Abstract

Soil-rock mixture is a typical two-phase composite material. The physicomechanical properties and relative quantities of each component greatly influence the macroscopic mechanical properties of the soil-rock mixture. This study takes the macroscopic and mesoscopic coupling perspective and uses the discrete element direct shear test as the main method to comprehensively investigate the effects of rock content and rock particle size on the mechanical properties of the soil-rock mixture. The results show that the macroscopic shear strength of soil-rock mixture specimens increases with the increase of rock content. The initial packing state and compactness of specimens affect their shear dilation performance to some extent. The contact force chain distributions within specimens under different soil-rock combinations differ significantly. However, a very obvious force chain band is observed in the specimens at the end of the shearing (ranging from the upper left of the shearing box to its lower right). The contact force branch vectors within the force chain band are thick and dense, with obvious directionality (all from top left to bottom right). Under the same vertical load, the average coordination number of particles on the shear surface decreases with the increase of rock content. Within the same specimen, the average coordination number of particles on the shear surface increases with the increase of vertical load.

Similar content being viewed by others

Introduction

Soil-rock mixtures are widely distributed in the upper reaches of the Yangtze River, the Three Gorges Reservoir, the middle and upper reaches of the Yellow River, the southwest region, Guangdong, Fujian, Jiangsu, and Zhejiang in China1,2,3,4,5,6. With the recent large-scale construction of water conservancy, hydropower, and transportation projects in China, more and more geotechnical projects are inevitably conducted on sites with soil-rock mixtures7,8,9. Thus, properly handling and rationally using such materials become key issues requiring urgent solutions. However, such geotechnical mediums as soil-rock mixtures are not explicitly listed in the existing geotechnical engineering codes and manuals10. Medley11 defined soil-rock mixtures as a class of mixtures consisting of blocks embedded in fine-grained matrices and considered the study of such materials to be of important engineering significance, naming them bimrocks. According to the relative ratio of soil and rocks in such composite materials, You et al.12 believed that the rock content of soil-rock mixtures should be 10% to 90% and further subdivided them into rocky soil, mixed soil, and earthy rocks according to the rock content. On this basis, Xu et al.2,3 focused on the physicomechanical properties of soil-rock mixtures and defined them as extremely uneven loose geotechnical medium systems with certain rock contents formed since the Quaternary period composed of blocks with certain engineering scales and high strength, fine-grained soil, and pores.

The most intuitive way to study the mechanical properties of soil-rock mixtures is through physical model testing. However, relatively few specimens are involved in previously reported on-site and indoor physical tests on soil-rock mixtures due to objective factors such as large test instrument size and high research cost13,14,15,16,17,18. Rock content is an important factor affecting the mechanical properties of soil-rock mixtures, and its effects are mainly reflected in the stress–strain curve characteristics, shear strength, and failure modes and characteristics. Meanwhile, each mechanical property index shows a relatively complex nonlinear relationship with the rock content19,20. The soil-rock threshold is a key factor in determining the rock content. Many scholars chose 5 mm as the boundary to distinguish soil and rocks in physical tests, while some scholars believe this boundary is related to the specific specimen size in the physical test8. In addition, the problems of maximum block size and oversized block treatment must be solved when using remodeling materials for indoor physical tests8,9. The particle size composition and shape factors of the blocks also affect the strength parameters and volume change characteristics of the specimens to a certain extent21,22,23,24,25. Studies on the size effect of physical test specimens have shown that large particle size blocks in small-sized specimens more significantly increase the strength of the material. In the case of similar specimen particle size composition, the peak shear strength of the soil-rock mixture increases as the specimen size decreases, while the volume shrinkage decreases as the specimen size decreases8.

Given the complex influence of the intrinsic mesoscopic structures of soil-rock mixtures on their macroscopic mechanical properties and the limitations of existing test methods, numerical calculation methods for continuous medium represented by the finite element method (FEM) and finite difference method (FDM) have received attention and been applied to study the mechanical behavior of soil-rock mixtures26,27,28,29. Li et al.26 investigated the effects of different fabric characteristics of soil-rock mixture using plane strain models of FLAC3D. With comparison with CT images, cracks usually first appeared at the soil/gravel interfaces where the shear stress is prone to accumulate. Meng et al.27 developed a random generation method of RVE model for soil-rock mixtures in 2D FEM, and studied the influences of model size, rock aggregate orientation and fraction on the macroscopic elastic parameters of SRM. Brito et al.28 proposed a new constitutive model for soil-rockfill mixtures, which was able to reproduce reasonably well the response of SRM considering the intrinsic variability of the tested specimens. Zhao et al.29studied the stabilities of SRM slopes with different block size distribution and rock content by a plane strain model of FDM. However, simulation methods based on the continuous medium hypothesis prove difficult to consider the dynamic contact relationship of blocks caused by displacement, and the spatial grid dividing faces some difficulties. Compared with FEM, discrete element methods (DEM)30,31can better capture the bulk nature of the granule material and effectively simulate the interaction between blocks in the soil-rock mixture32,33,34,35,36,37,38,39. Masson et al.32 employed a 2D cylinder model of DEM for simulations of direct shear tests on loose and dense samples of a granular material. Ueda et al.33studied the effects of particle size ratio and volume fraction on shear strength of binary granular mixture with the 2D DEM and physical experiments. Considering that 2D particle sets can only expand in a plane, while collection of particles in actual space can expand in two directions orthogonal to the load, 3D scale virtual experiments were considered as the most appropriate way to reproduce the actual situation35,36,37,38,39. Lopez et al.35 investigated the effect of stress level on the resilient modulus for binary mixtures of elastic spheres under triaxial loading using the 3D DEM. Jin et al.36 analyzed the macroscopic mechanical properties and mesoscopic failure mechanism of cemented soil-rock mixture based on a series of large-scale triaxial tests and the 3D particle flow code (PFC3D). In their modeling, irregularly shaped rock blocks were depicted more finely by clumps made up of balls that may overlap to any extent. Yan et al.37discussed influences of the content, spatial distribution and shape of rocks on shear strength of rock-soil mixture materials through numerical direct shear tests with the 3D DEM. However, given practical problems of long time consumption and excessive influencing factors in 3D numerical simulation, 2D numerical computation remains an effective research method for systematic study of complex problems26,27,29,34,40.

Based on the above discussion, this study aimed to further understand gravel effects on the shear behaviors of soil-rock mixture considering rock content and rock particle size. The 2D DEM-based direct shear test was adopted, and the numerical specimens and calibration for their mesoscopic parameters were according to the indoor direct shear test results of Wei et al.7. The DEM models were used to study the shear deformation behaviors of soil-rock mixture in depth, and explore the effects of rock content and rock particle size on their macroscale and mesoscale responses.

Discrete Element Model

Contact in DEM

The linear contact stiffness model (normal) and the slip model (tangential) were selected as the mechanical models in the DEM-based direct shear test. For the disk-disk contact showed in Fig. 1(a), as the distance between centroids of two disks is less than the sum of their radii, a contact force \(F_{i}\) would occur between the entities.

Schematic diagram for contact in DEM5. (a) Disk-disk contact, (b) Disk-wall contact.

\(F_{i}\) can be resolved into normal and shear components with respect to the contact plane as:

The normal contact force is expressed by

where \(K^{n}\) is the normal stiffness at the contact; \(U^{n}\) is the relative contact displacement in the normal direction; and \(n_{i}\) denotes the unit normal that defines the contact plane.

The shear contact force is computed in an incremental fashion, and can be denoted as:

where \(k^{s}\) is the shear stiffness; and \(\Delta U_{i}^{s}\) denotes the shear component of the contact displacement increment occurring over a time-step of \(\Delta t\).

The contact is checked for slip conditions by calculating the maximum allowable shear contact force:

where \(\mu\) is the friction coefficient.

If \(F{}_{i}^{s}\) is larger than \(F{}_{\max }^{s}\), then slip is allowed to occur (during the next calculation cycle) by setting the magnitude of \(F{}_{i}^{s}\) equal to \(F{}_{\max }^{s}\):

Typical disk-wall contact is shown in Fig. 1(b). The procedure of wall contact is quite similar to the disk-disk contact procedure30,31.

Numerical specimens

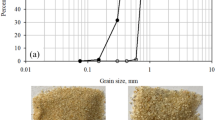

The numerical specimens and their mesoscopic parameters were based on the indoor direct shear test results of Wei et al.7 The strain-controlled loading method was adopted. The clearance geometry of the shearing box was 500 × 500 × 410 mm. The rock content of the physical specimen was 48.7%.

As shown in Fig. 2, the numerical specimen was 500 × 410 mm (length × height). The soil and rock particles were simplified into disks, and the soil-rock threshold was 5 mm. The soil particle size was 1 to 5 mm, and its mass proportion was 48.7%. The block size was 5 to 50 mm41. The porosity of the prepared specimen, abbreviated as n, was 0.110 (Fig. 2a).

The shearing box model consisted of 8 segments of wall units. Prior to shearing, a vertical load was applied to the particle set by the servo program. The strain-controlled shear loading was adopted, i.e., the upper shearing box moved at a constant rate while the lower shearing box was fixed. The shear velocity was (0.05 ~ 0.15) × 10−7 m/step.

Mesoscopic parameters

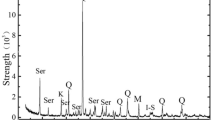

The back calculation method was used to determine the mesoscopic mechanical parameters. Figure 3 compares the shear stress-shearing displacement curves from numerical direct shear tests using the calculation parameters in Table 1 and the physical direct shear test results. Overall, the established DEM numerical model and the determined mesoscopic parameters are reasonable and can reflect the mechanical properties of the soil-rock mixture under different working conditions.

Effect of rock content (volume percentage)

Numerical models with different rock contents

The DEM numerical specimens of the soil-rock mixture with rock contents (volume percentage) of 0%, 25%, 50%, 75%, and 100% are shown in Fig. 4. The mechanical parameters are shown in Table 1. In order to improve the calculation efficiency, the soil particle size was 1 to 5 mm, and the blocks were simplified to combinations of three particle sizes of 35 mm, 15 mm, and 7.5 mm (the volume ratio was 1:1:2).

A brief introduction to the specimen preparation process is as follows: Firstly, randomly generate rock particles within the shearing box space; Secondly, fill soil particles with a porosity of 0.1 between rock particles; Next, load 1 g of gravity, and the DEM program will bounce apart the overlapping particles in the subsequent calculation process and deposit them under gravity conditions. When the maximum unbalanced force in the specimen is less than 10–5 N, the specimen is considered to have been generated (Fig. 4).

Shear strength (Shear stress corresponding to 50 mm shear displacement)

As shown in Fig. 5, all groups of soil-rock mixtures exhibit strain-hardening characteristics in the test, without exhibiting peak strength. With the same rock content, the shear strength of the specimens increases with the increase of the vertical load. Under the same vertical load, the elastic modulus of different specimens in the early stage of shearing gradually increases with the increase of rock content. With the vertical load kept constant, the shear stress-shearing displacement curves of specimens with rock contents between 0 and 50% show no significant change. When the rock content increases to 75% and 100%, respectively, the shear strength of the specimens increases significantly compared to those with medium and low rock contents, and the increments are larger with increased vertical load. Meanwhile, the test curves of specimens with high rock contents (75% and 100%) show more obvious fluctuations under low vertical loads (50 kPa and 100 kPa), similar to the curves obtained from the DEM simulation experiments of Yan et al.37.

Figure 6a shows that under the vertical load of 50 kPa, the shear strength increases slightly with the increase of the rock content. Under vertical loads between 100 and 200 kPa, the shear strength of low rock content (≤ 25%) specimens show no significant change with the rock content. The shear strength of mixtures with medium and high rock contents (25% to 75%) increases significantly with the increase of rock content. As the rock content increases from 75 to 100%, the shear strength of the specimens begins to show weakened or even negative increments. This is similar to the strength threshold law of soil-rock mixtures obtained by Dong42 in physical experiments, further illustrating the credibility of the model established in this article. Figure 6b represents the fitted linear regression lines of shear strength at different rock contents. Overall, the macroscopic shear strength of soil-rock mixture specimens increases with the increase of rock content. This is consistent with the results obtained by Wei et al.7.

Shear dilation

As shown in Fig. 7, the test results of specimens with different rock contents under the same vertical load are grouped into one group. Each group of data has the following characteristics: The degree of shear contraction of soil-rock mixtures with rock contents between 0 and 75% roughly decreases with the increasing rock content until shifting to shear dilation characteristics (specimens with a rock content of 75% show strong shear dilation under the 4 loading grades). However, the specimens’ volume change characteristics present more obvious shear contraction characteristics as the rock content reaches 100%. Meanwhile, more and more specimens in each group show shear contraction characteristics in the test with the increase of vertical load. The analysis shows that the stress required for the particles inside the specimens to dislocate and overturn is high under high vertical loads. In turn, the probability of particle overturn and dislocation decreases, rendering it more difficult to exhibit shear dilation. In each group, specimens with a 75% rock content show strong shear dilation, mainly due to the compact structure of the skeleton formed under the soil-rock proportion with this rock content and the high compactness of the mixture (Fig. 4d, n = 0.080). Although the specimens with a rock content of 100% are composed entirely of blocks, they show shear contraction characteristics in each group of tests. The analysis shows that with the specimens composed entirely of large particle size blocks, the pores between the blocks are large (Fig. 4e, n = 0.158) and not filled with fine grains, rendering it relatively easy to compress under load. In general, the initial packing state and compactness of the discrete element particles affect their shear dilation performance to some extent.

Contact force chains

Figure 8 shows the distribution of contact forces between particles in soil-rock mixture specimens with different rock contents at the end of the numerical direct shear test, where the confining pressure of the specimens is 150 kPa, and the shearing displacement is 90 mm.

Figure 4 shows that the mesoscopic structures inside the specimens have changed significantly with the increase in rock content. Upon completion of the direct shear test (Fig. 8), very obvious differences are observed in the magnitude and distribution of the force chains inside the specimens with different rock contents. However, the force chains are concentrated in the area from the upper left of the shearing box of the specimen to the lower right, which is the main load-bearing area of the specimens in the direct shear test. The contact forces between particles in other areas of the specimens are relatively small and relatively sparsely distributed. With the rock content of 0%, the particle size in the specimens is uniform, with more uniform contact force magnitude and distribution. With a rock content of 25%, the low-content blocks are suspended in the soil mass, with many soil grains filling between them, basically preventing them from contacting each other, and the external load is mainly borne by the soil mass. With the rock content of 50%, the increased blocks have a greater chance of contact, and some blocks contact to form a skeleton. At this time, the force chains thicken significantly and distribute unevenly, and the external load is jointly borne by the soil mass and the blocks. With a rock content of 75%, most of the blocks in the specimens have contacted each other, and soil grains fill the gaps between the blocks. At this time, the force chains between the grains are mainly between the blocks, with significantly uneven distribution, and the external load is mainly borne by the blocks. With a rock content of 100%, the specimens have no fine grains but a block skeleton structure, and the external load is completely borne by the blocks.

Therefore, as the rock content increases, the contact between the blocks inside the soil-rock mixture specimens gradually increases, and the specimens evolve from external load mainly borne by the soil mass to jointly borne by the soil mass and blocks and mainly borne by the blocks8,9. Meanwhile, the chance of contact between blocks also increases, and the force chains between particles thicken. Accordingly, the initial elastic modulus and strength of the specimens also change with the change of the main bearer of the external load.

Coordination number

Figure 9 depicts the variation of the average coordination number of the specimens (particles on the shear plane at the completion of shearing) with the rock content under various vertical loads. It can be observed that under the same vertical load, the average coordination number of particles on the shear surface decreases with the increase of rock content. In specimens with the same rock content, the average coordination number of particles on the shear surface increases with the increase of vertical load. The reason for this is as follows. With the increase of rock content, the composition of the soil-rock mixture gradually transitions from dense with suspended blocks, dense with block skeleton, to porous with block skeleton, and the main bearer of the external load inside the specimen changes accordingly (transforming from soil-soil, soil-rock, to rock-rock contacts). The increasing number of block skeleton structures increases the probability of void formation near the shear surface after shearing, and the average coordination number decreases accordingly. These findings correspond to the gradual increase in the non-uniformity of the contact force chain field in Fig. 8. Meanwhile, the larger confining pressure compresses the particles to greater compactness, and the enhanced contact and interlocking between the particles make it more difficult for relative displacement43.

Effect of rock particle size

Numerical test protocol

Based on the established soil-rock mixture numerical specimens in Section "Effect of rock content (volume percentage)", numerical simulation. tests under 6 working conditions were designed according to the relative volume ratios of rock particle. sizes of 7.5 mm, 15 mm, and 35 mm while keeping the rock content (volume percentage) of 50%. Detailed protocols are shown in Table 2. The numerical shear test specimens with different rock particle sizes are shown in Fig. 10 and 11. The soil particle grading and mesoscopic parameters of the soil-rock mixture are the same as in Section "Effect of rock content (volume percentage)".

s

Shear stress-shearing displacement curve

Single-particle size rocks

Figure 12shows that all curves obtained from the tests on single-rock size soil-rock mixtures exhibit strain-hardening characteristics regardless of the different rock sizes and the confining pressure. As the shear strain increases, the shear stress increases rapidly first. As the shearing displacement increases to about 10 mm, the shear stress increment with the increase in shear strain slows down until the end of the test. The curves have no obvious spikes. Under the same vertical load, the fluctuation magnitudes of the shear stress-shearing displacement curves are to some extent affected by the rock particle size, and the shear strength of the material with 7.5 mm rocks is slightly higher than those of the other two cases. The reason for this is analyzed. With a fixed rock content of 50%, the proportions of rocks near the shear surface of different specimens are roughly similar. However, the rocks with a particle size of 7.5 mm have a larger quantity and more uniform distribution, and the probability of soil-rock and rock-rock contact increases accordingly40. Meanwhile, the shear strength of specimens with the same soil-rock mixing proportion increases significantly with the increase of the vertical load, consistent with the situation in Section "Shear strength (Shear stress corresponding to 50mm shear displacement)".

Double particle size rocks

Figure 13 shows that the shear stress-shearing displacement development pattern of specimens with double-particle size rocks is basically the same as that of specimens with single-particle size rocks described above. Under the same vertical load, the fluctuation magnitudes of the shear stress-shearing displacement curves are to some extent affected by the rock particle size. The difference is that the shear strength of the material with 15–35 mm rocks is slightly higher than those of the other two cases. The reason for this is as follows. With a fixed rock content of 50%, the proportions of rocks near the shear surface of different specimens are roughly similar. However, the structure of the mixture formed by the combination of 15–35 mm rocks and soil grains is denser and uniform, (Fig. 11(c), n = 0.096), and the probability of soil-rock and rock-rock contact is correspondingly higher. Meanwhile, the shear strength of the specimens with the same soil-rock mixing proportion increases significantly with the increase of the vertical load.

Shear strength

Single-particle size rocks

Figure 14 shows the fitted linear regression lines of shear strength of the numerical specimens with rock particle sizes of 7.5 mm, 15 mm, and 35 mm respectively. It can be considered that in the case of single-particle size rocks, the macroscopic shear strength of specimens with the same rock content is to some extent affected by the particle size of the rocks, and the shear strength of the material with 7.5 mm rocks is slightly higher than those of the other two cases.

Double-particle size rocks

Figure 15 shows the fitted linear regression lines of shear strength of the numerical specimens with rock particle sizes of 7.5–15 mm, 7.5–35 mm, and 15–35 mm respectively. It can be concluded that in the case of double-particle size rocks, the macroscopic shear strength of specimens with the same rock content is to some extent affected by the particle size of the rocks, and the shear strength of the material with 15–35 mm rocks is slightly higher than those of the other two cases.

Shear dilation

In the case of single-particle size rocks (Fig. 16), the 7.5 mm and 15 mm single-particle size rock groups exhibit shear dilation characteristics under the low vertical load (50 kPa), while the 35 mm single-particle size rock group exhibits shear contraction. As the vertical load increases to 100 kPa, only the 7.5 mm single-particle size rock group shows shear dilation characteristics, while the other two groups show shear contraction characteristics. With the vertical load increased further, all single-particle size rock groups show shear contraction characteristics, and the shear contraction degree of the 7.5 mm single-particle size rock group is most sensitive to the confining pressure.

In the case of double-particle size rocks (Fig. 17), all three double-particle size rock groups exhibit obvious shear dilation characteristics under the low vertical load (50 kPa). As the vertical load increases to 100 kPa, only the 7.5–15 mm double-particle size rock group shows shear dilation characteristics, while the other two groups show shear contraction characteristics. With the vertical load increased further, all double-particle size rock groups show shear contraction characteristics, but the correlation between the shear contraction degrees of the three specimens and the vertical loads is not strong.

Contact force chain

Figure 18 shows the distribution and variation of the contact force between particles of the specimens during the numerical direct shear test under the 6 rock particle size combinations, where the vertical load is 150 kPa, and four states, namely, initial consolidation completion and shearing displacements of 30 mm, 60 mm, and 90 mm, are selected.

Contact force chain distribution and changes during shearing (unit: N). (a) Rock particle size of 7.5 mm, (b) Rock particle size of 15 mm, (c) Rock particle size of 35 mm, (d) Rock particle size combination of 7.5 to 15 mm, (e) Rock particle size combination of 7.5 to 35 mm, (f) Rock particle size combination of 15 to 35 mm.

It can be observed that although the force chain distribution in the specimens with different rock particle size combinations varies greatly, a very obvious force chain band is observed in the specimens at the end of the shearing (ranging from the upper left of the shearing box to its lower right). The contact force branch vectors within the force chain band are thick and dense, with obvious directionality (all from top left to bottom right). This is consistent with the results obtained by Ren et al.44. In the specific test process, the specimens only reach balance at the shearing displacement of 0 mm under vertical loading, where the force chain distribution is relatively uniform, and the branch vectors are mainly vertical, with no obvious force chain band. At the shearing displacement of 30 mm, the stress begins to transfer and concentrate on the upper left and lower right shearing plates, but the force chains inside the specimens still show no significant difference. At the shearing displacement of 60 mm, the force chain band becomes more obvious, and the contact force branch vectors thicken and show more obvious directional deflection. At the end of the test, the force chain band coverage reaches the maximum, the distribution of thick contact force chains is denser, and the direction deflection of the contact force branch vector field is more obvious.

Different rock particle size combinations are discussed. In the case of single-particle size rocks, theforce chain distribution becomes increasingly uneven as the rock particle size increases, and the main load bearer gradually shifts to rocks rather than the soil mass. Taking the rock particle size of 35 mm as an example, stress concentration is more likely to occur around the blocks with a large grain size. At this time, the local soil grains between the rocks mainly play the load transmission role, while the soil grains playing the filling role are assigned smaller loads. The stress concentration inside the force chain band is also more obvious than in specimens with the other two rock particle sizes. In the case of double-particle size rocks, the stress concentration inside the force chain band becomes increasingly obvious overall with the increase of the average rock particle size, and the force chain field distribution is closer to that of the 35 mm single-particle size rock specimens above.

Coordination number

Figure 19 shows the average coordination number variation trends (particles on the shear band) during the shearing of specimens with different rock size combinations under a vertical load of 150 kPa. Overall, the average coordination number of particles on the shear band of each group of specimens during the direct shear test shows certain fluctuations, but the maximum amplitude is within ± 0.15. In the single-particle size rock specimens, the average coordination number of the shear band increases with the increase of rock particle size. In the double-particle size rock specimens, the average coordination number of the shear band also roughly increases with the increase of the average rock particle size.

Figure 20 shows the relationship between the average coordination number of the shear band and the vertical load during the shearing process of the 15–35 mm double-particle size rock specimen group. It can be found that the average coordination number of the shear band increases with the increase of the vertical load, similar to the results reported by Luo et al.43. Under a constant vertical load, the average coordination number of the shear band increases first and then decreases during the shearing process, and this trend becomes more obvious with the increase of the vertical load.

Conclusions

This study uses a DEM-based direct shear test and takes the macroscopic and mesoscopic coupling perspective to discuss the sensitivity of the mechanical properties of soil-rock mixtures to the influence of key factors such as rock content and rock particle size. The following conclusions were reached.

-

(1)

With the same rock content, the shear strength of the specimens increases with the increase of the vertical load. Under the same vertical load, the elastic modulus of different specimens in the early stage of shearing gradually increases with the increase of rock content. On the whole, the macroscopic shear strength of soil-rock mixture specimens increases with the increase of rock content.

-

(2)

Keeping the rock content of 50%, in the case of single-particle size rocks or double-particle size rocks, the macroscopic shear strength of soil-rock mixtures is to some extent affected by the particle size of the rocks.

-

(3)

The initial packing state and compactness of soil-rock mixtures affect their shear dilation performance to some extent.

-

(4)

The contact force chain distributions within specimens under different soil-rock combinations differ significantly. However, a very obvious force chain band is observed in the specimens at the end of the shearing (ranging from the upper left of the shearing box to its lower right). The numerical test process shows that the specimens only reach balance under vertical load at the initial moment, where the contact force chain distribution is relatively uniform, and the branch vectors are mainly vertical, with no obvious force chain band. With the increase of the shearing displacement, the stress begins to transfer and concentrate on the upper left and lower right shearing plates, the force chain band becomes gradually obvious, and the contact force branch vectors become thick and dense, with more obvious directional deflection.

-

(5)

Under the same vertical load, the average coordination number of particles on the shear surface decreases with the increase of rock content. Within the same specimen, the average coordination number of particles on the shear surface increases with the increase of vertical load.

Data availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

References

Li, X., Liao, Q. L. & He, J. M. In-situ tests and a stochastic structural model of rock and soil aggregate in the three gorges reservoir area, China. Int. J. Rock Mech. Min. Sci. 41(S1), 702–707 (2004).

Xu, W. J., Xu, Q. & Hu, R. L. Study on the shear strength of soil-rock mixture by large scale direct shear test. Int. J. Rock Mech. Min. Sci. 48(8), 1235–1247 (2011).

Xu, W. J., Hu, R. L. & Tan, R. J. Some geomechanical properties of soil-rock mixtures in the Hutiao gorge area. China. Géotechnique. 57(3), 255–264 (2007).

Chen, X. B. Study of dilatancy effect of redstone coarse grained soil by large scale triaxial tests. Chin. J. Rock Mech. Eng. 29(S1), 3145–3149 (2010).

Zhang, H. Study on earthquake induced behaviors of slopes covered by deposits. Ph.D. Thesis, Southwest Jiaotong University, Chengdu (2011).

Zhang, M., Zhang, S. L., Shen, S. W. & Zhang, W. L. Study on shear failure and crack propagation characteristics of soil-rock mixture. Environ. Earth Sci. Res. J. 8(4), 153–158 (2021).

Wei, H. Z., Wang, R., Hu, M. J., Zhao, H. Y. & Xu, X. Y. Strength behaviour of gravelly soil with different coarse-grained contents in Jiangjiagou Ravine. Rock Soil Mech. 29(1), 48–51 (2008).

Zhang, H. Y. Research on the meso-structural mechanics and scale effect of soil-rock mixture. Ph.D. Thesis, Tsinghua University, Beijing (2016).

Gong, J. Study on the microscopic mechanical characteristic of soil-rock mixture. Ph.D. Thesis, Dalian University of Technology, Dalian (2017).

Compilation Committee of Geological engineering handbook. In Geological engineering handbook (5th ed) (China Architecture, Building Press, 2018).

Medley, E. W. The engineering characterization of melanges and similar block-in-matrix rocks (bimrocks). Ph.D. Thesis, University of California at Berkeley, Berkeley (1994).

You, X. H., He, G. & Li, X. Classification of earth-rock mixed construction proposal. J. Eng. Geol. 10(S), 448–452 (2002).

Zhang, Z. L., Xu, W. J., Xia, W. & Zhang, H. Y. Large-scale in-situ test for mechanical characterization of soil-rock mixture used in an embankment dam. Int. J. Rock Mech. Min. Sci. 86, 317–322 (2016).

Zhang, Z. P. et al. A non-linear ultimate strength criterion for soil-rock mixture based on rock block proportion. Chin. J. Rock Mech. Eng. 40(8), 1672–1686 (2021).

Vallejo, L. E. & Lobo, G. S. The elastic moduli of clays with dispersed oversized particles. Eng. Geol. 78, 163–171 (2005).

Sonmez, H., Gokceoglu, C., Medley, E. W., Tuncay, E. & Nefeslioglu, H. A. Estimating the uniaxial compressive strength of a volcanic bimrock. Int. J. Rock Mech. Min. Sci. 43(4), 554–561 (2006).

Chandler, R. J. Inclination of talus, arctic talus terraces, and other slopes composed of granular materials. J. Geol. 81(1), 1–14 (1973).

Vallejo, L. E. Interpretation of the limits in shear strength in binary granular mixtures. Can. Geotech. J. 38(5), 1097–1104 (2001).

Chang, W. J. & Phantachang, T. Effects of gravel content on shear resistance of gravelly soils. Eng. Geol. 207, 78–90 (2016).

Yagiz, S. Brief note on the influence of shape and percentage of gravel on the shear strength of sand and gravel mixtures. Bull. Eng. Geol. Environ. 60, 321–323 (2001).

Guo, Z. G., Chen, X. L., Xu, Y. & Liu, H. F. Effect of granular shape on angle of internal friction of binary granular system. Fuel. 150(15), 298–304 (2015).

Coli, N., Berry, P., Boldini, D. & Bruno, R. The contribution of geostatistics to the characterisation of some bimrock properties. Eng. Geol. 137–138, 53–63 (2012).

Li, Y. R. Effects of particle shape and size distribution on the shear strength behavior of composite soils. Bull. Eng. Geol. Environ. 72, 371–381 (2013).

Li, Y. R., Huang, R. Q., Chan, L. S. & Chen, J. Effects of particle shape on shear strength of clay-gravel mixture. KSCE J. Civil Eng. 17(4), 712–717 (2013).

Zhong, W. H. et al. Development of a preparation method of transparent soil-rock mixture for geotechnical laboratory modeling. Eng. Geol. 301, 106622. https://doi.org/10.1016/j.enggeo.2022.106622 (2022).

Li, C. S., Zhang, D., Du, S. S. & Shi, B. Computed tomography based numerical simulation for triaxial test of soil-rock mixture. Comput. Geotech. 73, 179–188 (2016).

Meng, Q. X., Wang, H. L., Xu, W. Y. & Cai, M. A numerical homogenization study of the elastic property of a soil-rock mixture using random mesostructure generation. Comput. Geotech. 98, 48–57 (2018).

Brito, A., Maranha, J. R. & Caldeira, L. M. M. S. A constitutive model for soil-rockfill mixtures. Comput. Geotech. 95, 46–56 (2018).

Zhao, L. H. et al. A new method for constructing finite difference model of soil-rock mixture slope and its stability analysis. Int. J. Rock Mech. Min. Sci. 138, 104605. https://doi.org/10.1016/j.ijrmms.2020.104605 (2021).

Itasca Consulting Group Inc. PFC2D (Particle Flow Code in 2 Dimensions) user’s manual, version 5.0. Itasca Consulting Group Inc., Minneapolis (2015).

Cundall, P. A. & Strack, O. D. L. A discrete numerical model for granular assemblies. Géotechnique. 29(1), 47–65 (1979).

Masson, S. & Martinez, J. Micromechanical analysis of the shear behavior of a granular material. J. Eng. Mech. 127(10), 1007–1016 (2001).

Ueda, T., Matsushima, T. & Yamada, Y. Effect of particle size ratio and volume fraction on shear strength of binary granular mixture. Granul. Matter. 13(6), 731–742 (2011).

Yao, Y. S., Li, J., Ni, J. J., Liang, C. H. & Zhang, A. S. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 141, 104476. https://doi.org/10.1016/j.compgeo.2021.104476 (2022).

Lopez, R. D. F., Ekblad, J. & Silfwerbrand, J. Resilient properties of binary granular mixtures: A numerical investigation. Comput. Geotech. 76, 222–233 (2016).

Jin, L., Zeng, Y. W., Xia, L. & Ye, Y. Experimental and numerical investigation of mechanical behaviors of cemented soil-rock mixture. Geotech. Geol. Eng. 35, 337–354 (2017).

Yan, Y., Zhao, J. F. & Ji, S. Y. Discrete element analysis of the influence of rock content and rock spatial distribution on shear strength of rock-soil mixtures. Eng. Mech. 34(6), 146–156 (2017).

Lopera Perez, J. C., Kwok, C. Y. & Senetakis, K. Effect of rubber size on the behaviour of sand-rubber mixtures: A numerical investigation. Comput. Geotech. 80(199), 214 (2016).

Asadi, M., Mahboubi, A. & Thoeni, K. Towards more realistic modelling of sand–rubber mixtures considering shape, deformability, and micro-mechanics. Can. Geotech. J. 60(2), 182–197. https://doi.org/10.1139/cgj-2021-0710 (2023).

Zhang, P. & Li, Q. Q. Evaluation of rock size on the mechanical behavior and deformation performance of soil-rock mixture: A meso-scale numerical and theoretical study. Arab. J. Geosci. 14, 1448. https://doi.org/10.1007/s12517-021-07854-1 (2021).

Wang, L. Macro-meso mechanical behavior of soil-rock mixture. M.Sc. Thesis, Southwest Jiaotong University, Chengdu (2022).

Dong, Y. Experimental study on intensity character of rock-soil aggregate mixture. Rock Soil. Mech. 28(6), 1269–1274 (2007).

Luo, J. et al. Study on shear characteristics of TBM excavated materials under different rock block proportions. J. Eng. Geol. https://doi.org/10.13544/j.cnki.jeg.2022-0697 (2023).

Ren, M. H., Zhao, G. S., Pu, H., Yin, Q. & Wang, T. Structural effects on shearing properties of loose cohesionless soil-rock mixture and development of strength model. Chin. J. Rock Mech. Eng. https://doi.org/10.13722/j.cnki.jrme.2023.0845 (2024).

Acknowledgements

This research was financially supported by the Sichuan Applied Foundation Project (No.2019YJ0667), and supported by Sichuan Science and Technology Program (No. 2024NSFSC0172).

Author information

Authors and Affiliations

Contributions

Hua Zhang: Conceptualization, Formal analysis, Writing-review & editing, Resources, Funding acquisitions, Supervision. Meng Lei: Visualization, Formal analysis, Methodology. Lei Wang: Data curation, Methodology, Writing-original draft. Mingming Cao: Investigation, Funding acquisition. Wanqing Huang: Methodology, Funding acquisition. Shihai Ding: Formal analysis, Data curation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, H., Lei, M., Wang, L. et al. Multiscale numerical investigation into the effects of rock content and rock particle size on the macroscopic and mesoscopic mechanical characteristics of soil rock mixture. Sci Rep 15, 7336 (2025). https://doi.org/10.1038/s41598-025-91543-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-91543-6