Abstract

The moisture sensitivity of asphalt concrete is one of the most important failures that roads face during their service life. In recent years, many efforts have been made to reduce this failure in asphalt concrete. Anti-stripping additives are one of the most widely used methods to mitigate this failure, but the effect of these additives on the main mechanisms of moisture sensitivity has received less attention. This study examined the impact of using dodecyl amide, nano-calcium carbonate, and dry resin additives to decrease moisture sensitivity and its mechanisms in asphalt concrete. The materials used were granite, limestone, and PG 64 − 16 bitumen. Nano-calcium carbonate (0.5% and 1%), dry resin (2% and 4%), and dodecyl amide (0.5% and 1% by the weight of bitumen) were used as the bitumen modifiers. The modified Lottman in 1, 2, and 3 freeze-thaw cycles and Pull Off test in cohesion and adhesion failure states were used to assess the moisture sensitivity of asphalt concrete samples. All three additives increased the indirect tensile strength ratio in multiple freeze-thaw cycles and, thus, improved these samples’ performance against moisture. The greatest indirect tensile strength improvements ranged from 37 to 80% for nano-calcium carbonate and 32–79% for dry resin, while dodecyl amide caused increases from 11 to 40%. The samples’ tensile strength ratio increased by 20–60%, with the highest results for 1% NCC and 4% dry resin. Pull Off test results demonstrated that changing the aggregate did not affect the cohesion Pull Off, but changing the aggregate and bitumen affected the adhesion Pull Off resistance. The Pull Off test results indicated that nano-calcium carbonate provided better performance in cohesion states with increases of 1.2 to 3.2 kPa for limestone and 1.3 to 3.3 kPa for granite. Dry resin excelled in adhesion states with increases of 1.5 to 3.6 kPa for limestone and 1.8 to 3.8 kPa for granite. These results highlight the need for further attention to the mechanisms of cohesion in identifying moisture damage in asphalt mixtures.

Similar content being viewed by others

Introduction

Quick advancements in transportation infrastructure have increased demands for new asphalt concrete (AC). Additionally, the expansion of the social economy has significantly increased the traffic volume and weight, requiring improved performance from asphalt mixtures1,2,3. Utilizing additives is one of the primary methods to enhance the performance of asphalt mixtures. These substances can improve various properties, such as crack resistance, flexibility, stability against temperature changes, and resistance to the damaging effects of moisture and heavy traffic. Additives include polymers, fibers, and waterproofing agents, selected based on the specific needs of the project. These materials extend the service life of roads and reduce the need for frequent repairs, which in turn saves costs and increases road safety. Recycling waste materials in asphalt mixtures helps lower the costs of pavement construction, reduce solid waste, and conserve raw materials4,5.

Moisture can damage ACs; in other words, it can cause a failure in the bitumen or the bitumen-aggregate contact surface. Moisture-induced damage in AC is referred to as moisture sensitivity. Moisture alters the properties of the bitumen and weakens it against cohesive failure. Moreover, the introduction of water into the AC causes adhesive and cohesive ruptures, especially in hydrophilic aggregates. Two categories of factors affect the performance of AC in relation to the occurrence and severity of moisture sensitivity. The first category involves internal factors, including the properties of bitumen, aggregate, and air void (AV) of AC. The second category involves factors related to conditions outside of AC, which include environmental conditions, traffic, etc6. It is necessary to change the factors affecting the occurrence of moisture damage; however, environmental and traffic conditions are mostly beyond the control of the pavement designer.

There are two ways to improve the bitumen-aggregate adhesion and increase the resistance of AC against moisture sensitivity. The first is to use anti-stripping agents as bitumen modifiers. These materials are mainly chemical activators that improve bitumen coverage on the aggregate surface and enhance the bitumen-aggregate adhesion. Amines or amido amines are the main chemical compounds of liquid anti-stripping agents7,8. The second is to coat the surface of aggregates, especially acidic aggregates that are sensitive to moisture, with a suitable material. The material used for coating must be made of basic material so that it has proper adhesion with the surface of acidic aggregates, as well as good adhesion with bitumen as an acidic material. This coating is a contact surface between two acidic materials that cannot have proper adhesion to each other7,8. The present study investigated the effect of using dodecyl amide, nano-calcium carbonate (NCC), and dry resin in reducing the moisture sensitivity of AC.

Literature review

Aksoy et al.9 studied the effect of Wetfix I, Lilamin VP 75P, Chemcrete, and rubber on the moisture damage of ACs. The results showed that the additives reduced the moisture sensitivity of ACs. Podolsky et al.10 also showed that Wetfix BE improved the adhesion of bitumen and aggregate and increased the deformation stability of the AC at high temperatures. Abed et al.11 evaluated the impact of adding Wetfix with styrene-butadiene-styrene (SBS) polymer on the moisture sensitivity of ACs before and after exposure to wet conditions. The indirect tensile strength (ITS), Marshall, and double punching shear tests were used to estimate the properties of the mixture. The modified ACs had better resistance to moisture damage. It was observed that 0.5% Wetfix and 3% SBS provided more favorable properties of AC.

Hamedi and Moghadas Nejad12 identified the effective mix design and thermodynamic parameters on moisture damage of ACs. Cohesion free energy, adhesion free energy, specific surface area (SSA) of aggregates, and the thickness of the bitumen film on the aggregate’s surface directly affected the moisture resistance of ACs. Additionally, the debonding energy and permeability harmed the resistance of AC against moisture. Nataadmadja et al.13 evaluated the moisture sensitivity of AC with the addition of anti-stripping materials, including Wetfix-BE and Wetbond-SP. Three tests, including Marshall, Cantabro abrasion, and ITS, were performed to evaluate moisture sensitivity. Both additives increased the resistance of AC against moisture. The improvement in moisture resistance was greater in Wetbond-SP samples compared to Wetfix-BE samples. You et al.14 conducted a laboratory investigation on premature stripping in asphalt pavements beneath chip-seals, utilizing pavement cores extracted from Minnesota. The study employed Michigan Tech’s newly developed Interface Bond Test to assess the bond strength at the chip-seal interface and the direct tensile strength of underlying asphalt layers. Findings indicate that intact chip-seals serve as an effective protective layer, significantly enhancing pavement durability. However, partial damage within the chip-seal compromises structural integrity, accelerating distress and deterioration in the asphalt pavement due to weakened bonding and increased moisture susceptibility. Yousefi et al.15 evaluated asphalt mixtures using dynamic creep, indirect tensile strength, and semi-circular bending tests to assess rutting, moisture susceptibility, and cracking resistance. Results showed that aromatic extract and tall oil reduced moisture susceptibility, while triglycerides and fatty acids increased it. Although rejuvenators generally decreased rutting resistance, they enhanced cracking resistance, particularly in mixtures with triglycerides and fatty acids. In another study, You et al.16 developed a laboratory-based method to evaluate the shear bond strength of chip-seal applications with asphalt pavement. Their study examined various asphalt-aggregate combinations and asphalt-emulsion application rates while assessing the impact of temperature variations and freeze-thaw (F-T) cycles on bond durability. The findings indicated that weak shear bonding in chip-seal systems is largely attributed to repeated F-T cycles and the properties of raw materials used, highlighting the importance of optimizing materials to enhance performance.

Nataadmadja et al.17 (2020) analyzed the moisture sensitivity of AC with anti-stripping additives. The samples prepared using hydrated lime performed better than samples prepared using other additives. Moreover, Muis et al.18 used the Marshall test to evaluate the use of Wetfix-Be in AC. The results demonstrated that 0.4% Wetfix-Be had the greatest increase in Marshall stability. Hamedi19 also studied the effect of Wetfix N422 and Wetfix 312 on the moisture sensitivity of AC. One, three, and five freeze-thaw (F-T) cycles were applied to the samples to evaluate the effect of additives more accurately. The additives increased the indirect tensile strength ratio (TSR) of dry and wet ACs.

Xiao et al.20 examined moisture damage in ACs with an amine-based antistripping agent (ASA). They measured the surface free energy (SFE) of both ASA-modified asphalts and aggregates, evaluating compatibility and moisture resistance. ASA improved asphalt adhesion and coating quality, thereby increasing the energy ratio (ER) and moisture resistance. The study concluded that selecting compatible asphalt-aggregate combinations is more effective than using ASA alone. TSR results correlated well with SFE-based criteria for HMA material selection.

Liu et al.21 examined 69 bitumen-aggregate combinations with thermodynamic models to assess the strength of ACs against moisture. The relationship between the chemical composition of bitumen (saturated, aromatic, resin, asphaltene, and wax) and the moisture stability of the ACs was evaluated. More resin and less asphaltene in bitumens led to better moisture stability of the dry and wet ACs. Another study evaluated the use of dry resin polymer additive to create a moisture-resistant AC and compared it with mixtures containing hydrated lime. The effects of additives were studied by ITS and thermodynamic tests. Dry resin polymer increased the basic part and decreased the acidic part of bitumen, which improved the adhesion work of ACs22.

Cui et al.23 utilized silicone resin polymer as a sealing material. They evaluated the moisture sensitivity and high-temperature performance of ACs modified with silicone resin polymer. The surface properties of silicone resin effectively separated moisture and thus improved the moisture resistance of AC. Furthermore, Bahmani et al.21 proposed an approach to investigate the effect of epoxy resin on the moisture sensitivity of ACs. The epoxy resin increased the adhesion of bitumen and aggregates and the surface wettability of aggregates with bitumen. It reduced the moisture sensitivity of ACs containing granite, which is a sensitive aggregate in the presence of water.

Razavi and Kavussi24 investigated the effects of various nanomaterials and fillers on asphalt mixes’ moisture resistance. They utilized four nanomaterials (nano-CaCO3, nano-hydrated lime, nano-bentonite, and nano-silica) and two fillers (hydrated lime and CaCO3). Homogenous distribution was verified using FE-SEM. The modified Lottman test and F-T cycles showed that 4% nano-hydrated lime exhibited the most resistance. ITSM tests determined TSR and IRMr parameters. Adding 20% hydrated lime and 4% nano-hydrated lime increased TSR by 60%. Using 5% CaCO3 and 4% nano-CaCO3 resulted in a 60% increase in TSR. Resilient modulus tests validated these results.

Kumali et al.25 examined the effects of different mineral fillers (baghouse dust, lime kiln dust, and hydrated lime) on the rheology and moisture resistance of asphalt binders and concrete mixtures. Dynamic shear modulus tests and rolling bottle tests evaluated their impact. Mineral fillers, particularly hydrated lime, stiffened the asphalt binder/mastic, improving dynamic shear modulus, affinity, and moisture resistance. The filler type had a greater influence on asphalt properties than the binder type. Hydrated lime provided the best results and was used in the final stage to examine moisture resistance at the mixture scale.

Sarkar et al.26 investigated the impact of various additives, including warm-mix additives, an anti-stripping agent, and graphene nano-platelets, on the moisture and cracking resistance of stone matrix asphalt. They utilized Fourier transform infrared spectroscopy (FTIR), sessile drop tests, and modified Lottman tests. Graphene nano-platelets enhanced moisture resistance and improved adhesion and debonding properties, although their TSR was slightly below AASHTO T283 standards. Overall, warm-mix additives effectively improved resistance to cracking and moisture damage.

Another study examined the effect of coating the aggregate surface with nanomaterials on the moisture sensitivity of AC. The nanoparticles decreased the moisture sensitivity of ACs by improving the adhesion work and ITS of control samples. This improvement was more obvious in the samples manufactured with granite27. Moreover, Hamedi et al.28 used NCC (nano-CaCO3) as an anti-stripping agent. They added different contents (0, 2, 4, and 6%) of this material to the bitumen. The samples of ACs were made with these modified bitumens and two aggregate samples (limestone and granite), and their moisture resistance was evaluated using the SFE method and the modified Lottman mechanical test. Based on their experiments, the parameters of ITS and adhesion free energy increased by adding this substance to bitumen.

Ameri and Sadeghiavaz29 evaluated the effectiveness of microwave healing on asphalt mixtures with iron powder (IP) filler. Modified Lottman tests assessed moisture sensitivity, while fatigue-based and fracture-based methods measured healing ability. The results indicated that higher IP content improved ITS, TSR ratio, fatigue life, toughness, and microwave healing indices.

Gupta et al.30 evaluated the moisture susceptibility of reclaimed asphalt foamed bituminous mix (fbm) with reclaimed asphalt pavement (RAP) as a replacement for fresh aggregates. Moisture susceptibility was assessed using TSR and resilient modulus ratio (RMR), subjected to conditioning procedures, such as AASHTO T283. Incorporating RAP in FBM improved moisture resistance, with 100% RAP showing the least moisture susceptibility regardless of conditioning type. Zhang et al.31 investigated the mixing conditions and performance effects of dry-modified Styrene–Butadiene–Styrene (SBS) using molecular simulations, fluorescence microscopy, infrared spectroscopy, and asphalt performance tests. Results show that increasing SBS dosage from 4 to 6% enhances diffusivity by 20% and interface strength by 32%, with optimal diffusion achieved at a 90-second mixing time. The best preparation parameters for maximum pavement performance are 6% SBS, a mixing temperature of 180–185 °C, 90 s of mixing, and a 30-minute storage time. Sarkar et al.26examined the effects of warm-mix additives, an anti-stripping agent, and graphene nanoplatelets on the moisture and cracking resistance of stone matrix asphalt in wet regions. Laboratory tests, including surface free energy and mechanical evaluations, reveal that graphene nanoplatelets enhance wettability, adhesion, and moisture resistance more effectively than other additives. They also improve cracking resistance by 34.1%, though their tensile strength ratio (0.76) falls below the AASHTO T283 threshold for moisture damage resistance. Overall, warm-mix additives improve performance and are cost-effective.

As observed in the literature review, most studies used the ratio of mechanical tests in wet-to-dry conditions as an index for moisture sensitivity in different ACS. Furthermore, they evaluate the use of various additives based on these indices. However, different additives may exhibit varying performances depending on their dosage, type of bitumen, and type of aggregate in different mixtures. Therefore, this study utilized a combination of aggregates along with antistripping additives. Besides conventional mechanical tests, this study employed direct tensile tests (Pull Off test) in both cohesion and adhesion failure states to assess the effect of each additive on the failure mechanisms under wet conditions.

Statement of the problem and objectives

The efficiency of AC depends on the aggregate-bitumen system’s cohesion and adhesion. Moisture in ACs causes the loss of adhesion and cohesion, resulting in stripping and bleeding. Chemical and organic additives are currently used to increase the adhesion, cohesion, and durability of ACs. As seen in the literature review, many studies have focused on the effect of anti-stripping materials on the moisture sensitivity of ACs; however, these studies have focused on the overall performance of ACs against moisture while neglecting the effect of anti-stripping additives on moisture damage mechanisms. Therefore, the present study examined the effect of dodecyl amide, dry resin, and NCC as anti-stripping agents on the moisture sensitivity of AC. In addition to the modified Lottman mechanical test, the Pull Off test was performed to determine the mechanisms of AC failure (adhesive and cohesive). The objectives of this study were:

-

Investigating the effect of dodecyl amide, NCC, and dry resin on the cohesion mechanism of bitumen under dry conditions.

-

Studying the effect of dodecyl amide, NCC, and dry resin on the adhesion mechanism under dry conditions.

-

Evaluating the effect of dodecyl amide, NCC, and dry resin on cohesive failure under wet conditions.

-

Investigating the effect of dodecyl amide, NCC, and dry resin on adhesive failure under wet conditions.

Laboratory plans, materials, and tests

Laboratory plans

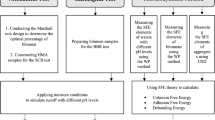

For the laboratory procedure, first, the aggregates, bitumens, and additives were prepared. The Marshall samples were prepared to calculate the optimum bitumen content. The ITS test, according to the AASHTO T283 standard, was used to determine the general performance of AC against moisture damage, and the Pull Off test was performed to detect the mechanisms of failure. The materials used to make the samples were two types of granite and limestone, PG 64 − 16 bitumen, and three types of additives, namely dodecyl amide, dry resin, and NCC. First, control samples were manufactured with the optimum bitumen content associated with each type of aggregate. Subsequently, the samples were modified with dodecyl amide, dry resin, and NCC. All the samples were tested in both dry and wet conditions (AASHTO T283). The Pull Off test was performed in modes of adhesive and cohesive failure. Figure 1 illustrates the research procedure.

Note that three repetitions were conducted for the ITS tests and five repetitions for the Pull Off tests.

Materials

Limestone and granite aggregates were used to manufacture the AC samples. Table 1 presents the chemical composition of the aggregates, and Fig. 2 displays the limits of gradation and its diagram. Limestone and granite are known as hydrophobic and hydrophilic aggregates, respectively.

This study used PG 64 − 16 bitumen, which is the most common type of bitumen used in Iran. This bitumen is manufactured by the Pasargad Oil Company (Iran), and its properties are given in Table 2.

Dodecyl amide is an anti-stripping liquid that improves the adhesion property of bitumen-aggregate by creating thermal stability. Because this substance is heat-resistant, it can be stored in a barrel for a week. It is commonly used between 0.1% and 0.5% of the bitumen’s weight for hot and warm ACs, selected according to the type of bitumen and aggregate. Dodecyl amide is stored in metal tanks whose temperature should be between 10 °C and 40 °C. Due to complex amines, this substance may cause skin and eyes to burn in case of contact32. Table 3 lists the characteristics of dodecyl amide.

The structure of NCC is similar to that of hydrated lime. It has even been claimed that NCC is better than hydrated lime in terms of performance. For example, the solubility index of calcium hydroxide (hydrated lime) is 1.73 (kg/m3) of water at 20 °C, while this parameter is 0.013 (kg/m3) for calcium carbonate, which is considered practically insoluble in water. This parameter is critical in the hydrophobicity of aggregates. NCC is a substance in nano dimensions with the molecular structure of CaCO3 and the international number 1-34-471. This material has advantages such as uniform particle size distribution, high SSA, and low water absorption33,34,35. The physical properties of NCC are shown in Table 4.

Resin primarily consists of volatile monoterpenes and non-volatile diterpenic resin acids. By undergoing a distillation process, resin can be divided into turpentine (30%) and rosin (70%). Rosin, also known as colophony, is the solid residue left after turpentine evaporates. It has various applications in products such as paints, varnishes, coatings, and adhesives. The composition of rosin can vary depending on its origin, plant species, and geographical location. X-ray diffraction diffractograms conducted on rosin have exhibited characteristics of an amorphous substance36. Dry resin is a polymeric powder obtained from vinyl and acrylate. It forms an emulsion in water, which, after drying, provides good adhesion with different surfaces, high flexibility, and appropriate strength in wet areas. Table 5 presents the physical properties of dry resin.

A mixer was used to mix dodecyl amide with the bitumen. The bitumen was heated to 160 °C and, then, the material was added to it. The mixture was stirred for 5 min at 2000 rpm until the ingredients were completely mixed. Finally, the modified bitumen was used to make samples containing dodecyl amide. Based on previous research37, 0.5% and 1% of dodecyl amide by the bitumen’s weight were used. Moreover, NCC was used at two contents of 0.5% and 1% by the weight of bitumen, according to previous research38. A high-speed mixer was employed for this purpose. This mixer could rotate up to 12,000 rpm, and its maximum rotational capacity was used in this study. For bitumen modification, the bitumen was heated to 160 °C, and NCC was slowly and gradually added to it. This mixing was continued for 15 min to obtain a homogeneous composition. Finally, based on previous research37,39, two contents of dry resin (2% and 4% by the weight of bitumen) were used for bitumen modification. First, the bitumen was heated to 160 °C, and then the material was added to it. The mixture was stirred for 15 min at 4000 rpm until the ingredients were completely combined. This mixer is shown in Fig. 3. A heater surrounded the bitumen container to prevent the temperature of the bitumen from decreasing. Table 6 presents the important parameters in bitumen modification with these three materials.

Tests

Marshall mix design

The optimum content of bitumen was based on a combination of Marshall resistance, flow, density, and void analysis results. The optimum bitumen content that had the maximum unit weight and Marshall stability was calculated. Then, the AV corresponding to 4% was identified, and the optimum bitumen content was obtained based on that. If any of the criteria did not meet the regulation’s values, the mix design would have to be revised.

Moisture sensitivity of ACs

The moisture sensitivity of ACs, according to the AASHTO T283 standard, was used to determine the general performance of AC against moisture damage40. The ACs were compacted to have an AV of 6–8% to match the field conditions. Therefore, the first step in this test was to create AC samples with an AV of 6–8%. According to the combined modes of this experiment, six samples were created for each combination. Samples with 45 and 75 blow numbers were made, and after obtaining their AV, the blow numbers to manufacture a sample with a 7% AV were calculated through interpolation. After determining the number of blows based on interpolation, the samples were prepared according to the interpolated number of blows, and their AV percentage was checked against the standard criteria (AV of 7 ± 0.5%). The samples were then exposed to dry and wet conditions. The steps to create wet conditions were as follows:

The samples reached 70–80% saturation by a vacuum pump (under a pressure of 35 kPa).

If S was less than 70%, the saturation procedure had to continue to the desired level. If S was more than 80%, the sample had failed. To apply the F-T cycles, the samples were placed in plastic bags and then inside another plastic bag containing 10 ml of water. They were kept in a freezer at -18 °C for 16 h. Then, the samples were placed in a 60 °C water bath for 24 h. They were placed in a water bath at 25 °C for 2 h and, finally, prepared for testing40.

The rate of loading was 5.08 (cm/min) until failure. Using Eq. 1, the value of ITS was calculated for all six samples of each AC combination:

where P is the failure force (N), t is the thickness of AC (mm), and d is the diameter of AC (mm).

The TSR is calculated according to Eq. 2.

where ITScond represents the ITS of wet samples (kPa), and ITSuncond represents the ITS of dry samples (kPa). The minimum permissible TSR is 70%; it is also considered 80% in areas with humid weather40.

Pull off test

The Pull Off test is used as a direct tensile test to measure adhesion Pull Off (AP) and cohesion Pull Off (CP). The Pose test AT-A instrument, AASHTO TP-9141, and ASTM D454142 standards were used in this study. This test measures the tensile strength of the bitumen attached to a plate. The pressure needed to separate the samples under the conditions is calculated at 25 °C using a pneumatic adhesion tester.

Before testing, the surface of the aggregate should be placed in an ultrasonic device for one hour, and the surface of the stabs should be cleaned from any pollutants, dust, and oxidation. Then, the heated bitumen is poured onto the aggregate surface. At this stage, plastic molds with a diameter of 20 mm are used on the aggregate surface to prevent the bitumen from spreading to other areas. The bitumen thickness on the surface of each aggregate is 1 mm for cohesive failure and 0.5 mm for adhesive failure43. The bitumen is allowed to reach room temperature. Then, the Pull Off device’s stubs are adhered to the bitumen surface using glue. Glue is used to ensure that failure does not occur at the bitumen-dolly interface or that the dolly does not detach from the bitumen (Fig. 4).

The prepared bitumen-aggregate-stub samples, which are to be tested under wet conditions, are placed in a water bath at 40 °C for 24 h. After the samples are removed from the water bath, they are kept at lab temperature (25 ℃) for 1 h, and then a load is applied to them. The samples that are to be tested under dry conditions do not undergo these conditions and are only kept at laboratory temperature for 24 h after attaching the stub to the bitumen. Then, the loading test is performed on them. The rate of pulling is 690 (kPa/s)41.

The Pull Off test is conducted on the bitumen layer adhered to the aggregates in both cohesion and adhesion failure modes. The only difference between these two modes is that the bitumen thickness is higher in the cohesion failure than in adhesion failure mode to ensure that failure occurs within the bitumen thickness.

Results and discussion

The results of the ITS test

The results of the ITS test in the dry state are shown in Fig. 5. Evidently, the ITS in granite samples was generally higher than in limestone samples. The changes in the ITS of samples with similar aggregates in dry conditions can be attributed to the type of bitumen or modifiers. According to Fig. 5, NCC, dry resin, and dodecyl amide increased the ITS in dry conditions in the samples made with limestone and those made with granite. NCC resulted in the highest ITS values, which can be attributed to the nano-scale effect of NCC that increases the surface area for interaction and, thus, enhances the bitumen-aggregate bond. The increased viscosity and stiffness of the modified bitumen with nano-additives contribute to the improved load distribution and resistance to deformation under tensile stress. This is particularly significant for granite samples, which inherently exhibit higher ITS values due to their mineralogical composition and structural integrity. The best and worst performance in the samples belonged to those containing granite and bitumen modified with 1% NCC, and the samples made with limestone and control bitumen, respectively. The differential performance of samples containing granite and limestone underscores the importance of aggregate type in determining the overall effectiveness of bitumen modification.

Figure 6 displays the percentage changes in the ITS of the samples made in the dry state. NCC in both types of aggregates performed better than dry resin and dodecyl amide. When using 0.5% NCC, the samples manufactured with limestone showed a 37% increase, and the samples containing granite showed a 66% increase in dry ITS. This increase in ITS due to using 1% NCC was 57% and 80%, respectively, in limestone and granite samples. The substantial increase in ITS values with NCC, particularly at 1%, underscores its superior capability in improving the asphalt mixture’s stiffness and adhesive properties. The nano-scale structure of NCC enhances the bitumen’s molecular interaction with aggregates, leading to better load distribution and resistance to deformation. This effect is more pronounced in granite samples, likely due to the aggregate’s mineralogical composition and higher SSA, which provides more interaction sites. Using 2% dry resin, the samples produced with limestone indicated a 32% increase, and the samples containing granite showed a 68% increase in dry ITS. This increase in ITS due to using 4% dry resin was 49% and 79%, respectively, in limestone and granite samples. Dry resin also showed significant improvement, attributed to its polymeric nature that enhances the bitumen’s viscoelastic properties. Finally, when utilizing 0.5% dodecyl amide, samples made with limestone showed an 11% increase, and samples with granite indicated a 34% increase in dry ITS. This increase in ITS when using 1% dodecyl amide was 24% and 40%, respectively, in limestone and granite samples. However, the improvement with dodecyl amide, while notable, was less than that with NCC and dry resin. This could be due to its lower influence on the bitumen’s viscosity and stiffness compared to the other two additives.

In general, using additives in granite samples caused a greater improvement in dry ITS compared to limestone. As mentioned before, utilizing dry resin and NCC additives increased the stiffness of the bitumen, thus enhancing its resistance to indirect tension. In addition, NCC, as a basic substance, reduced bitumen’s acidity when combined with bitumen and hence increased the adhesion between bitumen and granite (which is acidic). Therefore, compared to the other two additives, it yielded a better result in increasing the dry ITS of the samples.

Figures 7 and 8, respectively, present the results of the wet ITS in limestone and granite samples. The ITS of the samples decreased by exposure to F-T cycles. Moreover, the samples made with limestone had a higher resistance to moisture sensitivity than those produced with granite. This behavior is attributed to the mineralogical structure of the aggregates; most constituent minerals of granite are acidic, increasing the hydrophilicity of these aggregates. As a result, their bonds are broken, and they lose their resistance when exposed to moisture. All three types of additives increased the ITS of samples made with limestone and granite. This improvement in the ITS of the samples was enhanced by increasing the content of the additive. Therefore, incorporating 1% NCC as a bitumen modifier yielded better results than using 0.5% of this material. This phenomenon was observed in both granite and limestone, as well as when using dry resin and dodecyl amide.

Overall, the weakest performance in wet ITS was observed in granite specimens produced with unmodified control bitumen and subjected to three freeze-thaw cycles. This trend aligns with the intrinsic properties of granite, as its acidic nature leads to increased hydrophilicity, making it more vulnerable to moisture-induced deterioration. With repeated freeze-thaw cycles, the adhesive bond between bitumen and granite weakens significantly, resulting in reduced ITS values. Conversely, the highest ITS performance was recorded in limestone specimens containing 1% NCC-modified bitumen and exposed to a single freeze-thaw cycle. This superior performance can be attributed to the alkaline characteristics of limestone, which promote enhanced bitumen adhesion. Furthermore, the incorporation of NCC, a nano-modifier, effectively enhances bitumen viscosity and stiffness, optimizing load distribution and improving resistance to tensile stresses. These findings underscore the critical influence of aggregate mineralogy and the efficacy of NCC in improving moisture resistance and the mechanical durability of asphalt mixtures.

Table 7 shows the results of the t-test to evaluate the influence of moisture conditions and additives on ITS values. The p-value in the two compared groups (dry & 1 F-T cycle and 1 F-T cycle & 2 F-T cycle) was less than 0.05. In the other compared groups (dry & 2 F-T cycle, dry & 3 F-T cycle, 2 F-T cycle & 3 F-T cycle), the p-values were less than 0.05. This shows that the application of moisture conditions decreased the resistance of AC in the dry state. Besides, increasing the number of F-T cycles had a significant effect on reducing ITS values. In other words, the moisture conditions increased the moisture sensitivity of AC by reducing its adhesion and cohesion, and the increase in F-T cycles intensified this moisture sensitivity. Table 7 also shows that incorporating 0.5% NCC, 2% dry resin, and 0.5% dodecyl amide did not significantly increase the resistance of the control AC under dry and wet conditions. However, increasing the amount of these additives (NCC to 1%, dry resin to 4%, and dodecyl amide to 1%) led to a significant increase in ITS values and, as a result, improved the moisture sensitivity of the control AC.

The data related to the TSR are presented in Figs. 9 and 10, respectively. Since the samples were exposed to F-T cycles, their resistance decreased compared to the dry condition. The data presented in the previous sections also indicate that the resistance of ACs in wet conditions decreased compared to similar samples in dry conditions. In general, the decrease in the TSR of samples can be attributed to the loss of bitumen-aggregate adhesion or bitumen cohesion due to moisture. This loss of adhesion and cohesion compromised the structural integrity of AC, making it more susceptible to moisture-induced damage. The superior performance of NCC, dry resin, and dodecyl amide additives in increasing the TSR highlights their effectiveness in mitigating moisture damage. By improving the adhesive and cohesive properties of bitumen, these additives enhance the overall moisture resistance of AC. The effect of different aggregates and additives on moisture sensitivity is quite noticeable. NCC, dry resin, and dodecyl amide additives increased the TSR of the samples compared to the controls.

The samples made with limestone demonstrated more resistance to moisture sensitivity than those with granite. One of the most important factors affecting the resistance of aggregates to moisture sensitivity is the structure of the aggregate minerals. The SiO2 and CaO or CaCO3 minerals determine the aggregate’s degree of hydrophilicity or hydrophobicity. The higher the percentage of SiO2, the greater the hydrophilicity of aggregates; conversely, the higher the percentage of CaO, the greater the hydrophobicity of aggregates. Granite, which has been identified as an acid aggregate in previous research, has a large amount of SiO2 minerals and, therefore, strong hydrophilic properties. On the other hand, limestone, which contains a large amount of calcium oxide or calcium carbonate, possesses hydrophobic properties. In previous studies, limestone has been defined as a basic aggregate.

Figure 11 presents the percentage increase in TSR attributed to the incorporation of the studied additives (NCC, dry resin, and dodecyl amide). The addition of these modifiers in asphalt mixtures containing both aggregate types effectively enhanced moisture resistance and improved TSR values. These additives reinforced the interfacial bonding between bitumen and aggregate by increasing bitumen stiffness, thereby mitigating the detrimental effects of moisture-induced degradation. As depicted in Fig. 11, the beneficial impact of additives on TSR improvement was particularly pronounced in limestone specimens as the number of freeze-thaw cycles increased. This behavior can be attributed to limestone’s inherently hydrophobic nature, which helps preserve adhesion under prolonged exposure to moisture fluctuations.

The results of the pull off test

The Pull Off test was carried out in dry and wet conditions with high and low bitumen thicknesses. The dry state caused a rupture in the bitumen film or a cohesive failure. The wet state was equivalent to a rupture of the bitumen-aggregate contact surface or adhesive failure. The results of the CP in samples made with limestone and granite are presented in Figs. 12 and 13, respectively. The type of aggregate did not affect the CP. The reason could be the thickness of the bitumen film. The high thickness in this test led to failure in the bitumen film and not at the bitumen-aggregate contact surface. This factor caused bitumen properties to have a more significant effect than the type of aggregate. In addition, the CP decreased by exposing the samples to F-T cycles. This was predictable based on the weakening of the samples due to moisture.

As mentioned before, the type of bitumen affects CP. The results indicated that NCC, dry resin, and dodecyl amide additives increased the CP of dry samples and samples subjected to F-T cycles. Dry resin and NCC raised the cohesion resistance by increasing the bitumen’s viscosity and stiffness. In general, the greatest increase in CP was observed in both types of aggregates in samples made with bitumen modified with 1% NCC. NCC, in particular, demonstrated the most substantial improvement attributed to its nano-scale structure, which enhanced the molecular interaction and adhesion between the bitumen and aggregate. The weakest CP belonged to the samples manufactured with the control bitumen.

Figures 14 and 15, respectively, present the results of the AP in samples made with limestone and granite. The types of aggregate and bitumen were important factors in AP, contrary to CP, which was only affected by the type of bitumen. Similar to CP, the AP of the samples exposed to the F-T cycles decreased. This reduction rose with an increase in the number of cycles and, subsequently, with an increase in the samples’ exposure to moisture.

In the unmodified control state, limestone exhibited a higher AP than granite. This can be attributed to its greater surface porosity and inherently basic chemical nature, which facilitated stronger adhesion with bitumen. However, in specimens incorporating modified bitumen, granite generally demonstrated superior AP. As previously noted, the additives employed possessed basic characteristics, and upon interaction with bitumen-a relatively acidic binder-they effectively increased its alkalinity. This modification enhanced the chemical affinity between the bitumen and granite, an aggregate with acidic surface properties, thereby improving adhesion performance.

The highest AP was observed in granite specimens incorporating bitumen modified with 1% NCC and those with bitumen modified with 4% dry resin. Conversely, the lowest AP was recorded in samples prepared with unmodified control bitumen. Among the control bitumen specimens, limestone exhibited the highest AP, likely due to the favorable adhesion between bitumen-characterized by its relatively acidic nature-and the basic surface chemistry of limestone. The progressive decline in AP with increasing freeze-thaw cycles underscores the detrimental effects of moisture intrusion, which progressively degrades adhesive bonding at the bitumen-aggregate interface. The superior performance of chemical modifiers in enhancing bitumen adhesion highlights their critical role in developing moisture-resistant asphalt mixtures. These findings emphasize the necessity of selecting appropriate additive-bitumen combinations based on aggregate surface characteristics to optimize AP and overall pavement performance.

Tables 7 and 8 demonstrate the results of the t-test to investigate the significance of the impact of moisture conditions and additives on CP and AP values. The p-value in the two compared groups (dry & 1 F-T cycle and 1 F-T cycle & 2 F-T cycle) was less than 0.05. In the other groups (dry & 2 F-T cycle, dry & 3 F-T cycle, 2 F-T cycle & 3 F-T cycle), p-values were less than 0.05. This demonstrates that the moisture conditions decreased the CP and AP of dry AC. Moreover, increasing F-T cycles significantly lowered AP and CP. In other words, the moisture conditions increased the failure potential in the AC at the bitumen phase (cohesion failure) or at the bitumen-aggregate boundary (adhesive failure). Furthermore, increasing the F-T cycles intensified the cohesion failure and adhesive failure of AC.

Tables 8 and 9 also show that using 0.5% NCC and 2% dry resin did not significantly increase the AP and CP of the control AC under dry and wet conditions. However, raising the amount of these additives (NCC to 1% and dry resin to 4%) significantly increased AP and CP values; as a result, it improved the resistance of AC against adhesive and cohesive failure. Adding 0.5 and 1% of dodecyl amide did not significantly alter the CP and AP of AC. Accordingly, 1% NCC and 4% dry resin had the best performance in enhancing AC’s resistance against moisture damage in adhesive and cohesive failure.

Conclusions

Moisture sensitivity is one of the most important failures of roads during their service life. In recent years, many efforts have been made to control this type of failure in ACs. Utilizing anti-stripping additives is one of the most commonly employed methods to mitigate this failure. However, the impact of these additives on the primary mechanisms of moisture sensitivity has received less attention. Hence, this study investigated the effect of dodecyl amide, NCC, and dry resin on reducing the moisture sensitivity of AC. The following important conclusions were drawn:

-

1.

Samples made with granite aggregate exhibited superior mechanical performance under dry conditions, whereas samples made with limestone demonstrated enhanced resistance to moisture-induced degradation in wet environments, particularly with increasing freeze-thaw (F-T) cycles. The differential response highlights the intrinsic material properties governing durability under variable exposure conditions.

-

2.

The incorporation of NCC, dry resin, and dodecyl amide significantly improved the ITS of both limestone and granite specimens across dry and wet conditions. The observed enhancement was proportional to the additive concentration, confirming the role of chemical modification in optimizing adhesion and cohesion properties.

-

3.

All three additives effectively enhanced the TSR and mitigated moisture susceptibility in the asphalt mixtures, with higher dosages yielding more pronounced improvements. These findings underscore the critical role of additive concentration in achieving optimal durability and resistance against environmental degradation.

-

4.

The type of aggregate exhibited negligible influence on CP due to the considerable thickness of the bitumen film, ensuring uniform stress distribution. However, a significant impact was observed on AP, with limestone demonstrating superior AP relative to granite, attributed to its inherently porous and alkaline surface characteristics that facilitate aggregate-bitumen adhesion.

-

5.

The highest AP performance was recorded in granite specimens modified with 1% NCC-enhanced bitumen and 4% dry resin-modified binder, highlighting the synergy between aggregate mineralogy and binder composition. The AP enhancement was more pronounced in the modified bitumen-granite system, suggesting the pivotal role of chemical modification in optimizing adhesion properties.

-

6.

Asphalt mixtures with low bitumen content exhibited superior cohesive strength, while those with higher binder content displayed enhanced adhesive resistance to moisture intrusion. Given the differential performance of additives in either cohesive or adhesive states, direct tension testing using the Pull Off method is recommended to systematically evaluate additive efficacy based on asphalt binder coverage on aggregate surfaces.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Singh, A. & Gupta, A. Mechanical and economical feasibility of LDPE Waste-modified asphalt mixtures: pathway to sustainable road construction. Sci. Rep. 14 (1), 25311 (2024).

Franesqui, M. A. et al. Cleaner technologies for asphalt mixtures combining reuse of residual aggregates, waste crumb rubber and warm mix asphalt additive. Sci. Rep. 13 (1), 8153 (2023).

Ali, A. S. B. et al. Chemical properties of peat micro particles modified asphalt. Sci. Rep. 14 (1), 26873 (2024).

Zhang, R., Wang, J. & Kang, H. Effect of waste cooking oil on the performance of EVA modified asphalt and its mechanism analysis. Sci. Rep. 14 (1), 14072 (2024).

Buruiana, D. L. et al. Recycling micro polypropylene in modified hot asphalt mixture. Sci. Rep. 13 (1), 3639 (2023).

Little, D. N. & Jones, D. Chemical and mechanical processes of moisture damage in hot-mix asphalt pavements. In National Seminar on Moisture Sensitivity of Asphalt Pavements (Transport Research Board of the National Academies San Diego, 2003).

Xiao, R. et al. Thermodynamic properties of aggregate coated by different types of waste plastic: adhesion and moisture resistance of asphalt-aggregate systems. J. Mater. Civ. Eng. 35 (8), 04023261 (2023).

Cui, P. et al. Effect of coarse aggregate morphologies on the hydrodynamic pressure–resulted moisture susceptibility of asphalt mixtures. J. Mater. Civ. Eng. 32 (11), 04020343 (2020).

Aksoy, A. et al. Effects of various additives on the moisture damage sensitivity of asphalt mixtures. Constr. Build. Mater. 19 (1), 11–18 (2005).

Podolsky, V. P. et al. The study of operating capacity of asphalt concrete modified with an additive wetfix be. Scientific herald of the Voronezh state university of architecture and civil engineering. Constr. Archit., 2016 (1), 75–83 .

Abed, A. H. et al. The effect of hybrid anti-stripping agent with polymer on the moisture resistance of hot-mix asphalt mixtures. Cogent Eng. 6 (1), 1659125 (2019).

Hamedi, G. H. & Moghadas Nejad, F. Evaluating the effect of mix design and thermodynamic parameters on moisture sensitivity of hot mix asphalt. J. Mater. Civ. Eng. 29 (2), 04016207 (2017).

Nataadmadja, A. D. et al. Evaluation of moisture susceptibility of hot mix asphalt. In AIP Conference Proceedings (AIP Publishing, 2019).

You, L., You, Z. & Dai, Q. Performance evaluations of pavement underlying chip-seal: Laboratory testing on pavement cores. In International Conference on Transportation and Development 2020 (American Society of Civil Engineers Reston, VA, 2020).

Yousefi, A. A. et al. Performance of warm asphalt mixtures containing reclaimed asphalt pavement, an anti-stripping agent, and recycling agents: A study using a balanced mix design approach. Constr. Build. Mater. 363, 129633 (2023).

You, L. et al. Laboratory shear bond test for chip-seal under varying environmental and material conditions. Int. J. Pavement Eng. 22 (9), 1107–1115 (2021).

Nataadmadja, A. et al. Analysis of moisture susceptibility of hot mix asphalt with waterproofing additives. In IOP Conference Series: Materials Science and Engineering ( IOP Publishing, 2020).

Muis, Z. A. et al. Measurement of anti-stripping agent content in asphalt mixture with colorimetric test. Geomate J. 17 (63), 378–385 (2019).

Hamedi, G. The laboratory study of the effect of using liquid anti-stripping materials on reducing moisture damage of Hma. Aut J. Civil Eng. 1 (1), 23–30 (2017).

Xiao, R. et al. Moisture damage mechanism and material selection of HMA with amine antistripping agent. Mater. Design. 220, 110797 (2022).

Liu, X. et al. Influence of asphalt chemical composition on moisture susceptibility of asphalt mixtures. Pet. Sci. Technol. 36 (16), 1258–1264 (2018).

Jajin, M. G. & Hamedi, G. H. Examining the effect of dry resin on moisture sensitivity of asphaltic mixtures. Civil Eng. J. 4 (7), 1714–1727 (2018).

Cui, P. et al. Silicone resin polymer used in preventive maintenance of asphalt mixture based on fog seal. Polymers 11 (11), 1814 (2019).

Razavi, S. H. & Kavussi, A. The role of nanomaterials in reducing moisture damage of asphalt mixes. Constr. Build. Mater. 239, 117827 (2020).

Kumlai, S., Jitsangiam, P. & Nikraz, H. Assessments of moisture damage resistance of asphalt concrete mixtures and asphalt mastic with various mineral fillers. Transp. Eng. 7, 100106 (2022).

Sarkar, M. T. A., Elseifi, M. A. & Hossain, Z. Effects of warm-mix additives, anti stripping agent, and graphene nanoplatelet on the cracking resistance, moisture susceptibility, and cost effectiveness of stone mastic asphalt. Constr. Build. Mater. 438, 137250 (2024).

Hamedi, G. H. & Moghadas Nejad, F. Use of aggregate Nanocoating to decrease moisture damage of hot mix asphalt. Road. Mater. Pavement Des. 17 (1), 32–51 (2016).

Hamedi, G. H., Moghadas, F., Nejad & Oveisi, K. Investigating the effects of using nanomaterials on moisture damage of HMA. Road. Mater. Pavement Des. 16 (3), 536–552 (2015).

Ameri, M. & Sadeghiavaz, M. Microwave healing properties and moisture sensitivity of asphalt mixture containing iron powder filler. Sci. Rep. 14 (1), 23154 (2024).

Gupta, L., Kumar, R. & Kumar, A. Moisture susceptibility evaluation of RAP based foamed bituminous mix. In Green and Intelligent Technologies for Sustainable and Smart Asphalt Pavements 332–337. (CRC Press, 2021).

Zhang, Z. et al. Evaluation on the interface characteristics, mechanism and performance of the dry modified SBS asphalt mixtures by multiscale methods. Sci. Rep. 15 (1), 11393 (2025).

Hamedi, G. H., Ghalandari, K., Shamami & Ghasemdoost Abadi, K. Effect of antistripping additives on the cohesion, adhesion, and performance of different asphalt mixtures in dry and wet conditions. J. Mater. Civ. Eng. 34 (9), 04022225 (2022).

Albayati, A. H. et al. Enhancing asphalt performance and its long-term sustainability with nano calcium carbonate and nano hydrated lime. Sustainability 16 (4), 1507 (2024).

Boyjoo, Y., Pareek, V. K. & Liu, J. Synthesis of micro and nano-sized calcium carbonate particles and their applications. J. Mater. Chem. A. 2 (35), 14270–14288 (2014).

Li, X. & Cao, M. Recent developments on the effects of Micro-and Nano-Limestone on the hydration process, products, and kinetics of cement. Materials 17 (9), 2133 (2024).

Cabaret, T. et al. A study of the physico-chemical properties of dried maritime pine resin to better understand the exudation process. Holzforschung 73 (12), 1093–1102 (2019).

Amirkhanian, S. N., Xiao, F. & Corley, M. Laboratory Performance of Liquid Anti-stripping Agents in Asphalt Mixtures Used in South Carolina (Dept. of Transportation, 2018).

Yarahmadi, A. M., Shafabakhsh, G. & Asakereh, A. Laboratory investigation of the effect of nano Caco3 on rutting and fatigue of stone mastic asphalt mixtures. Constr. Build. Mater. 317, 126127 (2022).

Bahmani, H., Sanij, H. K. & Peiravian, F. Estimating moisture resistance of asphalt mixture containing epoxy resin using surface free energy method and modified Lottman test. Int. J. Pavement Eng. 23 (10), 3492–3504 (2022).

AASHTO, AASHTO T283- Resistance of compacted asphalt mixtures to moisture-induced damage. (American Association of State Highway and Transportation Officials: Washington, DC, 2022).

AASHTO & AASHTO TP-91- Standard method of test for determining asphalt. Binder bond strength by means of the binder bond strength (BBS) test. (American Association of State Highway and Transportation Officials: Washington, DC, 2015).

ASTM, ASTM D4541-standard test method for pull-off strength of coatings using portable adhesion testers. (American Society for Testing and Materials: West Conshohocken, PA, 2022).

Yalghouzaghaj, M. N. et al. Evaluation of the effect of UHMWPE on the low-temperature cracking of hot-mix asphalt. J. Mater. Civ. Eng. 33 (3), 04020488 (2021).

Author information

Authors and Affiliations

Contributions

Gholam Hossein Hamedi and Mohammad Hosein Dehnad wrote the main manuscript text and prepared figures. Both authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hamedi, G.H., Dehnad, M.H. Effects of dodecyl amide, nano calcium carbonate, and dry resin on asphalt concrete cohesion and adhesion failures in moisture conditions. Sci Rep 15, 14451 (2025). https://doi.org/10.1038/s41598-025-99661-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99661-x