this test, \(\text{Pr}=6.2\), \({\text{E}}_{\text{d}}=5\times {10}^{11}\), and \(\text{Ra}={10}^{7}\). Figure 3 illustrates the impact of the number of elements on both the maximum von Mises stress and the average Nusselt number over time. As observed from the data, we can confidently choose mesh IV to represent the results. Figure 4 shows a view of the mesh employed for the subsequence simulations.

Validating a numerical study involves assessing the accuracy, reliability, and credibility of the numerical results and simulations against known or expected outcomes. To guarantee the accuracy and precision of the simulation outcomes in the current research, comparisons are drawn between the results of this study and those presented in prior works10,23,24,25. In Fig. 5, a comparison is made between the outcomes of the current investigation and those documented by Xu et al.23, focusing on an unsteady scenario. Their study characterizes the transient aspects of natural convection within a divided square chamber, triggered by an abrupt temperature disparity between the fluids on either side of the divider. Xu et al.23 assumed an extremely thin and thermally conductive solid divider within the chamber, consequently disregarding the impact of conductive heat transfer within the divider. We compare the documented temperature evolution over time for a specific point located non-dimensionally at (0.0083, 0.375) near the partition. Figure 5 demonstrates a high level of agreement between the temporal evolution of the current study and the outcomes presented by Xu et al.23.

Temperature at a specific point of \((\text{x},\text{y})\) from the study conducted by Xu et al.23 and present work.

In the context of unsteady FSI, this study juxtaposes its findings with those of Küttler and Wall24 to establish a comparative analysis. Küttler and Wall24 delved into a study centered around a lid-driven square enclosure with a dynamic lower wall. The enclosure’s dimensions are standardized, and the upper wall, acting as a lid, experiences a controlled periodic velocity defined as \({\text{u}}_{{\text{x}}} = \left( {1 - {\text{cos}}\left( {2\uppi {\text{t}}/5} \right)} \right) \,{\text{m}}/{\text{s}}\). As shown in Fig. 6, a comparison is drawn between the dynamic deformation of the chamber wall in our study and the investigation conducted by Küttler and Wall24. A notable concurrence is observed between the findings of the current study and the outcomes presented by Küttler and Wall.

Comparison between the results reported by Küttler and Wall24 and the present work.

As part of the comparative analysis with experimental outcomes of the enclosure featuring solid dividers, this study considers the experimental findings documented by Nishimura et al.10. Nishimura et al.10 conducted experiments on natural convection heat transfer within a rectangular enclosure. The enclosure was divided into subdomains using multiple dividers and had a height-to-length ratio of four. The upper and lower enclosure walls were effectively insulated, while the lateral walls maintained a constant temperature gradient, with \({\text{T}}_{\text{h}}\) on one side and \({\text{T}}_{\text{c}}\) on the other. Nishimura et al.10 examined the enclosure under three different conditions: a partitionless enclosure (\(\text{N}=0\)), an enclosure with a single rigid partition (\(\text{N}=1\)), and an enclosure with two rigid partitions (\(\text{N}=2\)). In Fig. 7, a comprehensive comparison unfolds between the experimental findings obtained by Nishimura et al.10 and the numerical outcomes derived from the present study. Remarkably, a striking concurrence between the numerical simulations and the experimental data is observed.

Results and discussion

The key parameters investigated include the location of the active walls, the positioning of the flexible separator, the Rayleigh number (\(\text{Ra}\)), and the elasticity modulus (\({\text{E}}_{\text{d}}\)). However, the Prandtl number, (\(\text{Pr}\)) is set to 6.2

Effect of the location of the active walls and the positioning of the flexible partition

First, the time evolution of the streamlines and thermal patterns is discussed, as illustrated in Figs. 8 and 9. These figures depict, respectively, the streamlines and the isothermal contours as they change with time in the cavity for case 10, which represents a differentially heated cavity with a flexible separator positioned diagonally from the lower left to the upper right. Initially, when the walls are activated, the entire cavity has the same temperature as the cold walls (as explained in section “Problem description”). For this reason, during the first period, negligible changes are observed in the right portion of the cavity, where the cold wall is located. On the other hand, flow occurs in the left half. The fluid heated near the left hot wall has a lower density compared to its surroundings, so it moves upwards due to its decreased density, while the neighboring colder fluid moves downwards, resulting in clockwise circulation. In brief, buoyancy-driven free convective flow takes place. The positive and negative directions of the streamlines represent counterclockwise and clockwise flows within the domain, respectively. As time goes on, heat is transferred through the flexible separator to the right half of the enclosure, and a similar convective flow occurs in the other half. At the end, a steady state is reached a steady state is reached, with flow patterns becoming symmetrical around the separator and featuring a clockwise recirculation zone in each half of the cavity. The isothermal contours confirm the observations. Heat is initially conducted from the heated wall towards the adjacent fluid. Then, as the flow begins, the isotherms extend into the left part of the enclosure due to thermal convection. The isotherms are parallel to the separator in its vicinity, thanks to the conduction taking place at that boundary. At steady state, the isothermal lines become horizontal in the middle of each half-cavity, indicating that heat transfer in the cavity is dominated by convection, except in the zones neighboring the active walls and the separator where conduction is the main heat transfer mode.

The flow intensity reaches its peak just before heat is fully transmitted through the separator to the right compartment, i.e., before convection strengthens in the right half, as indicated by the stream function values. Before that, the behavior was as if the cavity was confined to its left compartment, resulting in high circulation intensity as the flow was limited to a smaller region. Once the convective flow covers the entire enclosure, its intensity diminishes as it covers more space until it reaches a steady state. Regarding the flexible separator, its shape is affected by the surrounding flow. As convection occurs, the flexible baffle is pushed to the right in the upper region of the cavity. In contrast, the opposite happens in the lower portion of the enclosure, where cold fluid flows down from the right. This results in the observed S-shape of the separator, as shown in the figures.

In addition to the buoyancy force driven by density gradients, the pressure gradient plays a significant role in the fluid motion within the cavity. The pressure gradient in the cavity is strongly influenced by the hot and cold walls as well as the flexible separator. Near the hot wall, the fluid heats up, expands, and becomes less dense, causing it to rise due to buoyancy forces. This upward motion of the fluid creates a region of relatively lower pressure near the hot wall. Conversely, near the cold wall, the fluid cools, contracts, and becomes denser, causing it to sink. This downward motion of the fluid results in a region of relatively higher pressure near the cold wall. This pressure difference establishes a horizontal pressure gradient that drives fluid motion from the high-pressure region (near the cold wall) toward the low-pressure (near the hot wall) region. The pressure gradient works in conjunction with the buoyancy force to sustain circulation and maintain the flow structure, influencing both the velocity field and heat transfer characteristics. The flexible separator further modulates the pressure gradient by dynamically adjusting its shape in response to the flow, altering the local pressure distribution. This interaction between the flexible separator and the pressure gradient enhances the complexity to the flow field, affecting both the velocity patterns and heat transfer.

The impact of the heating location on the thermal and flow patterns is illustrated in Figs. 10 and 11. Six cases (1–6) are considered, all corresponding to cavities with a vertical separator in the middle, but differing in the placement of the hot and cold walls. As a first observation, the streamlines and isotherms are symmetrical around the separator middle only in cases 3 and 4. This is because these are the only ones considered where the active walls present symmetry around the cavity center. In all cases, buoyancy-driven recirculation zones take place in the cavity. As indicated by the stream function values, the intensity of the flow is enhanced when the vertical distance from the cold wall to the hot wall is higher. For example, in case 1, where the hot and cold walls are located on the bottom left and bottom right of the cavity, respectively, convective flow predominantly occurs in the left half of the cavity. Here, the hot fluid rises from the bottom to the top. In contrast, this effect is less pronounced in the right half, as the colder fluid is already near the bottom.

In case 2, when the cold wall is moved to the right middle, the right half of the cavity experiences stronger convective effects due to the increased space available for the cold fluid to flow. These effects intensify further when the cold wall is moved higher, as seen in case 3. A similar trend is observed when comparing cases 4 and 5, where the hot wall remains fixed at the mid-left position, but the cold wall is shifted from the middle right (case 4) to the top right (case 5). In case 6, the hot wall is moved upward to the upper left. Here, effects opposite to previous observations occur, though similar outcomes are observed in the left portion. Convective effects in the left half are weaker because the hot fluid is already near the top, and its buoyancy-driven upward circulation is restricted. The isothermal contours align with the flow patterns, but heat transfer remains dominated by convection in each half of the cavity and by conduction near the separator. A final observation is that raising the hot wall reduces flow intensity, as seen by comparing cases 2 and 4 or cases 3 and 5. This reduction is due to the diminished buoyancy effects when the hot wall is positioned closer to the top.

The temporal variations of the maximum magnitude of the stream function (\({\uppsi }_{\text{max}}\)), the average temperature (\({\text{T}}_{\text{avg}}\)), the average Nusselt number (\({\text{Nu}}_{\text{avg}}\)), and the maximum stress (\({\upsigma }_{\text{max}}\)) are illustrated in Fig. 12 for different active walls’ locations, encompassing cases 1 to 6. \({\uppsi }_{\text{max}}\) initially increases gradually as the fluid begins to heat in the vicinity of the hotter wall. It then increases sharply when the convective flow is established in the left compartment of the enclosure. Subsequently, it starts to decrease slowly as heat is transmitted through the separator to the right compartment. Finally, it reaches a steady-state value when convective flow encompasses the entire cavity. Among the considered configurations, \({\uppsi }_{\text{max}}\) is highest in case 3 and lowest in case 6. In case 6, the hot wall’s position at the top left hinders convective effects, consequently diminishing flow intensity as previously discussed. Conversely, in case 3, the hot wall is located at the bottom left while the cold wall is at the top right. This configuration enhances convection in both halves of the cavity, resulting in the maximum \({\uppsi }_{\text{max}}\). Overall, moving the hot wall upwards reduces the steady-state value of \({\uppsi }_{\text{max}}\) by four times.

Effect of active walls location on (a) the maximum value of streamline (\({\uppsi }_{\text{max}}\)), (b) the average temperature (\({\text{T}}_{\text{avg}}\)), (c) the average Nusselt number (\({\text{Nu}}_{\text{avg}}\)), and (d) the maximum value of von Misses stress (\({\upsigma }_{\text{max}}\)) for the enclosure with the vertical flexible separator.

The average temperature (\({\text{T}}_{\text{avg}}\)) starts from 0, as the entire cavity is initially at the cold temperature. It then increases gradually as mixing within the fluid intensifies through convection and conduction across the separator. Finally, it reaches its steady-state value. \({\text{T}}_{\text{avg}}\) decreases when the hotter and/or colder wall is moved upwards. This is because significant convective effects occur in the left half of the cavity when the hotter wall is located near the bottom. The resulting mixing leads to an increase in the average temperature of the fluid. Conversely, moving the cold wall towards the bottom diminishes the convection of cold fluid in the right part. This inhibits the cooling effect of the cold fluid, consequently increasing the average temperature. \({\text{T}}_{\text{avg}}\) increases more than 2.7 times when both active walls are moved from the top (case 6) to the bottom (case 1).

In case 1, the hot wall at the bottom heats the fluid directly, causing it to rise due to natural convection. However, the cold wall positioned at the bottom reduces its ability to directly cool the fluid in the cavity, minimizing its cooling effect. This combination leads to a dominance of the heating effect over the cooling effect, resulting in the highest average temperature within the cavity. Conversely, in case 6, when both the hot wall and cold wall are positioned at the top, the heating effect of the hot wall is less effective because the heated fluid cannot significantly rise further—it is already at the top. Similarly, the cooling effect of the cold wall becomes more pronounced because the cooled fluid sinks, influencing the cavity more uniformly. This configuration minimizes the overall heating effect and enhances the cooling effect, resulting in the lowest average temperature within the cavity.

\({\text{Nu}}_{\text{avg}}\) starts from a maximum value as the temperature gradient is initially at its highest near the hot boundary. As convective flow develops, the gradient near the boundary diminishes, and \({\text{Nu}}_{\text{avg}}\) decreases substantially until it slowly reaches its steady-state value. The shape and variation of \({\text{Nu}}_{\text{avg}}\) is very similar in all cases. It is minimal in case 6, where the location of the hotter wall at the top inhibits convection in the left part of the enclosure and around the heated boundary. \({\upsigma }_{\text{max}}\) starts from zero in the absence of the flow. It then increases sharply as the flexible separator is impacted by the flow circulation and stabilizes upon reaching the steady state. \({\upsigma }_{\text{max}}\) is minimized in cases where convection is inhibited in one or both halves of the cavity. This occurs in:

-

Case 1, where the colder wall is positioned at the bottom, resulting in reduced convection in the right half.

-

Case 6, where the hotter wall is positioned at the top, resulting in reduced convection in the left half.

-

Case 4, where both active walls are located at the mid-level of the cavity, partially diminishing convection in both halves.

Figure 13 shows the temporal variations of \({\uppsi }_{\text{max}}\), \({\text{T}}_{\text{avg}}\), \({\text{Nu}}_{\text{avg}}\), and \({\upsigma }_{\text{max}}\) for various active wall locations. These results correspond to cases 7 to 12, which involve cavities with a separator inclined at a positive slope. \({\uppsi }_{\text{max}}\) attains its highest value when the convective effects are intensified in both halves of the cavity. This occurs in case 9, where the hotter wall is positioned at the bottom and the colder wall is positioned at the top, enhancing the buoyancy in both sides of the cavity. \({\text{T}}_{\text{avg}}\) decreases when the hot or cold walls are moved upwards, as explained in the previous paragraph. Consequently, \({\text{T}}_{\text{avg}}\) is maximum in case 7, where both active walls are positioned at the bottom, and minimum in case 12, where they are both positioned at the top. The value of \({\text{T}}_{\text{avg}}\) is 2.5 times higher in case 7 than in case 12. \({\text{Nu}}_{\text{avg}}\) is slightly affected by the change of the active walls’ location. However, it remains at its minimum value in case 12, where the hotter wall is moved upwards, inhibiting convection in the left portion of the cavity containing the heated wall. \({\upsigma }_{\text{max}}\) is also minimized when convection is suppressed in the cavity, as previously discussed. This occurs in cases 7 (cold wall at the bottom) and 12 (hot wall at the top).

Effect of active walls location on (a) the maximum value of streamline (\({\uppsi }_{\text{max}}\)), (b) the average temperature (\({\text{T}}_{\text{avg}}\)), (c) the average Nusselt number (\({\text{Nu}}_{\text{avg}}\)), and (d) the maximum value of von Misses stress (\({\upsigma }_{\text{max}}\)) for the enclosure with the inclined flexible separator at a positive slope.

The effect of the active walls’ location on the temporal variations of \({\uppsi }_{\text{max}}\) is illustrated in Fig. 14. These results correspond to cases 13 to 25, which involve a flexible separator inclined with a negative slope. To enhance clarity, cases 13–19 and 20–25 are separately depicted in Figs. 14I,II, respectively. It is first noted that for cases 13 to 16, in which the hotter wall is placed at the bottom of the enclosure, \({\uppsi }_{\text{max}}\) does not reach a steady state and continues to oscillate even after an extended period. This behavior can be attributed to the following: changes in flow characteristics, such as pressure fluctuations, induce deformations in the flexible separator. Conversely, the movement of the separator influences the flow field. This dynamic interaction between the fluid and the separator creates a continuous feedback loop of changes, ultimately resulting in the observed unsteady flow. In these cases, \({\uppsi }_{\text{max}}\) increases when the cold wall is moved towards the top. It reaches its highest value in case 16 and its lowest value in case 13. Indeed, these cases share the same hot wall location, indicating that the position of the cold wall significantly influences convective effects. For cases that reach a steady state, \({\uppsi }_{\text{max}}\) attains its maximum when the hotter wall is positioned at the down-left corner (cases 18, 19 and 20) and its minimum when the hot wall is located at the top-left corner (cases 24 and 25).

Figures 15, 16, and 17 illustrate the temporal variations of \({\text{T}}_{\text{avg}}\), \({\text{Nu}}_{\text{avg}}\), and \({\upsigma }_{\text{max}}\) for the cases 13 to 25. For better clarity, cases 13–19 and 20–25 are displayed separately in figures labeled (a) and (b), respectively. The different plots confirm the observations discussed in Fig. 12 and 13. \({\text{T}}_{\text{avg}}\) increases when the active walls are moved downwards. Therefore, it is maximum in cases 13 and 17 (active walls at the bottom left and right) and minimum in cases 24 and 25 (active walls at the top left and right). \({\text{Nu}}_{\text{avg}}\) is slightly affected by the location of the active walls. However, it reaches its lowest value in cases 24 and 25, where the hotter wall is moved upwards. \({\upsigma }_{\text{max}}\) The stress reaches its maximum when convective effects are significant in both halves of the cavity. This implies that the hot wall should be positioned at a lower height compared to the cold wall. Furthermore, convection in each half should remain unobstructed, which occurs when the active walls are not adjacent to the flexible separator. These specific conditions are observed in cases 18, 19, and 22.

To address the impact of the flexible separator location on the results, the time evolution of the flow and thermal contours is depicted in Fig. 18 for cases 3, 9, and 19. All these cases involve cavities with the same active wall configuration (hot wall at the bottom left and cold wall at the top right). However, the separator is vertical in case 3, inclined with a positive slope in case 9, and inclined with a negative slope in case 19. Similar behaviors are observed in the three cases: two convection-induced recirculation zones are present in the two halves of the enclosure. Isotherms indicate convection-dominated heat transfer in each half cavity, while conduction dominates near the walls and the flexible separator. Additionally, the flow exerts pressure on the separator, pushing its upper portion to the right and its lower portion to the left. Regarding flow intensity, it is highest in case 9 compared to the other two cases. This enhancement is attributed to the positive inclination of the separator in case 9. This inclination creates more space at the top of the left half of the cavity and at the bottom of the right half. Since the heating and cooling sources are located on the left and right, respectively, this increased space allows for greater upward movement of hot fluid on the left and downward movement of cold fluid on the right. Consequently, the positively inclined separator enhances buoyancy-driven convective flow.

A summary of the values of \({\uppsi }_{\text{max}}\), \({\uppsi }_{\text{steady}}\) (steady-state stream function value), \({\upsigma }_{\text{max}}\), \({\upsigma }_{\text{steady}}\) (steady-state von Mises stress), and \({\text{Nu}}_{\text{total}}\) (total Nusselt number) for all the cases is presented in Table 2. First, the results of cases 3, 9, and 19 are analyzed to provide a clearer understanding of the findings presented in Fig. 18. Regarding the flow intensity, \(\uppsi\) is highest in case 9, as this is the configuration that is most favorable for convection as discussed in the previous paragraph. This also leads to the highest \({\text{Nu}}_{\text{total}}\) in case 9. The value of the steady-state stream function is around 1.3 and 1.6 times higher in case 9 compared to cases 19 and 3, respectively. Case 19 leads to the highest \(\upsigma\), as the separator is impacted at a shorter distance by the rising hot fluid. Similar observations can be obtained by comparing, for instance, cases 2, 8, and 18, or cases 1, 7, and 17. Regarding the other cases, we focus on identifying the configurations that yield the maximum value for each parameter. \({\uppsi }_{\text{max}}\), as discussed in Fig. 8, occurs at the onset of heat transmission through the separator from the left to the right compartment. It is therefore maximum when the heated wall is placed at the bottom left, and there is room for the fluid to rise without obstruction. This corresponds to cases 13 to 16 and 17 to 20. \({\uppsi }_{\text{max}}\) is the minimum when the heated wall is in the top left, and the separator is located at a negative slope. The value of the steady-state stream function corresponds to the flow intensity when the steady state is reached. It is therefore maximized when convection is maximized in both halves of the cavity. This occurs when the heated wall is positioned at the bottom left and the colder wall is positioned at the top right. In addition, the room for circulation of the hot and cold fluids should be the largest. This corresponds to case 9. \(\upsigma\) is maximized when convective effects are significant and when the impact of the resulting flow on the separator is greatest. Since hot fluid circulation is more pronounced at the top and cold fluid circulation is more pronounced at the bottom, a separator inclined at a negative slope experiences the greatest impact from the fluid flow at both its top and bottom portions. The combination of these effects leads to maximum \(\upsigma\) in cases 18, 19, and 22. Maximum \({\text{Nu}}_{\text{total}}\) corresponds to the strongest convection, which is also found for maximum \(\uppsi\). This occurs in case 9. Its minimum occurs when the heated wall is moved upwards, limiting the available space for hot fluid circulation. This happens in cases 6 and 24.

Effect of Rayleigh number on the dynamic and thermal characteristics of the enclosure (Case 9 which is the best in terms of Nusselt number is chosen)

The flow patterns and isotherms for various values of Rayleigh number (\(\text{Ra}\)) are shown in Fig. 19, for case 9. When \(\text{Ra}={10}^{4}\), the flow intensity is minimized relative to the other considered values of \(\text{Ra}\). When \(\text{Ra}\) is low, flow intensity is minimal compared to other considered \(\text{Ra}\) values. Additionally, isotherms remain parallel to the active walls, indicating that heat transfer throughout the enclosure is dominated by conduction. As \(\text{Ra}\) increases, flow intensity intensifies, and isotherms begin to deviate from their parallel orientation to the walls, exhibiting greater disturbance, particularly in the middle of each half-cavity. This indicates that convection is gradually dominating heat transfer within these zones. This behavior is attributed to the definition of \(\text{Ra}\), which represents the relative importance of buoyancy forces compared to viscous forces. An increase in \(\text{Ra}\) signifies an enhancement of convective flows, as buoyancy forces overcome the resistive effects of viscosity.

Figures 20 and 21 illustrate the impact of \(\text{Ra}\) on the temporal variations of \({\text{T}}_{\text{avg}}\), \({\text{Nu}}_{\text{avg}}\), and \({\upsigma }_{\text{max}}\). The steady-state value of \({\text{T}}_{\text{avg}}\) is not affected by \(\text{Ra}\), as this value depends mainly on the locations of the active walls, as mentioned previously. Nonetheless, the steady-state mode is reached more rapidly at higher \(\text{Ra}\) values, due to enhanced mixing resulting from intensified thermal convection. Regardless of the Rayleigh number, the heat transfer process ensures that the total energy added to the system balances the energy dissipated, leading to the same final temperature distribution and \({\text{T}}_{\text{avg}}\). As for \({\text{Nu}}_{\text{avg}}\), it is initially higher for lower \(\text{Ra}\), as the conduction mechanism dominates heat transfer in the initial stages. As time goes on, the convection mechanism becomes the dominant mode, resulting in higher \({\text{Nu}}_{\text{avg}}\) in elevated Ra values. The stress \({\upsigma }_{\text{max}}\) increases substantially with increasing \(\text{Ra}\). This is because fluid flow is the primary driver of stress within the flexible separator, resulting from fluid–structure interaction. Therefore, increasing \(\text{Ra}\) intensifies the flow and leads to an increase in \({\upsigma }_{\text{max}}\).

Effect of elasticity module on the dynamic and thermal characteristics of the enclosure (Case 9 which is the best in terms of Nusselt number is chosen)

Figure 22 depicts the streamlines and the isotherms in the cavity corresponding to case 9, for various values of the modulus of elasticity (\({\text{E}}_{\text{d}}\)) of the flexible separator. It is observed that the overall shape of the flow and temperature patterns remains largely consistent across all cases. However, flow intensity exhibits slight variations. A lower value of \({\text{E}}_{\text{d}}\) represents more flexibility, indicating that the separator is less stiff and more susceptible to deformation. For this reason, the separator takes an S-shape for \({\text{E}}_{\text{d}}=5 \times {10}^{11}\) while it remains almost unchanged for \({\text{E}}_{\text{d}}={10}^{14}\). The more flexible separator (lower \({\text{E}}_{\text{d}}\)) facilitates easier fluid flow, intensifying the convection mechanism. In fact, by deforming in response to fluid flow, the flexible separator can create more favorable flow paths for the circulation of hot and cold fluids, such as reducing obstructions to their movement.

The temporal variations of \({\text{T}}_{\text{avg}}\), \({\text{Nu}}_{\text{avg}}\), and \({\upsigma }_{\text{max}}\) are plotted in Figs. 23 and 24 for various values of \({\text{E}}_{\text{d}}\). Almost no changes are observed in \({\text{T}}_{\text{avg}}\) for all the values of \({\text{E}}_{\text{d}}\), as all the considered cases have the same active wall location. A slight increase of 5% in \({\text{Nu}}_{\text{avg}}\) is observed with decreasing \({\text{E}}_{\text{d}}\), as fluid circulation is facilitated in this scenario. The most effect is found in \({\upsigma }_{\text{max}}\), which increases with higher values of \({\text{E}}_{\text{d}}\). A stiffer separator exhibits more resistance to deformation imposed by the flow, resulting in higher stress levels.

Conclusions

The natural convection in an octagonal cavity separated into two compartments by an elastic separator was investigated. One wall is heated on the left and another is cooled on the right. The position of each active wall can be adjusted while keeping the cold wall at the same level or above the hot one. The separator can be vertical in the middle of the cavity or inclined at either a positive or negative slope. The influence of different parameters, including the location of the active walls and the separator, Rayleigh number (\(\text{Ra}\)), and the elasticity modulus of the separator (\({\text{E}}_{\text{d}}\)) on the flow and temperature patterns as well as on the maximum stream function value (\({\uppsi }_{\text{max}}\)), the maximum von Mises stress (\({\upsigma }_{\text{max}}\)), the average temperature (\({\text{T}}_{\text{avg}}\)), and the average Nusselt number (\({\text{Nu}}_{\text{avg}}\)) was analyzed.

It was found that the location of the active walls greatly affects the results. Moving the heated wall downwards and/or the colder wall upwards enhances convection due to the intensification of the buoyancy effects, leading to an increase in \({\uppsi }_{\text{max}}\) and \({\upsigma }_{\text{max}}\). Locating both active walls near the bottom increases \({\text{T}}_{\text{avg}}\). \({\text{Nu}}_{\text{avg}}\) is slightly affected by the change of the active location. However, it is minimized when the heated wall is moved to the top due to the suppression of convection effects in the left compartment of the enclosure. Moreover, it was determined that a separator inclined at a positive slope provides the most favorable configuration for convective heat transfer. Conversely, when the heated wall is at the bottom, a negatively sloped separator blocks the rising hot fluid, reducing convection and increasing stress within the separator. Increasing \(\text{Ra}\) intensifies the free convection, which leads to higher values of \({\text{Nu}}_{\text{avg}}\) and \({\upsigma }_{\text{max}}\). Furthermore, it was found that using a more flexible separator slightly enhances the heat transfer rate, while substantially reducing the stress in the separator.

In this work, an octagonal shape for the cavity and three possible locations of the separator were considered. Addressing new geometrical configurations with various shapes and properties of flexible separators or separated into compartments with different sizes presents interesting topics for future studies.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- \({\text{E}}\) :

-

Young’s modulus (\({\text{Pa}}\))

- \({\text{E}}_{{\text{d}}}\) :

-

Dimensionless elasticity modulus

- \({\text{c}}_{{\text{p}}}\) :

-

Specific heat capacity (\({\text{J}}/{\text{kg}}.{\text{K}}\))

- \({\text{D}}_{{\text{s}}}\) :

-

Acceleration of separator’s deformation (\({\text{m}}/{\text{s}}^{2}\))

- \({\text{F}}_{{\text{v}}}\) :

-

External forces acting on the separator (\({\text{N}}\))

- \({\text{G}}_{{\text{s}}}\) :

-

Strain energy density function (\({\text{Pa}}\))

- \({\text{g}}\) :

-

Gravity acceleration (\({\text{m}}/{\text{s}}^{2}\))

- \({\text{L}}\) :

-

Characteristic length (\({\text{m}}\))

- \({\text{k}}\) :

-

Thermal conductivity (\({\text{W}}/{\text{m}}.{\text{K}}\))

- \({\text{Nu}}\) :

-

Nusselt number

- \({\text{p}}\) :

-

Pressure (\({\text{Pa}}\))

- \({\text{Pr}}\) :

-

Prandtl number

- \({\text{Ra}}\) :

-

Rayleigh number

- \({\text{S}}_{1}\) :

-

Non-dimensional length of the hot wall

- \({\text{T}}\) :

-

Temperature (\({\text{K}}\))

- \({\text{t}}\) :

-

Time (\({\text{s}}\))

- \({\text{t}}_{{\text{p}}}\) :

-

Thickness of the separator (\({\text{m}}\))

- \({\text{u}}\) :

-

X velocity component (\({\text{m}}/{\text{s}}\))

- \({\text{v}}\) :

-

Y velocity component (\({\text{m}}/{\text{s}}\))

- \({\text{V}}\) :

-

Velocity vector of fluid (\({\text{m}}/{\text{s}}\))

- \({\text{W}}\) :

-

Velocity vector of mesh (\({\text{m}}/{\text{s}}\))

- \({\text{x}},{\text{ y}}\) :

-

Axes in cartesian coordinates

- \({\upalpha }\) :

-

Thermal diffusivity (\({\text{m}}^{2} /{\text{s}}\))

- \({\upbeta }\) :

-

Thermal expansion (\(1/{\text{K}}\))

- \({\upsigma }\) :

-

Cauchy stress tensor (\({\text{Pa}}\))

- \(\vartheta\) :

-

Shear modulus (\({\text{Pa}}\))

- \({\uppsi }\) :

-

Stream function

- \({\upomega }\) :

-

First Lame parameter (\({\text{Pa}}\))

- \({\upnu }\) :

-

Poisson’s ratio

- T:

-

Transpose of matrix

- *:

-

Dimensional properties

- \({\text{avg}}\) :

-

Average value

- \({\text{c}}\) :

-

Cold

- \({\text{F}}\) :

-

Fluid

- \({\text{h}}\) :

-

Hot

- \({\text{ls}}\) :

-

Left side

- \({\text{r}}\) :

-

Properties ratio of fluid to separator

- \({\text{rs}}\) :

-

Right side

- \({\text{s}}\) :

-

Separator

- \({\text{total}}\) :

-

Total value

References

Deng, Q.-H. & Tang, G.-F. Numerical visualization of mass and heat transport for conjugate natural convection/heat conduction by streamline and heatline. Int. J. Heat Mass Transf. 45(11), 2373–2385 (2002).

Anandalakshmi, R. & Basak, T. Heat flow visualization for natural convection in rhombic enclosures due to isothermal and non-isothermal heating at the bottom wall. Int. J. Heat Mass Transf. 55(4), 1325–1342 (2012).

Ben-Nakhi, A. & Chamkha, A. J. Conjugate natural convection in a square enclosure with inclined thin fin of arbitrary length. Int. J. Therm. Sci. 46(5), 467–478 (2007).

Yaseen, D. T. et al. Controlling convective heat transfer of shear thinning fluid in a triangular enclosure with different obstacle positions. Case Stud. Therm. Eng. 61, 105003 (2024).

Varol, Y., Oztop, H. F. & Koca, A. Effects of inclination angle on conduction—natural convection in divided enclosures filled with different fluids. Int. Commun. Heat Mass Transf. 37(2), 182–191 (2010).

Priam, S. S. et al. Conjugate natural convection in a vertically divided square enclosure by a corrugated solid partition into air and water regions. Therm. Sci. Eng. Progress 25, 101036 (2021).

Oztop, H. F., Varol, Y. & Koca, A. Natural convection in a vertically divided square enclosure by a solid partition into air and water regions. Int. J. Heat Mass Transf. 52(25), 5909–5921 (2009).

Tatsuo, N., Mitsuhiro, S. & Yuji, K. Natural convection heat transfer in enclosures with an off-center partition. Int. J. Heat Mass Transf. 30(8), 1756–1758 (1987).

Kahveci, K., Natural convection in a partitioned vertical enclosure heated with a uniform heat flux (2007).

Nishimura, T. et al. Natural convection heat transfer in enclosures with multiple vertical partitions. Int. J. Heat Mass Transf. 31(8), 1679–1686 (1988).

Ciofalo, M. & Karayiannis, T. G. Natural convection heat transfer in a partially—or completely—partitioned vertical rectangular enclosure. Int. J. Heat Mass Transf. 34(1), 167–179 (1991).

Khatamifar, M. et al. Conjugate natural convection heat transfer in a partitioned differentially-heated square cavity. Int. Commun. Heat Mass Transf. 81, 92–103 (2017).

Rabhi, M., Bouali, H. & Mezrhab, A. Radiation–natural convection heat transfer in inclined rectangular enclosures with multiple partitions. Energy Convers. Manag. 49(5), 1228–1236 (2008).

Yaseen, D. T., Salih, S. M. & Ismael, M. A. Mixed convection in a variable size cavity: effect of flexible wall characteristics. Int. J. Therm. Sci. 203, 109137 (2024).

Jamesahar, E., Ghalambaz, M. & Chamkha, A. J. Fluid–solid interaction in natural convection heat transfer in a square cavity with a perfectly thermal-conductive flexible diagonal partition. Int. J. Heat Mass Transf. 100, 303–319 (2016).

Ghalambaz, M. et al. Fluid–structure interaction of free convection in a square cavity divided by a flexible membrane and subjected to sinusoidal temperature heating. Int. J. Numer. Meth. Heat Fluid Flow 30(6), 2883–2911 (2020).

Mehryan, S. A. M. et al. Free convection in a trapezoidal enclosure divided by a flexible partition. Int. J. Heat Mass Transf. 149, 119186 (2020).

Mehryan, S. A. M. et al. Analysis of fluid-solid interaction in MHD natural convection in a square cavity equally partitioned by a vertical flexible membrane. J. Magn. Magn. Mater. 424, 161–173 (2017).

Ghalambaz, M. et al. MHD natural convection of Cu–Al2O3 water hybrid nanofluids in a cavity equally divided into two parts by a vertical flexible partition membrane. J. Therm. Anal. Calorim. 138(2), 1723–1743 (2019).

Yaseen, D. T., Salih, S. M. & Ismael, M. A. Effect of the lid-driven on mixed convection in an open flexible wall cavity with a partially heated bottom wall. Int. J. Therm. Sci. 188, 108213 (2023).

Yaseen, D. T., Ismael, M. A. & Salih, S. M. Discrete heating of turbulent FSI in a vented lid-driven enclosure. Int. Commun. Heat Mass Transfer 158, 107910 (2024).

Reddy, J. N. & Gartling, D. K. The Finite Element Method in Heat Transfer and Fluid Dynamics (CRC Press, 2010).

Xu, F., Patterson, J. C. & Lei, C. Heat transfer through coupled thermal boundary layers induced by a suddenly generated temperature difference. Int. J. Heat Mass Transf. 52(21), 4966–4975 (2009).

Küttler, U. & Wall, W. A. Fixed-point fluid–structure interaction solvers with dynamic relaxation. Comput. Mech. 43(1), 61–72 (2008).

Churchill, S. Free convection in layers and enclosures. Heat Exch. Design Handb. 2 (1983).

Acknowledgements

The authors extend their appreciation to the Deanship of Research and Graduate Studies at King Khalid University for funding this work through Large Research Project under grant number (R.G.P2/349/45).

Author information

Authors and Affiliations

Contributions

MB: Conceptualization, Methodology, Formal analysis, Writing-original draft; AA: Methodology, Formal analysis, Validation, Funding acquisition; SM: Formal analysis, Data curation, Software, Supervision; SA: Investigation, Data curation, Software; AH: Writing-original draft, Resources; NS: Project administration, Supervision, Validation; IM: Investigation, Supervision, Writing—review and editing; NK: Investigation, Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Boujelbene, M., Abidi, A., Mehryan, S.A.M. et al. Thermo-mechanical analysis of free convection in an octagonal cavity with adjustable active walls and flexible separator. Sci Rep 15, 4769 (2025). https://doi.org/10.1038/s41598-025-88852-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-88852-1

Keywords

This article is cited by

-

Numerical study of MHD thermo-convective flows in a square cavity with a deformable wall: effects of heating plate inclination

Journal of Thermal Analysis and Calorimetry (2025)