Abstract

Self-service machines provide round-the-clock access to various services, enhancing operational efficiency, reducing waiting times, and minimizing human errors. However, their design has traditionally prioritized business functionality and user experience, with minimal attention to sustainability principles. As finite resources and environmental concerns gain prominence, embedding sustainability into self-service machine design is crucial for promoting resource efficiency, environmental protection, and social responsibility. Current sustainable product design methods tend to focus on environmental features, often overlooking the multidimensional requirements necessary for a balanced approach. Addressing this gap, this study proposes an enhanced multidimensional requirement-oriented quality function deployment method, which uses multiple one-dimensional quality of houses to independently process requirements across different dimensions. This approach effectively reduces the complexity associated with traditional quality function deployment, enabling a more comprehensive and strategically aligned design process. By prioritizing key sustainability dimensions, this method offers a robust framework for developing sustainable self-service machines, aligning design outcomes with sustainability goals.

Similar content being viewed by others

Introduction

In the context of severe global challenges related to resources and the environment, sustainable development is a crucial concept that enables current generations to meet their own needs while safeguarding the living and development space for future generations1. In 2015, the United Nations convened the summit on sustainable development, during which a programme document entitled “Transforming our world: the 2030 Agenda for Sustainable Development” was formally adopted. At the core of this agenda are the 17 sustainable development goals (SDGs), which provide a comprehensive and detailed interpretation of the international community’s current understanding of the concept of sustainable development. The SDGs are comprised of 17 goals and 169 targets, each of which contains relevant monitoring indicators2. The 17 SDGs reflect the necessity for sustainable development to encompass multiple dimensions, emphasising its comprehensive and inclusive approach to addressing a range of interrelated fields, including economic, social and environmental issues. Given the comprehensive approach outlined in the SDGs, product design must increasingly account for sustainability at all stages3,4. This requirement extends to technologies like self-service machines, which are now integral in various industries. Self-service machines, now widespread across industries such as banking, retail, healthcare, and residential services, provide operational efficiencies but often overlook sustainable development in their design and functionality5,6,7,8.

Thus far, the design methodologies for self-service machines can be broadly categorized into two primary types. The first type emphasizes designing self-service machines tailored to meet the needs of the intended users, adopting a user-centric approach. For example, Park et al.9 investigated the accessibility challenges associated with self-service machine from the perspective of individuals with disabilities. Subsequently, they delineated a set of design considerations for self-service equipment, emphasizing the importance of incorporating accessibility features. Henderson et al.10 conducted a study to evaluate the interaction between users and a large number of self-service devices, detailing the usability issues that arose, exploring the connections and consequences among these problems, and proposing a series of design considerations. The second type, however, focuses on functionality as its core design principle. For example, Alnowaini et al.11 have focused their efforts on developing a series of integrated subsystems that collectively enable the detection and recognition of Yemeni banknotes. These subsystems are being deployed in a self-service terminal within the banking industry. The majority of contemporary design strategies for self-service machines prioritise user requirements or business functionality, yet fail to adequately integrate the concept of sustainability into the design process. In summary, user-centered designs focusing on accessibility, usability, and user experience, and functionality-driven designs targeting operational requirements and integration capabilities. However, both approaches often neglect sustainability factors.

In light of the growing emphasis on sustainable development within human society, the field of research on sustainable product design methodologies has made significant progress. For example, Vinodh12 puts forth a fuzzy quality function unfolding methodology with the objective of designing sustainable products. The methodology is based on two ranking steps. Initially, the parameters affecting sustainability are prioritised according to customer requirements. Subsequently, the environmental design measures are prioritised according to the key sustainability parameters. Zhang et al.13 proposed a sustainable product design methodology, the key of which is to expand sustainable requirements such as environmental, economic and social needs into customer requirements, and then use quality function deployment (QFD) to transform these requirements into functional modules. Sarker et al.14 proposes a new software project management framework, “SQ-Framework”, which integrates sustainability with quality factors to enhance product quality, project efficiency, and organizational success, addressing the lack of sustainability practice in software engineering and providing execution guidance based on the Karlskrona manifesto for various stakeholders. He and Mao15 put forth a method for leveraging the Internet of Things (IoT) to obtain comprehensive product lifecycle data, integrating digital twin technology with low-carbon design to enhance product sustainability. Camañes et al.16 proposed an eco-design methodology based on life cycle assessment (LCA) aimed at designing sustainable products. LCA is a methodology frequently employed in the design of sustainable products. This approach integrates the quantification of environmental factors with the qualification of the product’s intrinsic characteristics and the characteristics of the production process. The objective is to enhance the environmental characteristics of the product and ensure compliance with environmental standards17. However, the UN’s 17 sustainable development goals indicate that sustainable development is a multifaceted concept, with environmental attributes representing only one aspect thereof18. Another type of approach for the development of sustainable products is quality function deployment. The fundamental principle of this approach is the utilisation of the House of Quality (HoQ) to facilitate the translation of sustainability objectives, such as environmental targets, into product design specifications. In addition to considering the sustainability of the product, the design process must also take into account the requirements of the intended users, the operational requirements of the business, and a multitude of other factors. However, when the number of requirements and the scale of engineering characteristics are considerable, the HoQ matrix may prove unwieldy due to its size.

Despite the effectiveness of current self-service machines in enhancing user experience and business functionality, there is a significant gap in integrating sustainable development into their design. This gap reflects a broader deficit in sustainable product design methodologies that consider environmental, economic, and social requirements in a cohesive framework. This study addresses the following research questions: (1) How can the sustainable development characteristics of self-service machines be fully integrated into the design process? (2) What methodologies are most effective for balancing sustainability with user and business requirements in self-service machine design?

In this work, the objective is to develop a comprehensive and systematic approach to designing the sustainable self-service machine (SSSM) based on quality function deployment. This methodology enables the integration of diverse requirements throughout the design process, ensuring that the self-service machines can satisfy the specific requirements related to sustainable development and other dimensions.

Methods

To achieve comprehensive integration of sustainability, user requirements and business needs into a product, it is essential to consider a vast array of requirements throughout the design process. An increase in the number of requirements will result in an increase in the number of engineering characteristics used to realise the requirements, which will in turn lead to a very large relationship matrix. To control the size of the relationship matrix and effectively balance the various types of requirements, this paper improves the traditional QFD approach by introducing a requirement dimension and proposes an enhanced multidimensional requirement-oriented quality function deployment (EMR-QFD) method.

The enhanced multidimensional requirement-oriented quality function deployment method

The EMR-QFD are comprised of n one-dimensional houses of quality and a foundation. One-dimensional houses of quality are used to deal with the requirements of one dimension. The main structures of the one-dimensional House of Quality include: left wall, roof, ceiling, room, right wall, and basement. Foundations are employed to integrate a plurality of one-dimensional houses of quality into a unified whole, thereby facilitating the aggregation and balancing of requirements from disparate dimensions (see Fig. 1).

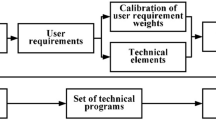

The calculation process for the EMR-QFD comprises two distinct stages. In the first stage, n one-dimensional houses of quality are employed in parallel to address requirements across various dimensions. Within each of these one-dimensional houses, a sequential computation is carried out encompassing six key steps: determining the left wall, ceiling, roof, room, right wall, and basement. In the second stage, four key calculations are completed in the foundation including: calculating the importance of dimensions, deriving engineering characteristics, identifying the critical engineering characteristics and finally assessing the technical competitiveness (see Fig. 2).

Left wall

The left wall consists of dimensional requirements and their importance. Dimensional requirements are a collection of requirements descriptions for a product based on selected dimensions. Dimensions can be orientated towards any type of reasonable requirements for a product, and they are open and extensible, not limited to being customer orientated. For example, the sustainable development dimension understands product requirements in terms of realising the sustainable development of human society; and the smart system dimension understands product requirements in terms of the product’s intelligence.

The importance of dimension requirement (IDR) is used to describe the relative importance of a requirement within that dimension. IDR is tied to the dimension in which it resides, and there is no correlation between the importance of requirements in different dimensions. Typically, the dimensional requirements of a SSSM are not only numerous and hierarchical, but also these requirements may be interdependent and constrained. Therefore, calculating IDR is essentially a decision-making problem.

The analytical network process (ANP) is distinguished by a nonlinear structure and considers the interdependence and dominance of elements. It is an appropriate method for analysing complex network structures with interwoven elements19. Consequently, the ANP is employed to determine the importance of dimensional requirements. Because the ANP calculation process is designed to be very complex with super matrix operations, Super Decisions software was used to assist in the calculations.

Ceiling

Ceilings are used to describe the engineering characteristics of a product in a particular dimension. It is the dimensional engineering characteristics that are proposed for the product from a technical perspective in order to satisfy the dimensional requirements of that dimension.

The essence of product-service system (PSS) emphasizes integrating tangible products and intangible services into a complete system20,21. Given that the SSSM is inherently a PSS, this paper puts forth a PSS-based design methodology for dimensional engineering characteristics. The method is comprised of two distinct steps.

Step 1 Selecting requirements.

Selecting requirements is the key to designing a PSS. In multidimensional requirement-oriented House of Quality, the dimension requirements in the House of Quality for that dimension are used as the object of analysis.

Step 2 Hardware and services analysis.

Hardware and service analyses consist of two phases, decomposition and consolidation. In the decomposition phase, each dimension requirement is mapped into service components and hardware components. A service component is a collection of closely related intangible service functions that fulfil the dimension requirement. Hardware components are the tangible physical structures that support the services that fulfil the dimension.

In the merge phase, the components are first examined to determine the relationship between the two components. As illustrated in Fig. 3, four types of relationships exist between components: equivalence, irrelevance, intersection and inclusion. These relationships are pivotal to the consolidation process, as they dictate how components are integrated or retained to optimize system coherence and eliminate redundancies. Equivalence means that two components have different names but are essentially the same. Irrelevance means that there is no hardware or service overlap between the two components. Intersection means that there is hardware or service overlap between the two components. Inclusion means that the hardware or services of one of the two components are fully included in the other component.

After determining the relationship between two components, merge them according to the following rules (see Table 1).

The precise classification of relationships (see Fig. 3) is essential, as misidentification may lead to flawed consolidation outcomes, such as functional gaps or resource conflicts. For instance, erroneously labeling intersecting components as equivalent could result in the loss of critical overlapping functionalities, while overlooking inclusion relationships might introduce unnecessary complexity. Thus, rigorous adherence to these relationship definitions ensures a robust framework for component integration, directly contributing to the system’s functional integrity and efficiency.

Roof

The roof is used to describe the degree of correlation between the engineering characteristics of a product within a specified dimension, also called the correlation matrix (CM). There may be interactions between the engineering characteristics of a product. One engineering characteristic may be unrelated to another, may favour another, or may have a counteracting effect on another. The expert voting method is used to obtain the correlation of dimensional engineering characteristics.

Room

Rooms describe the interrelationships between dimensional requirements and dimensional engineering characteristics of specified dimensions, also called relationship matrices (RM). Constructing a RM is essentially a decomposition of requirements and mapping them to the corresponding engineering characteristics. The matrix elements represent the degree of relationship between the requirement and the engineering characteristic. A value of 0 indicates that the two are not relevant, a value of 9 indicates that the two have a stronger relationship, and other integers between 0 and 9 are used to indicate different degrees of relationship that gradually increase from not relevant to stronger. The expert scoring method was used to obtain the dimensional requirements and dimensional engineering characteristics relationship matrix for the dimensions.

Right wall

The right wall is used to describe the dimensional market competitiveness of a product. The dimensional market competitiveness is used to describe the product’s advantage in the marketplace relative to the original product as well as competitors in a given dimension, which reflects the product’s ability to satisfy dimensional requirements.

Express the market competitiveness of dimensional requirements as follows:

where \(MC_{i|1 \ldots l}\) denotes the market competitiveness matrix of the dimension requirements of dimension i. l denotes the length of the dimension. \(mc_{j}\) denotes the market competitiveness of the jth requirement of dimension i.

A dimensional market competitiveness analysis is conducted through a four-step method.

Step 1 Expert scoring.

A comparative analysis and quantitative scoring of market competitiveness related to the dimensional requirements is conducted by relevant experts based on the prescribed dimensions. The object of assessment may be an existing product, a new product, or a competitor’s product. The score can be taken as the following five values:

-

1 indicates that there is no competitiveness to speak of, the product will be backlogged, no sales.

-

2 indicates low competitiveness. The market share is decreasing.

-

3 indicates that it is possible to enter the market, but does not have an advantage.

-

4 indicates that it has an advantage in the domestic market competition.

-

5 indicates that it has a big advantage in the domestic market competition and can participate in the international market competition. It has a certain international market share.

Step 2 Calculate the score.

Based on the expert scores, the arithmetic mean was used as the dimension market competitiveness score and saved in the matrix \(MC_{i|1 \ldots l}\).

Step 3 Calculate the correction factor.

Calculate the correction factor according to Eq. (2).

where \(cf_{j}\) is the correction coefficient of the jth dimension requirement of the specified dimension. \(idr_{j}\) is the importance of the dimension requirement. \(mc\_new_{j}\) is the market competitiveness of the jth dimension requirement of the new product. \(mc\_old_{j}\) is the market competitiveness of the jth dimension requirement of the original product. \(a_{j}\) is the emphasis factor, which is used to highlight the degree of satisfaction of a certain dimension requirement so that the product has distinctive features. \(a_{j}\) is an empirical value, usually between 1 and 1.5, based on expert voting.

If there is no original product that can be compared, the correction factor is calculated according to Eq. (3).

Step 4 Calculate the dimensional market competitiveness index.

Calculate the dimensional market competitiveness index according to Eq. (4).

where \(DMCI_{i}\) denotes the market competitiveness index of dimension i. The larger the value of \(MCI_{i}\) the stronger the market competitiveness in this dimension. The value of \(cf_{j}\) is the correction factor of the jth requirement of the specified dimension. \(mc_{j}\) denotes the market competitiveness of the jth requirement of the specified dimension. m is the length of the requirement of the dimension.

Basement

Critical dimensional engineering characteristics. Critical engineering characteristics are those that contribute significantly to meeting the requirements. Finding critical engineering characteristics helps to optimise design and develop products that meet requirements and is particularly important when there are constraints such as cost control. Focus is clarified according to this importance, and efforts are concentrated on achieving the critical engineering characteristics to maximise the use of human and material resources.

The method for determining the critical engineering characteristics for a given dimension is comprised of three steps.

Step 1 Calculate the importance of dimensional engineering characteristics.

The equation for calculating the importance of dimensional engineering characteristics is as follows:

where \(IDEC_{i|i = 1 \ldots l}\) denotes the importance matrix of the engineering characteristic in dimension ith. l denotes the length of the dimension. \(idec_{k}\) denotes the importance of the kth engineering characteristic within dimension i. n denotes the length of the dimensional engineering characteristic. \(idr_{j}\) denotes the importance of the jth dimensional requirement of dimension i. \(rer_{jk}\) denotes the degree of relationship between the jth requirement and the kth engineering characteristic of the dimension. m denotes the length of the dimensional requirement.

If the kth engineering characteristic is closely related to several dimension requirements and these dimension requirements are more important, \(idr_{j}\) is larger, then \(idec_{k}\) takes a larger value, which means that the engineering characteristic is more important.

Step 2 Calculate the average of the importance of dimensional engineering characteristics.

The method of calculating the average of the importance of dimensional engineering characteristics is shown in Eq. (7).

where \(Average\_IDEC_{i|1 \ldots l}\) denotes the mean value of the importance of the engineering characteristic in dimension i. l denotes the length of the dimension. \(idec_{k}\) denotes the importance of the kth engineering characteristic within dimension i.

Step 3 Select critical dimensional engineering characteristics.

A threshold is set to filter dimensional engineering characteristics whose importance of dimensional engineering characteristics exceeds the threshold as critical dimensional engineering characteristics. The importance of critical dimensional engineering characteristics should be significantly higher than the importance of general dimensional engineering characteristics. For example, dimensional engineering characteristics whose importance degree is more than 1.25 times higher than the average importance degree can be regarded as critical dimensional engineering characteristics.

Technical competitiveness of dimensions. The dimensional technical competitiveness assessment analyses the degree of satisfaction of each dimensional engineering characteristic corresponding to new, existing and competitors’ products.

Express the dimensional technical competitiveness as follows:

where \(TC_{i|i = 1 \ldots l}\) denotes the technical competitiveness matrix of the engineering characteristics in dimension i. l denotes the length of the dimension. \(tc_{k}\) denotes the technical competitiveness of the kth engineering characteristic in dimension i.

A three-step method is utilised for the purpose of conducting a dimensional technical competitiveness analysis.

Step 1 Expert scoring.

A comparative analysis and quantitative scoring of the technical competitiveness of dimensional engineering characteristics by relevant experts according to specified dimensions. The object of assessment may be an existing product, a new product, or a competitor’s product. The score can be taken as the following five values:

-

0 indicates that this engineering characteristic is not available.

-

1 indicates a low level of skill.

-

2 indicates that the technology level is average.

-

3 indicates that the technological level reaches the advanced level of the industry.

-

4 indicates that the technological level reaches the domestic advanced level.

-

5 indicates that the technology level reaches the international advanced level.

Step 2 Calculate the score.

Based on the expert scores, the arithmetic mean was used as the dimensional technical competitiveness score and saved in the matrix \(TC_{i|i = 1 \ldots l}\).

Step 3 Calculate the dimensional technical competitiveness index.

After synthesising the dimensional technological competitiveness \(TC_{i|i = 1 \ldots l}\), the dimensional technological competitiveness index \(DTCI_{i}\) for dimension i of the product is obtained as follows:

where n is the length of the dimensional engineering characteristic in the ith dimension. \(idec_{k}\) denotes the importance of the kth engineering characteristic within dimension i. \(tc_{k}\) denotes the technical competitiveness of the kth engineering characteristic in dimension i.

A larger dimension technical competitiveness index indicates that the product is more technologically competitive in that dimension.

Foundation

Once the construction of the one-dimensional House of Quality for each dimension has been completed, the information obtained in each dimension, including dimensional engineering characteristics, technological competitiveness of dimensional engineering characteristics, and so forth, is aggregated and analysed in order to obtain the product architecture.

Importance of dimensions. Analytical hierarchy process (AHP) is a mathematical method used for multi-criteria decision making. The core idea of AHP method is to decompose the elements related to decision making into a hierarchy of objectives, criteria, and scenarios, on the basis of which qualitative and quantitative analyses are performed22,23. The hierarchy of the requirement dimension in the multidimensional House of Quality is simple and clear, so the AHP method is used to calculate the importance of dimensions.

Express the importance of dimensions as follows:

where l denotes the length of the dimension. \(id_{i}\) denotes the importance of the ith dimension.

A number of relevant experts, working independently, conducted a comparative analysis of the dimensions of the SSSM, rating the relative importance of the machine based on the two dimensions according to the scoring criteria (see Table 2).

The l dimensions of SSSM are filled into the first row and the first column of the judgement matrix respectively. Then fill in the corresponding position of the judgement matrix with one expert’s rating to form the judgement matrix.

Express the judgement matrix as follows:

where \(c_{ij}\) denotes the relative importance of dimension i with respect to dimension j for the realisation of the SSSM. And \(c_{ij} = 1/c_{ij}\).

The judgement matrix is normalised by columns according to Eq. (12).

Sum vector by rows using Eq. (13).

Calculate the weight vector by regularising the sum vector according to Eq. (14).

Calculate the largest eigenroot using Eq. (15).

Equation (16) is used to calculate the consistency index (CI). When CI is 0, it means that there is complete consistency; when CI is close to 0, there is satisfactory consistency; the larger CI is, the more serious the inconsistency is.

To measure the size of the CI, the consistency ratio was calculated using Eq. (17).

where \(CR\) is the consistency ratio. \(RI\) is the random consistency indicator.

When \(CR\) is less than 0.1, the degree of inconsistency of C is within tolerance, there is satisfactory consistency, and the consistency test is passed.

Assuming that there are n experts in total, n weight vectors will be obtained. Each weight vector has the same length of l.

The arithmetic mean vector of these n weight vectors is first calculated and normalised according to Eq. (18). Then, the normalised mean vector is used as the dimensional importance according to Eq. (19).

Engineering characteristics. The dimensional engineering characteristics of each dimension are extracted to form a collection of engineering characteristics of the product. Specific information includes: dimensional engineering characteristics, dimensional engineering characteristic importance, dimensional technology competitiveness, critical engineering characteristics of the dimension, and engineering characteristics for which there is a strong negative correlation and a negative correlation.

Another important task in this section is to check and mark the equivalent engineering characteristics. Equivalent engineering characteristics are a set of special engineering characteristics that exist in different dimensions, have different names, but have the same or similar same function or performance, and have the same or similar engineering characteristic metrics. Equivalent engineering characteristics need to be labelled and renamed uniformly.

In the event of an inclusion relationship being identified between the engineering characteristics of different dimensions, those with a larger scope are retained within the collection.

Renaming engineering characteristics that have the same name but different functions or properties is also required. Use dimensions as prefixes to qualify descriptions of engineering characteristics.

Critical engineering characteristics. The critical engineering characteristics are calculated as follows.

Step 1 Calculate the importance of engineering characteristics.

The equation for calculating the importance of engineering characteristics is as follows:

In this context, \(S_{h}\) represents the set comprising the product of the dimensional importance of the equivalent or included dimensional engineering characteristic of the hth engineering characteristic and the product of the dimensional importance of the aforementioned dimensional engineering characteristic. \(iec_{h}\) denotes the hth product engineering characteristic, the product has H engineering characteristics in total.

Step 2 Calculate the average of the importance of engineering characteristics.

The method of calculating the average of the importance of engineering characteristics is shown in Eq. (22).

where \(Average\_iec\) denotes the mean value of the importance of the engineering characteristic.

Step 3 Select critical engineering characteristics.

Thresholds are used to filter engineering characteristics. If the importance of an engineering characteristic exceeds the threshold, it is treated as a critical engineering characteristic of the product. The importance of critical engineering characteristics should be significantly higher than the importance of general engineering characteristics. For example, the threshold can be set to 1.25 times higher than the average importance. That is, the critical engineering characteristic is 1.25 times more important than the average engineering characteristic importance.

Technological competitiveness of the product. The technical competitiveness of a product is used to assess the relative competitive position of the product in the market. It is a reflection of the product’s competitive advantage in the marketplace after taking into account requirements, engineering characteristics, business conditions, and market conditions. The technical competitiveness index is usually used to assess the overall technical level of a product and its competitive position in the market. Equation (23) is used to calculate the technical competitiveness index of a product.

where \(iec_{h}\) denotes the hth product engineering characteristic, the product has H engineering characteristics in total. \(tc_{h}\) denotes the technical competitiveness of the hth engineering characteristic in dimension i.

Results and discussion

The object of this study is a sustainable self-service property certificate printer. This device is employed extensively by pertinent government agencies in China, facilitating the completion of property-related enquiries and the printing of relevant certificates for both personal and business users. In this study, the device is referred to simply as a SSSM. To protect the privacy of the participants, the names of the participants and their organisations have been made private in the paper. To protect the privacy and intellectual property rights of the organisations concerned, the data appearing in this study are research-related and not complete product design data.

Left wall

Dimensions and dimensional requirements

The SSSM has many attributes, so it is possible to examine the design of SSSM from many dimensions. According to the requirements of enterprises to protect their intellectual property rights, this study only describes some of the dimensions: the sustainable development dimension, the intelligent dimension, and the remote management and monitoring dimension. Among them, the focus is on describing the sustainable development dimension, and the intelligent dimension and the remote management and monitoring dimension are only used to match the description of the relevant functions.

Based on the sustainable sevelopment goals (SDGs) formulated by the United Nations in 2015 and China’s National Plan on Implementation of the 2030 Agenda for Sustainable Development in China in 2016, the sustainable development dimension of self-service machine in China comprises 13 requirements18,24. The requirements are organised hierarchically into two tiers and three groups (see Table 3).

Importance of dimensional requirements

The DR32 has the greatest importance of 0.169786. The least significant factor, DR23, has an importance value of 0.007781. The mean value of the demand importance is 0.076923. The overall importance of the P Group is 0.391112, the overall importance of the CE Group is 0.208823 and the overall importance of the E Group is 0.400065 (see Fig. 4). The detailed calculation process data can be accessed in the “Left wall” section of the Supplementary.

The importance of dimensional requirements is more evenly distributed in the P Group, but slightly higher weights are given to the quality (DR11) and safety (DR14). The CE Group’s weights are mainly concentrated on DR21, DR22 and DR24, suggesting that more importance is given to resource efficiency, adoption of environmentally friendly technologies and industrial processes, and product recycling. The weights of Group E are mainly concentrated on DR32 and DR33, indicating that higher importance is given to inclusive services and accessibility services. The overall importance of Groups P and E are close to each other, whereas the overall importance of Group CE is relatively low, indicating that performance indicators are more important when assessing the sustainable development attributes of the SSSM. Among all the dimension requirements, inclusive service (DR32) has the highest importance, which shows that inclusive service is seen as one of the most important factors in the sustainability dimension of the SSSM.

Ceiling

After a careful process of both decomposition and merging stages, 21 hardware components and 25 service components were obtained as engineering characteristics for the House of Quality of the SSSM’s sustainable development dimension (see Table 4). The detailed calculation process data can be accessed in the Supplementary Table S23 and Supplementary Table S24.

Roof

In the roof of the one-dimensional houses of quality, the relationships between engineering characteristics in the dimension are recorded. In the sustainable development dimension for the SSSM, there are a total of 46 engineering characteristics, including 21 hardware components and 25 service components. Therefore, the size of the correlation matrix (CM) is 46 × 46. It is evident that the multidimensional requirement-oriented House of Quality, when employed to decompose requirements into multiple dimensions, enables the control of the size of the CM of the one-dimensional houses of quality to a relatively reasonable extent. The detailed data can be found in Supplementary Fig. S2 to Supplementary Fig. S4.

Room

The relationship matrix

The data presented in the room demonstrate the strength of the relationship between the dimensional requirement and the engineering characteristic within the sustainability dimension (see Supplementary Fig. S5 and Supplementary Fig. S6). There are 13 dimensional requirements and 46 engineering characteristics. Therefore, the size of the relationship matrix (RM) is 13 × 46. It can be observed that the multidimensional requirement-oriented House of Quality is capable of regulating the scale of the relationship matrix associated with the one-dimensional houses of quality within a relatively acceptable range following the decomposition of the requirements into multiple dimensions.

The relationships between dimensional requirements and dimensional engineering characteristics

Firstly, the dimensional requirements and the number of components that have a strong or stronger relationship with them are examined (see Fig. 5). It is observed that DR8 has a strong relationship with two components, which is the least of all the dimensional requirements. Therefore, it can be concluded that there is no situation where there are dimensional requirements that do not have a strong or stronger relationship with any engineering characteristic. Consequently, there is no need to consider augmenting engineering characteristics.

There is a strong correlation between DR1 and DR9 and 46 components. It can be seen that DR1 and DR9 are closely related to the majority of engineering characteristics. Consequently, it is necessary to analyse these two requirements in order to ascertain the associated scores. The DR1 pertains to the quality of the SSSM. It is imperative that the SSSM exhibit a high level of quality to ensure optimal functionality and prevent any potential errors. It is essential that the software and hardware components, including the operating software, touchscreens and printers, are designed to be durable in order to minimise the occurrence of breakdowns and to maximise customer satisfaction. It is therefore reasonable to conclude that the quality of the SSSM is closely related to all components of a SSSM. The DR9 concerns the reuse of the SSSM. Insofar as is feasible, the machine or its components should be designed for reuse, either as a whole or as parts in other systems. It is recommended that, where feasible, the machine or its components should be designed for reuse, either as a whole or as parts in other systems. This has the effect of extending the product’s life cycle and promoting the principles of a circular economy. It is reasonable to posit that the reuse of the SSSM is closely related to all components of the machine.

Secondly, an examination is conducted of the engineering characteristics and the number of dimensional requirements that have a strong or stronger relationship with them (see Figs. 6 and 7). It can be observed that the minimum value of the number of dimensional requirements with which there is a strong or stronger relationship in the hardware component is 3. Similarly, in the service component, the minimum value of the number of dimensional requirements with which there is a strong or stronger relationship is also 3. Consequently, it can be concluded that all engineering characteristics have a strong or stronger relationship with at least 1 dimensional requirement. Therefore, there are no engineering characteristics that need to be cancelled.

The H4 component demonstrates a more robust correlation with the 10 dimensional requirements. Given that there are a total of 13 requirements within the sustainability dimension, H4 is associated with the majority of the dimension requirements and thus necessitates examination. In the SSSM, H4 Industrial Control Host is the core key component, which is closely related to quality, reliability, cost, security, resource-use efficiency, and resilience of the SSSM. Furthermore, the provision of inclusive services, accessible services and the ability to collect statistics and generate sustainability information are also contingent upon the functionality of H4 components. Additionally, H4 plays a pivotal role in fulfilling the requirements for reuse. Consequently, it is logical that H4 is closely associated with these 10 dimensional requirements.

The S4 component exhibits a more robust interconnection with the 8 dimensional requirements. Given that there are a total of 13 requirements within the sustainability dimension, the S4 component is associated with the majority of these requirements, necessitating its examination. In the context of the SSSM, the S4 business service module serves as a pivotal component for delivering business services, intimately tied to factors such as quality, reliability, cost, security, and resilience. Furthermore, the principles of inclusive and accessible services must be incorporated into the Business Service Module. Additionally, S4 meets the requirement for reusability. Therefore, it can be reasonably concluded that S4 is closely associated with the aforementioned 8 dimensional requirements.

Right wall

The Dimensional Market Competitiveness Index represents a comprehensive measure of a product’s relative competitiveness within the marketplace. The Dimension Market Competitiveness Index of the sustainable development dimension reflects the ability of the SSSM to meet the requirements of sustainable development and to outperform other similar products. The Dimensional Market Competitiveness Index of the newly developed product is 0.787026, which is approximately 72.64% higher than that of the previously available product, which is 0.455880. The detailed calculation process data can be found in Supplementary Table S25 and Supplementary Table S26.

This notable disparity suggests that the new product is considerably more sustainable than the existing model and exhibits enhanced competitiveness in meeting the requirements of sustainable development. This may be attributed to the fact that the design of the new product incorporates the 13 requirements of sustainable development in a comprehensive manner, and the hardware and service components of the product are designed in a targeted manner, with notable enhancements in inclusive services, accessible services, recycling, reuse, and other areas, thus enabling the product to more effectively fulfil the sustainable development requirements.

Basement

Critical dimensional engineering characteristics

A total of 21 hardware components and 25 service components comprise the SSSM. Among these, 6 components, accounting for 13.04% of the total, exhibit the importance of dimensional engineering characteristics above the specified threshold. These are S4, S15, S16, S23, H4 and H16 (see Fig. 8). The detailed data can be located in Supplementary Table S27 to Supplementary Table S29.

It is recommended that the number of critical dimensional engineering characteristics be kept to a minimum, avoiding an excessive number that would result in a lack of focus on the most critical issues and a dispersion of resources. The current ratio of 13.04% is deemed appropriate.

The H4 Industrial Control Host represents the central processing unit of the SSSM, responsible for executing all essential functions and logic. The performance, stability, and reliability of this component directly impact the overall operational effectiveness and user experience of the SSSM. The H16 cabinet serves as the physical support and protection structure for the SSSM. Consequently, the rationality of its design, the quality of its materials, and the manufacturing process are also crucial to the long-term stable operation of the SSSM. Therefore, it is reasonable to consider the H4 and H16 as critical dimensional engineering characteristics.

The S4 Business Service Module is responsible for the management of all functions pertaining to business logic, which serves as the primary determinant for the optimal execution of scheduled business operations by the SSSM. The S15 Power Service Module is tasked with ensuring a stable and reliable power supply for the SSSM, which is a fundamental prerequisite for the machine’s normal operation. The S16 Cabinet Service Module is responsible for monitoring the cabinet environment, managing energy consumption, and providing security protection. These functions are essential for ensuring the long-term reliability of the SSSM in providing their intended services. The S23 User Evaluation Service Module is responsible for the collection of user feedback, which enables the timely understanding of the utilisation of the SSSM, the identification of existing issues and the determination of user expectations. This is of significant importance in providing a foundation for subsequent improvement and service optimisation. Accordingly, the S4, S15, S16 and S23 are deemed to be reasonable as critical dimensional engineering characteristics.

Technical competitiveness of dimensions

The Dimension Technological Competitiveness Index serves as a principal indicator of the capacity of the technical aspects of the SSSM to satisfy the requirements of the sustainability dimension. This capacity can directly reflect the competitive advantage of the product in terms of sustainability. The Dimensional Technical Competitiveness Index of the newly developed product is 0.736880, which is approximately 57.85% higher than that of the previously available product, which is 0.466741. The detailed data can be accessed in Supplementary Table S30 and Supplementary Table S31.

This notable discrepancy indicates that the technical competitiveness of the novel product is considerably superior to that of the existing model in terms of fulfilling the sustainability requirements of the SSSM. This may be attributed to the implementation of a PSS-based dimensional engineering characteristic design methodology, which effectively separates the sustainability requirements into hardware and software components. Nevertheless, the Dimension Technological Competitiveness Index of the new product remains relatively low. This suggests that the engineering characteristics of the SSSM still have significant room for improvement and require continuous enhancement.

Foundation

Importance of dimensions

In the D1 dimension, the maximum value observed is as high as 0.730645, while the minimum value is as low as 0.285714, indicating a notable span of values. With regard to the D2 dimension, the maximum and minimum values are 0.571429 and 0.188394, respectively, thereby reflecting a wide range of variation (see Fig. 9). This notable discrepancy may be attributed to the significant divergence of opinions and preferences among experts regarding the value of the sustainable development dimension and the Intelligent Dimension in the design of the SSSM. The detailed data can be found in Supplementary Table S32 to Supplementary Table S37.

In contrast, the D3 dimension exhibited greater uniformity in terms of dimensional importance, with maximum and minimum values of 0.142857 and 0.080961, respectively, and a mean value of 0.118030 (see Fig. 9). This indicates that experts were more consistent in their opinions on this dimension. The experts concurred that the Remote Management and Monitoring Dimension is of lesser importance than the other two dimensions.

Collection of engineering characteristics

The construction of a collection of engineering characteristics of a product represents a fundamental task in the foundation. The detailed process data can be located in Supplementary Table S38 to Supplementary Table S41.

In Remote Management and Monitoring Dimension, components H1, S1, and S3 are not associated with any of the components in the other dimensions through an inclusion and equivalence relationship. Consequently, these 3 components are incorporated into the collection of engineering characteristics pertaining to the SSSM. The Cabinet Status Monitoring Module is included with H16 in the sustainable sevelopment dimension on the grounds that it forms part of the Cabinet hardware. Furthermore, S2 is associated with S16 in the sustainable development dimension due to the fact that the Cabinet Fault Prognostic Service Module constitutes a component of the Cabinet Service Module. It thus follows that H2 and S2 need not be included in the engineering characteristic collection for the SSSM.

In the Intelligent Dimension, the S8, S9, S10, and S11 components are not included in, nor are they equivalent to, any of the components in the other dimensions. Consequently, these 4 components are incorporated into the SSSM’s engineering characteristic collection. All other components may be considered to have corresponding equivalent components in the sustainable development dimension, and thus need not be added to the SSSM’s collection of engineering characteristics (see Table 5).

The incorporation of elements from all 3 dimensions within the engineering characteristics of the SSSM suggests that each dimension can inform the design of the SSSM (see Table 6). The existence of equivalence or inclusion relationships between engineering characteristics from different dimensions also indicates that these engineering characteristics are interdependent and mutually reinforcing. Consequently, when designing the SSSM it is essential to consider all dimensions holistically and systematically, rather than focusing on a single dimension in isolation.

Critical engineering characteristics

The SSSM is comprised of 22 hardware components and 31 service components. Of these, 8 components, representing 15.09% of the total, exhibit the importance of engineering characteristic that exceed the specified thresholds. These are S4, S15, S16, S23, S28, H4, H15 and H16 (see Fig. 10). The detailed process data can be accessed in Supplementary Table S42 to Supplementary Table S44.

It is recommended that the number of critical engineering characteristics be kept to a minimum, in avoidance of an excessive number that would result in a lack of focus on the most critical issues and a dispersion of resources. The current ratio of 15.09% is deemed appropriate.

The Industrial Control Host can be defined as the central processing unit of the SSSM, with the responsibility of executing all basic functions and logic. The performance, stability and reliability of this component have a direct impact on the overall operational effect and user experience of the SSSM. The Power Supply is responsible for providing a stable power source to the SSSM, thereby ensuring its uninterrupted operation on a 24-h basis. This is a fundamental requirement for the efficient functioning of the self-service system. The Cabinet provides the physical support and protection structure for the SSSM. Consequently, the rationality of its design, the quality of the materials used, and the manufacturing process are also crucial to the long-term stable operation of the SSSM. Therefore, it is reasonable to consider H4, H15, and H16 as critical engineering characteristics for the SSSM.

The S4 Business Service Module is the primary entity responsible for the management of all functions pertaining to business logic. This serves as the primary determinant for the optimal execution of scheduled business operations by the SSSM. The S15 Power Service Module is responsible for ensuring a stable and reliable power supply for the SSSM, which is a fundamental prerequisite for the machine’s normal operation. The S16 Cabinet Service Module is responsible for monitoring the cabinet environment, managing energy consumption, and providing security protection. These functions are vital for guaranteeing the long-term dependability of the SSSM in the fulfilment of their designated functions. The S23 User Evaluation Service Module is the primary mechanism for the collection of user feedback, which enables the timely understanding of the utilisation of the SSSM, the identification of existing issues and the determination of user expectations. This is of significant importance in providing a foundation for subsequent improvement and service optimisation. The S28 Intelligent User Interface Service streamlines the operational process, responds expeditiously to user requirements, and augments the user experience through the utilisation of intelligent identification and interaction technologies. In light of the aforementioned considerations, it is reasonable to conclude that the S4, S15, S16, S23 and S28 are critical engineering characteristics.

Technological competitiveness of the product

The Technical Competitiveness Index is a measure of the competitive advantage of the SSSM in terms of technology. The Technical Competitiveness Index for newly developed products is 0.740521, representing a 67.80% increase over the Technical Competitiveness Index of 0.441329 for older products. The detailed data can be found in Supplementary Table S45 and Supplementary Table S46.

This notable discrepancy illustrates that the technical competitiveness of the novel product is markedly superior to that of the preceding model. This is a consequence of the EMR-QFD, which was capable of integrating the three dimensions of sustainable development, intelligence, and remote management and monitoring into its design. Nevertheless, the Technical Competitiveness Index of the new products remains relatively low. This indicates that the engineering characteristics of the SSSM still require significant improvement and ongoing enhancement.

Quantitative comparison with traditional QFD

To demonstrate the effectiveness of the EMR-QFD, a quantitative comparison of the correlation matrix scale was conducted. Traditional QFD requires constructing a single global correlation matrix, while EMR-QFD decomposes it into submatrices across dimensions. Taking the SSSM case as an example, the engineering characteristics (ECs) in three dimensions (sustainable development, intelligent, and remote management and monitoring) are 46, 18, and 5, respectively.

-

Traditional QFD: The global correlation matrix scale is (46 + 18 + 5)2 = 4761 elements.

-

EMR-QFD: The total submatrices scale is 462 + 182 + 52 = 2465 elements.

The comparison reveals that EMR-QFD reduces the analysis effort by 51.8%, significantly lowering correlation matrix complexity. This improvement enhances cross-dimensional requirement balancing efficiency and mitigates the burden of expert subjective evaluations, validating EMR-QFD’s superiority in handling large-scale requirement scenarios.

The benefits of the EMR-QFD for business organisations

Firstly, the decomposition of overall requirements into multiple dimensional requirements, followed by the analysis and design of each dimensional requirement separately using the one-dimensional House of Quality, not only effectively reduces the size and complexity of the traditional House of Quality matrix, but also focuses on the most critical dimensions and requirements. This method facilitates a more comprehensive understanding and management of the House of Quality for business organisations.

Next, once a product’s requirements have been decomposed into multiple dimensions, an organisation may choose to examine only one or a few of these dimensions initially. This allows for a rapid understanding of the engineering characteristics necessary to meet the corresponding dimensional requirements. By employing this streamlined approach that is grounded in dimensional requirements, the EMR-QFD can serve as a more pragmatic and valuable instrument for business organisations, enabling them to efficiently translate diverse requirements into technical specifications and thereby enhance their overall product development process.

Finally, the EMR-QFD is a tool that assists organisations in the design of products that encompass multiple dimensions of requirements throughout the product design process. These dimensions may include sustainability requirements, intelligence requirements, or other dimensions of interest to the enterprise, such as operation and maintenance costs. By incorporating more enterprise-oriented perspectives into product design in the multidimensional requirement-oriented House of Quality, the relevance of the EMR-QFD to business decision-making will be enhanced, facilitating its integration into the strategic planning process.

Limitations and future work

While the EMR-QFD method has demonstrated efficacy in designing a sustainable self-service property certificate printer, its generalizability to other self-service platforms remains uncertain. A notable limitation stems from the absence of validation in contexts beyond property certificate printing—for instance, in high-security environments like banking ATMs or time-sensitive healthcare kiosks.

Future research will prioritize two interconnected avenues. First, the adaptation of EMR-QFD to broader self-service contexts, such as banking ATMs, ticketing kiosks, and time-sensitive healthcare self-service machines, will be explored. This adaptation process will involve refining requirement dimensions—for example, security protocols for ATMs and time-sensitive operational requirements for healthcare self-service machines—and validating the method’s flexibility through comparative case studies. Second, to support the practical implementation of EMR-QFD, computational tools will be developed to facilitate the construction and completion of relevant calculations, while integrating data visualization techniques to enhance their indispensability and applicability in enterprise product design. These efforts aim to establish EMR-QFD as a generalizable framework for sustainable self-service machine design.

Conclusion

Sustainable development represents a balanced approach to fulfilling current needs while preserving resources and environmental integrity for future generations. In the realm of technology, integrating sustainability into the design of self-service machines enhances their efficiency and convenience, while also advancing resource utilization, environmental protection, and social responsibility. It is therefore necessary to develop a comprehensive and systematic methodology for the design of self-service machines, with the objective of guaranteeing that the requirements of different dimensions, such as sustainability and intelligence, are taken into account throughout the design process.

This work presents an EMR-QFD method. Initially, the requirements from multiple dimensions, such as sustainability and intelligence, are processed separately by utilising multiple One-Dimensional Quality of Houses. Subsequently, the information obtained from each dimension, including that pertaining to dimensional engineering characteristics, is aggregated and analysed in order to develop a design solution for a sustainable self-service machine.

The method enables enterprises to adapt their product design processes to incorporate multi-dimensional perspectives—sustainability, intelligence, and cost management—ensuring a strategic and comprehensive approach. This adaptability makes it an invaluable tool for product innovation and long-term enterprise planning.

Future research efforts will be centered on adapting EMR-QFD to self-service contexts like banking ATMs and healthcare kiosks by refining requirements and validating adaptability through case studies. They will also develop computational tools with data visualization to enhance applicability, establishing it as a universal sustainable design framework.

Data availability

Data are provided in the manuscript or Supplementary Information document and are available upon request from corresponding author L.Z.

References

Keeble, B. R. The Brundtland report: ‘Our common future’. Med. War 4, 17–25 (1988).

Schneider, F. et al. How can science support the 2030 agenda for sustainable development? Four tasks to tackle the normative dimension of sustainability. Sustain. Sci. 14, 1593–1604 (2019).

Rihar, L. & Kušar, J. Implementing concurrent engineering and QFD method to achieve realization of sustainable project. Sustainability (Switzerland) 13, 1–28 (2021).

Relich, M. A data-driven approach for improving sustainable product development. Sustainability (Switzerland) 15, 6736 (2023).

Sharma, P., Ueno, A. & Kingshott, R. Self-service technology in supermarkets—Do frontline staff still matter?. J. Retail. Consum. Serv. 59, 102356 (2021).

Ding, M., Song, Y. & Hu, Y. Supply-demand matching of smart parcel lockers in a residential area: Insights from Tianjin. Buildings 13, 2088 (2023).

Iberahim, H., Mohd Taufik, N. K., Mohd Adzmir, A. S. & Saharuddin, H. Customer satisfaction on reliability and responsiveness of self service technology for retail banking services. Procedia Econ. Finance 37, 13–20 (2016).

Shin, H. & Perdue, R. R. Self-service technology research: A bibliometric co-citation visualization analysis. Int. J. Hosp. Manag. 80, 101–112 (2019).

Park, S., Kim, H. K., Lee, Y. & Park, J. Kiosk accessibility challenges faced by people with disabilities: An analysis of domestic and international accessibility laws/guidelines and user focus group interviews. Univ. Access Inf. Soc. https://doi.org/10.1007/s10209-023-01028-4 (2023).

Henderson, H. et al. From parking meters to vending machines: A study of usability issues in self-service technologies. Int. J. Hum. Comput. Interact. 40, 1–15 (2023).

Alnowaini, G., Alttal, A. & Alabsi, A. Design and development SST Prototype for Yemeni paper currency. In 2021 International Conference of Technology, Science and Administration, ICTSA 2021 (2021). https://doi.org/10.1109/ICTSA52017.2021.9406534.

Vinodh, S., Manjunatheshwara, K. J., Karthik Sundaram, S. & Kirthivasan, V. Application of fuzzy quality function deployment for sustainable design of consumer electronics products: A case study. Clean Technol. Environ. Policy 19, 1021–1030 (2017).

Zhang, F., Duan, J., Chen, J. & Song, N. Critical functional modules identification method for product sustainable design. Jisuanji Jicheng Zhizao Xitong Comput. Integr. Manuf. Syst. CIMS 25, 1828–1838 (2019).

Sarker, K. U., Bin Deraman, A., Hasan, R. & Abbas, A. SQ-framework for improving sustainability and quality into software product and process. Int. J. Adv. Comput. Sci. Appl. 11, 69–78 (2020).

He, B. & Mao, H. Digital twin-driven product sustainable design for low carbon footprint. J. Comput. Inf. Sci. Eng. 23, 060805 (2023).

Camañes, V., Tobajas, R. & Fernandez, A. Methodology of eco-design and software development for sustainable product design. Sustainability (Switzerland) 16, 2626 (2024).

Ahmad, S., Wong, K. Y., Tseng, M. L. & Wong, W. P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 132, 49–61 (2018).

Zhu, L. & Husin, M. H. A proposed metrics based on sustainable development goals (SDGs) for public self-service machines. Sustainability (Switzerland) 15, 1–14 (2023).

Saaty, T. L. Decision Making with Dependence and Feedback: The Analytic Network Process Vol. 4922 (RWS Publications, 1996).

Geng, X., Chu, X., Xue, D. & Zhang, Z. An integrated approach for rating engineering characteristics’ final importance in product-service system development. Comput. Ind. Eng. 59, 585–594 (2010).

Cui, H. et al. An integrated approach for selecting design parameters in smart product-service system conceptual design. Procedia CIRP 119, 278–283 (2023).

Saaty, T. L. The analytic hierarchy process (AHP). J. Oper. Res. Soc. 41, 1073–1076 (1980).

de Oliveira, L. M. V., dos Santos, H. F., de Almeida, M. R. & Costa, J. A. F. Quality function deployment and analytic hierarchy process: A literature review of their joint application. Concurr. Eng. Res. Appl. 28, 239–251 (2020).

The Chinese Government. China’s National Plan on Implementation of the 2030 Agenda for Sustainable Development 1–66 (Government of China, 2016).

Author information

Authors and Affiliations

Contributions

L.Z. and M.H.H. conceptualized and developed the methodology. L.Z. performed data processing and analysis. L.Z. wrote the main manuscript text and prepared Figs. 1, 2, 3, 4, 5, 6, 7, 8, 9 and 10. M.H.H. conducted the supervision. All authors reviewed and edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhu, L., Husin, M.H. An enhanced multidimensional requirement oriented quality function deployment method for sustainable self service machine design. Sci Rep 15, 15200 (2025). https://doi.org/10.1038/s41598-025-99732-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99732-z