Abstract

This study focuses on the identification of type, abundance, and distribution patterns of the clay minerals within the Kashafrud Formation, a Middle Jurassic sedimentary rock sequence in the Khangiran gas field, Kopet-Dagh Basin, northeast Iran. This investigation shed light on the identification of type, abundance, and distribution patterns of the clay minerals obtained from 10 representative core samples by employing laboratory techniques, such as powder X-ray diffraction, polarizing light microscopy, and scanning electron microscopy. Results from the XRD analysis revealed quartz as the dominant mineral (49–65%), accompanied by the clay minerals (illite 8–18%, kaolinite 2–6%, chlorite 3–11%), alkali feldspar (7–16%), and plagioclase (3–10%), with occasional presence of ankerite (2–7%) or pyrite (1–3%). Polarizing light microscopy indicated a composition mainly of quartz and feldspar grains, categorized as arkose. Furthermore, the SEM studies highlighted that the pore filling pattern as the prevailing distribution pattern of clay minerals with occasional instances of pore coating pattern. The clay portion of each sample was separated and analyzed by an electron microscope device that identified silicon, oxygen, and aluminum as the primary elements. Furthermore, the findings of this study showed the average weight percentages of clay minerals, including kaolinite, chlorite, and illite in the mentioned formation were 4.3%, 7.4%, and 11.1%, respectively, contributing to an overall clay mineral content of 23.7%. The presence of illite, kaolinite, and chlorite could lead to a significant formation damage. Eventually, the observed distribution pattern and clay mineral content suggest the Kashafrud Formation leans towards a predominantly shaly-sand composition.

Similar content being viewed by others

Introduction

The clay minerals are hydrated aluminosilicates categorized as phyllosilicates, characterized by two-dimensional infinite sheets. They denote substances primarily comprised of fine particles with a size smaller than 2µ1. The presence of clay minerals in hydrocarbon reservoirs poses a significant challenge to the extraction of hydrocarbon. These kinds of minerals that are mostly find in the clastic formations, playing a crucial role in the governing reservoir characteristics, including porosity, permeability, capillary pressure, density, natural radioactivity, wettability, and water saturation. Nevertheless, the capacity to generate energy from these reserves remains considerably below their potential capacity due to the role of clay minerals. A key reason behind this problem lies in the prevalence of clay minerals within the reservoir rock. These minerals, prevalent in the fine-grained sediments, gas hydrate-bearing sediments, sandstone, mudstone, and shale, notably impact the reservoir quality by introducing numerous micropores into the existing intra-granular pore space2. Comprehensive understanding of clay minerals is vital in the evaluation process of hydrocarbon reservoirs. Even in small quantities, clay minerals play a significant influence on petroleum reservoir properties and can impact the recordings from various well logging tools3,4,5,6,7. Hence, an extensive grasp of clay mineralogy becomes crucial for both reservoir modelling and logging data interpretation2,8,9.

Clay minerals, include kaolinite, chlorite, illite, and illite–smectite mixed layer (I/S), are remarkably complex, often intergrown and encompassing a wide array of solid solutions formed through diverse processes. They arise across varying pressure, temperature, rock, and fluid compositions10,11. Identifying clay minerals precisely poses challenges because of the natural presence of interlayered phases, where different clay species e.g., illite and smectite (I/S) coexist in the layers. The issue arises from overlapping peaks of these constituent minerals solely and the similarity in their diffraction patterns when not treated with ethylene glycol. For instance, illite and I/S clays significantly impair reservoirs by diminishing pore-throat size and connectivity10. This similarity complicates identification, particularly in cases of low clay contents12,13.

Illite resulting from the transformation of potassium feldspars or muscovite, possesses a 2:1 structure1. Illite can have distinct shapes based on the levels of potassium saturation during its formation. When there is a high level of potassium saturation, hexagonal illite tends to precipitate, while lower saturation leads to the formation of lath-shaped illite. The presence of fibrous illite particularly hinders fluid flow in sandstones. Consequently, the primary morphology of illite significantly impacts reservoir permeability, underscoring the importance of finding its distribution and morphology for predicting sandstone reservoir properties14. Chlorite, a three-layer non-swelling clay mineral, plays a crucial role in regulating reservoir quality in various siliciclastic rocks. In deeply buried reservoirs, chlorite coating on sand grains inhibits the formation of quartz cements, resulting in unexpectedly favorable reservoir quality. Conversely, an abundance of chlorite, as seen in clay-rich siltstone and sandstone, causes pore throats to become obstructed, leading to extremely low permeability15. Taking into account the influence of clay mineralogy on a clastic reservoir, illite, chlorite, and kaolinite have the potential to significantly impact reservoir characteristics, such as porosity7.

Montmorillonite remains a significant and extensively utilized clay mineral in various industries. It falls under the category of di-octahedral smectites and originates from the chemical modification of volcanic ashes due to weathering. Smectites represent phyllosilicates of the 2:1 type, encompassing minerals, such as montmorillonite, bentonite, nontronite, saponite among others. They exhibit diverse compositions of Na, Al, Fe, and Mg. Kaolinite, on the other hand, arises from the transformation of aluminum-rich silicates like feldspars and muscovite1. Reservoir quality primarily depends on lithological characteristics rather than chlorite coatings. Kaolinite in reservoir is mostly formed from the chemical alteration of feldspar, chlorite emerges as clay coatings transformed from clay precursors due to the flocculation of suspended detrital clays or crystallization of pore fluids, while illite forms from the illitization of smectite group, K-feldspars, and authigenic kaolinite10.

The unique features of clay minerals, such as abundance, generally low specific gravity, low electrical resistivity, and swelling problems make them highly important for hydrocarbon resource exploration. Research on these properties is conducted globally and applied in various fields, including identifying clay cap rocks or cap rocks in geothermal systems, improving understanding of geothermal reservoirs, and tracking their changes over time. In certain geothermal systems, they can reduce permeability, necessitating thorough investigation16.

Alansari et al.17 explored the significance of considering the microporosity of clay minerals in the formation evaluation stage. They advocated for an integrated approach involving core analysis, well logs, and petrography by SEM and thin section studies, rather than relying solely on well logs. Griffiths et al.18, Sun et al.10, and Wang et al.2 highlighted the characteristics, content, types, distribution, and impacts of clay minerals on reservoir properties. The layered arrangement of clay minerals can be essential for comprehending the formation of methane hydrate in marine environments which was a topic of interest for Li et al.19 in a research about \({\text{CH}}_{4}\) hydrate formation in kaolinite particles with different surface contacts. They stated that molecular dynamics simulations revealed that the nucleation of methane hydrate is significantly influenced by the surface interactions of kaolinite particles which play a crucial role in the formation of aggregates within natural sediments. Jiu et al.6 examined the influence of clay minerals and cementation on pore throat in tight sandstone gas reservoirs. Zhou et al.20 investigated two critical parameters in the assessment of reservoir quality, including porosity and permeability changes following water injection in low permeability sandstone reservoirs. Clays can pose serious challenges for well logging operations. Jozanikohan and Abarghooei7 documented studies on clay mineralogy in clastic reservoirs using Fourier transform infrared spectroscopy (FTIR). Hou et al.21 explored the effects of clay mineral types and content on the effectiveness of lacustrine organic-rich shale reservoirs. Belghazdis and Hachem1 investigated the impact of diverse production climates and clay sources on clay structures and types. Deon et al.13 employed XRD, SEM analyses, and reflectance spectroscopy to detect interlayered illite/smectite clay minerals. The presence of clay minerals in terms of quantity, distribution, and structure significantly influences the most of physical characteristics of reservoirs, such as porosity, permeability, density, natural radioactivity, electrical conductivity, water content in petroleum fields. Studies indicate that the porosity of sandstone reservoirs is remarkably impacted by the clay mineral13,22. Aigbadon et al.23 highlighted the dominance of calcite in formations from the southern Benue Trough and the Dahomey Basin in Nigeria, suggesting their potential as limestone reservoirs with quartz and chlorite indicating siliciclastic input and diagenetic alterations. The study provided valuable insights into the depositional environments, diagenetic processes, and the role of elements in the evolution of carbonate deposits. The primary mineral composition of shale lithofacies associations can be accurately predicted using neural network analysis, whole-rock X-ray diffraction data, and wire-line log data, offering a foundation for lithofacies identification in shale intervals at well locations without core and test data24. The surface groups of clay minerals play a crucial role in CO2 hydrate nucleation by altering the distribution of water molecules and CO2. This, in turn, affects CO2 storage in deposits and has significant impacts on geochemical processes, including the interfacial interactions between clay surfaces and water molecules25. Conventionally, estimating two critical reservoir parameters, including volume of shale and porosity involves a very high error rate which led to the use of the multilayer perceptron (MLP) artificial neural network (ANN) to minimize this error. Implementing MLP proved that the error percentages for volume of shale and porosity significantly reduced from 89.46% and 58.3% in the traditional petrophysical approaches to1.28701 E−9 and 2.78731 E−4, respectively. The validation of the research findings from the MLP method considering the core data indicates that the estimation of these parameters in the studied field has been evaluated to be highly accurate26. Porosity and permeability tests indicated that a 5% increase in clay content (i.e., kaolinite, smectite, and illite) leads to a reduction in both porosity and permeability of rocks. Moreover, the findings suggested that the alterations in clay content have a more pronounced effect on permeability compared to porosity. A rise in the clay content significantly enhances the formation of chemical products in the reactions between cement and clay minerals. Challenges arise in accurately determining clay volume parameter which is crucial for reservoir characterization, impacting estimations of water saturation and reservoir productivity. An elevation in clay volume estimation may diminish rock porosity calculations, crucial for net pay value assessment27,28,29,30.

Various analytical methods, including X-ray fluorescence (XRF), Fourier transform infrared spectroscopy (FTIR), and X-ray diffraction are crucial for comprehensive clay mineral characterization1. Among these, the XRD stands out as a popular and non-invasive method31,32, which has been employed in geological studies and also for the purpose of identifying and measuring minerals in earth science33,34,35,36,37,38,39,40. It aligns well logs with mineralogical data effectively, especially for fine-grained clay minerals41. However, traditional XRD methods require careful sample preparation, risking damages or alterations to clays7,32,42,43. Scanning electron microscope (SEM) images can aid in precise microstructure examination44.

Previously, Ardebili et al.26 conducted a study on estimating the shale volume of the Kashfroud Formation in the Khangiran Gas Field using an artificial neural network. In the present study, however, the authors address a crucial gap in the comprehensive understanding of clay mineralogy in the formation which is essential for optimizing hydrocarbon extraction from clastic reservoirs. While prior research has focused on various clay mineral properties and their effects on reservoir characteristics globally, detailed studies specific to the formation, particularly with a comparative approach across distinct laboratory techniques, e.g., powder X-ray diffraction (PXRD), polarizing light microscopy, and scanning electron microscopy (SEM/EDX) remain limited. The present study’s innovation lies in its integrative approach, leveraging these three analytical methods to offer a precise understanding of the distribution, type, and abundance of clay minerals within the Formation. By combining these methodologies, the investigation aims to provide more accurate insights into clay mineral impacts on reservoir properties, a knowledge that is pivotal for enhancing reservoir evaluation and extraction techniques in the region.

Geological setting

This study has been conducted on the Kopet-Dagh sedimentary basin extending from northeastern Iran into southern Turkmenistan and east of the South Caspian Basin45,46. Positioned within the collision zone of the Iran Microplate and the Laurasian plates, the Kopet-Dagh Range plays a crucial role47. The Kopet-Dagh sedimentary basin stands as Iran’s second most significant hydrocarbon region following the Zagros and provides two main reservoir formations: Shurijeh (contains sweet gas), and Mozduran (contains sour gas)45 has been located in this basin and the Kashafrud Formation is the last drilled formation in the wells of Khangiran Gas Field.

The Khangiran Gas Field, has been located in this basin and Kashafrud Formation45,46. According to the National Iranian Oil Company (NIOC) report, drilled formations in the Khangiran Gas Field from surface to depth, including Khangiran, Chehel Kaman, Pestehleigh, Kalat, Neyzar, Abtalkh, Abdaraz, Aitamir, Sanganeh, Sarcheshmeh, Tiregan, Shurijeh, Mozduran, and Kashafrud48. The stratigraphic columns of the understudied Well, which the authors called it well #3, in the Khangiran Gas Field is depicted via version 5 of Strater software (Fig. 1). These formations date back from around 35 million years ago in the late Eocene period to approximately 165 million years ago in the upper Middle Jurassic period45.

The Khangiran Gas Field, situated in northeastern Iran within the Kopet-Dagh basin, stands out as a significant field and holds a considerable importance from the hydrocarbon perspective. Its structure spans northwest to southeast within the northeastern region of Mashhad province of Iran, and bordering Turkmenistan. This Field is located approximately 180 km northeast of Mashhad city and 25 km northwest of Sarakhs49,50.

The research studies by Afsharharb51 and Poursoltani and Gibling52 demonstrates that the Kashafrud Formation, dating (aging Middle Jurassic), serves as a hydrocarbon source for gas fields in the Kopet-Dagh basin. Furthermore, sedimentological and geochemical studies conducted by Ershadinia et al.53 also confirm the Kashafrud Formation’s reservoir potential. This formation, primarily composed of shale, sandstone, and conglomerate, extending over a significant area in the Kopet-Dagh basin in the northeastern area of Iran52. In the Formation, Jurassic siliciclastic unit (Lower–Middle Jurassic) is considered the main source of hydrocarbon within the Kopet-Dagh basin54. From a diagenetic perspective, the Kashafrud sandstones exhibit signs of various diagenetic activities, such as compression, solidification, dissolution, and creation of minerals formed within the rock47.

Materials and methods

Core data

The present investigation was carried out on core samples extracted from well #3, originating from the Kashafrud Formation situated within the Khangiran Gas Field. The drilled well aimed to investigate the hydrocarbon potential of the Kashafrud Formation, and assess the production of hydrocarbon from the Formation. The well #3 was specifically drilled down to the Kashafrud Formation, reaching a drilled thickness of 433 m. According to the published report made by NIOC48, during the drilling phase within this gas formation, a total of nine core boxes with 0.9 m length were recovered, which belonged to the depths between 3080.5 and 4397.5 m. Subsequently, 10 representative core samples were selected and extracted. Furthermore, a database consists of the depth and code of samples belonging to each core sample was collected.

Core washing is a highly critical process to ensure the removal of any surface contaminants, achieved through a series of rigorous cleaning and crushing steps. Recent advancements in core washing techniques emphasize the importance of reducing particle size and using solvents, e.g. propanol to maintain sample integrity during analysis13,39. In order to avoid from any possible contaminations, the inner parts of each core sample were crushed and then analyzed. The crushing stage provided a size of less than millimeter, and then core fully mixed. After crushing stage, each sample was ground using propanol solution to avoid any possible phase changes. To avoid non-clay minerals contaminating the fine grain fraction, specific clay minerals tests were conducted on a coarser fraction (< mm)31. In contrast, the general XRD analysis was carried out on the milled sample (< 75 µm fraction).

Wireline logging data

From wireline logging stage conducted in the Kashafrud Gas Formation, a dataset of 2263 logging data with a depth distance of 0.061 m were available. Due to inconsistencies in the depths of given core samples, a depth matching process was conducted. This involved a straightforward approach of averaging between upper and lower depths for depths where well logging dataset was not available. These samples underwent a comprehensive analysis to distinguish the type of sand contents in the clay minerals, aiming to quantify their meticulous and precise proportions accurately.

Method

Core analyses

To analyze 10 core samples, the X-ray diffraction (XRD) device was used, located in the X-ray laboratory of the School of Mining Engineering, University of Tehran, to determine how much clay content existed in the Kashafrud Gas Formation. To accomplish this, in the first step of this study, the general X-ray diffraction analysis was performed from 4 to 70° 2θ on 10 core samples. An area of 4.91 cm2 and a depth of 1 mm were analyzed on a circular sample holder made of plastic for full-rock XRD. An advanced Bruker D8 diffractometer, manufactured by Bruker AXS company, a joint product of Germany (Siemens) and the United States (Bruker company), which works with copper radiation Kα = 1.5406 Å, with the θ–2θ goniometry was employed to run the measurements. The samples were exposed to Nickle-filtered Cu Kα radiation at 40 kV and 30 mA with an angular speed of 1.2 \(^\circ\)/min. In the next step, the clay fraction was extracted by the proper procedure described in the subsequent sections, and then the PXRD analysis was performed from 4 to 40° 2θ on the clay fraction to fully identify the type of clay minerals.

From the 10 core samples taken from well #3 of the Khangiran Gas Field, three selected samples included codes #1, #3, and #9 for the preparation of thin section and polarizing microscope studies were chosen. The thin sections were prepared from uncrushed core samples at the School of Mining Engineering. Following this, studies on these samples were carried out by the Zeiss Axioplan 2 polarizing light microscope device.

In order to detect the type of constituent minerals, texture, crystals’ size, and microscopic conflicts, four samples coded #5, #7 (two samples) and #10, respectively underwent preparation using the Scanning Electron Microscope (SEM/EDAX) Camscan MV2300 model equipped with elemental analysis model XFlash 6l10, made by Bruker, Germany. These samples were studied in the laboratory of the School of Metallurgical Engineering at University of Tehran. To enhance conductivity, thin coatings were applied to each sample with several rounds of gold–palladium coating. For each sample, imaging with the secondary electron (SE) method involving low energy and penetration depth was used to determine surface characteristics and show variations in the samples. Besides, the backscattered electron method in the compositional mode was used to perform point analysis. The voltage used by the device during imaging was 20 kV, with a depth of field ranging from 15.9 to 16.7 mm.

To identify clay minerals, laboratory studies, which will be discussed in detail in the subsequent section, included the preparation of core samples, imaging, general XRD analysis with interpretation, SEM/EDAX analysis on the selected samples, and preparation as well as thin sections analyze. Then, for the specific identification of clay minerals types by the PXRD test, special preparations were made (incl. the removal or minimization of non-clay minerals using both physical and chemical methods, saturated processing with ethylene glycol steam, and heating to a temperature of 550 °C).

Laboratory studies

The preparation of samples

The preparation of core samples from well #3 in the Khangiran Gas Field (Fig. 2A) in the Mineral Processing Laboratory of the School of Mining Engineering was accomplished by crushing the core samples into several centimeter-sized pieces with a geological hammer (Fig. 2B). A geological hammer was used with the aim of reducing the dimensions of the given core samples from a minimum of 10 cm to a maximum of 2 cm. Then, for the next tests, a powder with dimensions of 75 µm was ground into a powder device (polarizer) for 30 min (Fig. 2C). The powdered sample is shown in the watch glass in Fig. 2D. Also, a piece of lump was kept for conducting thin section studies from the selected core samples.

PXRD analysis

The X-ray method is an approach for general analysis and identification of minerals and specialized identification of clay minerals which provides useful information about their composition, type, and content31. Using the advanced diffractometer 2θ–θ, D8-Advance model, in the X-ray laboratory of the School of Mining Engineering, University of Tehran, the minerals that made up 10 core samples were identified. It is worth to mention that the purpose of this analysis is to identify the type of clay minerals and their weight percentage. In this test, the weight of the samples was at least 3 g in the form of powder with a size of 75 µm (under sieve 200 mesh). Constituent minerals in the studied samples, based on the PXRD analysis report, in order of abundance, were: clay minerals, alkali feldspars, plagioclase, ankerite, and pyrite. In Fig. 3, the average weight percentage of minerals of all samples is drawn separately.

According to the pie chart, quartz mineral had the highest percentage of constituent weight among the eight minerals identified in the samples. Also, illite and alkali feldspar minerals stood at the second and third ranks, respectively. According to Table 1, samples #10 and #4 had the highest and lowest amounts of clay with a total of 33.5% and 6.20%, respectively. Among these minerals, samples with high clay content were chosen for the SEM studies, while those with low to medium clay content were assigned for the thin section studies.

Specialized identification of clay minerals by the PXRD test

The preparation of samples for quantitative PXRD test involves eliminating potential interferences, especially when clay minerals are not the primary components. Different treatments were used to reduce non-clay mineral interference, enabling precise identification of clays for analysis. These methods involved separating minerals, removing impurities such as iron oxides, and employing settling techniques. The decantation method played a crucial role in isolating clay fractions for a successful PXRD identification.

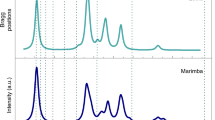

The specialized identifications revealed the clay minerals in the sample in order of abundance were illite, chlorite, and kaolinite. Figures 4 and 5 present both the general XRD and comparative graphs for these tests, respectively, for two of the samples. The percentages of the most common clay minerals in all samples along with the average and total weight percentages values are presented in Table 1. The qualitative identification curves of the clay minerals from these two samples are drawn in Figs. 6 and 7. These samples had the highest and lowest amounts of clay compared to the other samples.

Qualitative identification curves of clay minerals from one of the core samples in the studied formation with the highest clay content. (A) Diagram dried in air after removing or minimizing non-clay minerals, (B) diagram heated to 550 °C, (C) graph of sample saturated with ethylene glycol, and (D) graph after boiling in hydrochloric acid.

Qualitative identification curves of clay minerals from one of the core samples in the studied formation with the lowest clay content. (A) Diagram dried in air after removing or minimizing non-clay minerals, (B) diagram heated up to 550 °C, (C) graph of sample saturated with ethylene glycol, and (D) graph after boiling in hydrochloric acid.

The results of the PXRD test are generally based on weight percentage. In order to have a comprehensive understanding from the results of the laboratory examinations, the weight percentage of each samples converted into volume percentage (Table 2).

Based on the results of the experiments, it can be concluded that sample #10 with a total of 12.8% at a depth of 4390 m had the highest content of clay minerals. Conversely, sample #2 with a total of 6.7% at a depth of 4397 m accounted for the lowest content of clay minerals. Figure 8 shows the volume percentages of these common minerals in all samples.

Polarizing light microscopy studies

According to 10 core samples taken from well #3 of the Khangiran Gas Field, samples with codes #1, #3, and #9 were selected for the preparation of thin section and light microscope studies. This selection was based on their clay content which means that these three samples had low to medium clay content compared to other remained samples. Thin sections were prepared from crushed core samples. Subsequently, Zeiss Axioplan 2 polarizing light microscope was used for detailed examination in the Optical Mineralogy and Mineralography Laboratory at the School of Mining Engineering. The sandstones in the samples were classified following the Folk (1980) classification system. The samples then were analyzed based on petrographic observations considering lithological, textural, structural criteria, sedimentary facies, diagenetic changes, and sedimentary environment of sandstones.

The sample, labelled #1 (Fig. 9A and B) corresponds to the classification of arkose according to the Folk’s classification. The studied sample falls within the clastic sedimentary rock group, specifically in the subgroup of sandstones. The main grains comprising the stone’s framework consist of quartz and feldspar, while minerals with low abundance (3–5% by volume) include chlorite, biotite, and muscovite. The size of grains varies between 80 and 300 µm, with an average exceeding 125 µm. Therefore, the sample is categorized as fine to medium-grained sandstones with moderate sorting. The grains were semi-rounded to semi-angular shape. Some quartz fragments show stretch and extension, indicating a locally semi-oriented orientation and angular—stylolite bordersas a result of diagenesis processes and bearing compressive stress. Also, the effects of recrystallization can be seen in some quartz crystals in the form of polycrystalline fragments. Feldspar grains were mostly displayed in the form of argillite and sericite, their complete pieces were rarely found. Autogenous minerals resulting from feldspars alteration were mainly in situ and had a little movement. Small pieces of rock fragments were of the type of chert with interlayers of mica. The matrix was less than 5% by volume and it was considered as semi-mature to mature. The matrix includes clay minerals, phyllosilicate minerals e.g., chlorite, sericite, muscovite, and microcrystalline silica. The distribution of matrix in the rock was heterogeneous and was locally more concentrated in some parts. Furthermore, the cementation was small (less than 1%) and included anhydrite, iron oxide-hydroxides, clay minerals, sericite, muscovite and chlorite.

Scanning electron microscope analysis (SEM/EDAX)

Among 10 available samples, according to the percentage of clay minerals, three samples were selected for SEM/EDAX analysis. These three samples coded #5, #7 (1 and 2), and #10 were studied after preparation with Camscan MV2300 scanning electron microscope equipped with XFlash 6l10 elemental analysis at the laboratory of School of Metallurgical Engineering, Faculty of Engineering, University of Tehran. Their images were recorded and are present in Fig. 10.

The interpretation of SEM images of clay lam sample extracted from sample #5

The magnification of the studied image (Fig. 10A) is 2500 times and the depth of field is 20.4 mm. In the studied field, clay minerals of kaolinite, illite, and chlorite had stuck together in a coated form due to their adhesive properties and had created concretion structures (circle-like, spherical structures). It can be assumed that all kinds of clay minerals were placed inside these structures with a coated form. In addition, plate-shaped clay minerals were also seen in the background. Kaolinite clay minerals were visible in locations J-7, I-6, K-7, N-8, and O-8. Additionally, kaolinite clay mineral in the background was spread in the plates form in the area from M-3 to M-7. The maximum size of kaolinite clay pieces in the studied sample is 40 µm, with an average size of 4.7 µm and a minimum size of 2 µm. Regarding the sizes of illite and chlorite fragments, they cannot be measured because of being coating and inter-layered shape, forming spherical shapes. The distribution pattern of the clays in this sample was pore-filling type, and in a few cases, it can also be classified as covering. The pore-filling pattern can be clearly seen in different parts of the studied field.

The interpretation of SEM images of clay lam sample extracted from the first image of sample #7-1

The magnification of the studied image (Fig. 10B) is 5000 and the depth of field is 20 mm. In this sample, clays were better separated from each other and clay plates were completely visible. However, similar to the previous sample, there was a very different dimensional distribution. That is, from very small pieces of clay, e.g., kaolinite clay in C-7 and D-5 locations, to larger types in D-6 and C-5 locations. Clays were strongly intertwined and stuck together. The advantage of the image being studied was that the plates can be seen independently of each other with a high resolution. The distribution pattern of the particles was also similar to the previous example, i.e., as a pore-filling and in some cases as a covering pattern. The minimum, average, and maximum particle sizes are 1.4 μm, 2.7 μm, and 13.7 μm, respectively. Moreover, a highly heterogeneous distribution of clay minerals types e.g., illite, chlorite, and kaolinite with various sizes was available in the studied field. In locations G-4 and B-2, one or more illites can be seen scattered in a small number. In the H-2 location, illite can be observed in the form of fibrous. In the range from F-7 to H-4, there were areas where a mixture of chlorite and kaolinite which can be seen in an intertwined form.

The interpretation of SEM images of clay lam sample extracted from the second image of sample #7-2

The magnification of the studied image (Fig. 10C) is 5000 and the depth of field is 20.1 mm. In another field of the same sample (code #7), the coated clay minerals were significantly crushed, forming a concretion. It should be noted that concretions were a mixture of clay minerals e.g., chlorite, kaolinite, and illite.

Some parts of the image that appeared very bright in color, (e.g., position N-11), seemed to contain iron-bearing clay fragments, possibly of the ferric chlorite type. This brightness could be attributed to the presence of elements with high atomic numbers (e.g., iron), found in chlorite. In this image, there was a mixture of clays e.g., kaolinite, chlorite, and illite coated and inter-layered. The only kaolinite piece that existed in an open form is the O-15 piece, and measuring its dimensions was not possible due to the pieces being chipped.

The interpretation of SEM images of clay lam sample extracted from sample #10

The magnification of the studied image (Fig. 10D) is 5000 and the depth of field is 1.20 mm. In sample #10, which was related to a shallower depth than the other samples, there was a lower degree of scaling and kaolinite pieces were mainly in the form of rounded plates. Some of these places are: B-10, C-10, D-11, E-11, E-12. The clay minerals in this sample appeared separately, although they were actually in a location where the background was a mixture of different types of clay minerals, e.g., kaolinite in the C-13 location, which was on a matrix. Kaolinite was the dominant mineral observed in the study field, but illite and chlorite can also be identified in the matrix in an interlock form. The maximum, average, and minimum sizes of kaolinite particle are 12.3 μm, 5.5 μm, and 2 μm, respectively. An important issue was the rotation of the kaolinite plates in this sample, potentially attributed to the shallow depth of this sample or other diagenetic reasons, e.g., alteration because of changes in temperature and pressure. The dominant pattern of clay distribution was of the covering type and the sub-pattern in this field was the pore-filling pattern. Moreover, a very long linear illite fragment with kaolinite fragments was observed from locations F-11 to D-12. In general, the SEM studies confirm the identification of clays types from the PXRD test. Furthermore, the distribution pattern of clay minerals and their changes in particle size were also investigated.

The field seen in the SEM diagram of Fig. 11 was subjected to general elemental analysis and the results are as follows. According to the diagram, the main peaks for three elements namely silicon, aluminum, and oxygen are clearly noticeable (the gold peak appears due to the coating of the sample with a gold–palladium alloy), which are the constituents of aluminosilicates or clay minerals in the sample. The origin of silicon and oxygen elements can also be related to the presence of quartz in the sample. Because the SEM analysis was conducted by performing the test on the slide of the clay section extracted from the sample, the amount of quartz was minimized and not completely removed due to the resistant nature of this mineral. Therefore, its peaks can be seen in the form of Si and O elements.

The fourth abundant element is sodium, which is related to plagioclase or some alkaline feldspars. Therefore, given the simultaneous presence of plagioclase and alkali feldspar in the PXRD test, sodium might be associated with these two minerals either separately or together. Calcium ranks as the fifth most abundant element in Fig. 11. Considering the presence of carbonate phases, e.g., ankerite and calcite, as indicated by the PXRD results, hence calcium is associated with these carbonate phases. Thus, calcium can be attributed to ankerite minerals or various types of classical plagioclase.

The sixth most abundant element is sulfur. The presence of this element can be justified due to the appearance of the cubic pyrite mineral in the PXRD test. The next long peak is related to the Fe element, which is probably due to the presence of ancrete, pyrite, and chlorite-type clay minerals. The eighth abundant element is Mg, undoubtedly present in chlorite. In total, the main phases of the sample are: oxygen, silicon, to some extent sodium, aluminum and calcium. The general elemental analysis prepared from the sample in the form of a map (Fig. 12) indicates that the dominant constituent phases of the sample were made of oxygen, silicon and aluminum. This means that the main producers were clay and quartz minerals. The results of the elemental analysis of sample #10 are listed in Table 3.

It can be seen that the majority of samples in the studied field were composed of silicon, oxygen, and aluminum elements, which are the main producers of clay minerals (aluminosilicates). Figure 13 shows the general view of the sample, presenting the elements separately.

Results and discussion

The evaluation of the present investigation indicates that the burial depth exceeded 5 km, the burial basin temperature of the study area was above 150 °C and it is classified as the metagenesis stage, which only gas generation occurs during this stage55. Sandstones, as the most significant reservoir rocks for both oil and gas, represent porous siliciclastic properties and manifest a wide range of textures and compositions due to their deposition in diverse environments. These minerals, especially the fine-grained ones, often contribute to a substantial reduction in permeability of a reservoir by migrating and consequently obstructing interconnecting pore throats. Found in both sandstones and certain carbonate formations, these clay minerals are mobile, particularly when encountering fresh or low-salinity water due to the absence of confining pressure. The type, ratio, and distribution mode (be it as cement or pore filling) of clay minerals within sandstones exert a significant influence on petrophysical properties and overall reservoir qualities56,57,58,59,60,61,62.

When clay minerals are trapped in tiny pore throats, it can lead to a dramatic increase in fluid pressure needed for sustained flow, resulting in an overall reduction in permeability across porous media. Most hydrocarbon formations contain these minerals, and their interaction with water, especially low-salinity fluids, prompts fines migration and clay swelling. The porous structure of sandstone represents a network of pores connected through narrower channels. The dispersed presence of clay minerals within these pore spaces and permeability channels leads to provide a decrease in pore throat dimensions, subsequently, overall permeability within the reservoir rock. Among the prevalent clay minerals in sandstone reservoirs, authigenic kaolinite often forms flakes that are considered pore-filling type57,59,61,62. The accurate estimations of both the water saturation and porosity can be obtained by finding out how much clay is present within a reservoir. Bedsides, the calculation of the effective porosity can be done more accurately by having a good knowledge of the reservoir clay content63,64.

Based on the results of PXRD studies which were also confirmed by other laboratory methods, the minerals of Kashafrud Formation include aluminosilicates, quartz, plagioclase, alkali feldspar, ancrete, calcite, pyrite, and chlorite. The determination of clay content in the reservoir formations is of top priority, because of the importance of the subject. To identify the constituent clays in the studied samples accurately, specialized tests were performed to identify the clay minerals, and the results of these tests showed that clay minerals in the formation in terms of abundance were illite, chlorite, and kaolinite.

Based on the results of polarizing light microscopy, the sample was considered a sandstone classified by Folk’s system, featuring primarily quartz and feldspar grains. It had also fine to medium-grained structure, shows evidence of diagenesis, with semi-rounded to semi-angular grains, and a matrix comprising clay minerals and phyllosilicates, unevenly distributed within the rock. The SEM studies were performed to determine the distribution pattern of the clay minerals. Based on these studies, the distribution pattern of clay minerals was mainly of pore filling type and in some limited cases, pore coating type was identified. In addition, the size of clay minerals was a minimum of from 1.4 μm to a maximum of 13.7 μm. The performed EDAX analysis indicated that silicon, oxygen, and aluminum elements were witnessed in the majority of samples taken from the Kashafrud Formation which the minerals that were identified through the PXRD method were further validated through subsequent PXRD tests.

Conclusions

Prior to this study, comprehensive research on the identification and distribution of clay minerals within the Kashfroud Formation was lacking. This study addressed this gap and provided original insights valuable to petroleum exploration and mining engineering. Utilizing polarizing light microscopy, scanning electron microscopy equipped with energy dispersive X-ray spectroscopy (SEM/EDX), and X-ray diffraction (XRD), the clay mineralogy of the Kashafrud Gas Formation was analyzed. 10 core samples from well #3, positioned at depths of 4320–4753 m within the Khangiran Gas Field, northeast Kopet-Dagh sedimentary basin, Iran, were examined.

Qualitative analysis revealed that the Kashafrud Formation primarily consists of illite, chlorite, kaolinite, quartz, and alkali feldspar. The distribution of clay minerals, determined through specialized tests, followed the order: illite (1.11 wt%), kaolinite (3.4 wt%), and chlorite (4.7 wt%). Polarizing light microscopy indicated that the studied sample was a fine- to medium-grained sandstone composed mainly of quartz and feldspar grains, exhibiting diagenetic features, such as stretching and extension in quartz fragments. The SEM/EDX analysis further detailed the presence of kaolinite, illite, and chlorite forming concretion structures, with kaolinite averaging 4.7 µm in size. Moreover, variations in clay distribution patterns, including pore-filling and covering, were observed, highlighting heterogeneity in particle sizes and orientations.

The proposed approach not only provides a quantitative assessment of clay mineral distribution owing to advanced analytical techniques but also accounts for the inherent heterogeneity and diagenetic influences affecting mineral composition. The findings emphasize the role of diagenetic processes and environmental factors in mineral alterations within the formation.

Data availability

The datasets generated and/or analysed during the current study are not publicly available due to the limitations, but are available from the corresponding author on reasonable request.

References

Belghazdis, M. & Hachem, E. K. Clay and clay minerals: a detailed review. Int. J. Recent Technol. Appl. Sci. (IJORTAS) 4(2), 54–75. https://doi.org/10.36079/lamintang.ijortas-0402.367 (2022).

Wang, R. et al. Clay mineral content, type, and their effects on pore throat structure and reservoir properties: Insight from the Permian tight sandstones in the Hangjinqi area, north Ordos Basin, China. Marine Petrol. Geol. 115, 104281. https://doi.org/10.1016/j.marpetgeo.2020.104281 (2020).

Attia, M. M., Abudeif, A. M. & Radwan, A. E. Petrophysical analysis and hydrocarbon potentialities of the untested Middle Miocene Sidri and Baba sandstone of Belayim Formation, Badri field, Gulf of Suez, Egypt. J. Afr. Earth Sci. 109, 120–130. https://doi.org/10.1016/j.jafrearsci.2015.05.020 (2015).

Abudeif, A. M., Attia, M. M., Al-Khashab, H. M. & Radwan, A. E. Hydrocarbon type detection using the synthetic logs: A case study, Baba member, Gulf of Suez, Egypt. J. Afr. Earth Sci. 144, 176–182. https://doi.org/10.1016/j.jafrearsci.2018.04.017 (2018).

Hasan, M. N., Yeasmin, R., Rahman, M. J. J. & Potter-McIntyre, S. Diagenetic clay minerals and their controls on reservoir properties of the Shahbazpur gas field (Bengal Basin, Bangladesh). Geosciences 10(7), 250. https://doi.org/10.3390/geosciences10070250 (2020).

Jiu, B., Huang, W., Li, Y. & He, M. Influence of clay minerals and cementation on pore throat of tight sandstone gas reservoir in the eastern Ordos Basin, China. J. Natl. Gas Sci. Eng. 87, 103762. https://doi.org/10.1016/j.jngse.2020.103762 (2021).

Jozanikohan, G. & Abarghooei, M. N. The Fourier transform infrared spectroscopy (FTIR) analysis for the clay mineralogy studies in a clastic reservoir. J. Petrol. Explorat. Prod. Technol. 12(8), 2093–2106. https://doi.org/10.1007/s13202-021-01449-y (2022).

Hong, D. et al. Authigenic clay minerals and calcite dissolution influence reservoir quality in tight sandstones: Insights from the central Junggar Basin, NW China. Energy Geosci. 1(1–2), 8–19. https://doi.org/10.1016/j.engeos.2020.03.001 (2020).

Lai, J. et al. Qualitative and quantitative prediction of diagenetic facies via well logs. Marine Petrol. Geol. 120, 104486. https://doi.org/10.1016/j.marpetgeo.2020.104486 (2020).

Sun, X. L. et al. Characteristics and distribution of clay minerals and their effects on reservoir quality: Huagang Formation in the Xihu Sag, East China Sea Basin. Austral. J. Earth Sci. 66(8), 1163–1174. https://doi.org/10.1080/08120099.2019.1610795 (2019).

Chang, J. et al. Differential impact of clay minerals and organic matter on pore structure and its fractal characteristics of marine and continental shales in China. Appl. Clay Sci. 216, 106334. https://doi.org/10.1016/j.clay.2021.106334 (2022).

Jozanikohan, G. On the development of a non-linear calibration relationship for the purpose of clay content estimation from the natural gamma ray log. Int. J. Geo-Eng. 8(1), 21. https://doi.org/10.1186/s40703-017-0058-7 (2017).

Deon, F., van Ruitenbeek, F., van der Werff, H., van der Meijde, M. & Marcatelli, C. Detection of interlayered Illite/smectite clay minerals with XRD, SEM analyses and reflectance spectroscopy. Sensors 22(9), 3602. https://doi.org/10.3390/s22093602 (2022).

Weibel, R. et al. Illite distribution and morphology explaining basinal variations in reservoir properties of Upper Jurassic sandstones, Danish North Sea. Marine Petrol. Geol. 116, 104290. https://doi.org/10.1016/j.marpetgeo.2020.104290 (2020).

Worden, R. H. et al. Improved imaging and analysis of chlorite in reservoirs and modern day analogues: New insights for reservoir quality and provenance. Geol. Soc. Lond. Spec. Publ. 484(1), 189–204. https://doi.org/10.1144/SP484.10 (2020).

Ledésert, B. A. Application of minerals for the characterization of geothermal reservoirs and cap rock in intracontinental extensional Basins and Volcanic Islands in the context of subduction. Minerals 14(3), 263. https://doi.org/10.3390/min14030263 (2024).

Alansari, A., Salim, A. M. A., Janjuhah, H. T., Abd Rahman, A. H. B. & Fello, N. M. Quantification of clay mineral microporosity and its application to water saturation and effective porosity estimation: a case study from Upper Ordovician reservoir, Libya. J. Natl. Gas Geosci. 4(3), 139–150. https://doi.org/10.1016/j.jnggs.2019.04.005 (2019).

Griffiths, J. et al. Estuarine clay mineral distribution: Modern analogue for ancient sandstone reservoir quality prediction. Sedimentology 66(6), 2011–2047. https://doi.org/10.1111/sed.12571 (2019).

Li, Y. et al. Methane hydrate formation in the stacking of kaolinite particles with different surface contacts as nanoreactors: A molecular dynamics simulation study. Appl. Clay Sci. 186, 105439. https://doi.org/10.1016/j.clay.2020.105439 (2020).

Zhou, Y., Yang, W. & Yin, D. Experimental investigation on reservoir damage caused by clay minerals after water injection in low permeability sandstone reservoirs. J. Petrol. Explorat. Prod. Technol. https://doi.org/10.1007/s13202-021-01356-2 (2022).

Hou, L. H. et al. Effects of types and content of clay minerals on reservoir effectiveness for lacustrine organic matter rich shale. Fuel 327, 125043. https://doi.org/10.1016/j.fuel.2022.125043 (2022).

Risha, M., Tsegab, H., Rahmani, O. & Douraghi, J. The impact of clay minerals on the porosity distribution of clastic reservoirs: a case study from the Labuan Island, Malaysia. Appl. Sci. 13(6), 3427. https://doi.org/10.3390/app13063427 (2023).

Aigbadon, G. O. et al. Sedimentary: Carbonate microfacies and mineralogy of the southern Benue Trough and eastern Dahomey basin, Nigeria. Unconvent. Resour. 4, 100082. https://doi.org/10.1016/j.uncres.2024.100082 (2024).

Cui, Q., Yang, H., Li, X. & Lu, Y. Identification of lithofacies and prediction of mineral composition in shales–A case study of the Shahejie Formation in the Bozhong Sag. Unconvent. Resour. 2, 72–84. https://doi.org/10.1016/j.uncres.2022.09.002 (2022).

Li, Y. et al. Insights into carbon dioxide hydrate nucleation on the external basal surface of clay minerals from molecular dynamics simulations. ACS Sustain. Chem. Eng. 10(19), 6358–6369. https://doi.org/10.1021/acssuschemeng.2c01046 (2022).

Ardebili, P. N., Jozanikohan, G. & Moradzadeh, A. Estimation of porosity and volume of shale using artificial intelligence, case study of Kashafrud Gas Reservoir, NE Iran. J. Petrol. Explorat. Prod. Technol. 14(2), 477–494. https://doi.org/10.1007/s13202-023-01729-9 (2024).

Balaky, S. M. et al. Sedimentological and petrophysical heterogeneities controls on reservoir characterization of the Upper Triassic shallow marine carbonate Kurra Chine Formation, Northern Iraq: Integration of outcrop and subsurface data. Marine Petrol. Geol. 149, 106085. https://doi.org/10.1016/j.marpetgeo.2022.106085 (2023).

Hussain, W. et al. Prospect evaluation of the cretaceous yageliemu clastic reservoir based on geophysical log data: A case study from the Yakela Gas Condensate Field, Tarim Basin, China. Energies 16(6), 2721. https://doi.org/10.3390/en16062721 (2023).

Iltaf, K. H. & Butt, S. E. H. Energy geoscience. Energy 4, 100143. https://doi.org/10.1016/j.engeos.2022.100143 (2023).

Iranfar, S., Karbala, M. M., Shakiba, M. & Shahsavari, M. H. Effects of type and distribution of clay minerals on the physico-chemical and geomechanical properties of engineered porous rocks. Scientific Reports 13(1), 5837. https://doi.org/10.1038/s41598-023-33103-4 (2023).

Jozanikohan, G., Sahabi, F., Norouzi, G. H., Memarian, H. & Moshiri, B. Quantitative analysis of the clay minerals in the Shurijeh Reservoir Formation using combined X-ray analytical techniques. Russ. Geol. Geophys. 57(7), 1048–1063. https://doi.org/10.1016/j.rgg.2016.06.005 (2016).

Abd Elmola, A. et al. Clay mineral signatures of fault-related fluid flows in a sandstone reservoir: a case study from the Teloua Formation, Tim Mersoї Basin, Niger. J. Afr. Earth Sci. 168, 103840. https://doi.org/10.1016/j.jafrearsci.2020.103840 (2020).

Pappas, N. Calculating retained austenite in steel post magnetic processing using X-ray diffraction (2006).

Liu, Z. et al. Source-to-sink transport processes of fluvial sediments in the South China Sea. Earth-Sci. Rev. 153, 238–273. https://doi.org/10.1016/j.earscirev.2015.08.005 (2016).

Bristow, T. F. et al. Clay mineral diversity and abundance in sedimentary rocks of Gale crater. Mars. Sci. Adv. 4(6), eaar3330. https://doi.org/10.1126/sciadv.aar3330 (2018).

Thorpe, M. T., Hurowitz, J. A. & Dehouck, E. Sediment geochemistry and mineralogy from a glacial terrain river system in southwest Iceland. Geochimica et Cosmochimica Acta 263, 140–166. https://doi.org/10.1016/j.gca.2019.08.003 (2019).

Szopa, K., Skreczko, S., Chew, D., Krzykawski, T. & Szymczyk, A. Multi-Tool (LA-ICPMS, EMPA and XRD) investigation on heavy minerals from selected Holocene peat-bog deposits from the Upper Vistula River Valley. Poland. Miner. 10(1), 9. https://doi.org/10.3390/min10010009 (2019).

Tzvetanova, Y., Petrov, O., Kerestedjian, T. & Tarassov, M. Quantitative phase analysis of skarn rocks by the Rietveld method using X-ray powder diffraction data. Minerals 10(10), 894. https://doi.org/10.3390/min10100894 (2020).

Ali, A., Chiang, Y. W. & Santos, R. M. X-ray diffraction techniques for mineral characterization: A review for engineers of the fundamentals, applications, and research directions. Minerals 12(2), 205. https://doi.org/10.3390/min12020205 (2022).

Xiao, J., Song, Y. & Li, Y. Comparison of quantitative X-ray diffraction mineral analysis methods. Minerals 13(4), 566. https://doi.org/10.3390/min13040566 (2023).

Ashraf, U. et al. Classification of reservoir facies using well log and 3D seismic attributes for prospect evaluation and field development: A case study of Sawan gas field, Pakistan. J. Petrol. Sci. Eng. 175, 338–351. https://doi.org/10.1016/j.petrol.2018.12.060 (2019).

Moore, D. M., & Reynolds Jr, R. C. X-ray Diffraction and the Identification and Analysis of Clay Minerals (Oxford University Press (OUP), 1989).

Al-Ameri, S. A. & Kadhim, L. S. Heavy mineral distribution and clay mineralogy of Injana Formation at Zawita and Daigala Northern Iraq. Tikrit J. Pure Sci. 28(1), 40–46. https://doi.org/10.25130/tjps.v28i1.1263 (2023).

Yu, Q. et al. Identification of rock pore structures and permeabilities using electron microscopy experiments and deep learning interpretations. Fuel 268, 117416. https://doi.org/10.1016/j.fuel.2020.117416 (2020).

Ghorbanpour Yami, H., Naqibi, A., Alaviyan, S. M. & Bahari, A. Different qualities of cement banding in geological formations of Khangiran Gas Field, NE Iran. J. Petrol. Res. 33(1402–1), 40–58. https://doi.org/10.22078/PR.2022.4901.3191 (2023).

Kamyabi Shadan, H. & Taherpour Khalil-Abad, M. The first record of sexual dimorphism in Toxasterid Echinoid Heteraster from the Early Cretaceous deposits of the Kopet-Dagh Basin, NE Iran. Acta Geologica Sinica-English Edition https://doi.org/10.1111/1755-6724.15092 (2023).

Poursoltani, M. R., Fürsich, F. T. & Ghaemi, F. Petrology and mineralogy of Middle Jurassic siliciclastic rocks of the Kopet-Dagh rift basin, NE Iran: A comparison with the Binalud intramontane basin. Mar. Petrol. Geol. 150, 106026. https://doi.org/10.1016/j.marpetgeo.2022.106026 (2023).

NIOC (Exploration Directorate), 1994. Supplementary report of well number 3 of the Khangiran Gas Field. National Iranian Oil Company Records, Tehran, Iran.

Mashayekhi, Z., Kadkhodaei, A., Solgi, A., Baba Zadeh, A. & Aleali, M. Facies analysis, diagenesis processes and sedimentary environment of Shurijeh Formation in Khangiran gas field. J. Petrol. Res. 32(1401–4), 36–59. https://doi.org/10.22078/PR.2022.4650.3090 (2022).

Zaiery, M., Kadkhodaie, A., Arian, M. & Maleki, Z. Application of artificial neural network models and random forest algorithm for estimation of fracture intensity from petrophysical data. J. Petrol. Explor. Prod. Technol. https://doi.org/10.1007/s13202-023-01661-y (2023).

Afsharharb, A. Stratigraphy, Tectonic and Petroleum Geology of Kopet-Dagh Region, Northeast Iran. PhD Dissertation, College of Science and Technology, University of London, England (1979).

Poursoltani, M. R. & Gibling, M. R. Composition, porosity, and reservoir potential of the Middle Jurassic Kashafrud Formation, northeast Iran. Mar. Petrol. Geol. 28(5), 1094–1110. https://doi.org/10.1016/j.marpetgeo.2010.11.004 (2011).

Ershadinia, M., Ghaemi, F. & Homam, S. M. Permian to recent tectonic evolution of the Palaeotethys suture zone in NE Iran. J. Asian Earth Sci. 251, 105658. https://doi.org/10.1016/j.jseaes.2023.105658 (2023).

Aghababaei, A. et al. Influence of rift geometry over successive post-rift sedimentation: Tectonostratigraphy of the eastern Kopeh Dagh Belt (NE Iran). Mar. Petrol. Geol. 142, 105729. https://doi.org/10.1016/j.marpetgeo.2022.105729 (2022).

Jiang, S. Clay minerals from the perspective of oil and gas exploration. In Clay Minerals in Nature-Their Characterization, Modification and Application 21–38 (2012). https://doi.org/10.5772/47790

Azari, M. & Leimkuhler, J. M. Formation permeability damage induced by completion brines. J. Petrol. Technol. 42(04), 486–492. https://doi.org/10.2118/17149-PA (1990).

Wilson, M. D. & Pittman, E. D. Authigenic clays in sandstones; recognition and influence on reservoir properties and paleoenvironmental analysis. J. Sediment. Res. 47(1), 3–31. https://doi.org/10.1306/212F70E5-2B24-11D7-8648000102C1865D (1977).

Houseknecht, D. W. & Pittman, E. D. Origin, diagenesis, and petrophysics of clay minerals in sandstones. SEPM Soc. Sediment. Geol. https://doi.org/10.2110/pec.92.47 (1992).

Kaufman, P., Penny, G. S., & Paktinat, J. Critical evaluations of additives used in shale slickwater fracs. In SPE Shale Gas Production Conference (pp. SPE-119900). SPE (2008). https://doi.org/10.2118/119900-MS

Yustiningtyas, L. Clay minerals in sandstone reservoir rocks distribution, diagenetic evolution & potential formation damage. J. Ilmiah MTG (2014). https://doi.org/10.31315/jmtg.v5i2.239

Aksu, I., Bazilevskaya, E. & Karpyn, Z. T. Swelling of clay minerals in unconsolidated porous media and its impact on permeability. GeoResJ 7, 1–13. https://doi.org/10.1016/j.grj.2015.02.003 (2015).

Afrough, A., Zamiri, M. S., Romero-Zerón, L. & Balcom, B. J. Magnetic-resonance imaging of fines migration in Berea sandstone. SPE J. 22(05), 1385–1392. https://doi.org/10.2118/186089-PA (2017).

Causey, G. L. Computer determination and comparison of volume of clay derived from petrophysical and laboratory analysis (Doctoral dissertation, Texas Tech University) (1991).

Ahmed, T. Reservoir Engineering Handbook (Gulf Professional Publishing, 2018).

Acknowledgements

All authors would like to express their special thanks of gratitude to the X-ray laboratory, School of Mining Engineering, University of Tehran for kind participation and collaborations made throughout the present work, as well as providing very precise results.

Author information

Authors and Affiliations

Contributions

P.N.A. wrote and edited the main manuscript text and performed the research as a part of his M.Sc. thesis. G.J. has mainly resourced, supervised, and conceptualized the platform of research and conducted all of the analytical tests, as well as interpretations, and validation. She also has carefully reviewed the manuscript. A.M. was the co-supervisor of this research and all authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ardebili, P.N., Jozanikohan, G. & Moradzadeh, A. The characterization of clay minerals in the Kashafrud Formation in a gas field in northeast Iran. Sci Rep 15, 9000 (2025). https://doi.org/10.1038/s41598-025-93930-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-93930-5