Abstract

Aiming at the complex geometric nonlinearity and contact behavior of threaded connections, this study proposes a novel approach by constructing a finite element model equivalent to the Iwan model for nonlinear analysis. The innovation of this work lies in the development of a subroutine based on the Iwan model, which effectively simulates the nonlinear contact behavior inherent in threaded connections during tightening. This is followed by constructing a finite element model in Abaqus software to investigate the relationship between the applied torque and the preload force of the threads. The accuracy and nonlinearity of the model are verified against theoretical results. Furthermore, the study explores the impact of the coefficient of friction and rotational amplitude on the mechanical response of the threaded connection, providing new insights into how these factors influence preload force, stress concentration, and the risk of deformation. The results show that the finite element model based on the Iwan model can accurately capture the complex contact behavior of the threaded joint. Specifically, it is found that increasing the friction coefficient enhances the preload force but may also increase stress concentration and deformation risks. Similarly, increasing the rotational amplitude increases the preload force but may lead to plastic deformation and higher stress concentration, which has not been sufficiently addressed in previous studies.

Similar content being viewed by others

Introduction

As the most common fastening method in mechanical engineering, the mechanical properties of bolted connections are crucial to the overall safety and reliability of the structure. In practice, the preload force of a bolted connection is a key parameter to ensure the strength and stability of the connection. Traditionally, the method of controlling the preload force by tightening torque is widely used. However, due to the complex geometric nonlinearity and contact behavior of threaded connections, the relationship between torque and preload often exhibits significant nonlinear characteristics, which makes accurate prediction of it of far-reaching significance.

Nonlinear behaviors such as normal preload oscillations, interface separation, collisions, and adhesion, friction, and sliding in the tangential direction may occur at the interface of bolted complex structural joints, which can lead to energy dissipation and structural damping, and affect the dynamics of the structure. Li Weibo et al.1 investigated the modal characteristics of a combined rotor shaft system under axial preload, revealing the effect of preload on the stability of the threaded connection. Zhang Gongping et al.2 explored the influence of the screw head/nut constraint state on the thread loosening characteristics, which provided a new theoretical basis for the design of threaded connections. Wang Can et al.3 predicted the loosening characteristics of bolts based on Bayesian optimization neural network, which provided a new method for intelligent diagnosis and prevention of loosening problems. In the research of anti-loosening methods for threaded connections, He Kongde et al.4 considered the influence of connection gap wear on the functional reliability of floating bodies in water, which provided a reference for the anti-loosening design of threaded connections in special environments. Gong Hao et al.7,8 reviewed the threaded connection loosening mechanism and anti-loosening methods, summarized the existing research results, and made suggestions for future research directions. In addition, Chen Yan et al.9 analyzed the key factors affecting the uniformity of the axial force distribution of the threaded vice, which provided theoretical support for improving the stability of threaded connections. In order to simulate these complex mechanical behaviors, scholars have proposed a variety of contact models, among which the Iwan model has received widespread attention for its ability to systematically describe the microscopic stick-slip process at the interface and its simple parameter identification. The Iwan model was initially used for the elastic-plastic hysteresis behaviors of civil engineering structures, and then it was applied in the study of the contact mechanics of connecting interfaces and has been continuously improved. In recent years, finite element analysis (FEA), as a powerful numerical simulation tool, has been widely used in the study of complex engineering problems. In the study of threaded connections, the finite element method can provide detailed stress distribution and deformation, thus providing an important basis for optimized design. In terms of modeling and simulation of threaded structures, Li Jiuji et al.5 carried out accurate finite element modeling and effectiveness analysis of threaded structures, which provided the basis for numerical simulation of threaded connections. Zhou Fengjun et al.6 proposed an improved IWAN model for helical threaded connectors under torsional loading, which provides a new tool for the mechanical analysis of threaded connections. Other related studies include the analysis of the effects of aircraft landing gear threaded connections under impact loads by Miao Hong et al.10. Finite element analysis (FEA) have been extensively used to address these challenges. Uz et al.11 demonstrated that thread geometry and preload significantly influence the stability of bolted assemblies in steel construction, emphasizing the importance of accounting for nonlinearities in connection modeling. Similarly, Li12 highlighted the necessity of accurate preload modeling through FEA to ensure the safety of heavy-duty escalator trusses under full load conditions. Furthermore, Chen13 revealed that operational fatigue and thread wear result in preload loss and joint degradation, stressing the need for advanced models to predict long-term behavior in bolted joints.

Traditional bolt models often rely on linear assumptions, neglecting the nonlinear effects of friction, rotation amplitude, and other factors. However, bolted joints typically operate under complex loading conditions, where changes in friction coefficient and rotation amplitude can significantly impact performance. Most existing research focuses on individual factors, lacking a comprehensive analysis of their combined effects. This study introduces the equivalent Iwan model to analyze the influence of friction and rotation on bolt fastening behavior, offering a more accurate representation of nonlinear characteristics, especially under high load and complex conditions. The main objective of this study is to realize the numerical simulation of the complex geometric contact model based on ABAQUS software by writing subroutines for the material eigenmodal considering the Iwan model, so as to more realistically carry out the finite element analysis of the nonlinear contact behavior of the threaded joints, to explore the relationship between the tightening torque and the preloading force, and to simulate the mechanics of the threads in the process of tightening by setting different loading conditions. response of the thread during the tightening process by setting different loading conditions.

Finite element modeling considering the Iwan model

Implementation of UMAT for the Iwan model

The conventional Iwan model is used to describe the stick-slip behavior of the contact interface, which mainly considers the slip and adhesion phenomena under tangential loading. However, the failure to consider the initial gap at the contact interface leads to limited prediction accuracy. For this reason, the three-dimensionalities of the bolt gap is realized through the finite element method, and the material model of elastic-plastic follower reinforced intrinsic structure based on the Iwan model is defined at to realize the nonlinear finite element analysis of the bolted joint structure. For the bolt tightening process, a combination of implicit dynamics analysis step (Dynamic, Standard) and UMAT based on the Iwan model is used for the solution due to the high degree of nonlinearity in the solution.

For defining the force and displacement relationship according to the Iwan model:

where x is the displacement, F(x) is the force, K is the stiffness in the direction of the force, α is the residual stiffness after macroscopic slip, fq corresponds to the tensile force analogous to the yield tensile force when it enters fully into slip, β=-3/22*(1 + α), xs= 2fq/K is the turning point of the force-displacement relationship and xl=3/11*(1 + α)*xs.

Thus, the force and displacement relationship is converted to a stress-strain relationship:

where A is the contact area, ε and εe are the stress–strain values before and after the change, x is the displacement, and l is the original length of the sliding object.

For an elastic-plastic material exhibiting hybrid strengthening, its plastic properties are characterized by a combination of a follower strengthening component and an isotropic strengthening component. From the definition of the hybrid strengthening principal relationship, the plastic modulus Ep, the isotropic strengthening modulus EF, and the follower strengthening modulus Eb are respectively

\(Y\left( {{{\bar {\varepsilon }}^{\text{p}}}} \right)\)is the tensile stress-strain relationship for the material in unidirectional tension, i.e., the experimental curve. The yield condition applicable for finite element calculation is

Equations (3) and (4) are solved by iterative methods. Here the equation can be solved by Newtonian iterative method with reference to the calculation method provided by ABAQUS for isotropic reinforced materials. After the solution is completed, the back stress and increment\({\alpha _{ij}},\alpha _{{ij}}^{0},\Delta {\alpha _{ij}}{\eta _{ij}}\), plastic strain increment\(\Delta \varepsilon _{{ij}}^{{\text{p}}}\), stress σij and reinforcement directionηij for this incremental step are

Define again the derivative of the follower strengthening modulus Eb with respect to\({\bar {\varepsilon }^{\text{p}}}\) as

The equation of the intrinsic relationship for the incremental rate type hybrid reinforced material is given by

where\({\dot {\sigma }_{ij}}\) is the stress rate,\(\Delta {\epsilon _{ij}}\) is the strain rate, the stress rate and strain rate are the dependent and independent variables,\({\lambda ^*}\) and \({\mu ^*}\) are the transition parameters, material parameters: material Poisson’s ratio µ, bulk elastic modulus\(k=\frac{E}{{3(1 - 2\mu )}}\), Kronecker’s symbols \({\delta _{ij}}\), staggered unit tensor \({\eta _{ij}}\) and \({\eta _{kl}}\), of which E is the material elastic modulus, the unsolved parameters are: the yield stress \({\sigma _Y}\), the plastic modulus\({E_{\text{p}}}\), the direction of reinforcement\({\eta _{ij}}\), the equivalent force of the finite element cell \(\sigma\) and the equivalent strain\({\overline {\epsilon } ^P}\), and the plastic modulus Ep on the equivalent strain \({\bar {\varepsilon }^{\text{p}}}\) derivative H.

The dependent variable F and independent variable x are replaced by σ and εp, which can be obtained as the stress-strain relationship Eq.

Its derivative is

Its second order derivative is

By integrating the elastoplastic intrinsic model with the stress-strain relationship from the Iwan model, a material model that adheres to the force-displacement relationship defined by the Iwan model can be developed.

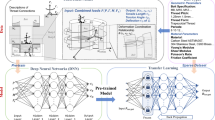

The Iwan model material constitutive relationship can be obtained by substituting Ep, H and parameters \({\bar {\varepsilon }^{\text{p}}}\) into Eq. (11). Based on the theoretical framework outlined above, a user subroutine has been written for ABAQUS, and its flow is depicted in Fig. 1. Initially, the UMAT subroutine serves as the main program to import the initial data for each parameter and compute the Jacobi matrix, which defines the elasticity stage. Subsequently, the UHARD subroutine, based on the Iwan model, is used as the secondary program to assess yield stresses, thereby defining the elastic-plastic and plastic stages. Finally, by invoking the UHARD subroutine to compute the stresses in the elastic-plastic phase, the material parameters are updated, ensuring that the connected parts’ material properties are represented by a finite element model based on the Iwan model stress-strain relationship.

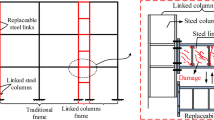

Finite element modeling

The finite element model of the threaded joint is constructed in Abaqus, consisting of a bolt, nut, upper plate, and lower plate, with the bolt specified as M18, as shown in Fig. 2. The material parameters for the Iwan equivalent model are defined through a subroutine in Abaqus, using the following properties: Young’s modulus E = 205 GPa, Poisson’s ratio ν = 0.3, and density ρ = 7850 kg/m3. The dimensions of the connecting plate are specified as 28.5 mm (thickness) × 125 mm (width) × 125 mm (length). In HyperMesh, the model is meshed with a focus on the critical regions, such as the thread contact surfaces, which are refined to capture detailed behavior. For all components, a hexahedral mesh with C3D8 elements is used. Import into ABAQUS, around the threads, the approximate size limits are 0.8, the connecting plate, the approximate size limits are 2. Contact pairs are defined between the mating surfaces of the threaded joint, and the General Contact method is applied to simulate interactions between these surfaces. The Penalty Method is used for tangential contact behavior with a friction coefficient of 0.1, while Hard Contact is employed for normal contact behavior. A coupling point is created at the center of the nut, with coupling constraints applied to the outer surface to control its rotation. The middle cross-section of the bolt is selected as the integral output section, and the axial force at this section is output as the preload force during tightening. Boundary conditions are applied as follows: the translational degrees of freedom of the nodes on the outer surfaces of the upper plate are constrained in the X and Y directions to prevent horizontal displacement during nut tightening, while the nodes on the outer surfaces of the lower plate are constrained in the X and Y directions, and Z-directions to ensure stability. The translational degrees of freedom of the bolt head nodes in the X and Y-directions are also constrained to prevent horizontal movement. In the initial analysis step, all translational and rotational degrees of freedom of the nut are constrained to keep it stationary, and in the tightening step, the translational degrees of freedom of the nut in the Z-direction (axial direction) are released, with a rotational displacement of 0.1 rad applied along the Z-axis.

For this paper, the nominal bolt diameter d is 18 mm, the pitch P is 2.5 mm, the friction coefficient of both the mating surface and the thread is 0.1, the diameter of the bolt head supporting surface dW is 24.9 mm, and the diameter of the bolt through-hole dh is 19 mm.

Model validation

In order to verify the accuracy of the simulation model, this paper uses the same theoretical and experimental comparison analysis. Among them, the theoretical model for comparison is the VDI 2230 standard theory14 Predict the relationship between the tightening torque and the bolt preload, that is, using the formula

included among these\({D_{Km}}=\frac{{{d_W}+{d_h}}}{2},{d_2}=d - 0.6495P\)

As shown in the flow chart in Fig. 3, the bolts and their connecting plates are selected for experiments consistent with the simulation parameters, and the preload extraction adopts ultrasonic sensors, which are installed in the head of the bolts by using the thread + adhesive fastening method, with a solid, safe connection and reliable signal transmission, and the external temperature sensors are used to monitor the ambient temperature for accurate temperature compensation, and configure the bolt preload monitoring and acquisition system, the names of the experimental equipment are as follows, the acquirer The mainframe is BTM-W2022C, the channel switcher (splitter) is BTM-W2022S, the preload force sensor is 2.5P16-25ZS, the installation wires are signal and communication wires, and the installation auxiliary materials are magnetic suction ring, bracket, tightening cap and glue. The experimental procedure begins by selecting an M18 bolt made of alloy steel as the monitoring point and installing an ultrasonic sensor, which is fixed to the bolt head using magnetic or adhesive methods. Next, the channel switcher and data acquisition main unit are connected to ensure simultaneous monitoring of the bolt data. After installation, the data is transmitted to the cabin control cabinet via wired or wireless communication and then uploaded to the server. The backend software collects and analyzes the data in real-time, displaying the variations in the bolt’s pre-tension force. The preload accuracy is ± 3%, the maximum number of monitoring channels of the data acquisition main unit is 300, the central frequency of the ultrasonic sensor is 0.5–10 MHz, the waveform sampling rate is 100 MHz, and the time-of-flight resolution is 1 ns. Torque extraction uses a torque wrench to extract the real-time torque, and the setup time is 10 s to bring the value of preload force to 238 N. The experiment involves fixing the bolt samples onto the loading platform and gradually applying the predetermined axial preload while recording the corresponding torque values. Then, the bolt is rotated with different amplitude settings to simulate real-world conditions. Throughout the process, torque, axial force, and rotation amplitude data are collected in real time, with experiment being repeated at least three times to ensure data reliability and statistical significance. All experiments are conducted in a temperature-controlled laboratory, maintaining the temperature within the range of 25 °C ± 2 °C to minimize the impact of temperature on the friction coefficient and mechanical properties of the bolt material.

As shown in Fig. 4, the finite element model is compared with the theoretical calculated values and experimental values, and the three are in good agreement, the VDI 2230 standard theory presents an approximately linear relationship, and the finite element model shows fluctuations in the preload force with the increase of the tightening torque, which suggests that the influence of nonlinear factors is more significant under high tightening torque, thus, the accuracy of the finite element simulation model in this paper is verified, and the model can better reflect the nonlinear characteristics than the theoretical formula.

From Fig. 5, it is evident that the finite element model proposed in this study demonstrates exceptional accuracy in predicting tightening torque errors during thread fastening. In Fig. 5a, the error between the proposed FEM and experimental data (FEM-Experiment) decreases with increasing preload and stabilizes in the high preload range (> 100 N) within ± 10%. This indicates that the proposed FEM effectively captures the nonlinear characteristics of friction and contact stiffness under real-world conditions. In the low preload range (0–50 N), although errors are larger due to nonlinear effects such as variations in the friction coefficient and changes in lubrication, the proposed FEM still aligns well with experimental trends. In contrast, the VDI model (FEM-VDI) shows significant deviation, particularly large positive errors, due to its oversimplified assumptions regarding friction and contact stiffness. Figure 5b further highlights the superior accuracy of the proposed FEM, with its error distribution being broader and symmetric (-40 N/mm to + 60 N/mm), reflecting its ability to model complex conditions and random errors without systematic bias. Conversely, FEM-VDI errors are narrower and biased towards positive values, indicating systematic deviations, likely caused by overestimations of parameters such as the friction coefficient or contact stiffness. In summary, the proposed FEM stands out for its precision and ability to accurately capture both random and nonlinear characteristics, making it a reliable tool for analyzing thread tightening and studying frictional behavior under real-world operating conditions.

As can be seen in Fig. 6a, the threads with the connecting plate are subjected to the highest load, and the larger values of stresses are mainly concentrated in the root position of the threads, which is in line with literature15. As can be seen in Fig. 6(b), the plastic strain occurs firstly at the root of the thread in the first turn of the bolt, as shown in literature15,16. As shown in the literature16, the fatigue fracture of the bolt in the actual engineering often occurs in the root of the first turn of the thread.

Model response analysis under torsional loading

Effect of coefficient of friction

The coefficient of friction has a significant effect on the mechanical response of the bolt in the finite element analysis of threaded connections under cyclic tightening. The friction coefficient determines the magnitude of friction between the contact surfaces, which affects the mechanical behavior of the bolt under preloading and loading. By setting different friction coefficients in the finite element model, it is possible to observe the variation of the preload force with the friction coefficient. Figure 7a demonstrates the preload force versus torque curves for different friction coefficients, which increases as the friction coefficient increases. This is due to the fact that higher coefficient of friction leads to an increase in friction between the contacting surfaces, thus requiring a higher torque to achieve the same preload force. Figure 7b further refines the effect of different friction coefficients on the mechanical response of the bolt under cyclic tightening. Higher friction coefficients lead to greater friction and thus more stable maintenance of preload during cyclic loading. As the friction coefficient increases, the friction force increases, and the energy dissipation increases. Meanwhile, the high friction coefficient helps to damp structural vibration to some extent and improves the dynamic performance of the system.

In summary, by adjusting the friction coefficient, the design of bolt connection can be optimized to improve the overall performance and stability of the structure. In practical application, it is necessary to reasonably select the friction coefficient according to the specific working conditions and balance the preload force and stress concentration and other factors.

Rotational amplitude effects

Under the action of cyclic tightening, the rotation amplitude also has an important influence on the mechanical response of the bolt in the finite element analysis of threaded connections. The rotation amplitude determines the degree of nut tightening, which directly affects the size of the preload force and the overall mechanical properties of the bolt. By setting different rotation amplitudes in the finite element model, the change of preload force with rotation amplitude can be observed. As shown in Fig. 8a, a larger rotation amplitude leads to a higher preload force, but may also increase the risk of stress concentration and deformation of the bolt, as shown in Fig. 8b, the larger the rotation amplitude is, the more the stress distribution on the contact surface of the bolt and the nut is concentrated, and the energy dissipation is also increased, a larger rotation amplitude may lead to plastic deformation in the stress concentration area, which may affect the service life of the bolt.

Conclusion

In this paper, the nonlinear relationship between tightening torque and axial preload force of bolts is investigated by using the UMAT subroutine of the equivalent Iwan model and the finite element software, then, the constructed finite element model is verified by comparing it with the theory, finally, the effects of friction coefficient and rotation amplitude on the mechanical response of threaded joints are investigated, and the conclusions are as follows:

-

1.

The finite element model based on the Iwan model is able to accurately capture the nonlinear contact behavior in threaded joints, which is in good agreement with the theoretical and experimental results, verifying the accuracy and reliability of the model.

-

2.

The coefficient of friction has a significant effect on the preload and torque of a threaded connection. Higher coefficients of friction increase the friction between the contacting surfaces, thus increasing the preload. However, too high a coefficient of friction may lead to increased risk of stress concentrations and deformation.

-

3.

The influence of the rotation amplitude on the bolt preload is also significant. Higher rotation amplitude increases the preload, but at the same time it may cause stress concentration on the thread contact surface and increase the risk of plastic deformation of the structure.

Data availability

The datasets generated and/or analyzed during the current study are not publicly available due to intellectual property protection involving the UMAT subroutine and HyperMesh three-dimensional finite element models. If you would like to obtain the relevant data, you can contact sunlitai@xauat.edu.cn.

References

Li, W. et al. Modal characterization of combined rotor shaft system under axial preload. Vib. Shock. 43(04), 76–86.https://doi.org/10.13465/j.cnki.jvs.2024.04.010 (2024).

Zhang, G. et al. Influence of head/nut constraint state on thread loosening characteristics. J. Aerosp. Dyn.. 1–11[2024-07-01].https://doi.org/10.13224/j.cnki.jasp.20230675

Wang, C., Han, S. & Sun, Q. Prediction of bolt loosening characteristics based on bayesian optimization neural network. Comput. Integr. Manuf. Syst. 30 (03), 917–925. https://doi.org/10.13196/j.cims.2022.1046 (2024).

He, K. et al. Functional reliability study of floating body in water considering connection gap wear. J. Southwest. Pet. Univ. (Nat. Sci. Ed.). 45 (02), 159–169 (2023).

Li, J. et al. Accurate finite element modeling and effectiveness analysis of threaded structures. Eng. Sci. Technol. 54 (03), 220–229. https://doi.org/10.15961/j.jsuese.202100256 (2022).

Li, J. et al. Improved IWAN modeling of helical threaded connectors under torsional loading. J. Jilin Univ. (Eng.). 53 (05), 1305–1314. https://doi.org/10.13229/j.cnki.jdxbgxb.20210914 (2023).

Gong, H., Liu, J. & Feng, H. A review of the research on loosening mechanism and anti-loosening methods of threaded connections. J. Mech. Eng. 58 (10), 326–347 (2022). +360.

Gong, H., Liu, J. & Ding, X. Research on the mechanism and influencing factors of thread preload decline under vibration conditions. J. Mech. Eng. 55(11), 138–148 (2019).

Chen, Y. et al. Analysis of key factors affecting the uniformity of axial force distribution in threaded vice. J. Northeastern Univ. (Nat. Sci. Ed.) 38 (08), 1142–1147 (2017).

Mu, H. et al. Effects of impact loads on threaded connections of aircraft landing gear. Vib. Shock. 29(02), 208–211 .https://doi.org/10.13465/j.cnki.jvs.2010.02.017 (2010).

Uz, M. E., Ozkat, E., Ersoy, M. C. & Salvan, N. Examining the effect of threaded bolt fasteners on steel construction. Sci. Rep. https://doi.org/10.1038/s41598-024-67428-5 (2024).

Li, N. et al. Experimental study and finite element analysis of heavy-duty escalator truss under full load conditions. Sci. Rep. https://doi.org/10.1038/s41598-024-55175-6 (2024).

Chen, Y., Luo, K., Wu, Q. & Fang, Y. Numerical simulation of thread wear in bolted connections during operational fatigue. Sci. Rep. https://doi.org/10.1038/s41598-022-09876-5 (2022).

Behrens, S. & Behrens, S. Evaluating the performance of virtual desktop infrastructures: VDI performance in theory and practice. In Proceedings of the 2010 International Conference on Advanced Information Networking and Applications Workshops, 787–792 (2010).

Eramo, M. D. & Cappa, P. An experimental validation of load distribution in screw threads. Exp. Mech. 31 (1), 70–75. https://doi.org/10.1007/BF02325760 (1991).

Pu, L., Chen, G. & Wu, L. Mechanical Design, 9th ed. (Higher Education Press, 2013).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 51975449) and the Natural Science Foundation of Shaanxi Provincial Department of Education (Grant No. 2024GX-YBXM-206). We express our sincere gratitude to these funding agencies for their support.

Author information

Authors and Affiliations

Contributions

L.S. wrote the main manuscript text and others prepared figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, L., Li, L. & Gao, X. Nonlinear finite element analysis of equivalent Iwan model considering threaded connections. Sci Rep 15, 4575 (2025). https://doi.org/10.1038/s41598-025-89135-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-89135-5