Abstract

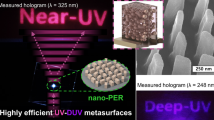

Dielectric metasurfaces with complementary shapes for the nanopatterns are fabricated using a polymer-based low-cost soft lithography approach, using a single master mould. The master mould is also fabricated in-house using a highly reliable inward-growing self-assembly process using colloids, thus making the over-all fabrication process to be simple and easy. Antireflective and anti-wetting properties of these metasurfaces, which possess graded index profiles, are studied. Antireflection characteristics of the metasurfaces are studied over a wide wavelength range of 400–2000 nm using experimental and numerical techniques. Nanodimple patterns present in the metasurfaces lower the specular reflection of glass by 67.5% in the visible range, whereas the nanobump patterns reduce the reflection by 80% throughout the wavelength range of 400 to 2000 nm. The graded index profile is calculated for both the metasurfaces from the fill fractions of the solid medium, by assuming the ideal shape of the pattern as well as from the real shape of the pattern obtained from the microscopic images of the surface. These index profiles provide the insight for the difference between nanobump and nanodimple patterns in realizing effective antireflection. The reflection spectra numerically calculated from the graded index profiles of the surfaces provide an excellent match with the measured spectra, and confirm the relative advantage of nanobump patterns over nanodimple patterns for superior antireflection even with shallow patterns. The anti-wetting and self-cleaning features of these metasurfaces are obtained from contact angle measurements. The potential application areas of these metasurfaces are in reducing the reflection losses and thus in improving the efficiency of optoelectronic devices such as the solar cells, light emitting diodes and low-light imaging sensors.

Similar content being viewed by others

Introduction

Some insects in nature, such as moths and a few species of butterflies, are model systems for understanding the most effective antireflective and anti-wetting surfaces. The eyes or wings of these insects consist of subwavelength-sized nanostructures with different profiles that create a smooth gradient in refractive index between the air and the corneal surface in the case of eyes and scales in the case of wings. Such structures reduce light reflection and increase the transmission at the surface across a wide range of incident angles and wavelengths1,2 enabling remarkable vision even in low-light conditions or transparency for merging with the surroundings. A similar effect of lowering the light reflection is also required to increase the efficiency of certain devices such as anti-glare glasses3, solar cells4,5, light emitting diodes (LED)6 and other optoelectronic devices7. The most common technique for reducing surface reflection in such devices is to use a layer of antireflection coating, which is based on the theory of destructive interference8. These coatings must have a specific value of refractive index that lies between the refractive indices of the two bounding media and must be a quarter wavelength thick9. These requirements restrict the use of these coatings to specific incidence angles and a narrow wavelength range10. This method has additional drawbacks, including low durability, poor adhesion on specific surfaces, mismatched thermal expansion, and expensive material selection, which has led the research groups to draw inspiration from nature11,12. Extensive research has been done on the implementation of bio-inspired structured surfaces; specifically, the replication of moth-eye structures has demonstrated improved antireflection characteristics with excellent optical transmittance13,14,15,16. These structures create lower-gradient effective refractive index profile between air and the surface of the object, which suppresses the Fresnel’s reflection loss over large ranges of incident angles and wavelengths8. While reducing reflection, certain periodic patterned structures can also provide high optical haze and thus increase the effective optical path lengths for the transmission of diffused light17. Additionally, these structures can aid in lowering the total internal reflection losses in optoelectronic devices such as LED18 due to the absence of a sharp refractive index variation. Moreover, according to Cassie-Baxter’s19 theory, texturing on surfaces makes the surface more hydrophobic20 which prevents contaminants from remaining on the surface, and this is important for preserving electronics for outdoor use.

It is an established practice to fabricate structured antireflective surfaces (ARS) on various polymers, including polymethyl methacrylate21, polydimethylsiloxane (PDMS)16,22, and polycarbonate13, due to their low cost, flexibility, ease of processing, and ability to encapsulate solar cells23,24,25. These surfaces can be fabricated using soft lithography technique, which is a simpler, cost-effective, large-scale patterning technique22,26 in comparison to other energy-intensive, expensive patterning techniques such as electron-beam lithography and photolithography. PDMS is the most commonly utilised polymer as an elastomeric stamp for this soft lithography approach because of its unique rheological features, such as high heat stability (150 °C), ultra-violet resistance, non-toxicity, chemical inertness, low interfacial free energy and high optical transparency. Furthermore, owing to the van der Waals force, the cured PDMS film has robust adhesion qualities with flat substrates, allowing it to be not only well-laminated on glasses or wafers, but also easily and reversibly detached from the surfaces if required27. Consequently, substantial research has been conducted employing structured PDMS as an ARS in a variety of geometries, design parameters, and lattice configurations. Random structures were replicated on PDMS from silicon (Si) master to increase the performance of thin film solar cell28. Here, the random structure on the Si master was created using the wet etching process. In a different work, a self-assembly approach was used to create a random nanoporous structure on a glass substrate. The pattern was then transferred on PDMS film to create an antireflection coating29. Apart from random structures, periodic patterns have also created ARS utilising PDMS as a substrate. Using soft lithography, an inverted periodic hexagonal compound eye micropatterned surface12 was created on PDMS polymer that helped to increase the generation of the power in single junction solar cell.

Studies have revealed that nanopatterned surfaces are just as efficient as micropatterned surfaces in improving the performance of solar cells. Inverted hexagonal conical structure on PDMS polymer improved the efficiency of organic solar cell16. Inverted hexagonal array was also fabricated on polymer surface to increase the performance of the perovskite solar cell26. In these studies, although the surfaces are fabricated using low-cost soft lithography approach, the patterned Si master from which the periodic structure was replicated on polymer was prepared using expensive fabrication techniques such as laser interference lithography and photolithography. In another work, to increase the efficiency of the Si solar cell, a nanodimple hexagonal array was fabricated on PDMS as an ARS by taking the replica from the top surface of a three-dimensional colloidal photonic crystal (3D-PhC)30. In this case, the master template was also prepared by cost effective self-assembly process. Most of the reports have used hard templates as master to replicate the design on a polymer to create ARS. In another study, inverted hexagonal moth-eye structure was fabricated on PDMS substrate by taking the replica using soft cyclic olefin polymer as a master mould31. However, in this case, the polymeric master mould was made by thermal nanoimprinting utilising a nanopatterned Si template, fabricated utilising a costly fabrication approach that combines dry etching and electron beam lithography32. With inverted structures, replication of identical structures was possible on polymers using a two-step lithography approach33,34. In such cases, the inverted replica is first taken on a separate material such as SiO233 or polyurethane acrylate (PUA)34, and the replica is then transferred to PDMS polymer. As these materials have higher refractive indices than PDMS, they do not act as an ARS. In addition, metasurfaces —the two-dimensional equivalent of metamaterials—have also emerged as antireflection coatings due to their unusual optical properties that are absent in the natural world35,36. The fabrication of these metasurfaces is sometimes cumbersome and is often done on hard surfaces.

In the present study, our approach is to fabricate flexible dielectric metasurfaces based on gradient-index profiles of two complementary pattern shapes, using soft lithography technique. This utilizes a single master mould which is simultaneously cost-effective, re-usable and prepared in the laboratory within a couple of hours by self-assembly. Two distinct types of metasurfaces, one with a periodic nanodimple array and the other with a periodic nanobump array, with the patterns arranged hexagonally on flexible PDMS substrate have been fabricated using a 3D-PhC as a master via soft lithography technique. The nanodimple metasurface is fabricated in a single step by obtaining a replica from the top surface of the 3D-PhC, as described in previous work22,30, whereas the nanobump metasurface is fabricated using an additional step of patterning with the nanodimple metasurface as a master. Thus, both the inverted and non-inverted replica of the master mould are transferred to PDMS polymer layer, and both the metasurfaces act as ARS. It was shown in previous reports22,26 that a nanodimple patterned surface with a smaller pitch size works well as an ARS in visible (VIS) region. In this study, we chose two different antireflective metasurfaces with complementary pattern shapes and the same pitch size, and found that the nanodimple metasurface is only effective as an ARS in the VIS region, whereas the nanobump metasurface is effective as an ARS over the VIS and the near infrared (NIR) region. The highlight of this work is that these metasurfaces exhibit good antireflection despite having shallow pattern height or depth in comparison to the operating wavelength range, and help in analyzing the role of pattern shape. They are effective over a wide range of incident angles and wavelengths. Furthermore, the fabrication technique is versatile enough to yield different samples with varying feature depth/height by re-using the same master mould. In addition to antireflecting properties, these surfaces are also hydrophobic in nature making them suited for outdoor use.

Fabrication details

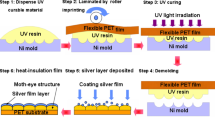

Figure 1(a) shows the schematic of the steps involved in fabricating the surfaces used in this work. The first step in the fabrication process of the metasurface is the preparation of the master mould. A clean glass substrate is kept in the horizontal position. A small quantity of an aqueous suspension containing monodispersed polystyrene colloids (from M/s Microparticles, Germany) with a specified value for the average diameter of the colloids is diluted in ethanol and deposited on a glass substrate using a micropipette and spread uniformly. As the solvents in the colloidal suspension evaporate, the colloids arrange themselves into a 3D-PhC by the inward growing self-assembly method under optimal conditions of room temperature and humidity37. Each layer of this 3D arrangement will have colloids present in a close-packed hexagonal arrangement. Once it is fully dried, the 3D-PhC will be adhered well to the glass substrate and can be kept in normal laboratory conditions. The pattern on the top surface of this PhC is used as the master pattern for the metasurface fabrication. Different ratios of silicone elastomer base to silicone elastomer curing agent are chosen to make the PDMS solution38. This allows the viscosity of the PDMS solution to be modified. PDMS solution of a known concentration is cast on the upper surface of 3D-PhC as a thin film and left undisturbed. After complete curing and drying of the PDMS layer for 72 h at room temperature, the layer is peeled off carefully from the PhC. This PDMS layer will have nanodimple patterns arranged in a hexagonal arrangement, which is the negative replica of the pattern on the top surface of the PhC. Though a monolayer of periodically arranged PS colloids is sufficient to obtain this pattern as the negative replica on PDMS as demonstrated in an earlier work39, the 3D arrangement in PhC provides the colloids on the top layer with a greater adherence to the layers below and the colloids do not get dislodged when the cured PDMS film is separated from the top surface of 3D-PhC. This allows the same PhC to be re-used in multiple replication trials and is thus an important advantage of this method. 3D-PhC inherently contains domains with periodic arrangement of colloids, with such domains separated by fine cracks created when the solvent evaporates. The single crystalline domains range in size over hundreds of µm. In our work, the crystal was grown on an area of ∼ 2.5 × 2.5 cm2 and then replicated in PDMS. To study the anti-reflective nature, a beam size of 2 × 2 mm2 was used which illuminates the area replicated from hundreds of single-crystalline domains separated by cracks. Therefore, it is also significant that the area of the replicated surface can be made larger by preparing larger areas of the master template (3D-PhC) using a larger quantity of colloidal suspension.

Structural details of the fabricated metasurfaces. (a) Schematic diagram of preparing metasurface with nanodimple and nanobump designs on PDMS via soft imprint lithography technique. The AFM images of the 3D-PhC, nanodimple layer and nanobump layer are shown as inset in the diagram. (b, c) AFM images in 2D view are shown for nanodimple and nanobump metasurfaces respectively. (d) Line Profile obtained from the 2D images of the samples. Average height, depth and height respectively of the 3D-PhC, nanodimple and nanobump structures are 121.1 nm, 134.4 nm and 85.3 nm.

The depth of the pattern replicated in PDMS can be controlled by the ratio of the base and curing agent of the PDMS solution22. This versatility allows the possibility of making patterns with different depths and different feature sizes, while the pitch (or the feature separation) remains the same as it is equal to the colloidal diameter of the 3D-PhC. When these depths and feature sizes are sub-wavelength for the source wavelength used in an application, the PDMS layer acts as a dielectric metasurface. We discuss studies on this metasurface in the following sections. The thin PDMS surfaces are flexible and are then placed on glass for providing mechanical stability during characterization. The flat (unpatterned) side of the PDMS layer has good adhesion to glass and remains undisturbed during the further studies. One of these negative replicas of the top surface of 3D-PhC obtained in PDMS is then coated with a thin layer of gold (Au) with a thickness of ∼ 30 nm using a sputtering system. This Au coated negative replica sample is then used as the master in soft lithography, and its replica is taken after covering the surface with the PDMS solution made with a known ratio of elastomer and curing agent to ensure a suitable viscosity. Once the deposited PDMS solution is fully cured at room temperature, the dried PDMS layer on the top is peeled off and thus another dielectric metasurface containing a nanobump pattern arranged in a hexagonal design is obtained. This is the positive replica of the top surface of 3D-PhC. This is also kept adhered to glass substrate using its unpatterned flat side. The coating of a thin film of Au on the negative replica, as mentioned above, increases the wettability between the PDMS solution and the PDMS master, allowing the PDMS solution to cover the entire surface when it is cast. Moreover, a thin Au film ensures that the two PDMS layers of master and its replica do not get stuck to each other as a single layer, allowing the replica to be peeled off easily from the master surface after replication39.

Structural characterization

After the metasurface samples were prepared, their surface morphology was studied using 2D and 3D images from an atomic force microscope (AFM, Asylum Research, MFP-3D Scanning Probe Microscope). In Fig. 1(a), 3D AFM images are shown as inset for the 3D-PhC, nanodimple metasurface and nanobump metasurface. For quantitative analysis, Fig. 1(b) and 1(c) depict the 2D view of the AFM images from an area of 5 × 5 µm2 of the PDMS metasurfaces with nanodimple and nanobump pattern respectively, made from the same 3D-PhC with average colloidal diameter of 757 nm. These images are taken by keeping the scanning parameters same for both the samples. The periodic arrangement of the patterns in a triangular lattice on the surface is clear in these images. Figure 1(d) shows the line profile of both the metasurfaces along with the line profile of the master 3D-PhC over a length of 5 μm. These are recorded along the diagonal of the triangular arrangement, shown by the dotted lines in Fig. 1(b, c). The pattern shape is complementary between the positive and the negative replica. The depth of the patterns in the nanodimple metasurface and the height of the patterns in the nanobump metasurface as well as the 3D-PhC master can be calculated from the line profiles shown in Fig. 1(d). As the area of the metasurface is large (2.5 × 2.5 cm2) in all the three cases, only the average values obtained from a scan area of 5 × 5 µm2 are provided here. The average height of the bump in the master is 121.1 nm while the average depth of the nanodimple in the PDMS metasurface is slightly larger at 134.4 nm. As the scanned areas are different in each case, the position coordinates are not identical in the images recorded for the master and replica. The average height of the bump in the fabricated nanobump PDMS metasurface is 85.3 nm. The values of average pitch (corresponding to the nearest-neighbour distance) of the patterns in the 3D-PhC master, nanodimple and nanobump metasurfaces in Fig. 1(d) are 723 nm, 715 nm and 720 nm respectively. These values are slightly lesser than the average colloidal size of 757 nm of the 3D PhC master mould because of the 5% variations in the monodispersed colloidal sizes as well as due to any small variations that occur in PDMS during the peeling-off process.

The maximum depth of the pattern possible in the negative replica will be equal to the radius of the colloids in the master. If this occurs, the dimples will be in contact with one another in a close-packed arrangement, and the PDMS layer can be referred to as fully patterned. Partially patterned negative replica metasurfaces can have any smaller value for the depth of the dimples. For the positive replica, the height of the nanobumps can maximally equal the depth of the nanodimple in its master mould. It can also have any value smaller than this, based on the viscosity of PDMS solution used in the second step of fabrication. Figure 1(b) and (c) illustrate that the shapes in this instance are not in contact with one another, indicating that our surfaces are partially patterned. This is further supported by the average depth and height values derived from Fig. 1(d). In this work, samples were made with different values of depth for the dimples and heights for the bumps, by using the same master 3D-PhC merely by adjusting the viscosity of the PDMS.

Characterization of antireflective nature

The optical characterization of all the samples was performed using a Perkin-Elmer UV-VIS-NIR Lambda 950 spectrophotometer over the visible to NIR range. Specular reflection spectra were measured at different incidence angles with the universal reflectance accessory of the instrument. Transmission spectra were measured at the same angles as the reflection spectra. Figure 2(a) and 2(b) show the reflection spectra of all the samples at the two incidence angles of 10° and 55° measured with unpolarized light having equal mixture of transverse electric (TE) and transverse magnetic (TM) polarization, by using an additional depolarizer within the spectrophotometer. Glass and flat (unpatterned) PDMS were also characterized as reference samples along with fabricated metasurfaces. Among all the samples studied here, it is seen that the glass substrate has the maximum reflectivity of 8% for near normal (10°) incidence. This value is more than the value (∼ 4%) expected for air-glass interface because of the reflection effect of both the top and bottom surfaces of glass. This is not of any consequence here, because all the samples studied are adhered on glass substrate during the optical measurements and the measured values are compared with each other. The reflectance (R) reduces when the flat PDMS is present on the glass slide. The reflectance value decreases further for the metasurfaces present on glass.

Measured optical spectra. Measured specular reflection spectrum of all the samples at an incidence angle of (a) 10° and (b) 55°. (c) Contour plot of reflectance variation shown for various angle of incidence in the dielectric NB metasurface with pattern height of 72.1 nm. Colour bar represents the reflectance value (d) Specular transmission spectrum measured at an incidence angle of 10°. (e) Extent of scattering for all the samples at an incidence angle of 10° obtained from measured specular reflection and transmission spectrum. (f) Reflection spectra of ND metasurface with pattern depth of 134.4 nm recorded after exposing it to a UV source for 30 min each, in 5 rounds.

The drop in the reflectance of metasurface with nanodimple arrays compared to the reflectance of flat PDMS is significantly more in the visible range and lesser in the NIR range. The reflectance drops even further for nanobump metasurfaces, and this occurs over the entire range (Vis-NIR). Two nanodimple (ND) metasurfaces having pattern depths of 134.4 nm and 248.6 nm, and two nanobump (NB) metasurfaces with pattern heights of 72.1 nm and 85.3 nm, were utilized for this characterization in our work. For ND metasurfaces, the reflectance decreases when the pattern depth increases, whereas for NB metasurfaces, the lowest reflectance is reached for lower pattern height as shown in Fig. 2(a). The extent of reduction in R from that of glass is very high in these surfaces. It is ~ 67.5% for the ND metasurface with higher depth (248.6 nm) at the wavelength of 400–800 nm and ∼80% for NB metasurface with lower height (72.1 nm) across the entire wavelength range shown in Fig. 2(a). The same trend is seen for higher angles of incidence too in Fig. 2(b). However, at the larger angle of incidence, the reflectance for all the samples increases slightly from the values at near-normal incidence, exactly as expected from Fresnel’s equations40. In Fig. 2(c), a contour plot of measured reflectance as a function of wavelength and incidence angle (over 10o to 55o) is shown for the NB metasurface which has a pattern height of 72.1 nm. The colour bar represents the reflectance value. In this sample, the reflectance remains below 2% over the entire wavelength range of our study even at the larger angle of incidence of 40o. The discontinuity seen at 888 nm in this figure is due to the detector change during the measurement.

However, improving the efficiency of optoelectronic devices such as solar cells require more than just lowering the surface reflectance. Optimizing the transmission is also necessary to ensure improved device performance. Therefore, Fig. 2(d) shows the measured specular transmission spectra for all the samples at the angle of incidence of 10°. Glass substrate has the highest transmittance, and it is lesser for nanostructured samples. Here, it is observed that even though the specular reflectance decreased significantly for the textured metasurfaces as seen in Fig. 2(a-b), the specular transmittance (T) does not increase proportionately for them. The trend of reduction in transmittance is the same as the trend in reduction of reflectance for the structured metasurface samples. This is because these measurements collect only the specularly transmitted light. To estimate the light that is scattered in non-specular directions, both in the reflection and transmission modes, the extent of scattering (obtained as 1-(R + T)) is shown for all the samples in Fig. 2(e), at the angle of near-normal incidence of 10° calculated using the data shown in Fig. 2(a) and 2(d) and assuming that the absorption is negligible.

It is observed in Fig. 2(e) that the extent of scattering is the least for glass while it is higher for the polymeric samples. The flat PDMS has slightly larger scattering than glass, while the patterned metasurfaces have much larger scattering. As R and T have the same trend with wavelength, (1-(R + T)) has a trend which is exactly the reverse of R and T among the various samples. Based on these estimations, it can be concluded that while the metasurfaces minimize specular reflection, they do not boost specular transmission. This suggests that the metasurfaces enable diffuse transmission38, which in turn improves total transmission (demonstrated later), and is thus helpful to enhance the efficiency of devices such as solar cells. In addition, by controlling the depth/height and shape of the metasurfaces, light wave can be manipulated for improving the performance of optoelectronic devices in their reflection or transmission geometries as reported earlier38. The multiple minima seen at specific wavelengths in Fig. 2(a, b, d) and the maxima at the same wavelengths in Fig. 2(e) are due to the presence of different chemical bonds in the composition of PDMS polymer25,41. These dips and peaks are observed in the optical spectra of flat PDMS too.

The durability of the metasurface was tested by optical characterization after exposing the ND metasurface of depth 134.4 nm under the UV light. For an accelerated aging test, the sample was placed in a UV exposure chamber (Model: custom-made Ultra UV-C1, Apex Instruments) which has a lamp at a wavelength of 365 nm and a wattage of 8 W. The exposure time was 30 min in each round and then the reflection spectrum was measured at 10° angle of incidence. This was repeated 5 times. The measured spectra were compared with each other and with the spectrum recorded before exposing the metasurface to UV light. These spectra are shown in Fig. 2(f). The close match of the different spectra with each other indicates that the metasurface is durable with no measurable performance degradation due to environmental effects.

Analysis of antireflective nature of the metasurfaces

The extent of antireflective nature in the metasurfaces with two complementary pattern shapes and the dependence on pattern depth / height is clear from the measured data. The reduction in specular reflection recorded in nanostructured metasurfaces is commonly explained from the effective medium theory (EMT) which helps us to estimate the effective refractive index of a composite medium. The effective refractive index (\(\:{n}_{eff}\)) of the textured metasurface depends on the topology of the surface and it is weighted by the volume fraction of the medium8,22. We calculated the variation of \(\:{n}_{eff\:}\)of the metasurfaces as a function of pattern height and depth in our samples to validate our experimental results. In the first step of the calculation, the fill fraction of the structures was calculated by considering the patterned section of the PDMS to have an effective index that varies spatially in a direction perpendicular to the surface, while the un-patterned section of the layer below the pattern was treated as a uniform medium with a fixed refractive index (1.45) corresponding to PDMS. In addition, the pattern shape and spacing were assumed from the master template while the pattern depth/height was used from the measured data.

The two pictures in Fig. 3(a) show the surface in xz plane for ND and NB metasurfaces respectively. The grey areas in Fig. 3(a) represent the PDMS material, whereas the white areas represent air. In the xy plane, the area of one unit cell of a triangular lattice is considered. The patterned layer is considered as a stack of planes with continuously varying fill fraction of air and PDMS across the planes. The shape of the pattern in each layer is considered as a perfect circle in this case, as the over-all shape of the dimples and bumps are part of a sphere (as dictated by the colloidal shape used in the master). The plane corresponding to zero depth and zero height (z = 0) is shown by the black dashed line in the respective schematic for the ND and NB metasurfaces, and the direction of change in depth / height is shown with an arrow. The fill fraction of PDMS (\(\:{f}_{PDMS}\)) increases in the direction of the arrow for the ND metasurface while it reduces in the direction of the arrow for the NB metasurface. As the surface has only the two components of PDMS and air, the fill fraction of air is 1 - \(\:{f}_{PDMS}\). The fill fraction of the PDMS and the variation of \(\:{n}_{eff}\) as a function of height (h) in the NB metasurface is given by Eqs. (1) and (2) respectively22:

Here, \(\:{h}_{max}\) denotes the maximum pattern height, while \(\:{n}_{PDMS\:}\) and \(\:{n}_{air}\:\)represent the refractive indices of PDMS and air having values of 1.45 and 1.00 respectively. The calculation of \(\:{n}_{eff}\) for ND metasurface will have d for the depth instead of h in Eqs. 1 and 2. The calculation of \(\:{n}_{eff\:}\)is discretized for a step size of 1 nm in z direction. Figure 3(b) shows the calculated value of \(\:{n}_{eff}\) as a function of z (height within the metasurface thickness), for the two NB metasurfaces with pattern heights of 85.3 nm and 72.1 nm (red lines). Since the value of \(\:{f}_{PDMS}\) is zero at the top of the NB metasurface, the value of \(\:{n}_{eff\:}\) is close to \(\:{n}_{air}\) (which is 1.0) at the top of the two NB metasurfaces. One of the lines terminates at the height of 72.1 nm while the other goes further till 85.3 nm to account for the two different pattern heights. At negative values of height (corresponding to thickness in the un-patterned portion), both the samples will have the same constant value of 1.45 for \(\:{n}_{eff\:}\).

Analysis of antireflection in metasurfaces. (a) Schematic of how the nanodimple and nanobump surfaces are modelled for the calculation of effective refractive index. The black dashed line defines the zero height and zero depth in calculation. (b) Variation of effective refractive index with height of nanobump surface (red lines) and depth of nanodimple surface (blue lines), calculated using ideal shape of patterns. (c) Reflection spectrum calculated using Fresnel’s equation with the index profile from (b). (d) Variation of effective refractive index with height of nanobump surface (red lines) and depth of nanodimple surface (blue lines), calculated using real shape of patterns from AFM images. Arrows in (b) and (d) indicate the y-axis corresponding to the data. (e) Reflection spectrum calculated using Fresnel’s equation with the index profile from (d). The inset shows the measured data. (e) Reflection spectra of nanodimple and nanobump metasurface of equal depth and height obtained from COMSOL calculation. In (b) and (d), height has positive values while depth has negative values due to the choice of z = 0 in (a).

The calculated values of \(\:{n}_{eff}\) as a function of z (depth within the thickness) are shown in Fig. 3(b) for the two ND metasurfaces with pattern depths of 134.4 nm and 248.6 nm (blue lines). One of the lines goes from depth = 0 till a depth of 134.4 nm, while the other line has a larger range of depth variation till 248.6 nm. It may be noted that \(\:{f}_{PDMS}\) is non-zero at the top of the ND metasurfaces as both of them are partially patterned. This in turn leads to higher values of \(\:{n}_{eff\:}\) at the top of ND metasurface corresponding to depth = 0. In addition, the two values of \(\:{n}_{eff\:}\) at the top are significantly different. This is because the depth of the two ND metasurfaces differ by more than 100 nm. More depth for the pattern implies that the adjacent patterns are closer together (as the spacing is the same in all cases), and the percentage of air is higher. The ND metasurface with larger depth thus shows a lower value of \(\:{n}_{eff\:}\)at depth = 0. The graded index variation within the height/depth is monotonic in these calculations based on EMT due to the ideal shapes assumed here. When we compare the trends obtained for ND and NB metasurfaces, there are distinct differences. The effective refractive index is close to 1 at the top of the NB surface and the index increases to 1.1 only at a distance of ~ 40 nm from the top; hence the contribution of the top few layers of the NB pattern to reflection is less than 2%. On the contrary, the value of \(\:{n}_{eff\:}\)at the top of the ND pattern (depth = 0) is larger than the value of NB pattern. The value is more than 1.1 even at its minimum value. Hence, its reflection will not be zero at any depth of the dimple and, overall, the ND metasurface is expected to result in a reflection value higher than that of the NB metasurface according to Fresnel’s equations.

Figure 3(c) depicts the reflectance for all the metasurfaces determined using Fresnel’s equations40 at normal incidence considering the incident medium to be air with a refractive index of 1, and the second medium as a metasurface which has a gradient index profile within its thickness according to Eq. 2. The calculations were performed by considering the metasurface as a stack of multiple layers, with each layer having the thickness of 1 nm and with the refractive index of the layer varying as shown in Fig. 3(b) with its value ranging from 1 to 1.45. The reflection coefficient was calculated for each layer using Fresnel’s equation assuming equal mixture of TE and TM polarization at normal incidence. As light travels through the thickness of the metasurface, the phase varies depending on the optical path in that layer and the wavelength of the incident light. The over-all reflectance of the metasurface is then calculated by appropriately combining the reflection coefficient of each layer along with the phase change in that layer and squaring the value. The reflectance is calculated for the wavelength range of 400 nm to 2000 nm, thus yielding the reflection spectrum. Along with the metasurfaces, the reflection spectra of glass and flat PDMS were also calculated with constant refractive indices of 1.5 (black dashed line) and 1.45 (green dotted line) respectively for the same wavelength range and shown in Fig. 3(c). The reflectance is maximum for glass which is 4%, while flat PDMS has a reflectance of 3.3% because PDMS has a lower refractive index than glass. For nanopatterned metasurfaces, the reflectance is further reduced as the effective refractive index is lower in them.

Among the metasurfaces, the ND metasurface with the smaller depth (134.4 nm) has higher reflectance, and the lowest reflectance is reached for the NB metasurface with the smaller pattern height (72.1 nm). This ordering among the four metasurfaces matches the variation shown in the measured reflectance data using unpolarized light (in Fig. 2(a)). It may be noted that the NB metasurface with a lesser height of 72.1 nm has the lowest effective refractive index among all the metasurfaces in Fig. 3 (b), and thus has the lowest reflectance in Fig. 3(c). For ND metasurface, the surface with larger pattern depth achieves lower reflectance since its effective refractive index is lower than that of the other ND metasurface with a smaller pattern depth of 134.4 nm.

In Fig. 3(c), the reflection spectrum for ND metasurfaces calculated using the EMT method assuming an ideal shape for the patterns shows a rapid rise in reflectance for wavelengths above 800 nm which was not seen in the measurements (Fig. 2(a)). Therefore, a refinement in the calculation of effective index is necessary. For a more realistic approach, the fill fraction of the metasurfaces was determined by following a method known as Minkowski measures (MK), where the real surface coverage of the patterns was extracted by using the 2D AFM image of the metasurface42. In this calculation, the surface coverage was determined by separating the information from the AFM pictures of each sample into high and low intensity levels since these metasurfaces contain air and PDMS, both of which have different phases derived from different materials. The relative areas of high intensity for the ND metasurface and low intensity for the NB metasurface were then determined and normalized to the overall image area as a function of intensity levels in z dimension. Then it was converted as a function of pattern depth or height depending on the value obtained from AFM analysis. In the next step, these values were inserted in Eq. 2 to calculate the effective refractive index as a function of depth and height. The variation of \(\:{n}_{eff}\) as a function of pattern depth and height calculated from MK analysis is shown in Fig. 3(d). The \(\:{n}_{eff}\:\)is lowest for the NB metasurface with a height of 72.1 nm, while the ND metasurface with a depth of 134.4 nm has the highest value of \(\:{n}_{eff}\), as predicted by our calculation using ideal shape (Fig. 3(c)). The variation of \(\:{n}_{eff}\) in MK method is not monotonic as in the case of the ideal pattern shape in Fig. 3(b). After determining the \(\:{n}_{eff}\) from the MK analysis, the reflectance for all the metasurfaces was determined using the same approach described above and is shown in Fig. 3(e). The trend is matched much better with the measured data shown in Fig. 2(a) (the relevant data is also shown in the inset of Fig. 3(e)), both quantitatively as well as over the entire wavelength range. The ND metasurface with pattern depth of 134.4 nm has the highest reflectance while the NB metasurface with pattern height 72.1 nm has the lowest reflectance. It is clear that the trend of \(\:{n}_{eff}\) variation with pattern depth / height is slightly different in Fig. 3(b) and Fig. 3(d), which makes the trend in reflection spectrum also to be different in Fig. 3(c, e), emphasizing the need to model the pattern shape precisely in these nanostructured metasurfaces. Only the patterned area of the metasurface was accounted in this computation, and it demonstrates the same trend as the experimental result. The PDMS thickness that remained unpatterned beneath the patterns was considered in this calculation as a bulk medium of index 1.45. Despite the fact that measurement was done at 10° angle of incidence and calculation is at 0°, the values obtained in Fig. 2(a) and 3(e) are comparable, as the angle-dependence of reflectance at smaller angles is negligible in Fresnel’s equations.

The samples made in this work had different values of pattern height and pattern depth, and were helpful in understanding the dependence of reflectance on those values. The two values of pattern depth of the ND metasurfaces were significantly different, but very large variation in pattern heights was not available for NB metasurfaces. As both the measured and calculated data showed that NB metasurfaces with smaller pattern heights are suitable for better antireflective nature, we calculated the specular reflection spectra of ND and NB metasurfaces with the large and equal pattern depth and height of 248.6 nm, and having the same pitch of 730 nm, using the wave optics module of COMSOL version 6 which is based on finite element method (FEM) technique. For complete analysis of the metasurfaces, the reflection from the unpatterned portion of PDMS is also included in the calculation by assuming a finite thickness of the material, along with the shape of the pattern and size effects arising from the pitch using COMSOL Multiphysics software. The shape of the individual pattern was assumed to be a part of a hemisphere for both ND and NB metasurfaces. Apart from the metasurfaces, reflection spectra of glass and flat PDMS are also calculated for reference. As our fabricated metasurfaces had ND and NB arrays arranged in a regular hexagonal pattern on thin PDMS film, we used a cuboid as our unit cell as shown in Fig. 3(a), with the metasurface layer in the x-y plane and the depth or height of the metasurface oriented along the z axis. For our metasurfaces, the periodicity along x axis differs than that along the y axis due to the triangular lattice. Floquet periodic boundary condition was applied along x and y directions while perfectly matched layer was applied along z axis to truncate the domain. The scattering boundary condition was also applied on the top and bottom surface of the unit cell to eliminate the unnecessary reflections. In our calculations, when the electric field of the incident light is along the y axis, it is considered as TM polarization, and when it is along the x axis, it is considered as TE polarization. For calculating the specular reflection, unpolarized light with equal contributions of TE and TM was assumed to be incident from air (along the -z axis) at normal incidence.

Figure 3(f) shows the reflection spectra calculated using COMSOL for glass, flat PDMS, ND metasurface with pitch 730 nm and depth 248.6 nm (parameters derived from AFM image analysis of our sample ND 248.6 nm), and NB metasurface with the same pitch as ND metasurface and pattern height 248.6 nm, in the wavelength range of 400–2000 nm. The refractive indices of PDMS and glass were considered as 1.45 and 1.5 respectively. The oscillations seen in the spectra are due to Fabry-Perot type of reflections in the small thickness of the samples. Glass surface has the maximum reflectance (~ 4.5%), which decreases when flat PDMS is present on it. The numerical value differs from the experimental observation shown in Fig. 2(a) because the calculation was performed at 0° angle of incidence while the experiment was performed at near normal (10°) incidence, and also because this calculation does not include the reflection from the bottom surface of glass/PDMS. The reflectance was further reduced when metasurfaces were considered on the glass substrate. In Fig. 3(f), the NB metasurface has lower reflectance than ND metasurface. At a few wavelengths, the reflectance is slightly higher for NB metasurface due to the oscillatory nature of the spectrum.

It is to be mentioned that in our fabrication method, the NB metasurface is fabricated using ND metasurface as master. Therefore, the overall thickness of the sample (which includes the patterned thickness as well as the unpatterned material below) for NB metasurface is lesser than that of the ND metasurface. To account for this, the thickness of the unpatterned portion of PDMS for ND metasurface is considered as 500 nm in the COMSOL calculation, while it is considered as 300 nm for NB metasurface. The calculation comparing identical pattern parameters of ND and NB metasurfaces indicates that the complementary shapes of the pattern with identical pitch and pattern feature size on the metasurface have different effect in reducing the reflectance in the chosen range of operating wavelength, even when the depth / height of the pattern is large. In addition, the total transmission for each sample was computed (not shown here), and it was found that it increases from that of glass when flat PDMS was kept on the glass slide, and it increased further when metasurfaces covered the glass slide. Our earlier work in reflection and transmission haze on these samples confirmed this in experiments38. It implies that these metasurfaces can improve solar cell efficiency by minimizing Fresnel reflection loss due to specular reflection, even while boosting total light transmission into the devices.

Even though the simulation and experiment used equal mixture of TE and TM polarization for incident light, some minor variations are be seen in the spectra. In Fig. 3(f), a sharp reduction in reflectance is observed between 600 nm and 700 nm. This is because the diffractive nature of the metasurface (for wavelengths below the pitch of the metasurface) switches to non-diffractive nature at longer wavelengths. This distinct feature is absent in the experimental result in Fig. 2(a). It is because the definition of TE and TM polarization for the simulation does not exactly match with the TE/TM polarizations in the measurement condition, as the hexagonal pattern is not visible to the naked eye. Therefore, slight difference in the reflectance value is also observed for the metasurfaces. As the cases of Fresnel reflection calculated using the graded index profile (obtained using fill factor from EMT) and FEM calculations of reflectance of metasurfaces using COMSOL used ideal shape of the patterns, these two cases show an increase in reflectance in NIR range. The reflection spectrum calculated using the MK method matches better with the experiment as it takes the more precise shape of the patterns from the AFM images.

Contact angle and self-cleaning nature of metasurface

Patterned surfaces are often chosen as self-cleaning surfaces for some particular outdoor applications, such as solar cells. Dust particles or stagnant rain water or any other contaminants on the cover glass of the encapsulated solar cells can impair the efficiency of the device. Therefore, the wettability of the metasurfaces is also studied by measuring the contact angle (CA) for water. CA for water was measured on various surfaces using a goniometer (Kruss, Drop Shape Anaylzer 25) and 5 µl volume of water was used for each sample at three different tilt angles. Figure 4(a) and (b) show 3D views of AFM images of ND and NB metasurfaces with average depth of 248.6 nm and average height of 72.1 nm, respectively. Figure 4(c-e) show the photographs of 5 µl water droplet on the sample shown in Fig. 4(a) at 0°, 10° and 15° tilt angles respectively, while Fig. 4(f-h) show for the sample of Fig. 4(b) at the same 3 angles. The CA at 0° tilt angle for the ND metasurface is approximately 135°, while the CA for the NB metasurface for the same tilt angle is approximately 126°. These surfaces are characterized as hydrophobic because their CA values exceed 90°, whereas the CA of a clean glass slide is less than 90° (~ 50°), making it a hydrophilic surface.

Verification of anti-wetting properties. AFM images in 3D view of (a) ND 248.6 nm and (b) NB 72.1 nm. Images of a water droplet on sample shown in (a) at (c) 0° (d) 10° (e) 15° tilt angles. Images of a water droplet on sample shown in (b) at (f) 0° (g) 10° (h) 15° tilt angles. (i) Self-cleaning behaviour of the metasurface samples is shown with the help of colored powder dissolved in water present on the surface, and its removal by tilting the surface.

In addition, the difference between the front contact angle (FCA) and the back contact angle (BCA) as marked in Fig. 4 (d) has to be small for a surface to be hydrophobic when the surfaces are tilted43. The details of the CA values for various samples at different tilt angles are given in Table-1, where it can be seen that the CA for a cleaned glass slide is < 90° implying the hydrophilic nature of the glass slide, and all the PDMS samples have CA > 90°, implying hydrophobic nature; in addition, patterning boosts the hydrophobicity even further. According to Cassie-Baxter’s theory19, patterning on a PDMS surface increases surface roughness, which effectively expands the interfacial area between the water drop and the PDMS. This, in turn, increases the angle between the water drop and the surface, making the surface more hydrophobic. It is to be mentioned that the error in the estimation of CA for all the samples is lesser than 4°. Furthermore, the difference between the FCA and BCA at tilted angles is greater for the glass slide; this decreases for the flat PDMS sample and decreases even further for the metasurfaces.

Table 1 shows that all the metasurfaces have CA > 123o. Moreover, ND metasurface with a pattern depth of 248.6 nm has the highest values in comparison to the other metasurfaces. One may note that the depth of the pattern in that ND metasurface is much larger than the height of the pattern in the two NB metasurfaces. Thus, it can be concluded that, while nanodimple patterns on the surface need larger depths to reach a certain level of hydrophobicity, nanobump patterns on the surfaces are effective enough to do so even with shallower pattern heights. Even though the CA obtained in our work is substantially lower than some of the earlier reports (CA ~ 150°)20,44,45, the fabrication of surfaces in those reports was done either by using costly equipment to texture the surfaces, or by involving multiple steps in fabrication, or an expensive master mould was used to take the replica on the PDMS surface. Comparatively, our fabrication technique involves fewer processes and much more economical fabrication of the master mould for replicating the surfaces.

In Table 1, it is seen that the CA differences are smaller for both types of patterns on the metasurfaces implying that these surfaces are more hydrophobic. Therefore, water drops will easily roll-off from the surface removing the contaminations present on the surface. Figure 4 (i) shows this self-cleaning property of the surfaces. To investigate the self-cleaning property of the metasurfaces, orange coloured sodium dichromate powder is kept on the samples as shown in the first column of Fig. 4(i). ND metasurface with pattern depth of 248.6 nm and NB metasurface with pattern height of 72.1 nm were chosen for this study because these two metasurfaces show lesser reflectance in comparison to the other metasurfaces of similar pattern shape. Clean glass slide and flat PDMS are also studied as reference samples. In Fig. 4(i), the first row displays photos of planar glass, whereas the second, third and fourth rows display photographs of flat PDMS, ND and NB surfaces, respectively. The first column in each case shows a picture of the sample before water was dripped on the powder. The second, third and fourth columns show the picture of the samples when 5, 25 and 50 drops of water were dripped on the samples at 0° tilt angle. Water droplets are seen to spread out on the glass slide, but not on the PDMS samples; instead, they take on a more spherical form on the metasurfaces than they did on the flat PDMS case. After dripping 50 water droplets on the samples while they were kept horizontally as shown in the fifth column of Fig. 4(i), the samples were tilted at 10⁰ using a homemade setup. Once they were tilted it is seen that water did not roll off the glass sample but slightly rolled off the flat PDMS. In the case of metasurfaces, the drops rolled off and reached the edge of the samples. At this point, 25 drops of water were again dripped on the samples, and as seen in the last column of Fig. 4(i), the surfaces of the ND and NB samples are nearly clean with only a few drops present at the edges. The glass substrate is not clean at all, and the water drop remains on the surface of the flat PDMS. This can be explained from the values of CA difference as shown in Table-1. Though the CA difference for flat PDMS is smaller than that of glass, it is slightly higher than that of the metasurfaces. Therefore, water drop remained on the flat PDMS surface as shown in Fig. 4(i). This demonstrates the self-cleaning property of the metasurfaces and the ease of cleaning them with water if required. They can be employed to protect any smooth hydrophilic surface present outdoors, such as solar panels, from damage due to dust or any other fouling in the external environment.

Table 2 shows the comparison between our work with the relevant earlier work. All these reports have the patterns on PDMS layer and are made by soft lithography technique, and hence this comparison is useful. In our work, we used a two-step lithography process for fabricating metasurfaces of various shapes with opposite curvature using a relatively inexpensive master 3D-PhC that can be easily fabricated without the use of complex equipment. Table 2 shows that the metasurfaces were tested over the widest wavelength range in our work, and the reflectance was less than 3% for the ND metasurface and less than 2% for the NB metasurface.

Though the two-step lithography technique was followed in some of the earlier reports as well, our work is unique as both the negative and positive replicas were taken on PDMS substrates, and therefore both the surfaces act as ARS. We establish that nanobump patterns can reduce reflection more efficiently than nanodimple patterns with significantly shallower patterns. Apart from fabrication and optical characterization of the antireflective nature of the metasurfaces, our work analyses the reflection spectrum using effective index calculated using the ideal and real pattern shapes. Simulated results from COMSOL aid further in understanding the significance of deep patterns and the spectral dependence of their reflection spectrum. In contrast to the recently reported hybrid structures46 that combine a few layers of antireflection coating with patterned top surfaces, the most lucrative feature of the single layer polymeric dielectric metasurfaces discussed here is their ability to be produced cost-effectively from economical master without the need for a complex fabrication method. Cost-effective soft lithography technique provides a large-scale fabrication platform47 which makes it more reliable for practical applications. In addition, there is a significant amount of work that is being pursued towards addressing the challenges in commercializing the metasurfaces, as well as in integrating them with device-level architectures for a larger impact48,49.

Conclusion

In this work, we have fabricated metasurfaces with complementary shapes of the individual patterns, having comparable pitch size, using two-step soft lithography technique. All the metasurfaces used here were replicated from the same 3D colloidal PhC, which was fabricated via a very simple and reliable self-assembly technique. Using the low-cost master for creating the surfaces makes it a more economical technique. In the first step of replication, the nanodimple metasurface was fabricated while in the next step of fabrication, the nanobump metasurface was fabricated. In both the replication processes, the replica was taken on PDMS substrate. Therefore, two different types of antireflective metasurfaces were fabricated using a single re-usable master template. Further, our fabrication technique is solution-based and therefore it is versatile enough to fabricate patterns with different feature sizes from the same master. From structural characterization, the feature sizes are obtained as well as the periodic nature of the samples is confirmed. It has been observed that these metasurfaces act as ARS for a very wide range of incidence angles as well as for a broad range of operating wavelengths. The reflectance of glass is reduced by ~ 67.5% at the wavelength of 400–800 nm with nanodimple metasurface with a pattern depth of 248.6 nm, while it is reduced by 80% throughout the wavelength range of 400 nm to 800 nm with nanobump metasurface with a pattern height of 72.1 nm, for near normal incidence. The depth-dependent fill fraction of PDMS and air in the metasurfaces, which results from the specific shape of the patterns, causes the variation in performance. The numerical calculation shows that the nanobump metasurface has lesser effective refractive index variation within the thickness of the layer and therefore has lower reflectance value in contrast to nanodimple metasurface. Further, the simulation results show that the reduction in specular transmission allows light to transmit through these surfaces into non-specular directions which eventually enhances the total transmission through the metasurfaces. Thus, by increasing the overall amount of light transmitted into the device and decreasing the Fresnel reflection loss, these metasurfaces can improve the efficiency of devices such as the solar cells. In addition, the contact angle measurement at both the normal angle and tilted angles shows that these metasurfaces are hydrophobic in nature which makes them resistant to contamination which is a specific advantage required for devices deployed outdoors. These affordable ARS possess multi-functional utility since they possess wide-angle minimisation of reflection loss over the entire spectral range from VIS to NIR, and self-cleaning capabilities that can prevent outdoor devices from performance degradation.

Data availability

All data needed to evaluate the conclusions in the paper are present in the main text.

References

Clapham, P. B. & Hutley, M. C. Reduction of lens reflexion by the Moth Eye principle. Nature 244, 281–282 (1973).

Han, Z. W. et al. Antireflective surface inspired from biology: a review. Biosurface Biotribology. 2, 137–150 (2016).

George, L., Vijaya, R. & Sumedha & Improving antireflection in near-infrared wavelength range by double-sided planar coating on common substrates. Indian J. Phys. 98, 733–740 (2024).

Aiken, D. J. High performance anti-reflection coatings for broadband multi-junction solar cells. Sol. Energy Mater. Sol. Cells. 64, 393–404 (2000).

Leem, J. W., Guan, X. Y., Choi, M. & Yu, J. S. Broadband and omnidirectional highly-transparent coverglasses coated with biomimetic moth-eye nanopatterned polymer films for solar photovoltaic system applications. Sol. Energy Mater. Sol. Cells. 134, 45–53 (2015).

Kim, J. H., Do, L. M., Choi, J. H., Park, J. & Lee, H. Enhancement of outcoupling efficiency of organic light-emitting diodes using a planarized moth-eye structure on glass substrate. Opt. Lett. 38, 3773–3775 (2013).

Lee, J. et al. Novel design procedure of broad-band multilayer antireflection coatings for optical and optoelectronic devices. J. Lightwave Technol. 16, 884–891 (1998).

Raut, H. K., Ganesh, V. A., Nair, A. S. & Ramakrishna, S. Anti-reflective coatings: a critical, in-depth review. Energy Environ. Sci. 4, 3779–3804 (2011).

Macleod, H. A. Thin-film Optical Filters. 2nd edn (McGraw-Hill, 1989).

Yang, S. M., Hsieh, Y. C. & Jeng, C. A. Optimal design of antireflection coating and experimental verification by plasma enhanced chemical vapor deposition in small displays. J. Vacuum Sci. Technol. A. 27, 336–341 (2009).

Kadakia, N., Naczas, S., Bakhru, H. & Huang, M. Fabrication of surface textures by ion implantation for antireflection of silicon crystals. Appl. Phys. Lett. 97, 191912 (2010).

Leem, J. W. & Yu, J. S. Artificial inverted compound eye structured polymer films with light-harvesting and self-cleaning functions for encapsulated III–V solar cell applications. RSC Adv. 5, 60804–60813 (2015).

Oh, S. S., Choi, C. G. & Kim, Y. S. Fabrication of micro-lens arrays with moth-eye antireflective nanostructures using thermal imprinting process. Microelectron. Eng. 87, 2328–2331 (2010).

Chen, Q. et al. Broadband moth-eye antireflection coatings fabricated by low-cost nanoimprinting. Appl. Phys. Lett. 94, 263118 (2009).

Ji, S., Song, K., Nguyen, T. B., Kim, N. & Lim, H. Optimal moth eye nanostructure array on transparent glass towards broadband antireflection. ACS Appl. Mater. Interfaces. 5, 10731–10737 (2013).

Leem, J. W. et al. Efficiency enhancement of organic solar cells using hydrophobic antireflective inverted moth-eye nanopatterned PDMS films. Adv. Energy Mater. 4, 1301315 (2014).

Choi, M., Leem, J. W. & Yu, J. S. Antireflective gradient-refractive-index material-distributed microstructures with high haze and superhydrophilicity for silicon-based optoelectronic applications. RSC Adv. 5, 25616–25624 (2015).

Leem, J. W., Lee, S. H., Guan, X. Y. & Yu, J. S. Inverted tetrahedron-pyramidal micropatterned polymer films for boosting light output power in flip-chip light-emitting diodes. Opt. Express. 23, 9612–9617 (2015).

Cassie, A. B. D. & Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 40, 546–551 (1944).

Tserepi, A. D., Vlachopoulou, M. E. & Gogolides, E. Nanotexturing of poly (dimethylsiloxane) in plasmas for creating robust super-hydrophobic surfaces. Nanotechnology 17, 3977 (2006).

Xie, G. et al. The fabrication of subwavelength anti-reflective nanostructures using a bio-template. Nanotechnology 19, 095605 (2008).

Haldar, A., Reddy, M. S. & Vijaya, R. Enhancement of light collection through flexible polymeric films patterned using self-assembled photonic crystals. J. Phys. D. 48, 265103 (2015).

Miller, D. C. et al. Durability of polymeric encapsulation materials in a PMMA/glass concentrator photovoltaic system. Prog. Photovoltaics Res. Appl. 24, 1385–1409 (2016).

Forcade, G. P. et al. Microstructured antireflective encapsulant on concentrator solar cells. Progress Photovoltaics Res. Appl. 30, 132–140 (2022).

Bindra, H. S., Kumar, A. K. & Nayak, R. Optical properties of a biomimetically prepared hierarchical structured polydimethyl siloxane template for potential application in anti-reflection and photovoltaic encapsulation. Mater. Res. Express. 4, 055501 (2017).

Kim, M. C., Jang, S., Choi, J., Kang, S. M. & Choi, M. Moth-eye structured polydimethylsiloxane films for high-efficiency perovskite solar cells. Nano-micro Lett. 11, 1–10 (2019).

Lötters, J. C., Olthuis, W., Veltink, P. H. & Bergveld, P. The mechanical properties of the rubber elastic polymer polydimethylsiloxane for sensor applications. J. Micromech. Microeng. 7, 145 (1997).

Kuo, S. Y. et al. Flexible-textured polydimethylsiloxane antireflection structure for enhancing omnidirectional photovoltaic performance of Cu(in,Ga)Se2 solar cells. Opt. Express. 22, 2860–2867 (2014).

Galeotti, F., Trespidi, F., Timò, G. & Pasini, M. Broadband and crack-free antireflection coatings by self-assembled moth eye patterns. ACS Appl. Mater. Interfaces. 6, 5827–5834 (2014).

Haldar, A., Reddy, M. S. & Vijaya, R. Inexpensive graded-index antireflective surfaces for silicon-based optoelectronic devices. JOSA B. 33, 2331–2338 (2016).

Hashimoto, Y. & Yamamoto, T. Fabrication of an anti-reflective and super-hydrophobic structure by vacuum ultraviolet light-assisted bonding and nanoscale pattern transfer. Micromachines 9, 186 (2018).

Hashimoto, Y., Mogi, K. & Yamamoto, T. Vacuum ultraviolet light assisted bonding and nanoscale pattern transfer method for polydimethylsiloxane. Microelectron. Eng. 176, 116–120 (2017).

Liu, Y. et al. Integrated super-hydrophobic and antireflective PDMS bio-templated from nano-conical structures of cicada wings. RSC Adv. 6, 108974–108980 (2016).

Kwon, Y. W. et al. Flexible near-field nanopatterning with ultrathin, conformal phase masks on nonplanar substrates for biomimetic hierarchical photonic structures. ACS nano. 10, 4609–4617 (2016).

Zhang, B., Hendrickson, J., Nader, N., Chen, H. T. & Guo, J. Metasurface optical antireflection coating. Appl. Phys. Lett. 105, 24 (2014).

Monti, A., Alù, A., Toscano, A. & Bilotti, F. Metasurface-based anti-reflection coatings at optical frequencies. J. Opt. 20, 055001 (2018).

Yan, Q., Zhou, Z. & Zhao, X. S. Inward-Growing Self-Assembly of Colloidal Crystal Films on Horizontal Substrates. Langmuir 21, 3158–3164 (2005).

Maity, A., Biswas, V. & Vijaya, R. Control of visible-range transmission and reflection haze by varying pattern size, shape and depth in flexible metasurfaces. Front. Optoelectron. 17, 25 (2024).

Hassanin, H., Mohammadkhani, A. & Jiang, K. Fabrication of hybrid nanostructured arrays using a PDMS/PDMS replication process. Lab. Chip. 12, 4160–4167 (2012).

Griffiths, D. Introduction to Elementary Particles (Wiley, 2020).

Prajzler, V., Nekvindova, P., Spirkova, J. & Novotny, M. The evaluation of the refractive indices of bulk and thick polydimethylsiloxane and polydimethyl-diphenylsiloxane elastomers by the prism coupling technique. J. Mater. Sci.: Mater. Electron. 28, 7951–7961 (2017).

Salerno, M. & Banzato, M. Minkowski measures for image analysis in scanning probe microscopy. Microsc. Anal. 19, 13–15 (2005).

Hejazi, V. & Nosonovsky, M. Contact angle hysteresis in multiphase systems. Colloid Polym. Sci. 291, 329–338 (2013).

Park, Y. B., Im, H., Im, M. & Choi, Y. K. Self-cleaning effect of highly water-repellent microshell structures for solar cell applications. J. Mater. Chem. 21, 633–636 (2011).

Cho, W. K. & Choi, I. S. Fabrication of hairy polymeric films inspired by geckos: wetting and high adhesion properties. Adv. Funct. Mater. 18, 1089–1096 (2008).

Rombaut, J., Martínez, S., Matera, U. M., Mazumder, P. & Pruneri, V. Antireflective Multilayer Surface with Self-Cleaning Subwavelength structures. ACS Photonics. 8, 894–900 (2021).

Seong, J., Jeon, Y., Yang, Y., et al., Cost-effective and environmentally friendly mass manufacturing of optical metasurfaces towards practical applications and commercialization, International Journal of Precision Engineering and Manufacturing - Green Technology, 11, 685-706 (2024).

Yang, Y., Seong, J., Choi, M., et al., Integrated metasurfaces for re-envisioning a near-future disruptive optical platform, Light: Science & Applications, 12, 152 (2023).

Yang, Y., Lee, E., Park, Y., et al., The road to commercializing optical metasurfaces: current challenges and future directions, ACS Nano, 19, 3008-3018 (2025)

Acknowledgements

The authors acknowledge the permission granted for the use of DC sputtering facility of Magneto optical imaging Lab in the Department of Physics, the AFM facility at the Department of Sustainable Energy Engineering and Contact angle measurement facility at the Centre for Nanosciences, IIT Kanpur. VB acknowledges Dr. Sivasurender Chandran and Mr. Pankaj Kumar Mahawar for providing help to understand the Minkowski analysis done in this work.

Author information

Authors and Affiliations

Contributions

VB prepared the samples, conducted the simulations and the experiments. RV supervised the research. Both the authors analysed the data and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Biswas, V., Vijaya, R. Broadband and wide-angle antireflective metasurfaces with complementary patterns. Sci Rep 15, 6322 (2025). https://doi.org/10.1038/s41598-025-89481-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-89481-4