Abstract

A novel Co@CaTiO₃ heterogeneous catalyst was synthesized via the sol–gel method, incorporating cobalt nanoparticles into a perovskite framework. The catalyst exhibited exceptional efficiency in the aqueous-phase synthesis of 1,2,3-triazoles through azide–alkyne cycloaddition (click reaction). Key reaction parameters, including catalyst loading, temperature, time, and solvent, were systematically optimized to achieve high yields. Comprehensive characterization using Fourier-Transform Infrared Spectroscopy (FT-IR), X-Ray Diffraction (XRD), Thermogravimetric Analysis (TGA), Energy Dispersive X-Ray Spectroscopy (EDX), Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), Brunauer–Emmett–Teller (BET) surface area analysis, and X-ray Photoelectron Spectroscopy (XPS) revealed its high surface area, thermal stability, and uniform distribution of cobalt nanoparticles. The Co@CaTiO3 catalyst demonstrated remarkable reusability, easy separation, and sustainable performance, positioning it as a promising candidate for green and efficient organic transformations in aqueous media.

Similar content being viewed by others

Introduction

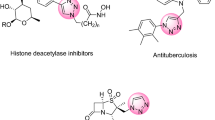

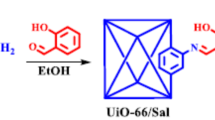

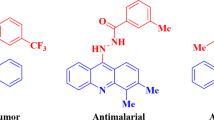

The design and synthesis of structurally complex heterocyclic compounds have garnered significant attention in organic and medicinal chemistry due to their diverse pharmacological applications1. Among these, triazoles-particularly N-substituted 1,2,3-triazoles have emerged as key intermediates in the development of pharmaceuticals with unique biological2 and pharmacological properties, antitubercular3, antidiabetic4, anticancer, anti-HIV5, and selective β3 adrenergic receptor agonist properties6. Copper has played a transformative role in catalysis, evolving from its historical use as a pigment to its modern applications in synthetic chemistry. As highlighted by Soleiman7, copper’s unique electronic properties and versatility make it an ideal catalyst for a wide range of organic transformations, including the synthesis of heterocyclic compounds.The synthesis of 1,2,3-triazoles through asymmetric alkynes often leads to the generation of two regioisomers under harsh reaction conditions. Notably, Sharpless et al. effectively generated these compounds at ambient temperature with remarkable regioselectivity utilizing the catalytic amounts of Cu(I)8. This approach, known as click chemistry, has become a cornerstone of modern synthetic methodologies, offering high efficiency and alignment with green chemistry principles by minimizing energy consumption and waste generation7 .In general, organic reactions in a homogeneous environment present several limitations, such as inadequate catalytic efficiency, challenging product purification, and non-reusability of the catalyst9. Despite the advantages of homogeneous catalysis, challenges such as poor catalyst recovery, difficult product purification, and limited reusability persist. Heterogeneous catalysts have emerged as a promising alternative, though issues like low activity and aggregation remain10. Recent advancements have focused on immobilizing metal nanoparticles (NPs) on various supports to address these limitations. For instance, recyclable Pd(0) − diethanolamine complexes grafted onto natural asphalt have demonstrated exceptional stability and reusability, making them ideal for sustainable organic transformations11. Similarly, boehmite nanoparticles have gained attention as eco-friendly supports for organic–inorganic hybrid catalysts due to their high surface area and stability12. Metal–organic frameworks (MOFs), particularly copper(II) Schiff-base complexes modified UiO-66-NH2(Zr), have shown remarkable catalytic activity in multi-step reactions, including Knoevenagel condensation and Michael addition-cyclizatio13. ABO3 perovskite oxides have also emerged as highly efficient catalysts due to their exceptional chemical stability14, high catalytic performance15, and versatility16. CaTiO3, a prototypical ABO3 perovskite, features Ca2+ at the A site, Ti4+ at the B site, and oxygen at the center of Ti4+ octahedra. The positioning of element B in ABO3 catalysts directly influences catalytic activity by modulating crystal defects and redox properties17. Transition metals at the B site, such as Cu, Co, Mn, or Fe, significantly enhance catalytic performance in reactions like toluene oxidation. The ability to introduce foreign cations at A or B sites further improves catalytic efficacy, selectivity, and long-term stability18. For example, cobalt-copper ferrite nanoparticles (CoCuFe2O4) have been employed in a single-step [3 + 2] cycloaddition of alkyl azides and alkynes at room temperature, yielding 1,2,3-triazoles with high efficiency19. Additionally, surface-enriched perovskite oxides like LaCoO3, fabricated via selective acid etching, exhibit enhanced catalytic activity due to abundant surface defects20.The integration of transition metals, such as Co and Cu, into catalytic systems has shown synergistic effects, further enhancing performance21. Green and sustainable chemistry has become a central focus in modern chemical research, driven by the need to minimize environmental impact and promote resource efficiency. Recent advancements in catalytic systems, such as recyclable catalysts and eco-friendly reaction media, have significantly reduced waste and energy consumption in organic synthesis. These innovations align with green chemistry principles and pave the way for more sustainable industrial processes22,23,24. In this study, we developed a Co@CaTiO3 nanocatalyst by supporting cobalt nanoparticles on CaTiO3 perovskite. The catalytic efficiency of Co@CaTiO3 was evaluated in alkyne-azide cycloaddition reactions, demonstrating its potential for sustainable organic synthesis. Building on the historical and modern significance of copper in catalysis, this work aims to advance the field by leveraging the synergistic effects of copper and cobalt.

Experimental

Materials and instruments

Sodium borohydride (98%), phenyl acetylene (99%), propargyl alcohol (98%), organic halides (benzyl chloride (98%), benzyl bromide (98%), 5-bromo-2-hydroxybenzaldehyde (98%), 5-chloro-2-hydroxybenzaldehyde (98%), 2-nitrobenzyl chloride (98%), 2-methyl-3-butyn-2-ol (98%), Co(NO3)2·4H2O (99%), Ca(NO3)2·4H2O (99%), sodium azide (98%), citric acid (99%), and solvents were sourced from Fluka and Merck and used without further purification. The synthesized catalyst was characterized using Fourier-transform infrared (FT-IR) spectroscopy (Tensor 27 Bruker), powder X-ray diffraction (XRD) (Tongda TD-3700), thermogravimetric analysis (TGA) (SDTAB51*), Inductively Coupled Plasma-Optical Emission Spectrometer (ICP-OES) (5000 DV), Brunauer–Emmett–Teller (BET) surface area analysis(Belsorp II at 77 k), and X-ray photoelectron spectroscopy (XPS)(Thermo Scientific Inc., U.K) MIRA3 TESCAN field emission scanning electron microscopy (FE-SEM) coupled with energy dispersive X-ray analysis (EDX), while structural properties were analyzed using transmission electron microscopy (TEM, FEI Tecnai 20) investigated morphological features.

Synthesis of CaTiO3 by sol–gel method

Tetrabutyl titanate (3.32 mmol) was dropwise added to 10 ml of anhydrous ethanol at stirring condition. Then 1.4g of citric acid as a chelating agent was added to the solution. To generate a solution with a molar ratio of 1:1 Ti and Ca, Ca(NO3)2.4H2O (3.34 mmol) was added to the solution and magnetically agitated at 50 °C for 1.5 h. Obtained solution was dried at 80 ºC for 12 h to produce xerogel. Finally, to produce white powder, the obtained xerogel was calcined at 700ºC for 5 h.

The procedure for synthesizing Co@CaTiO3

2.18 mmol of Co(NO3)2.3H2O was dissolved in 20 ml of methanol, and then 0.5 g of CaTiO3 was added to the solution. The obtained mixture was magnetically stirred for 24 h at room temperature. NaBH4 was added dropwise to the obtained mixture until the color changed from pink to dark then the mixture was centrifuged. The resulting powder was washed multiple times with water to remove the precursor and residual of NaBH4. The catalyst was dried at 50 ºC for 12 h in an oven.

General procedure for the azide-alkynes cycloaddition reactions in the presence of Co@CaTiO3

The azide-alkynes cycloaddition reaction was conducted in a round-bottom flask containing different quantities of Co@CaTiO3 catalyst (ranging from 0.002 to 0.008 mg), along with 2 mL of water, 0.5 mmol of alkyne, 0.55 mmol of organic halide, and 0.55 mmol of sodium azide (NaN3). The progress of the reaction was monitored using thin-layer chromatography (TLC). After the reaction, the mixture was subjected to centrifugation to isolate the catalyst, which was then removed by filtration. The resulting product was extracted twice with ethyl acetate (EtOAc, 10 mL each time) and used without further purification.

Results and discussion

Catalyst characterizations

Powder X-ray diffraction was utilized for the examination of the structural features of the catalysts that were synthesized. Figure 1 illustrates the XRD patterns observed for both CaTiO3 and Co@CaTiO3 samples. The diffraction peaks of CaTiO3 are in full agreement with the standard XRD data available for CaTiO3 (JCPDS card No. 81-561). Specifically, the peaks detected at 2θ = 23.23, 33.11, 39.47, 47.49, 59.70, and 69.67 degrees correspond to the crystallographic planes of (110), (112), (130), (220), (422), and (440), respectively. Furthermore, the peaks associated with cobalt (JCPDS card no. 15-0806) are observed at 2θ = 44.22 and 51.52 degrees, which can be attributed to the crystallographic planes of (111) and (200) respectively25 . The XRD patterns of the catalysts reveal that the recycled catalyst, after five cycles, exhibits a similarity to the CaTiO3 catalyst, with the peaks associated with cobalt almost completely disappearing, indicating the release of cobalt.

Figure 2 illustrates the FT-IR spectra of pristine CaTiO3, the Co@CaTiO3 nanocatalyst, and the regenerated catalyst post 4 cycles. The prominent bands observed within the range of approximately 400–600 cm−1 associated with all perovskite oxides (ABO) can possibly be linked to the M–O:(B–O) and M–O–M (A–O–B) bands. Moreover, the resonance peaks in the higher frequency region can be linked to the asymmetric stretching (1450–2482 cm-1) and bending vibration (1068–1770 cm-1) of the BO6 octahedron in the CaTiO3 perovskite (Fig. 2). The vibration related to Ti–O stretching and Ti–O–Ti bridging stretching mode are identified as peaks at 444 and 553 cm-1, respectively. This suggests the development of a structure similar to CaTiO3 perovskite A comparison of the FTIR spectra demonstrates that the spectrum of the recycled catalyst after five cycles exhibits a high degree of similarity to that of the CaTiO3 catalyst, which is indicative of cobalt release.

The XPS analysis of the perovskite structure reveals key information about the chemical states of cobalt (Co), titanium (Ti), calcium (Ca), and oxygen (O) (Fig. 3). The Co 2p spectrum features peaks at approximately 779.7, 781.3 eV (Co 2p₃/₂) and 795.9, 797.0 eV (Co 2p₁/₂), are characteristic of Co2+.The observed oxidation states likely resulted from the deposition of cobalt nanoparticles on the surface, where the presence of oxygen led to the oxidation of these cobalt particles. The XPS spectrum of Ti exhibits two prominent peaks at binding energies of 457.1 eV and 462.6 eV, corresponding to the Ti 2p3/2 and Ti 2p1/2 states, respectively. These peaks indicate the presence of Ti4+ in the CaTiO3 composite oxides. The Ca 2p spectrum shows peaks at approximately 345.2 eV (Ca 2p₃/₂) and 348.7 eV (Ca 2p₁/₂), characteristic of Ca2⁺. The O 1 s spectrum is composed of lattice oxygen (~ 530 eV) and surface oxygen (~ 532 eV), reflecting the structural integrity and surface chemistry of the perovskite26,27,28.

Figure 4a illustrate the BET analysis of Co@CaTiO3 catalyst. the textural characteristics of Co@CaTiO3, including its specific surface area, were determined using BET and Langmuir models. The analysis revealed that Co@CaTiO3 exhibits a high specific surface area of 211.54 m2 g⁻1, which is indicative of its potential for enhanced catalytic and adsorption applications due to the increased availability of active sites.

TGA curve of the Co@CaTiO₃ catalyst exhibits distinct weight loss regions, which can be attributed to several thermal events (Fig. 4b). The initial weight loss at lower temperatures (below 200°C) is likely due to the evaporation of adsorbed water or moisture from the catalyst surface. A more significant weight loss observed between 200°C and 400°C may correspond to the decomposition of organic residues or the removal of surface-bound hydroxyl groups. At higher temperatures (above 400°C), the gradual weight loss could indicate the decomposition of the catalyst’s structural components or phase transitions within the Co@CaTiO₃ framework. The overall TGA profile suggests that the catalyst maintains thermal stability up to a 500 °C temperature, beyond which structural degradation begins to occur.

In Fig. 5a, the elemental mapping images of the Co@CaTiO3 nanocatalyst are presented, revealing the spatial distribution of different materials. These images clearly exhibit the homogeneous dispersion of cobalt (Co) and other elements within the catalyst structure, indicating a well-balanced composition that is essential for ensuring consistent catalytic performance. Additionally, the EDX analysis plot in Fig. 5b, in conjunction with the mapping image, validates the presence of cobalt (Co) in the Co@CaTiO3 catalyst, offering concrete evidence of its elemental makeup. Also ICP-OES analysis of catalyst was showed cobalt concentration of 6.64%. This verification is imperative for gaining a comprehensive understanding of the catalyst’s characteristics and behavior during reactions, ultimately contributing to the progress of catalytic research and its practical applications.

Figure 6 illustrates the SEM images of the Co@CaTiO3 nanocatalyst, showcasing particles ranging in size from 15 to 40 nm with worm-like morphologies. The uniform shapes and distribution of these particles play a crucial role in enhancing the nanocatalyst’s reactivity by increasing the availability of active sites for various reactions, thereby optimizing its overall performance.

Figure 7 displays transmission electron microscopy (TEM) images of Co@CaTiO3 nanoparticles, exhibiting sizes ranging approximately from 30 to 70 nm.

Catalytic experiments

The 1,3-dipolar azide-alkyne cycloaddition reaction was executed utilizing the Co@CaTiO3 catalyst to assess its catalytic performance. A multi-component model procedure was employed to carry out the reactions. Within this model, benzyl chloride, phenylacetylene, and NaN3 were utilized in the azide-alkyne cycloaddition reaction, with water serving as a sustainable solvent. The reaction took place at 90°C under ambient conditions for a duration of 8 h. The outcomes of optimizing the reaction parameters, such as solvent type, catalyst quantity, reaction duration, and reaction temperature, are summarized in Table 1. Generally, the click reaction yielded identical 1,4-disubstituted 1,2,3-triazole compounds. To investigate the impact of the catalyst, a series of trials were conducted using 0.002, 0.004, 0.006, and 0.008 mmol of Co@CaTiO3 in H2O at 90 °C for 8 h (entries 1–5). The reaction did not progress in the absence of a catalyst (entry 1), highlighting the necessity of the Co@CaTiO3 catalyst for desired outcomes. Results indicated that increasing the catalyst quantity from 0.002 to 0.004 mmol improved the reaction efficiency from 62 to 99%, respectively. However, further increases in the catalyst amount from 0.006 to 0.008 mmol did not impact the isolated yield of the triazole product.

Temperature impact was examined in the context of the azide-alkyne cycloaddition reaction. Subsequently, escalation of the reaction mixture temperature resulted in an enhancement of reaction efficiency from 50 to 99% (entries 3 and 6–8). Furthermore, the optimal durations for reaction time were evaluated ranging from 2 to 8 h. The process attained its highest yield (99%) after 8 h of reaction time (entries 3 and 9–11). The effect of solvents on the catalytic performance of Co@CaTiO3 was explored under various solvent conditions. The production of 1-benzyl-4-phenyl-1,2,3-triazole in a water solvent exhibited the highest yield due to superior desolvation of sodium azide in water. A rise in the conversion of the reaction was noted in the sequence of H2O > C6H14 > C3H7OH > CH3CH2OH > C7H8 > CH3OH. Employing this optimized configuration, a variety of alkynes, including propargyl alcohol, phenylacetylene, and 2-methyl-3-butyn-2-ol benzyl halides (2-nitrobenzyl chloride, benzyl bromide, benzyl chloride, 5-Chloro-2-hydroxybenzaldehyde, and 5-bromo-2 hydroxybenzaldehyde) were scrutinized for their potential in initiating the synthesis of triazoles under ideal conditions (Table 2). The results indicate that aliphatic alkynes like propargyl alcohol and 2-methyl-3-but-2-ol exhibit lower yields compared to phenylacetylene. The decline in yields of aliphatic alkynes such as propargyl alcohol in contrast to phenylacetylene can be ascribed to the decrease in hydrogen bond interactions between propargyl alcohol and the water solvent. Moreover, the substitution from benzyl chloride to benzyl bromide resulted in a reduction in the reaction yield from 99 to 92%. This drop in yield might be due to distinct reactivity or solubility characteristics of the two benzyl halides. It is evident that the reaction efficiency for 5-chloro-2-hydroxybenzaldehyde is 52% compared to 71% of 5-bromo-2-hydroxybenzaldehyde owing to the greater strength of the Cl–C bond relative to the Br–C bond.

A proposed preliminary stepwise method Fig. 8 was suggested for Co(0)-catalyzed azide-alkyne cycloaddition processes, involving the formation of cobalt(0) acetylide through Co(0) insertion into the terminal alkynes, followed by the addition of the alkyl-azide intermediate.

Furthermore, an assessment was performed through an experimental approach on leaching in order to determine the heterogeneity or homogeneity exhibited by the catalyst that was generated. Following a duration of 4 h for the reaction, the catalyst underwent separation via centrifugation, and then the reaction proceeded for an additional 4 h without the catalyst present, resulting in no new findings. This observation indicates complete removal of the catalyst from the reaction, thus establishing its heterogeneous nature.

The examination of catalyst reusability was conducted by subjecting it to a series of reactions in a water solvent containing benzyl chloride, NaN3, and phenylacetylene. Upon completion of the initial run, the catalyst utilized was isolated from the reaction mixtures using centrifugation, Subsequently, the catalyst was washed with deionized water and dried at 50 °C to enable its reuse in subsequent cycles. The recovery rates of the catalyst were measured at 91.3%, 80.5%, 67.2%, 46%, and 12% after each successive run, respectively. This procedure was repeated five times, during which a gradual decline in catalytic efficiency was observed, particularly after the third reuse. The changes in the catalyst’s efficiency over the four reuse cycles are depicted in Fig. 9.

To highlight the efficiency and superiority of the present catalytic system, the performance of the Co@CaTiO3 catalyst was compared with previously reported transition metal-based catalysts. As illustrated in Table 3, Co@CaTiO3 demonstrates enhanced catalytic activity under milder reaction conditions than some earlier systems. In contrast to previously reported catalysts, our system operates efficiently without requiring harsh conditions such as excessive catalyst loading (entries 2–7) and the use of hazardous solvents (entries 4 and 7). Furthermore, key advantages of our approach include the straightforward preparation of the catalyst and the in situ synthesis of organic azides from sodium azide and various organic halides.

Conclusion

This study demonstrates the successful application of the Co@CaTiO₃ heterogeneous catalyst for the synthesis of 1,2,3-triazole derivatives via the azide-alkyne cycloaddition (click reaction). The catalyst exhibited excellent performance in water under optimized conditions (90 °C, 8 h, and 0.004 mg catalyst), showcasing its compatibility with green chemistry principles through the use of an eco-friendly solvent and its ability to be easily separated and reused. Unlike conventional catalysts, this hybrid system uniquely combines the structural stability of perovskites with the exceptional catalytic efficiency of cobalt nanoparticles. Comprehensive characterization using techniques such as FT-IR, XRD, TGA, SEM, TEM, BET, and XPS confirmed its structural stability, high surface area, and uniform distribution of cobalt nanoparticles. Leaching experiments further highlighted its reusability and minimal loss of activity, underscoring its potential as a sustainable and efficient catalyst. This work not only advances the field of click chemistry but also provides a reusable and environmentally friendly catalytic system, paving the way for future research in green chemical processes and industrial applications.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Taylor, A. P. et al. Modern advances in heterocyclic chemistry in drug discovery. Org. Biomol. Chem. 14(28), 6611–6637. https://doi.org/10.1039/c6ob00936k (2016).

Dheer, D., Singh, V. & Shankar, R. Medicinal attributes of 1, 2, 3-triazoles: Current developments. Bioorg. Chem. 71, 30–54 (2017).

Xiong, X. et al. Supported copper (I) catalyst from fish bone waste: An efficient, green and reusable catalyst for the click reaction toward N-substituted 1,2,3-triazoles. Appl. Organomet. Chem. 32(1), 1–10. https://doi.org/10.1002/aoc.3946 (2018).

Kharb, R., Sharma, P. C. & Yar, M. S. Pharmacological significance of triazole scaffold. J. Enzyme Inhib. Med. Chem. 26(1), 1–21. https://doi.org/10.3109/14756360903524304 (2011).

Bonandi, E. et al. The 1,2,3-triazole ring as a bioisostere in medicinal chemistry. Drug Discov. Today 22(10), 1572–1581. https://doi.org/10.1016/j.drudis.2017.05.014 (2017).

Dheer, D., Singh, V. & Shankar, R. Medicinal attributes of 1,2,3-triazoles: Current developments. Bioorg. Chem. 71(January), 30–54. https://doi.org/10.1016/j.bioorg.2017.01.010 (2017).

Soleiman-Beigi, M., Mohammadi, M. & Kohzadi, H. An overview on copper in industrial chemistry: From ancient pigment to modern catalysis. Coord. Chem. Rev. 2025, 529. https://doi.org/10.1016/j.ccr.2025.216438 (2024).

Chassaing, S., Bénéteau, V. & Pale, P. When CuAAC “click chemistry” goes heterogeneous. Catal. Sci. Technol. 6(4), 923–957. https://doi.org/10.1039/c5cy01847a (2016).

Zhang, X., Wang, B., Lu, Y., Xia, C. & Liu, J. Homogeneous and noncovalent immobilization of NHC-Cu catalyzed azide–alkyne cycloaddition reaction. Mol. Catal. 504, 111452 (2021).

Sirion, U., Yu, J. B., Byoung, S. L. & Dae, Y. C. Ionic polymer supported copper(I): A reusable catalyst for Huisgen’s 1,3-dipolar cycloaddition. Synlett 15, 2326–2330. https://doi.org/10.1055/s-2008-1078245 (2008).

Mohammadi, M. & Soleiman-beigi, M. Unlocking the nucleophilic functionalization potential of a natural asphalt: Grafting a Pd (0)—Diethanolamine complex as a recyclable catalyst for upgrading biaryl synthesis. Langmuir https://doi.org/10.1021/acs.langmuir.4c03523 (2025).

Mohammadi, M., Khodamorady, M., Tahmasbi, B., Bahrami, K. & Ghorbani-Choghamarani, A. Boehmite nanoparticles as versatile support for organic-inorganic hybrid materials: Synthesis, functionalization, and applications in eco-friendly catalysis. J. Ind. Eng. Chem. 97, 1–78. https://doi.org/10.1016/j.jiec.2021.02.001 (2021).

Ghobakhloo, F., Azarifar, D., Mohammadi, M., Keypour, H. & Zeynali, H. Copper (II) Schiff-base complex modified UiO-66-NH 2 (Zr) metal−organic framework catalysts for Knoevenagel condensation−michael addition−cyclization reactions. Inorg. Chem. 61(12), 4825–4841. https://doi.org/10.1021/acs.inorgchem.1c03284

Passi, M. & Pal, B. A review on CaTiO3 photocatalyst: Activity enhancement methods and photocatalytic applications. Powder Technol. 388, 274–304. https://doi.org/10.1016/j.powtec.2021.04.056 (2021).

Anjelin Ursula Portia, S., Rajkumar, S., Elanthamilan, E., PrincyMerlin, J. & Ramamoorthy, K. Effect of annealing temperature on structural, optical and visible light photocatalytic performance of CaTiO3 catalysts synthesized by simple sol–gel technique. Inorg. Chem. Commun. 119, 108051. https://doi.org/10.1016/j.inoche.2020.108051 (2020).

Karthikeyan, C., Thamima, M. & Karuppuchamy, S. Structural and photocatalytic property of CaTiO3 nanosphere. Mater. Sci. Forum 979, 169–174. https://doi.org/10.4028/www.scientific.net/MSF.979.169 (2020).

Sim, Y. et al. Catalytic behavior of ABO3 perovskites in the oxidative coupling of methane. Mol. Catal. 489(March), 110925. https://doi.org/10.1016/j.mcat.2020.110925 (2020).

Organic–Inorganic Lead–Halide Perovskite for Stable Optoelectronics (2019).

Matloubi Moghaddam, F., Pourkaveh, R. & Ahangarpour, M. Cobalt-copper ferrite nanoparticles catalyzed click reaction at room-temperature: Green access to 1,2,3-triazole derivatives. ChemistrySelect 3(9), 2586–2593. https://doi.org/10.1002/slct.201800134 (2018).

Chen, H. et al. Selectively etching lanthanum to engineer surface cobalt-enriched LaCoO3 perovskite catalysts for toluene combustion. Ind. Eng. Chem. Res. 59(23), 10804–10812 (2020).

Wang, D. & Astruc, D. The recent development of efficient earth-abundant transition-metal nanocatalysts. Chem. Soc. Rev. 46(3), 816–854 (2017).

Synthesis, E. X. Archive of SID. Ir efficient xanthene synthesis and its application for magnetic solid phase extraction of diazinon followed by its determination archive of SID. Ir Archive of SID. Ir Archive of SID. Ir. 8, 257–279 (2024).

Ebrahimzadeh, P., Maleki, B., Ghani, M. & Peiman, S. High-Performance Fe3O4@SiO2@Mel@DABCO catalyst for synthesis of chromene derivatives and solid phase microextraction of fipronil and prometryn in food samples followed by HPLC-UV determination. Chem. Methodol. 8(11), 833–855. https://doi.org/10.48309/chemm.2024.480851.1832 (2024).

Maleki, B. et al. A novel recyclable hydrolyzed nanomagnetic copolymer catalyst for green, and one-pot synthesis of tetrahydrobenzo[b]pyrans. Sci. Rep. 14(1), 1–22. https://doi.org/10.1038/s41598-024-81647-w (2024).

Shi, X. et al. Highly dispersed cobalt nanoparticles embedded in nitrogen-doped graphitized carbon for fast and durable potassium storage. Nano-Micro Lett. https://doi.org/10.1007/s40820-020-00534-x (2021).

Smyrnioti, M. & Ioannides, T. Synthesis of cobalt-based nanomaterials from organic precursors. Cobalt https://doi.org/10.5772/intechopen.70947 (2017).

Ehsan, M. A. et al. Fabrication of photoactive CaTiO3–TiO2 composite thin film electrodes via facile single step aerosol assisted chemical vapor deposition route. J. Mater. Sci. Mater. Electron. 30(2), 1411–1424. https://doi.org/10.1007/s10854-018-0411-4 (2019).

Abedi, M. et al. Influence of rapid heat treatment on the photocatalytic activity and stability of calcium titanates against a broad range of pollutants. Heliyon https://doi.org/10.1016/j.heliyon.2024.e34938 (2024).

Mekhzoum, M. E. M., Benzeid, H., Qaiss, A. E. K., Essassi, E. M. & Bouhfid, R. Copper(I) confined in interlayer space of montmorillonite: A highly efficient and recyclable catalyst for click reaction. Catal. Lett. 146(1), 136–143. https://doi.org/10.1007/s10562-015-1625-1 (2016).

Amini, M., Yousofvand, A., Hosseinifard, M., Bayrami, A. & Janczak, J. Synthesis and characterization of a new copper-based polyoxomolybdate and its catalytic activity for azide-alkyne cycloaddition reaction under UV light irradiation. Sci. Rep. https://doi.org/10.1038/s41598-023-50624-0 (2024).

Amini, A., Fallah, A., Cheng, C. & Tajbakhsh, M. Natural phosphate-supported Cu(Ii), an efficient and recyclable catalyst for the synthesis of xanthene and 1,4-disubstituted-1,2,3-triazole derivatives. RSC Adv. 8(72), 41536–41547. https://doi.org/10.1039/C8RA08260J (2018).

Yousofvand, A. A new nickel-based δ-isomer anderson-type polyoxometalates : Synthesis, crystal structure and catalytic activity in 1,2,3-triazoles production 1–15 (2023).

Chahdoura, F., Pradel, C. & Gómez, M. Copper(I) oxide nanoparticles in glycerol: A convenient catalyst for cross-coupling and azide-alkyne cycloaddition processes. ChemCatChem 6(10), 2929–2936. https://doi.org/10.1002/cctc.201402214 (2014).

Acknowledgements

The authors thank the University of Tabriz for financial support of this work.

Author information

Authors and Affiliations

Contributions

E.R., M. A. and A.A. K wrote the main manuscript text and E. R. and F.S. prepared Figs. 1–9 and tables 1–3. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rahimpour, E., Amini, M., Khandar, A.A. et al. Azide–alkyne cycloaddition reactions over cobalt (0) nanoparticles supported on CaTiO3 perovskite. Sci Rep 15, 16705 (2025). https://doi.org/10.1038/s41598-025-96984-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-96984-7