Abstract

India’s construction sector has made significant contributions to national growth. Heavy machinery is vital to construction. A concrete pump is an essential piece of equipment used for producing, mixing, and pouring concrete. From an execution and maintenance perspective, this equipment is vital. In order to prevent malfunctions when pouring concrete, a better maintenance plan is required for the concrete pump. The example company currently struggles with determining which maintenance tasks should come first, which drives up maintenance costs, reduces machine availability and profitability, and reduces production. The current effort aims to enhance maintenance strategies by utilising several multi-criteria decision-making (MCDM) techniques, such as modified TOPSIS, VIKOR, and PROMETHEE, to identify the most critical reason for failure and enhance concrete pump maintenance decision-making. Three MCDM strategies are then employed to construct the maintenance criticality ranking after the weight of each criterion is calculated using the fuzzy SAW method. Using three MCDM approaches, the best maintenance strategy is determined out of nine likely causes of failure. According to modified TOPSIS, VIKOR, and PROMETHEE rankings, material wear out is the most critical cause of failure, followed by rubber quality, and high pumping strokes are the least critical factor.

Similar content being viewed by others

Introduction

A report presented at the Global Construction-2030 international construction summit states that the global construction sector has the potential to grow to a value of over 85%, or US$15 trillion. Three countries, China, the United States, and India, will account for 57% of this growth, making them global leaders in the construction industry by 2030. India’s construction sector significantly boosts national growth by enhancing infrastructure, generating employment, and driving GDP through highways and urban housing projects. Rapid industry expansion increases demand for machinery like concrete pumps, as evidenced by rising equipment sales data, though supply chain constraints and skill shortages may temper this correlation1. Condition-based maintenance (CBM) activates maintenance actions on a parameter that indicates a machine aspect2. CBM optimizes resource use by monitoring real-time equipment health, reducing unnecessary interventions but requiring advanced sensors and data analysis, which can be costly3. Planned preventative maintenance (PPM) ensures reliability through scheduled upkeep, though it risks over-maintenance and higher downtime4. Selecting the right strategy depends on equipment criticality, failure predictability, budget, and operational goals. PPM requires routine tasks as predicted measurements and inspections rather than replacements and repairs, with actions taken only when absolutely essential5. A combined method was used to monitor and identify machine defects in complex industrial processes, such as fibre and textile production facilities. Magnetic Resonance Imaging (MRI), Nuclear Medicine, Ultrasonography, and Mammography are the associated imaging modalities. The three distinct multi-attribute scoring techniques are the simple additive weighting method, the technique for order preference by similarity to the ideal solution, and the weighted product method. Post-evaluation analysis is used to assess the findings and demonstrate the validity and robustness of the methodologies6. The multi-criteria approach known as “TOPSIS” best identifies the answers from a range of potential options. The optimum answer has the least distance from the positive ideal solution and the most significant distance from the negative ideal solution, according to this theory of how it operates. In order to achieve this, TOPSIS makes use of the relative weights, which must be determined using an appropriate approach while considering criteria relevance. It also uses first- and second-order matrices to calculate the outcomes. Based on this work, it has been suggested that drawn by higher-order matrices are less precise7.

Based on some literature studies, it has been observed that in order to survive in the fiercely competitive airline industry, several airlines have begun utilising a variety of alliance techniques, such as code sharing, equity sharing, and mergers and acquisitions8. In order to determine the factors that were important in deciding whether to merge or share codes, as well as to rank the airlines according to market priority, TOPSIS was used for the case study. A research work presents a model for optimising maintenance strategy based on fuzzy AHP and TOPSIS9. MCDM methods enhance the scientific and rationality of maintenance decisions lies in their ability to systematically evaluate complex, conflicting criteria; such as cost, reliability, and downtime using mathematical models like AHP or TOPSIS. By quantifying subjective factors and optimizing trade-offs, MCDM provides a structured, evidence-based framework, reducing bias and improving decision consistency10. MCDM technique outperforms the conventional FMEA approach. They proposed a method that computes criteria weights using Shannon’s entropy method and TOPSIS for decision-making. They tested the suggested maintenance strategy’s efficacy in the paper sector and concluded that, given the results’ close resemblance to reality, the suggested maintenance strategy may be used in any comparable situation11. MCDM methods can be flexibly applied to maintenance decisions by integrating equipment-specific factors such as age, criticality, failure modes, and operational context into the decision framework. Techniques like AHP or TOPSIS can prioritize maintenance tasks by weighting criteria, such as; cost, reliability, and downtime-tailored to diverse equipment types and operational needs. MCDM methods for pinpointing critical failure modes and devising corrective strategies12. Ensuring effective implementation in practical operations requires robust execution frameworks, such as real-time monitoring systems, clear accountability structures, and adaptive feedback loops. Integration with operational workflows and stakeholder buy-in further enhances success, mitigating risks of theoretical-practical disconnect. Grey theory can be used in conjunction with other MCDM techniques. They employed the suggested method to determine the approach’s effectiveness after combining the well-known MCDM techniques, TOPSIS and Simple Additive Weighting (SAW), with grey theory. The results were determined to be correct13. The TOPSIS method ensures objectivity and accuracy in multi-criteria decision-making by normalizing data and calculating distances from ideal and non-ideal solutions, minimizing bias through geometric comparisons14. The fuzzy SAW method enhances this by determining weights under uncertainty, using fuzzy logic to aggregate expert opinions, thus providing a robust, flexible weighting framework15. Hiring qualified staff is a significant benefit for organisational management, among many other things. They contend that in order to address difficult situations, one should use analytical techniques rather than jumping to emotional conclusions. They examined a range of staff selection techniques that were recorded in published works. They suggested using the SAW approach to make decisions while choosing personnel16. Machine maintenance techniques and their required parts might be challenging for an industry. Time-based preventative maintenance guidelines are used to build traditional maintenance programmes. Ge-code, based on the finite domain constraints paradigm, is used to create the automatic scheduler. This allows it to capture different constraints and model the unique aspects of the scheduling problem. The best candidate will be chosen for maintenance at a specific time because the scheduler can run anytime17. In order to prioritise pavement maintenance options, integrated the fuzzy analytic hierarchy process (AHP) with the VIKOR approach for the multi-criteria decision analysis (MCDA) process, considering a variety of pavement network indices in Tehran18.

The fuzzy TOPSIS method excels in handling uncertainty by integrating fuzzy logic, allowing it to manage imprecise or vague data effectively. Unlike traditional methods like AHP or crisp TOPSIS, it uniquely captures linguistic variables and subjective judgments, offering a robust framework for decision-making under uncertainty with greater flexibility and adaptability19. Various fuzzy models that have been used in the decision-making domain to provide a broad overview of the advancements of fuzzy TOPSIS approaches20. Bottani and Rizzi proposed a straightforward definition of fuzzy TOPSIS. To illustrate the TOPSIS approach for multi-criteria group decision-making schemes, they provided an example21. Based on previous study it has been observed that engineers face various issues in construction management. These issues are recorded as cases and are resolved through the application of MCDM techniques. They provided project managers and engineers with four different optimisation methodologies, each of which proposed a different approach for a particular problem. Lastly, they put out a nine-step method for handling challenging issues relating to construction management22.

FMEA methodologies to solve problems pertaining to modern technology products has several benefits23. MCDM methods rank or score options based on weighted criteria, but translating these into maintenance plans requires mapping results to actionable tasks24. Such as, prioritizing equipment repairs based on scores. Some other additional steps include defining operational constraints, assigning resources like personnel and tools, and integrating schedules. Expertise in domain-specific engineering and data analysis is essential. Ensuring independence and consistency in multi-criteria decision-making requires clear definitions and distinct measurement scales for each criterion, minimizing overlap25. Correlated criteria should be identified using statistical methods like correlation analysis, then either combined into composite indicators or adjusted via weighting techniques to reduce redundancy and maintain decision integrity.

The building sector in India is growing quickly. India is one of the markets with the most significant potential for the building industry. The nation’s expansion will accompany the construction of roads, bridges, flyovers, apartment buildings, public and private infrastructure, airports, railroads, ports, and other facilities. Thus, the entire construction infrastructure requires a sizable fleet of continuously operating gear. The foundation of construction is concrete. Numerous pieces of equipment are needed to prepare, mix, and pour concrete. Concrete pumps and batching plants are two of the most important among them. Since it is the production unit where concrete mixing is done, batching plants are regarded as the best26. Compared to batching plants, concrete pumps are more problematic to maintain for different reasons. Such as, Concrete will stop being poured if the batching factory shuts down. The condition of other machinery used with concrete is still acceptable. Only the concrete pump piping needs to be cleaned by running a rubber ball through it. If the concrete pump stops while pouring, the batching plant will need to have the entire pan mixer cleaned. Removing cemented concrete is a challenging undertaking once more falling under the purview of the maintenance staff. The lengthy and laborious process of manually cleaning the concrete pump pipeline will also be undertaken. The concrete pump is vital in construction for its efficiency in transporting liquid concrete to precise locations, especially in high-rise or hard-to-reach areas. Its main functions include pumping concrete at high volumes (e.g., 20–100 m³/h), reducing manual labour, and ensuring consistent placement27. Key roles involve accelerating timelines, enhancing structural integrity, and enabling complex designs.

In today’s era rapidly evolving business landscape, organizations must adopt intelligent production systems to enhance product and service quality, improve production efficiency, and strengthen environmental sustainability28,29,30. Industry 4.0 has significantly transformed the supply chain by integrating automation and data exchange in manufacturing processes, including product design, production, sales, and after-sales services31,32. Ensuring system dependability is essential, requiring the reduction of equipment and component failures to optimize productivity33,34. Manufacturers in Industry 4.0 must employ robust production tools and components. From the perspective of an industrial pressure valve manufacturer, quality professionals must anticipate potential failures and estimate the lifespan of pressure relief valves35. These valves are essential across various industrial sectors, including oil and gas production, manufacturing, and chemical processing. They are integral to power machinery systems such as internal combustion engines, heat engines, aero engines, and steam engines, primarily maintaining a predetermined pressure or preventing excessive pressure buildup within complex systems36. To enhance the durability of equipment and financial resource efficiency, decision-makers must ascertain critical characteristics that could lead to future failures37,38. Failure mode and effects analysis (FMEA) is a crucial tool for ensuring quality, safety, and reliability by systematically identifying potential failure causes and their impacts39. This study presents an FMEA-based approach to recognize critical failure modes and assist risk coordinators in formulating effective corrective strategies. The research provides an in-depth overview of applied methodologies, specifically a hybrid MCDM-FMEA framework. This work employs the TOPSIS instead of COPRAS and applies a distinct case study. The integrated methodology aims to generalize the combination of various MCDM methods, leveraging their collective advantages while ensuring objective ranking results. Given its numerous benefits, the proposed approach warrants further exploration across diverse industrial challenges with expanded datasets. A comprehensive equipment maintenance database can be established by integrating IoT sensors, CMMS software, and a centralized relational database to collect real-time performance data, failure logs, and maintenance histories40. MCDM methods, like AHP or TOPSIS, can be supported using cloud computing for scalability, machine learning for predictive analytics, and APIs for data interoperability41. Required resources include skilled data engineers, robust cybersecurity measures, and continuous updates to ensure data accuracy and relevance for practical applications.

This study seeks to present the methodology in a comprehensible manner, enabling practitioners to apply it effectively. A benchmark case study on industrial pressure relief valves validates the efficacy of the proposed framework in prioritizing critical failure modes. The managerial implications for decision-making are examined, highlighting the practical significance of this integrated approach. In order to prevent malfunctions when pouring concrete, a better maintenance plan is required for the concrete pump. Corrective, preventive, and planned maintenance are the current maintenance tactics used by the case company in the construction industry to maintain its construction equipment. The business has issues with preferences for maintenance tasks, which raises maintenance costs, reduces equipment availability, and lowers profitability. The current work aims to use MCDM techniques to enhance maintenance tactics. The Concrete Pump is maintained in this case study to determine the most practical maintenance plan.

The proposed research work aims to determine the optimal maintenance methodology for the construction industry by utilising MCDM techniques such as mTOPSIS, VIKOR, and PROMETHEE. VIKOR excels in concrete pump maintenance decision-making by balancing maximum group utility and minimum individual regret, unlike TOPSIS, which focuses solely on geometric proximity to ideal solutions42. PROMETHEE, meanwhile, offers a robust outranking approach, handling qualitative data and preference thresholds effectively, providing nuanced insights into trade-offs that TOPSIS might oversimplify. The research work is significant because it addresses the dearth of MCDM techniques applied to construction equipment in the challenging working conditions of India, as revealed by a literature review. The goals set forth for the current research work are as follows:

-

Assigning maintenance parameter objective weights.

-

To create a maintenance policy to rank the failure causes in order of importance.

Methodology

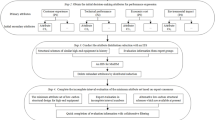

The experimental effort aims to identify the most important reason for failure for better concrete pump maintenance decision-making and to enhance maintenance strategies by utilising several MCDM techniques (modified TOPSIS, VIKOR, and PROMETHEE). First, in order to determine the criterion’s weight Following the application of the fuzzy SAW method, three MCDM techniques are used to generate the maintenance criticality ranking: the modified Technique for Order of Preference by Similarity to Ideal Solution (modified TOPSIS), the Serbian term VIekriterijumsko KOmpromisno Rangiranje (VIKOR), and the Preference Ranking Organisation Method for Enrichment Evaluation (PROMETHEE). In the fuzzy SAW method, weights reflect criteria importance, with skill requirements prioritized due to their critical impact on maintenance efficiency and error reduction. This conclusion aligns with actual operations, where skilled technicians enhance repair quality and downtime minimization, as evidenced by performance metrics and operational feedback loops. As shown in Fig. 1, methodology is used in this work.

Determination of factors

Three criteria are used to calculate maintenance criticality in the classic FMECA (Failure Mode Effect and Criticality Analysis) technique: asperity, failure occurring, and non-observation. However, in this case study, the maintenance importance of the form of failure is evaluated based on a total of six factors.

The next stage is to evaluate the essential factors that have been identified. This is accomplished by formulating a strategy to measure each failure mode’s criteria using a set of tables. Each factor is assigned a separate score (ranging from 1 to 9) and is divided into multiple classes based on varying criticality levels. The senior foreman (maintenance), mechanic, pump operator, maintenance manager, and maintenance engineer are the experienced maintenance staff members who assign the scores.

Chance of failure (CF)

This is a measure of how frequently failure occurs; a higher quantity indicates a higher priority for the item. The failure’s probability was evaluated using the median time between failures (MTBF) measure. Scores for chance of failure (CF) is shown in Table 1. The maintenance staff’s experience is combined with the data collected from logbooks and historical records to determine the mean time between failures (MTBF) of parts.

Non-detection of failure (NDF)

A number of factors affect the likelihood of observing a mechanism or matter of failure, such as the ability of maintenance staff or machine operators to do so with the use of equipment demonstrative aids like sensors, automated controls, and alarms or by routine inspections or with the unaided eye. Table 2 presents scores for non-detection of failure (NDF).

Level of skill requirements (SR)

An essential consideration is the level of competence necessary, or the amount of experience needed for a worker to complete the maintenance. The cost of maintenance will rise as experience requirements rise. Table 3 presents the scoring criteria.

Economic safety (ES)

This phrase refers to the structural, people, and equipment safety in the event of a mode of failure. Regarding the performance of the parts, scores are assigned. Mechanisms with more moving components receive higher scores since moving parts are more likely to cause accidents. The format for distributing the points for economic safety loss is shown in Table 4.

No. of workers required (WR)

It displays the quantity of labourers needed to complete the maintenance tasks. Because the machine’s parts are heavy, carrying, installing, and disassembling them sometimes requires multiple workers. Criticality will, therefore, rise as the number of workers increases. Table 5 shown as scores for number of workers.

Availability of spare parts (SP)

Machine repair requires a lot of unused parts. The likelihood of these spare parts being unavailable will have a big influence on machine maintenance for different parts. An arrangement for assigning priority scores is developed after accounting for the importance of machine replacement parts. For this reason, pieces are divided into three categories: desired, necessary, and vital. They are also divided into three groups: hard to find, easy to obtain, and scarce. Table 6 displays the results of their bilateral consolidation. Table 6 shows scores for availability of spare parts.

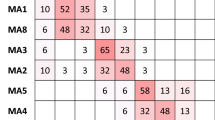

Assignment of scores to failure modes

This work presents the suggested methodology together with a case study of an Indian construction site. One of the primary and most crucial pieces of equipment on a building site is the concrete pump, and the focus of the current study is its upkeep. Pumping mixed concrete from the pouring site to the casting site is the aim of the concrete pump. The concrete pump’s rock valve, pumping rams and pipe line are essential parts. The root cause analysis (RCA) is used to determine the possible modes of failure of the aforementioned components as well as their impact and cause on the system performance. According to the scoring system displayed in the preceding section, numerical scores for the various failure causes that have been discovered are provided. Assignment of scores to failure modes is presented in Table 7.

Determination of criteria weights by fuzzy SAW

This part uses the fuzzy SAW method to determine the criteria weights. Every computation was done using an MS Excel spreadsheet. The first stage is normalising the ratings assigned to each element. In Table 8, the normalised matrix is shown.

Table 9 shows the obtained weights along with their ranking.

Results and discussion

Ranking of the alternatives with modified TOPSIS

Using the normalised values rij that have been computed and displayed in Table 10, construct the normalised decision matrix.

Table 11 shows the normalization of the decision matrix.

Distance from PIS and NIS are computed and presented in Table 12 along with modified TOPSIS score and final ranking.

Based on the scores, D7 is the most significant reason for failing.

Ranking of the alternatives with VIKOR

Decide the finest fi* and inferior fi− values of all the criteria which is shown in Table 13.

Calculate the values of Sj, Rj and Qj and shown in Table 14. Final Ranking of Alternatives are with Respect to Measures Sj, Rj and Qj (at v = 0.5).

Following a review of criterion C1 and C2, it is determined that both of them are met. D7 is hence the primary reason of failure.

Ranking of the alternatives with PROMETHEE

Construct the normalized decision matrix for which, normalized values fij are computed and displayed below in Table 15.

In accordance with scores, most critical cause of failure is D7 as shown in Table 16.

Comparison of methods

This work primary goal was to provide the maintenance criteria objective weights. The most important criterion in this case is the amount of competence necessary; other important criteria are the likelihood of failure, the availability of spare parts, the probability of failure, economic safety, and the number of people needed. The weights of these criteria were calculated using the fuzzy SAW method. Comparison of methods are shown in Table 17.

The second goal was to determine the most effective maintenance strategies. The second goal has been accomplished by applying three MCDM techniques: mTOPSIS, VIKOR, and PROMETHEE. The mTOPSIS, VIKOR, and PROMETHEE methodologies were used independently to generate the ranking of alternatives, which is presented systematically as follows:

mTOPSIS: D7 > D6 > D4 > D5 > D2 > D3 > D8 > D9 > D1.

VIKOR: D7 > D6 > D5 > D8 > D3 > D4 > D2 > D9 > D1.

PROMETHEE: D7 > D6 > D5 > D8 > D4 > D3 > D2 > D9 > D1.

As can be seen above, among the nine potential causes of failure that were found, material wear out (D7) is the most important cause (mTOPSIS, VIKOR, and PROMETHEE rankings), followed by rubber quality (D6), and high pumping strokes (D1), which is the least important cause. Material wear, rubber quality, and pumping strokes were likely selected as key criteria for prioritizing concrete pump maintenance due to their direct impact on performance and reliability. Wear affects structural integrity, rubber quality influences sealing and pressure retention, and strokes indicate usage intensity. Together, they broadly address critical failure points, though additional factors like hydraulic system health could enhance comprehensiveness.

Conclusions

Multi-criterion analysis has proven to be a valuable technique for carrying out a significant analysis on ranking the causes of failures to determine the need for additional corrective measures. This case study presents a combined technique for identifying the primary cause of concrete pump failure. The suggested strategy can meet both qualitative and quantitative requirements. The skill needed level is determined as the most important criterion in this methodology, followed by non-detection of failure, availability of spare parts, chance of failure, economic safety, and number of people necessary. The fuzzy SAW method was used to compute the criteria weights. Three MCDM techniques-TOPSIS, VIKOR, and PROMETHEE-help establish the criticality ranking. The two most important factors that need to be considered when choosing a concrete pump maintenance programme are the delivery tube’s material wear (D7) and the rams’ rubber quality (D6). Material wear was consistently ranked as the most critical failure cause in maintenance strategies using mTOPSIS, VIKOR, and PROMETHEE due to its direct impact on equipment reliability and downtime costs, as weighted by decision criteria. Sensitivity analyses across these methods suggest robustness, though variations in weighting could shift priorities, warranting further validation.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Ahmad, T., Madonski, R., Zhang, D., Huang, C. & Mujeeb, A. Data-driven probabilistic machine learning in sustainable smart energy/smart energy systems: key developments, challenges, and future research opportunities in the context of smart grid paradigm. Renew. Sustain. Energy Rev. 160, 112128 (2022).

Peng, Y., Dong, M. & Zuo, M. J. Current status of machine prognostics in condition-based maintenance: a review. Int. J. Adv. Manuf. Technol. 50, 297–313. https://doi.org/10.1007/s00170-009-2482-0 (2010).

Hornyak, O. The role of Condition-Based maintenance in minimizing operational costs. Prod. Syst. Inform. Eng. 11 (1), 43–53 (2023).

Shamayleh, A., Awad, M. & Abdulla, A. O. Criticality-based reliability-centered maintenance for healthcare. J. Qual. Maintenance Eng. 26 (2), 311–334 (2020).

Bittencourt, T. N., Futai, M. M., da Conceição Neto, A. P. & Ribeiro, D. M. Digital transformation of bridges inspection, monitoring and maintenance processes. In Bridge Maintenance, Safety, Management, Life-Cycle Sustainability and Innovations 11–30. https://doi.org/10.1201/9780429279119-2 (CRC Press, 2021).

Ngan, H. Y., Pang, G. K. & Yung, N. H. Automated fabric defect detection-A review. Image Vis. Comput. 29 (7), 442–458 (2011).

Olson, D. L. Comparison of weights in TOPSIS models. Math. Comput. Modell. 1 23–34. (2004).

Burton, J. & Hanlon, P. Airline alliances: cooperating to compete? J. Air Transp. Manage. 1 (4), 209–227 (1994).

Ilangkumaran, M. & Kumanan, S. Selection of maintenance policy for textile industry using hybrid Multi-criteria Decision-Making approach. J. Manuf. Technol. Manage. 20 (7), 1009–1022 (2009).

Wang, C. N., Yang, F. C., Vo, T. M. N., Nguyen, V. T. T. & Singh, M. Enhancing efficiency and cost-effectiveness: a groundbreaking bi-algorithm MCDM approach. Appl. Sci. 13 (16), 9105 (2023).

Sachdeva, A., Kumar, D. & Kumar, P. Multi-factor failure mode critically analysis using TOPSIS. J. Industrial Eng. Int. 5 (8), 1–9 (2009).

Khanfri, N. E. H., Ouazraoui, N., Simohammed, A. & Sellami, I. New hybrid MCDM approach for an optimal selection of maintenance strategies: results of a case study. SPE Prod. Oper. 38 (04), 724–745 (2023).

Kose, E., Kabak, M. & Aplak, H. Grey theory based MCDM procedure for sniper selection problem. Grey Systems: Theory Application. 3 (1), 35–45 (2013).

Mian, S. H. & Al-Ahmari, A. Comparative analysis of different digitization systems and selection of best alternative. J. Intell. Manuf. 30, 2039–2067 (2019).

Hosseinzadeh Lotfi, F. et al. Simple additive weighting (SAW) method in fuzzy environment. In Fuzzy Decision Analysis: Multi Attribute Decision Making Approach (117–140). Cham: Springer International Publishing. (2023).

Afshari, A., Mojahed, M. & Yusuff, R. M. Simple additive weighting approach to personnel selection problem. Int. J. Innov. Manage. Technol. 1 (5), 511 (2010).

Achouch, M. et al. On predictive maintenance in industry 4.0: overview, models, and challenges. Appl. Sci. 12 (16), 8081 (2022).

Babashamsi, P., Golzadfar, A., Yusoff, N. I. M., Ceylan, H. & Nor, N. G. M. Integrated fuzzy analytic hierarchy process and VIKOR method in the prioritization of pavement maintenance activities. Int. J. Pavement Res. Technol. 9 (2), 112–120 (2016).

Zhou, F. & Chen, T. Y. A synergetic intuitionistic fuzzy model combining AHP, entropy, and ELECTRE for data fabric solution selection. Artif. Intell. Rev. 58 (5), 137 (2025).

Sahoo, S. K. & Goswami, S. S. A comprehensive review of multiple criteria decision-making (MCDM) methods: advancements, applications, and future directions. Decis. Mak. Adv. 1 (1), 25–48 (2023).

Bottani, E. & Rizzi, A. A fuzzy TOPSIS methodology to support outsourcing of logistics services. Supply Chain Management: Int. J. 11 (4), 294–308 (2006).

Erdogan, N., Pamucar, D., Kucuksari, S. & Deveci, M. An integrated multi-objective optimization and multi-criteria decision-making model for optimal planning of workplace charging stations. Appl. Energy. 304, 117866 (2021).

Chang, T. W., Lo, H. W., Chen, K. Y. & Liou, J. J. A novel FMEA model based on rough BWM and rough TOPSIS-AL for risk assessment. Mathematics 7 (10), 874 (2019).

Mizrak, F., Mizrak, K. C. & Akkartal, G. R. Developing a strategic framework for airline destination selection: A multi-criteria decision-making approach applied to Turkish airlines. Transp. Res. Interdisciplinary Perspect. 29, 101322 (2025).

Liu, J., Zhang, Q., Xie, M., Lin, M. & Xu, Z. A blockchain platform selection method with heterogeneous multi-criteria Decision-Making based on hybrid distance measures and an AHP-EWM weight method. Expert Syst. Appl. 256, 124910 (2024).

Martins, J. V., Aguilar, M. T. P., Garcia, D. C. S., Santos, D. & W. J Management and characterization of concrete wastes from concrete batching plants in Belo Horizonte–Brazil. J. Mater. Res. Technol. 20, 1157–1171 (2022).

Mikhalev, D. et al. Practical insights and advances in concrete pumping. RILEM Tech. Lett. 9, 1–9 (2024).

ElMaraghy, H., Monostori, L., Schuh, G. & ElMaraghy, W. Evolution and future of manufacturing systems. CIRP Ann. 70 (2), 635–658 (2021).

Davis, J., Edgar, T., Porter, J., Bernaden, J. & Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 47, 145–156 (2012).

Esmaeilian, B., Behdad, S. & Wang, B. The evolution and future of manufacturing: A review. J. Manuf. Syst. 39, 79–100 (2016).

Awan, U., Sroufe, R. & Bozan, K. Designing value chains for industry 4.0 and a circular economy: A review of the literature. Sustainability 14 (12), 7084 (2022).

Rubmann, M. et al. Industry 4.0: the future of productivity and growth in manufacturing industries. Boston Consulting Group. 9 (1), 54–89 (2015).

Eti, M. C., Ogaji, S. O. T. & Probert, S. D. Integrating reliability, availability, maintainability and supportability with risk analysis for improved operation of the Afam thermal power-station. Appl. Energy. 84 (2), 202–221 (2007).

Yang, S., Meng, D., Yang, H., Luo, C. & Su, X. Enhanced soft Monte Carlo simulation coupled with support vector regression for structural reliability analysis. In Proceedings of the Institution of Civil Engineers-Transport 1–16. (Emerald Publishing Limited, 2024).

Bukowski, J. V., Goble, W. M., Gross, R. E. & Harris, S. P. The effects of maintenance actions on the average probability of failure on demand of spring operated pressure relief valves. J. Press. Vessel Technol. 137 (6), 061601 (2015).

Tahan, M., Tsoutsanis, E., Muhammad, M. & Karim, Z. A. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy. 198, 122–144 (2017).

Ruschel, E., Santos, E. A. P. & Loures, E. D. F. R. Industrial maintenance decision-making: A systematic literature review. J. Manuf. Syst. 45, 180–194 (2017).

Meng, D. et al. Kriging-assisted hybrid reliability design and optimization of offshore wind turbine support structure based on a portfolio allocation strategy. Ocean Eng. 295, 116842 (2024).

Huang, J., You, J. X., Liu, H. C. & Song, M. S. Failure mode and effect analysis improvement: A systematic literature review and future research agenda. Reliab. Eng. Syst. Saf. 199 106885 (2020).

Kang, J., Al Masry, Z., Varnier, C., Mosallam, A. & Zerhouni, N. A data quality management framework for equipment failure risk estimation: application to the oil and gas industry. Eng. Appl. Artif. Intell. 136, 108834 (2024).

Ali, Y., Khan, H. U., Khan, F. & Moon, Y. K. Building integrated assessment model for IoT technology deployment in the industry 4.0. J. Cloud Comput. 13 (1), 155 (2024).

Lamrani Alaoui, Y., Gallab, M., Tkiouat, M. & Di Nardo, M. A hybrid-fuzzy-decision-making framework for digital technologies selection. Discover Appl. Sci. 6 (10), 522 (2024).

Acknowledgements

Researchers Supporting Project (RSPD2025R630), King Saud University, Riyadh, Saudi Arabia.

Funding

Researchers Supporting Project (RSPD2025R630), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

Conceptualization: Dharmpal Deepa, Gurinder Singh Brar; Data curation: Dharmpal Deepa, Gurinder Singh Brar; Formal Analysis: Sulakshna Dwivedi, Harnam Singh Farwaha, Nishant Ranjan; Methodology: Dharmpal Deepak, Gurinder Singh Brar, Sulakshna Dwivedi, Harnam Singh Farwaha, Nishant Ranja, Basem A. Alkhaleel, Shatrudhan Pandey; Writing–original draft: Dharmpal Deepak, Gurinder Singh Brar, Sulakshna Dwivedi, Harnam Singh Farwaha, Nishant Ranja, Basem A. Alkhaleel, Shatrudhan Pandey; Writing–review & editing: Dharmpal Deepak, Gurinder Singh Brar, Sulakshna Dwivedi, Harnam Singh Farwaha, Nishant Ranja, Basem A. Alkhaleel, Shatrudhan Pandey.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Deepak, D., Brar, G.S., Dwivedi, S. et al. Optimizing concrete pump maintenance in the construction sector using enhanced MCDM techniques. Sci Rep 15, 13816 (2025). https://doi.org/10.1038/s41598-025-98481-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-98481-3