Abstract

Low-temperature and solar-thermal applications of a new thermal energy storage system (TESS) powered by phase change material (PCM) are examined in this work. At varying mass flow rates (0.0119 kg/s and 0.00277 kg/s) and heat transfer fluid (HTF) temperatures (75 °C and 85 °C), three distinct PCMs—paraffin wax, fatty acid, and a cascaded combination of both—had their charging and discharging properties studied. Evaluated across a 240-minute charging and discharging cycle were key performance parameters including energy efficiency, exergy efficiency, entransy analysis, and heat transfer efficacy. According to the results, higher HTF temperatures reduce exergy efficiency because to increased entropy formation even when they raise charging rate. Moreover, thermodynamic performance of the cascaded PCM system increased heat transfer efficiency by 100% and by 30% respectively. Moreover, charging and exergy efficiencies were realized as at 85.2% and 47.5% respectively. The liquid percentage of the PCM was found to be 0.85 under a mass flow rate of 0.0277 kg/s after 200 min of charging. These findings demonstrate the possibility of cascaded PCM-based TESS to optimize solar energy storage for usage requiring high efficiency and constant heat transfer.

Similar content being viewed by others

Introduction

General overview

Thermal energy storage (TES) refers to the short-term storage of thermal energy at either high or low temperatures. The concept of TES dates back to ancient times. It helps reduce the time or rate discrepancy between energy supply and energy storage. By increasing reliability and smoothing supply, energy storage enhances the performance of energy systems. For instance, storage improves the efficiency of power-generating plants by balancing the load, leading to cost savings and energy conservation. Some renewable energy sources can only produce energy intermittently. Although the sun is an abundant, safe, and clean energy source, its supply fluctuates due to daily and seasonal cycles, making it unpredictable and dispersed. Compared to traditional fossil fuel-based energy systems, such as coal- or oil-fired furnaces, solar energy has a lower flux density. However, both industrial and personal energy demands vary throughout the day and year, making solar energy storage essential. Alternatively, immediate utilization of solar energy is necessary. Currently, energy production from waterpower and fossil fuels is approximately 70 × 1012 kWh. However, the primary challenge in harnessing solar energy lies in its inefficient collection and storage1. One key feature of a storage system is its ability to retain energy for an acceptable duration with minimal losses. Converting solar energy into fuels such as hydrogen eliminates this time constraint. The TES systems lose energy, nevertheless, via conduction, convection, and radiation. The volumetric energy capacity—that is, the quantity of energy kept per unit volume—is another very vital characteristic. One wants a more compact storing method. Provided their mass-specific heat capacity is not negligible, denser materials occupy smaller volumes and provide greater energy capacity per unit volume. Space constraints for habitat and transportation also influence storage solutions. Current storage methods require substantial space, which may limit storage capacity. Additionally, cost plays a significant role in determining energy storage availability. However, the price of volumetric or floor space should be considered when determining the ideal storage size.

Related study

Combining conventional energy systems with renewable energy sources has attracted a lot of interest lately. This is especially pertinent in nations like India, where almost year-round sun radiation is accessible. One of the primary scientific challenges still remains effective use and storage of this plentiful energy source. Especially for solar-thermal uses, several initiatives have been undertaken to improve the efficiency and effectiveness of renewable energy sources1. Still, there are various difficulties include guaranteeing system lifetime, keeping efficiency under cover of clouds, and allowing midnight operation. TES systems store energy during non-operational and off-sunshine hours, therefore transforming energy storage. In several uses, including sun drying systems using latent and sensible heat storage2, desalination systems3, solar photovoltaic thermal systems4, and solar cookers5, TES systems have outperformed conventional alternatives. Development of energy storage devices is necessary for both system performance and energy economy to be enhanced.

Systems that store energy using latent heat absorb and release heat when the storage medium changes phases from a solid to a liquid. Over the past 20 years, research on latent heat-based TES systems using phase change materials (PCMs) has advanced quickly in comparison to sensible heat and thermochemical storage systems. PCMs provide two rather special benefits: low pressure and modest volume change during phase transitions6. Among the uses are residential heat pumps, batteries, photovoltaic cells, electronic components, thermal load management in solar thermal power plants, and improving of building energy efficiency7. Phase transitions from solid to gas or liquid to gas are usually impractical because to significant volume changes that complicate system design8. Consequently, the most often found materials are organic, inorganic, eutectic forms including fatty acids and paraffin wax9. As PCMs by themselves cannot be as effective heat exchangers, successful PCM-based TES deployment calls for a heat exchanger and a suitable heat transfer medium.

There are three primary methods for integrating PCMs into TES systems: using them as an independent heat gain unit, encapsulating them within a solar collector, or incorporating them into a water tank system. For instance, lauric acid has been used as a PCM in a shell-and-tube heat exchanger10. Studies indicate that integrating PCMs into collectors improves efficiency by 2–3%11. Experimental and numerical research has focused on enhancing TES system efficiency. To demonstrate TES systems’ superior heat-handling capabilities, researchers have embedded gradient porosity metal foam into PCM, reducing total melting time by 37.6% compared to systems without metal foam12. Comparatively to a single water tank layout, another research revealed that cascading PCMs with a water storage tank increased system efficiency by up to 30%13. Furthermore, excess energy from solar photovoltaic power plants has been effectively retained as thermal energy for domestic refrigeration14. Investigations have also explored the effects of porosity and particle diameter on the thermal behaviour of a three-PCM packed bed system. Furthermore, solvent-assisted emulsification has been used to develop novel PCMs, with performance comparisons against conventional PCMs15. Researchers have also conducted extensive studies on the thermophysical properties of TES systems for low- and medium-temperature applications (0–250 °C)16. Solar stills’ efficiency has been raised still more using TES systems17. Improving energy efficiency and integrating renewable energy sources across many uses depends critically on TES systems. Because of their high energy storage density and near-constant temperature functioning during phase transitions, latent heat storage systems using PCMs have drawn particular interest among TES technologies. Recent developments have expanded the field of PCM-based TES uses in many spheres.

PCMs are progressively included into building materials to control indoor temperatures, so lowering reliance on heating, ventilation, and air conditioning (HVAC) systems. Applications of PCM-Based Thermal Energy Storage Systems are observed in many other not limited but rather general ones. PCMs are used in solar power plants to save extra thermal energy at maximum sun. By using this stored energy during low sun irradiation, solar thermal systems’ general efficiency may be improved and a constant power source guaranteed. Waste heat produced by industries throughout different operations amounts very large. By means of PCM-based TES devices, this waste heat may be gathered and stored for later use in preheating materials or producing power, therefore enhancing process efficiency generally. The increasing heat generation resulting from the shrinking of electrical equipment may jeopardize lifespan and performance. Electronic components use PCMs to absorb and transmit heat, hence sustaining suitable working temperatures and raising device dependability. Medications and perishable goods have to be transported within certain temperature ranges. In cold chain logistics, PCM-based TES systems provide a constant way to regulate temperature that maintains product integrity all throughout transportation. In the automotive industry, PCMs assist to control thermal loads in a variety of parts, including passenger interiors and engine systems. Both passenger comfort and fuel efficiency are enhanced by this utilization. Thermal regulating capabilities of PCMs allow fabrics to be used in apparel that fits changing ambient temperatures, hence improving user comfort. PCMs are used in therapeutic treatments and medical equipment where exact temperature control is essential—including in organ transplant and thermal therapy. PCMs help to maintain ideal temperatures in greenhouses and storage facilities thereby improving agricultural yields and lowering losses after harvest. In desalination plants, thermal energy storage allows PCM integration to raise the water purifying process efficiency18.

Recent research aiming at increasing PCMs’ thermal conductivity will enable their operation in TES systems. Addition of nanoparticles, composite materials, and metal foams has addressed natural weak heat conductivity of conventional PCMs19. Moreover very promising in solar heat collecting technologies are the creation of nano-enhanced PCMs (NEPCMs), which boost thermal characteristics and energy storage capacity20. PCM-based TES systems improve energy economy and sustainability due to their versatility. PCMs are increasingly used in energy storage and temperature control systems as research and development increase their capacity.PCM-based TES systems’ versatility in a variety of applications shows their importance in sustainability and energy economy. PCMs are increasingly important in energy storage and temperature control systems as research and development increase their capacity.

Vision of the study

The study is pertinent to practical solar energy systems since it tackles particular issues including overnight energy storage and operation during cloud cover. The body of research mostly supports the design of a sustainable and effective thermal energy storage system for solar thermal uses. The present study aims to identify effective phase change materials under variable heat transfer fluid temperatures, taking into account mass flow rates in three distinct configurations. The study further examines imperative aspects of various solar thermal systems in the domain of solar energy applications.

The rest of the article is structured as follows: Section “Set-up and methodology”; Section “Result and discussion”; Section “Conclusion”; and Section “Future directions and managerial implications”.

Set-up and methodology

Materials selections

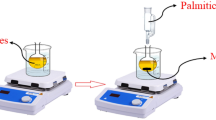

High latent heat of fusion and stable phase change behaviour are two well-known desirable thermal characteristics of paraffin wax and fatty acids. Their fit for TES uses comes from their effective absorption and release of heat. Furthermore, ensuring long-term dependability are both materials show low phase separation and degradation over long thermal cycles. The melting points of paraffin wax (55–57 °C) and fatty acids (65–67 °C) taken together create a cascade effect. This increases the general thermal storage efficiency by allowing a multi-stage heat absorption and release process, so improving energy consumption relative to a single PCM system.

Low heat conductivity is one of the key issues with TES systems; paraffin wax and fatty acid by themselves help to address this. Combining these two materials guarantees a more constant temperature distribution by absorbing and releasing heat more gradually, so lowering thermal stratification. Two rather reasonably priced PCMs are paraffin wax and fatty acids. For applications in large-scale energy storage, their low cost relative to inorganic PCMs such salt hydrates makes them appealing. As biodegradable and renewable, fatty acids also support environmental objectives. Low to medium temperature uses including industrial waste heat recovery, building heating, and solar-thermal storage find a balanced solution in paraffin wax mixed with fatty acids. Since it guarantees constant heat absorption and release, the designed melting process is quite helpful for systems needing continuous and steady thermal energy storage. Less research has examined the overall use of these PCMs than has looked at each one by itself. Our work closes that gap and significantly closes a research gap in the optimization of PCM-based TES devices by carefully analyzing their synergistic effects. Combining paraffin wax and fatty acid provides a fresh approach to increase the dependability and efficiency of TES systems, so making them more suitable for practical applications in renewable energy storage.

Maximizing thermal performance and enhancing the efficacy and usability of thermal energy storage (TES) systems by means of a range of phase change materials (PCMs) can Because of their unique thermal properties—which comprise varying melting temperatures, latent heat capacity, and thermal conductivities—some PCMs are suitable for specific uses. Organic PCMs (such fatty acids and paraffin wax) offer high latent heat storage, chemical stability, and non-corrosive properties. Their shortcomings are low heat conductivity and perhaps phase separation, though. Higher thermal conductivity and volumetric energy density inorganic PCMs—such as salt hydrates, metallic alloys—may cause problems including supercooling and phase separation. Heat transfer rates can be much improved by combining nano-enhanced PCMs (e.g., paraffin with carbon nanotubes). Greater mechanical stability and improved thermal cycling performance come from encapsulated PCMs. Better heat absorption and release over a larger temperature range is achieved by cascading several PCMs.

Experimental methodology

Like Fig. 1, the experiment used an in-house, lab-scale thermal energy storage system. Three horizontally spaced heat exchangers, each holding five kg of a different PCM—one with stearic acid, another with paraffin wax, and the third with a mix of both—made up it. The shell-and-tube heat exchangers were equipped with helical coils to facilitate heat transfer fluid (HTF) flow.

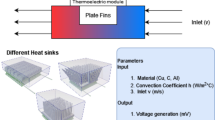

During the charging phase, tests were conducted under two conditions: (1) a constant mass flow rate with varying heat source temperatures (85 °C and 75 °C) and (2) a constant heat source temperature with different mass flow rates (0.0119 and 0.0277 kg/s). Under both charging and discharging, key parameters—including HTF inlet and outlet temperatures, PCM temperatures, ambient temperature, and cylinder surface temperature—were tracked. Evaluated also were energy input, thermal resistance, power loss, energy efficiency, and exergy-related measures. Figures 2 and 3 show respectively the schematic of the experimental setup and the arrangement of the cylinders with heaters. A systematic experimental procedure was carried out to evaluate the thermal performance of the phase change material (PCM)-based thermal energy storage (TES) system. The purpose of the experiment was to examine the charging and discharging properties of fatty acid, paraffin wax, and a cascaded mixture of the two under various mass flow rates and heat transfer fluid (HTF) temperatures.

The experimental setup consists of three shell-and-tube heat exchangers, each containing 5 kg of PCM. The system includes the following components:

-

Heat transfer fluid (HTF) system: A controlled water heating unit supplies HTF at two different inlet temperatures (75 °C and 85 °C) with variable flow rates (0.0119 kg/s and 0.0277 kg/s).

-

PCM containers: Stainless steel cylinders hold paraffin wax, fatty acid, and a cascaded PCM unit.

-

Instrumentation and sensors: RTD sensors monitor HTF inlet/outlet temperatures, PCM phase transition behavior, and ambient conditions.

-

Data acquisition system: Connected sensors continuously record real-time temperature profiles and liquid fraction data.

A regulated heating system preheated the HTF to the intended setpoint temperature. The heated fluid was run in contact with the PCM through the shell-and- tube heat exchanger. For 240 min overall, temperature data of the HTF inlet/outlet and PCM were recorded at intervals of five minutes. Temperature-based estimations helped one to observe and compute PCM’s liquid fraction. Mathematical formulations allowed one to ascertain heat transfer rates, energy stored, and exergy efficiency. Following the charging cycle, a cold fluid at room temperature replaced the HTF supply. Temperature profiles were noted at the same intervals as the PCM’s gradually released stored heat. Examining the phase change helped one to determine the effective use of latent heat storage. To evaluate PCM performance under discharging, exergy efficiency, efficacy, and heat loss were calculated. RTD sensors at several system sites continuously noted temperatures. Sensor calibration was completed before every experiment to help to lower systematic mistakes. We computed ± 0.5 °C as the temperature measuring uncertainty. Repeated experiments guaranteed consistency; averaging the data helped to reduce random errors.

Mathematical modelling

A detailed mathematical section is crucial to validate the findings and ensure the reliability of the study. This section provides the governing equations for heat transfer, energy balance, exergy efficiency, and thermal performance of the phase change materials (PCMs) used in the thermal energy storage (TES) system. The heat transfer process in PCM-based TES systems involves conduction, convection, and phase change mechanisms. The governing equation for transient heat conduction with phase change is given by Eq. (1)21,22:

where density is denoted with ρ is kg/m3, with thermal conductivity as k and heat transfer rate as Q.

Energy balance for PCM storage system

The energy stored in the PCM is expressed as by Eq. (2)21,22:

Equation (3) provides the heat that the PCM absorbs or releases21,22:

Exergy efficiency analysis

To find out how much useful energy is wasted and conserved in the system, energy analysis is crucial. Equation (4) provides the exergy efficiency (\({\eta}_{exergy}\))21,22:

The total exergy is calculated as per the Eq. (5)21,22:

where m is the mass of the PCM with specific heat is denoted with Cp.

Heat transfer effectiveness

Equation (6) provides the efficiency of the heat exchanger utilized to store PCM21,22:

Liquid fraction estimation

The fraction of PCM in the liquid phase (fl) is estimated using Eq. (7):

where H is the enthalpy in kJ/kg for liquid and solid phase.

The efficiency of charging period can be given by Eq. (8)

Accordingly, the efficiency of storing period and discharging period can be given by Eqs. (9–10) respectively.

To assess uncertainty in this experiment, the methodology proposed by Kline and McClintock23 is employed. If a parameter’s data is derived from certain measured quantities, the error in the measurement of said parameter (denoted as “y”) can be expressed as per Eq. (11).

where \(\delta x_{1} ,\delta x_{2} , \ldots \delta x_{n}\)are possible error in measurement of x1, x2, … xn, \(\delta y\) is known as absolute uncertainty and \(\frac{{\delta y}}{y}\) is known as relative uncertainty as per the Table 1. Thus, the total error margin for the experimental setup is approximately ± 3.4%, ensuring that the recorded values are within acceptable limits for scientific analysis.

The stainless-steel cylinders are used to store the PCMs and heat exchangers. Therefore, three cylinders are covered with polyurethane foam to prevent heat loss. During the charging process, the PCM absorbs heat from the heat transfer fluid (water), which it then releases during the discharging process. Moreover, the solar collector, parabolic trough collector, and other systems provide the energy supply to the PCMs for various applications. Tables 2 and 3 correspondingly list the system parameters and thermal characteristics of the evaluated materials. Moreover, the internal diameter, shell length, and shell thickness of the shell and tube heat exchangers are 140 mm, 450 mm, and 2 mm, respectively. A copper tube with a thermal conductivity of 300 W/mK is utilized with 11.5 mm and 12.7 mm internal and external diameters, respectively. Apart from this, the length of the tube and the number of spirals are 4500 mm and 18, respectively.

Results and discussion

Different sets of experiments with variable mass flow rates, typically 0.0119 kg/sec and 0.0277 kg/sec, of heat transfer fluid with varying source temperatures were conducted. The performance characteristics curves of PCM, fatty acids, and cascaded systems were retained using MatLab software with exergy and entrasy analysis of the systems. Figures 4 and 5 show the charging characteristics of PCM1 and PCM2, respectively, for 240 min of charging durations. Accordingly, it can be realized that charging efficiency was considerably higher compared to fatty acid in paraffin wax. Moreover, an average temperature of 80 °C was realized at the end of the charging.

Figure 4 shows that initially energy charging efficiency is high at about 90% but falls sharply within the first 30 min before stabilizing and then declines progressively over time. Originally following a declining trend, the PCM temperature first reaches a low around 40 min. After then, it rises sharply to indicate the phase change process and finally stabilizes at about 80 °C after 160 min. Simultaneously, power accumulated increases sharply in the early charging phase before leveling off as the system reaches saturation. The initial sharp drop in efficiency and PCM temperature can be attributed to early-stage thermal losses and inefficient heat absorption. Beyond forty minutes, the abrupt increase in PCM temperature points to a change from solid to liquid, in which case latent heat absorption improves thermal storage efficiency. Temperature and efficiency steady after 120 min, suggesting most of the PCM has melted and the system has reached thermal equilibrium. Rising thermal losses are expected to cause the declining energy efficiency over time, thus optimizing heat exchanger design and insulation becomes even more important to enhance storage performance. Through effective latent heat energy storage, the graph emphasizes the importance of phase change materials (PCMs) in controlling thermal energy storage, so improving heat retention, and so system performance.

According to Fig. 5, the trends for HTF inlet and HTF outlet temperatures show that the heat transfer fluid (HTF) enters the system at a relatively stable temperature, slightly fluctuating around 80 °C, while the outlet temperature gradually increases as the PCM absorbs heat. Indicating the latent heat absorption phase whereby the fatty acid undergoes a phase transition from solid to liquid, the PCM temperature curves (Tc2 and Tc3) show a steady rise with an initial rapid increase followed by a slower, more stable development. Represented by the square marker curve, charging efficiency starts at a high value, declines sharply in the first 20 min, and then stays low until roughly 100 min, at which point it starts to rise steadily. Large thermal losses and the high energy needed to start the phase change process cause this first efficiency drop. As the PCM stores heat effectively, the efficiency improves, eventually stabilizing around 0.7–0.8, signifying effective energy storage. The presence of a plateau in the PCM temperature curves around 60–70 °C suggests the phase change region, where the fatty acid absorbs latent heat without a significant rise in temperature. The delayed stabilization of the HTF outlet temperature compared to the PCM temperature indicates continuous heat exchange, reinforcing the effectiveness of the PCM in thermal energy storage. Whereas Fig. 6, illustrates the charging characteristics of a cascaded Thermal Energy Storage System (TESS) with a heat source temperature of 85 °C and a mass flow rate of 0.0119 kg/s. The temperature profiles of the two phase change materials (PCMs), denoted as Tpcm,2 and Tpcm,3, show a gradual rise over time, with Tpcm,2 reaching higher temperatures compared to Tpcm,3 due to its position in the cascading system. This indicates efficient heat transfer from the heat.

Studying rates of melting and solidification depends much on liquid fraction analysis. Figure 7a and b show PCM’s liquid fraction at several temperatures and mass flow rates. A shorter period of low liquid fractions was noted at a constant mass flow rate of 0.0119 kg/sec for both HTF temperatures. In contrast, at varying mass flow rates with an HTF temperature of 70 °C, a longer duration of low fractions was noted at lower flow rates. Additionally, Fig. 8a, b, and c depict exergy efficiency plotted against time, HTF temperature, and mass flow rate, respectively. As shown in Fig. 8b, higher HTF inlet temperatures during charging result in a greater temperature differential between the HTF and PCM, leading to increased entropy generation. This is because entropy production is directly proportional to the finite temperature difference. Consequently, to minimize entropy generation and maximize exergy performance, the HTF inlet temperature should be kept as low as possible, ideally close to the PCM’s initial temperature. However, a lower temperature differential significantly impacts the charging rate and heat transfer. Since the energy source availability is often unpredictable, particularly in latent heat thermal storage (LHTS) systems used for waste heat recovery applications, a high charging rate is desirable. Therefore, selecting an appropriate HTF inlet temperature involves balancing the required charging rate with energy efficiency. By lowering the HTF inlet temperature, maximum energy efficiency can be achieved. As demonstrated in Fig. 8c, variations in mass flow rate have a negligible effect on the system’s exergy efficiency.

Figure 9a and b illustrate the effectiveness of paraffin wax at varying mass flow rates and temperatures, respectively. In a single-unit PCM-based thermal energy storage system, the HTF temperature decreases along the direction of flow, which slows down the heat transfer rate and reduces the overall efficiency of the TESS. Specifically, the substantial temperature drop in the initial stage leads to a rapid decline in heat transfer. Maintaining a constant temperature differential throughout the storage unit enables a nearly uniform heat flux to the PCM, provided that multiple PCMs with different melting temperatures are arranged in descending order of their melting points along the HTF flow direction. This configuration allows for a steady heat transfer from the PCM to the HTF even during the discharge process.

The effectiveness metric exhibits a downward trend over time, which is expected since effectiveness is directly influenced by the temperature differential. However, compared to the single PCM design, the cascaded system demonstrates an average effectiveness improvement of up to 100%. This enhancement is primarily due to the greater uniformity in the HTF outlet temperature, as depicted in Fig. 6. Due to significant heat losses (Qloss) and a relatively constant temperature differential in the HTF, the charging efficiency of the cascaded thermal energy storage system (CTESS) remains low and stable over time, resulting in longer melting durations. On the other hand, Fig. 10 highlights a 30% increase in average energy efficiency. This type of TESS is particularly suitable for solar thermal applications, where thermodynamic performance is crucial but a high charging rate may not be a priority.

Furthermore, entransy analysis points to HTF’s thermal energy being used rather effectively. First, the entransy transferred for Fig. 11a is at its peak, indicating a strong heat transfer from the heat transfer fluid (HTF) to the phase change material (PCM). But the temperature gradient between HTF and PCM reduces with time, which causes a dramatic drop in entransy transfer. As the PCM progressively accumulates heat energy, the entransy kept also shows a declining trend, though at a slower rate. Entransy efficiency, which indicates the effectiveness of the heat transfer process, initially decreases before rising steadily, peaking at around 0.8. This behaviour is explained by the dynamic heat exchange between the HTF and PCM, where a more stable storage phase follows a fast heat inflow that dominates the initial charging stage. The ultimate decrease in entransy efficiency results from reduced temperature variations that reduce the driving potential for heat transfer. The observed trends underline the need of maximizing the HTF inlet temperature and flow rate to raise the general performance and efficiency of the thermal energy storage system. Furthermore, the entransy sent for Fig. 11b exhibits a changing trend: first declining greatly, then stabilizing, then declining gently over time. This suggests that as the system grows, less temperature difference between the phase change material (PCM) and the heat transfer fluid (HTF) reduces the heat transfer rate. The rather small and consistent trend of the stored energy with few fluctuations shows that, although some energy is saved, the system’s losses restrict the effectiveness of retention. Conversely, entransy efficiency shows a constant increasing trend and rises gradually during the charging process. This pattern implies that the cascaded design progressively increases total energy use efficiency due to enhanced thermal stratification and successive melting of PCMs with different melting points. Notwithstanding this improvement, the efficiency is still rather poor, which emphasizes the need of system design optimization to raise heat storage capacity. While thermal resistance and entropy generation reduce efficiency, the trends indicate that cascaded TESS configurations help to guarantee constant temperature gradient, so ensuring continuous heat transmission.

Results compared to published work

The main conclusions of this study are contrasted with earlier research on PCM-based thermal energy storage systems in Table 4. Thermal efficiency, exergy efficiency, charging/discharging time, and overall performance are among the parameters that are compared.

The results of the study reveal that the cascaded PCM system considerably raises thermal and exergy efficiency than single PCM systems. Though some studies—like Wang et al. (2022)—report somewhat higher efficiency—they have stability problems. All things considered, the cascaded configuration of fatty acid and paraffin wax provides a compromise between stability, efficiency, and utility. As indicated in Table 5, the cost analysis of Phase Change Materials (PCMs) takes into account the following factors: material cost, manufacturing and processing costs, installation and maintenance costs, and thermal performance efficiency26,18. Accordingly, PCM 1 is best suited for long-term applications with moderate energy storage needs. PCM 2 is the most cost-effective but requires frequent maintenance and proper encapsulation. Whereas, PCM 3 provides higher efficiency but comes with a higher upfront cost.

Conclusion

This work assessed, under varying heat transfer fluid (HTF), the thermal performance of a PCM-based thermal energy storage (TES) system using paraffin wax and fatty acid. These are the main conclusions:

-

Comparatively to single PCM systems, the cascaded PCM system showed a 30% increase in exergy efficiency and a 100% improvement in heat transfer effectiveness.

-

Achieved were exergy efficiency of 47.5% and maximum charging efficiency of 85.2%.

-

For a mass flow rate of 0.0277 kg/s, the liquid fraction reached 0.85 at 200 min.

-

Uncertainty study calculated a general error margin of ± 3.4%, so guaranteeing the accuracy of obtained values.

The results confirm that cascaded PCM systems maximize energy use, hence they are feasible for building thermal management, industrial waste heat recovery, and solar thermal applications as well as for recovery of other PCM systems. Advanced composite PCMs and long-term stability analyses for improved TES performance should be investigated in next studies.

Future directions and managerial implications

The present study leads the following research directions and managerial consequences.

-

Future work should investigate how to improve thermal conductivity and stability by means of nano-enhanced PCMs or composite PCMs.

-

Studies can centre on hybrid systems for enhanced efficiency combining sensible, latent, and thermochemical storage.

-

Crucially, we should investigate PCMs’ long-term thermal cycling stability and degradation under real-world settings.

-

TES designs should be enhanced using computational modeling and artificial intelligence-driven optimization methods.

-

Comprehensive cost-benefit and environmental impact studies can direct major application.

-

Designed for industrial uses, district heating, and grid-scale energy storage, modular and scalable TES solutions.

PCM can improve the storage efficiency of solar energy in case of a solar power plant so enabling continuous power production. Furthermore, included integration for energy-efficient climate control into walls, flooring, and HVAC systems. Apart from this, in food and pharmaceutical transportation, PCMs help to sustain temperature stability. Furthermore, thermal control of battery packs aims to increase lifetime and efficiency. TES should thus be applied in smart grids for management and storage of peak demand energy. Future studies can improve PCM-based TES systems’ applicability, efficiency, and sustainability by tackling these features, so guaranteeing larger acceptance in many sectors.

Data availability

Data will be made available on a reasonable request to the corresponding author.

References

Sharma, A., Tyagi, V. V., Chen, C. R. & Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 13(2), 318–345 (2009).

Andharia, J. K., Markam, B., Dzhonova, D. & Maiti, S. A comparative performance analysis of sensible and latent heat based storage in a small-scale solar thermal dryer. J. Energy Storage 45, 103764 (2022).

Işık, S. K. & El, E. Experimental investigation of distilled water production performance of conventional solar stills using CaCl2·6H2O phase change material reinforced with SrCl2·6H2O and graphene-based nanoparticles. Case Stud. Therm. Eng. 105184 (2024).

Kazemian, A., Khatibi, M., Entezari, S., Ma, T. & Yang, H. Efficient energy generation and thermal storage in a photovoltaic thermal system partially covered by solar cells and integrated with organic phase change materials. Renew. Sustain. Energy Rev. 188, 113705 (2023).

Mawire, A., Abedigamba, O. P. & Worall, M. Experimental comparison of a DC PV cooker and a parabolic dish solar cooker under variable solar radiation conditions. Case Stud. Therm. Eng. 54, 103976 (2024).

Pakalka, S., Valančius, K. & Streckienė, G. Experimental comparison of the operation of PCM-based copper heat exchangers with different configurations. Appl. Therm. Eng. 115138 (2020).

Ling, Z. et al. Review on thermal management systems using phase change materials for electronic components, Li-ion batteries and photovoltaic modules. Renew. Sustain. Energy Rev. 31, 427–438 (2014).

Parhizi, M. & Jain, A. The impact of thermal properties on performance of phase change based energy storage systems. Appl. Therm. Eng. 162, 114154 (2019).

Zalba, B., Marın, J. M., Cabeza, L. F. & Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl. Therm. Eng. 23 (3), 251–283 (2003).

Jospeh, A., Kabbara, M., Groulx, D., Alred, P. & White, M. A. Characterization and real-time testing of phase-change materials for solar thermal energy storage. Int. J. Energy Res. 40, 61–70 (2016).

Kılıçkap, S., El, E. & Yıldız, C. Investigation of the effect on the efficiency of phase change material placed in solar collector tank. Therm. Sci. Eng. Prog. 5, 25–31 (2018).

Wang, Z. et al. Experimental study on latent thermal energy storage system with gradient porosity copper foam for mid-temperature solar energy application. Appl. Energy 261, 114472 (2020).

Huang, H. et al. Improvement of the efficiency of solar thermal energy storage systems by cascading a PCM unit with a water tank. J. Clean. Prod. 245, 118864 (2020).

Beck, M., Müller, K. & Arlt, W. Storing surplus solar energy in low temperature thermal storage for refrigeration applications. Energy Build. 122, 192–198 (2016).

Cabaleiro, D. et al. Development of paraffinic phase change material nanoemulsions for thermal energy storage and transport in low-temperature applications. Appl. Therm. Eng. 159, 113868 (2019).

Da Cunha, J. P. & Eames, P. Thermal energy storage for low and medium temperature applications using phase change materials–a review. Appl. Energy 177, 227–238 (2016).

Tabrizi, F. F., Dashtban, M. & Moghaddam, H. Experimental investigation of a weir-type cascade solar still with built-in latent heat thermal energy storage system. Desalination 260 (1–3), 248–253 (2010).

Huggins, R. A. Energy Storage: Fundamentals, Materials and Applications 2nd edn (Springer, 2015).

Chebli, F. & Mechighel, F. Phase change materials: classification, use, phase transitions, and heat transfer enhancement techniques: A comprehensive review. J. Therm. Anal. Calorim. 1–59 (2025).

Rubel, R. I. et al. Phase change materials in high heat storage application: A review. Arab. J. Sci. Eng. 49(11), 14533–14551 (2024).

Zhang, X. & Liu, J. A comprehensive review on heat transfer enhancement in latent heat thermal energy storage systems. Renew. Energy. 145, 292–307 (2020).

Wang, T. & Zhao, H. Optimization strategies for PCM-based thermal energy storage systems: A numerical study. Appl. Therm. Eng. 185, 116290 (2022).

Kline, S. J. & McClintock, F. A. The description of uncertainties in a single sample experiments. Mech. Eng. 75, 3–8 (1953).

Liu, J., Fang, Y. & Lin, S. Capric–stearic acid/expanded graphite composites for efficient thermal management. J. Energy Storage. 40, 102355. https://doi.org/10.1016/j.est.2021.102355 (2021).

Fang, G. & Zhou, X. Enhanced stability of lauric–myristic acid/paraffin composites for thermal applications. J. Therm. Anal. Calorim. 137 (2), 567–578. https://doi.org/10.1007/s10973-019-08344-7 (2019).

Jensen, J. & Sørensen, B. Fundamentals of Energy Storage (Wiley-Interscience, 1984).

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

P.M.: Conceptualization, writing basic draft, project administration, V.P.: supervision, project administration, writing basic draft, S.K.: writing basic draft, review-edit, Vinay Sharma: methodology, conceptualization, writing basic draft, G.G.T.: project administration, writing basic draft and editing. A.J.S.: writing basic draft and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Mehta, P., Patel, V., Kumar, S. et al. Performance assessment of thermal energy storage system for solar thermal applications. Sci Rep 15, 13876 (2025). https://doi.org/10.1038/s41598-025-92458-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-92458-y